Table of Contents

Two practical methods for controlling the physical properties of mill tailings for underground stope backfill may be used. The first is classification to remove objectionably fine size fractions, and is commonly employed. The second method, flocculation, has had very limited application. It is the subject of this investigation.

This report covers preliminary laboratory studies of the effects of various flocculants on settling rates of fine-size tailings and comparative percolation rates of unflocculated and flocculated tailings slurries.

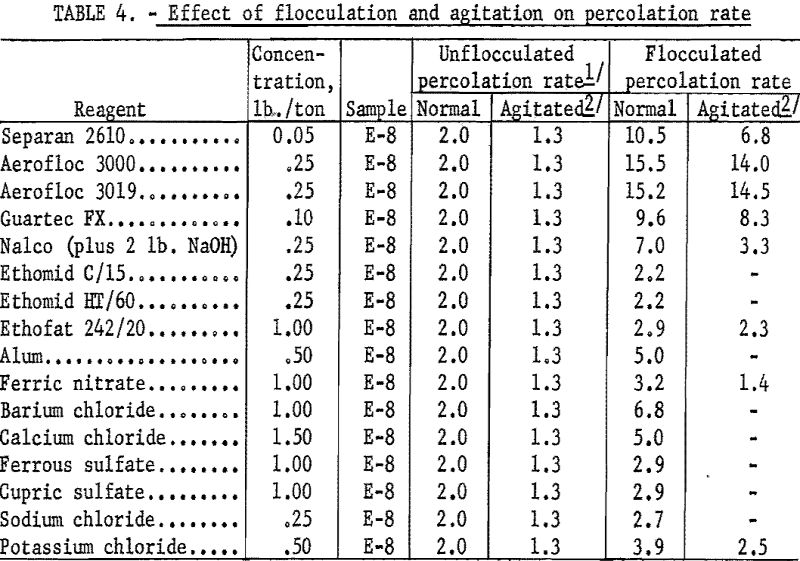

The 18 reagents tested included polyelectrolyte, trivalent, divalent, and monovalent flocculants, the tests indicated that the polyelectrolytes, particularly Separan 2610, Aerofloc 3000, Aerofloc 3019, and Guartec FX generally are more effective in action than the electrolyte reagents, regardless of valence.

Flocculation of tailings slurries with polyelectrolytes, and some of the electrolytes, especially calcium chloride, substantially reduced the slime thickness on top of the sand volume. Polyelectrolytes costs were generally higher than for the electrolytes.

No further testing of the effects of flocculant reagents in controlling the physical characteristics of mill tailings is planned.

The tests described herein were conducted on badly weathered 30- to 50-year-old tailings, and only three of numerous variables were controlled. Considerable caution must be exercised in evaluating or applying these data to other situations.

Laboratory Investigation of Fl0cculants

General Discussion of Flocculation

Some possible advantages of flocculation over classification in control of size fractions become apparent upon consideration of the following factors:

- The presence of slime in slurries in a stope fill-transport system may tend to increase viscosity and density and hinder settling of coarser particles in the slurry, permitting lower transport velocities and resulting in less pipe wear. The extremely fine material acts somewhat as a lubricant, tending to reduce pipe wear. Retention of fine material in a slurry depends upon whether the advantages outweigh the disadvantages.

- It may be difficult to dispose of classified fine tailing material where settling basin areas are restricted or unavailable.

- In some situations, transportation and loading costs applied against large tonnages of wasted-fine material may be prohibitive.

- Clean sand at the New Brunswick mine, even after long periods of standing, ran when the supporting walls were removed. Retained slimes provided a cementing action eliminating this problem.

- Where beneficiation practices require extremely fine grinding, large amounts of the total tonnages may be lost by removal of classified fine material. Flocculation of some or all of the fines increases the amount of material available for underground emplacement.

The principal objectives of this investigation were to test the effectiveness of various reagents for the flocculation of objectionably fine-size fractions of mill tailings being used in the Butte district as backfill material, and to determine approximately the optimum amount of reagents required for adequate flocculation of the fines. The effectiveness of the flocculant reagents was determined by comparing their settling and percolation rates.

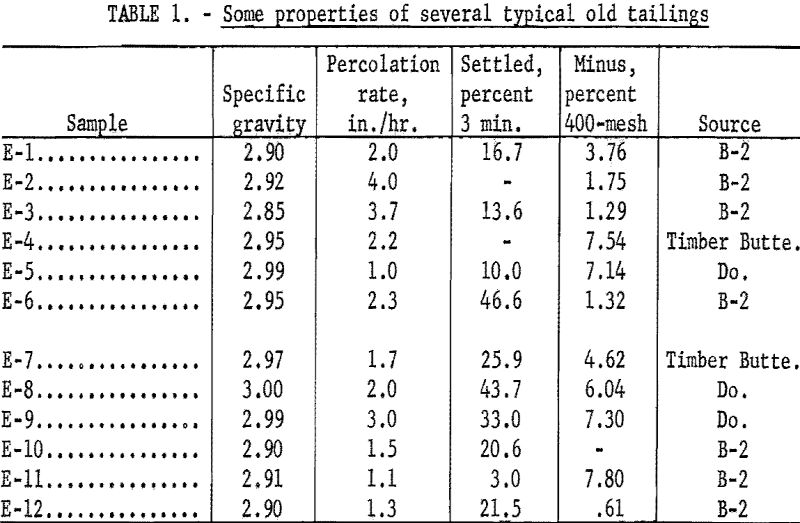

Butte and Anaconda mill tailings were used in the laboratory tests. These tailings had been partly classified by drainage while impounded in the tailings pond. The Timber Butte tailings impounded at Butte are more than 40 years old, and the B-2 tailings at Anaconda are approximately 30 to 40 years old. During these periods the feldspars and carbonates constituents of the tailings probably have been badly oxidized, accounting for their high slime content. The results of these tests probably cannot be applied to all tailings or even to other tailings in the district. Each tailing has its own peculiar characteristics.

In the laboratory tests, the three factors controlled were the kind of flocculant, concentration of the flocculant, and the simulated degradation effects of transport.

The four factors to be considered when selecting a flocculant reagent for hydraulic backfilling are resistance of the flocs to comminution during mixing and transport, ability to perform under practical operating conditions, ability to effectively reduce slime concentrations on the surface of the fill, and cost.

Definitions

Most of the following definitions were coined for these studies. They are not necessarily generally accepted or in common usage in backfill parlance.

Slimes are those materials that exhibit a tendency to settle as a surface layer in noticeable contact with the sand column and are generally considered to be minus-400-mesh or minus-37-microns.

Settling Distance is the interval expressed as a percentage of the total distance settled in 15 minutes unless otherwise indicated, such as a certain percent settled at 2, 3, and 4 minutes.

Settling Rate is the rate expressed in number of inches per hour that the solids settle in a column, measured at one, two, three, and so forth, minute intervals.

Degradation is the result of comminution of mineral particles and/or flocs in slurries by attrition and/or abrasion. For example, mineral particles and flocs rubbing against the wall of a pipe during transportation are degraded or comminuted by abrasion, but the particles and floes rubbing against each other and not in contact with the pipe are comminuted by attrition.

Percolation Rate is the number of inches per hour that tailings water percolates or filters through a 1-foot column of tailings.

Polyelectrolytes generally are high-molecular-weight long-chain polymers. They are organics and may either be synthetic or natural. A polyelectrolyte may have a molecular weight as high as 200,000.

Trivalent Electrolytes are three-valent inorganics; Divalent Electrolytes are two-valent inorganics; and Monovalent Electrolytes have a single valence.

Nature of the Tailings

Some of the characteristics of the tailings employed in this investigation are given in table 1.

X-ray analysis of the minus-400-mesh fraction of E-11 tailings by the geological laboratory of The Anaconda Company has established pyrite, quartz, and sericite as being the most abundant minerals. Minor amounts of kaolinite, plagioclase, orthoclase, and montmorillonite have been identified.

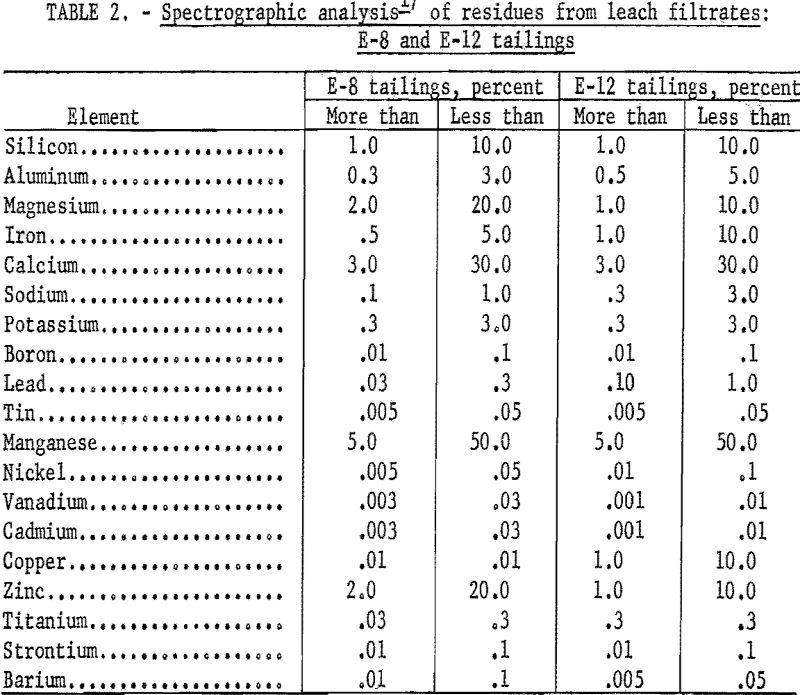

The soluble-ion content of the tailings, E-8 and E-12, respectively, (from the Timber Butte tailings pond in Butte, and from the B-2 tailings pond in Anaconda obtained by leaching the tailings), was found to be very high. Spectrographic analyses of residues obtained by evaporating the leach filtrates are shown in table 2.

Experimental Procedure

Laboratory investigations were performed on old mill tailings of the type used for hydraulic backfilling in the Butte district. To obtain samples in lots of approximately 100 pounds, vertical channels were dug in the loading face of each of the two locations. This procedure yielded a representative sample of a particular face at a particular time.

So as not to rely completely on a single sample from any loading face, material obtained at different times from several loading faces was used.

The behavior of various flocculants was studied mainly by comparison of settling rates and additionally by comparison of percolation rates. Only three of a large number of factors influencing flocculation were controlled. These were the kind of reagent, its concentration, and comminution effects of transport simulated in the laboratory by agitation. The remaining variables were allowed to behave as if under practical operating conditions.

The oven-dried samples of tailings to be treated were pulped with water at 60 percent solids by weight, a reasonable density for emplacement.

Tests were made on the settling rate of unflocculated tailings by mixing a representative sample of oven-dried tailings weighing 720 grams with 480 cubic centimeters of water, yielding 1,200 grams of pulp at 60 percent solids by weight. The pulp was transferred to a 1,000-cubic-centimeter closed, graduated cylinder and gently mixed by rotating the cylinder end for end several times. The cylinder was placed upright, and the level of the interface between the clear supernatant fluid and settling column were measured regularly at 1-, 2-, 3-, and 15-minute intervals, or at intervals desired. Settling rates are expressed in inches per minute or inches per hour. The same procedure was employed for flocculated pulp tests, using water with reagent added in the desired concentration instead of pure water.

Because the purpose of the investigation was concerned with reagent selection only generally, standard reagent concentrations were used. For the polyelectrolyte flocculants, 0.025, 0.05, 0.10, 0.25, 0.50, 1.00, and 1.50 pounds per ton of dry tailings were used; for the electrolyte flocculants, 0.10, 0.25, 0.50, 1.00, 1.50, 2.50, and 5.00 pounds per ton were used. Reagent concentrations in certain areas were more thoroughly investigated where conditions required. For purposes of comparison, an attempt was made to adhere to these concentrations as much as possible.

Slime removal, analogous to very clean classification, was done by siphoning the slimes from the percolation test column, leaving only clean sand for subsequent percolation tests.

The percolation rate test was made by mixing a sample of tailings with water, ascertaining that the slime balls were wetted and dispersed, and placing the sample in an 18-inch long, 1-½-inch-diameter percolation tube with a cotton cloth filter on the bottom. The sample should be of sufficient size to occupy a height of 12 inches in the tube. A siphon overflow tube was set up with its outlet 3 inches above the top of the tailing column. Water was introduced at the top in an amount in excess of the quantity of water percolating through the tailings sample column. The excess was siphoned off and discarded. The siphon maintained a constant 3-inch head on the column. Water was percolated through the sample until percolation became constant. The rate of flow through the sample was measured, and expressed in inches per hour.

A 15-second agitation period in a Waring blender was arbitrarily selected for comparison between unagitated and agitated pulps. This was done to simulate pulp degradation in pipelines. In practice, the amount of degradation or comminution received by a pulp during transport is affected by many variables, such as transport velocity, transport distance, and pulp density. The agitation experiments were performed in the same manner as the normal flocculation experiments.

The soluble-ion fraction was obtained by a wash-filter procedure. The tailings were first pulped at 60 percent solids by weight, then agitated for 30 minutes at 1,500 r.p.m. in a laboratory flotation cell. The pulp was filtered and immersed in water for 24 hours. The agitation cycle was repeated and the pulp filtered again. The total filtrate was evaporated to dryness, weighed, and submitted for spectrographs analysis.

Selection of Reagents

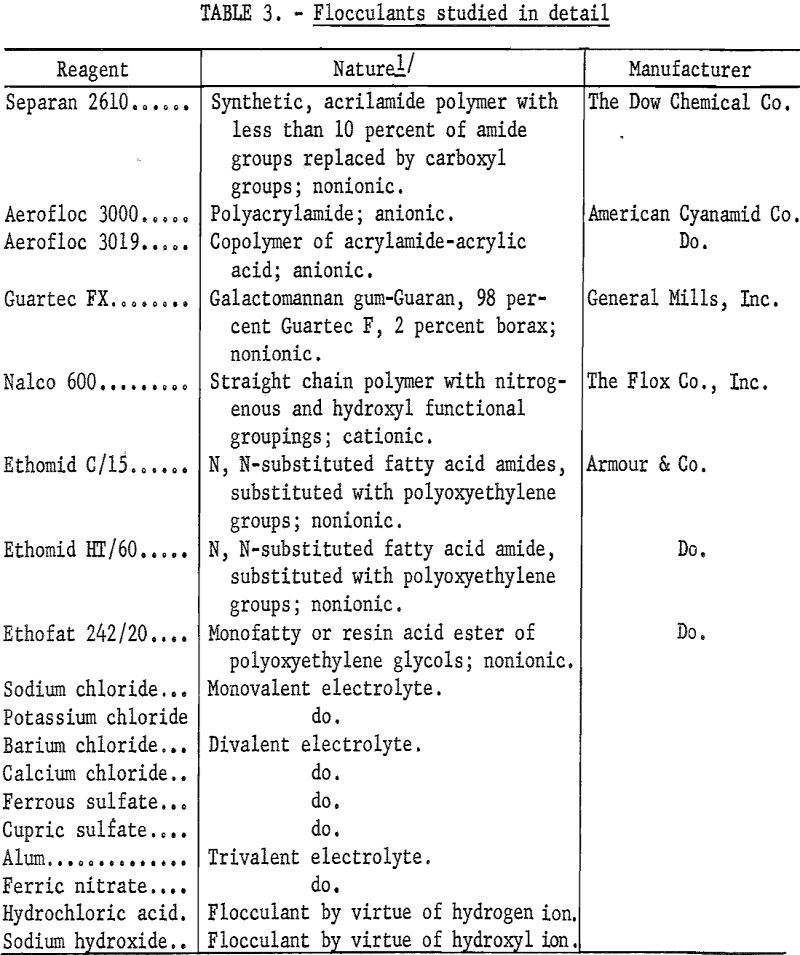

Four general classes of reagents selected for the investigations included, polyelectrolytes, as well as trivalent, divalent, and monovalent electrolytes. Polyelectrolyte flocculants were used because of current interest in such reagents in mineral beneficiation.

Table 3 contains a list of the flocculants studied in detail. The general nature of the reagents is stated, and, where applicable, the name of the manufacturers.

Other flocculants having possible use for treating stope fill tailings are listed in a table of flotation reagents.

Discussion of Test Results

Settling and Percolation Rates

The available settling time for flocculated tailings in stopes is usually of short duration, and depends upon the rate of emplacement, the percolation rate, and the stope dimensions. The percent-settled factor is expressed in time intervals of 2, 3, and 4 minutes, giving a practical range of useful information.

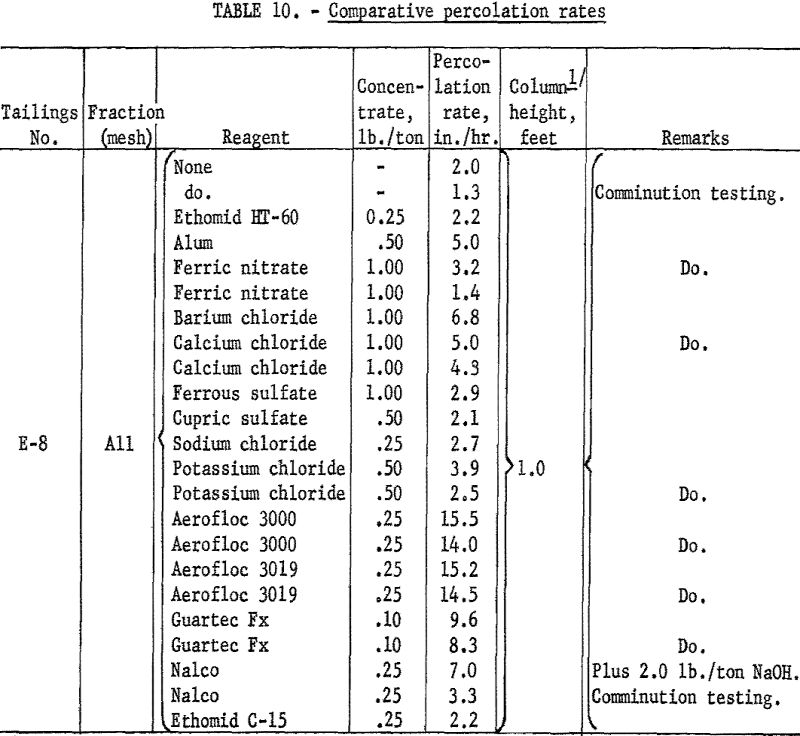

Table 4 and table 11 in the appendix show the effect of some flocculants on percolation rates.

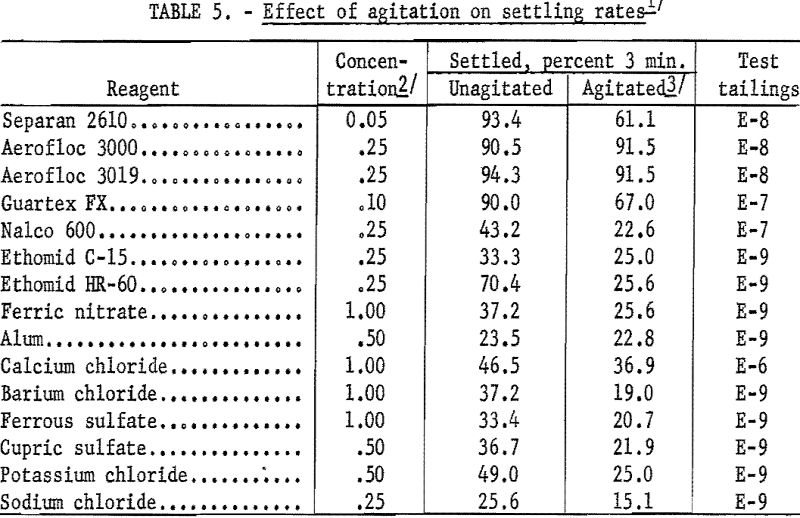

Table 5 shows the effect of agitation on settling rates for several tailings treated with various flocculants.

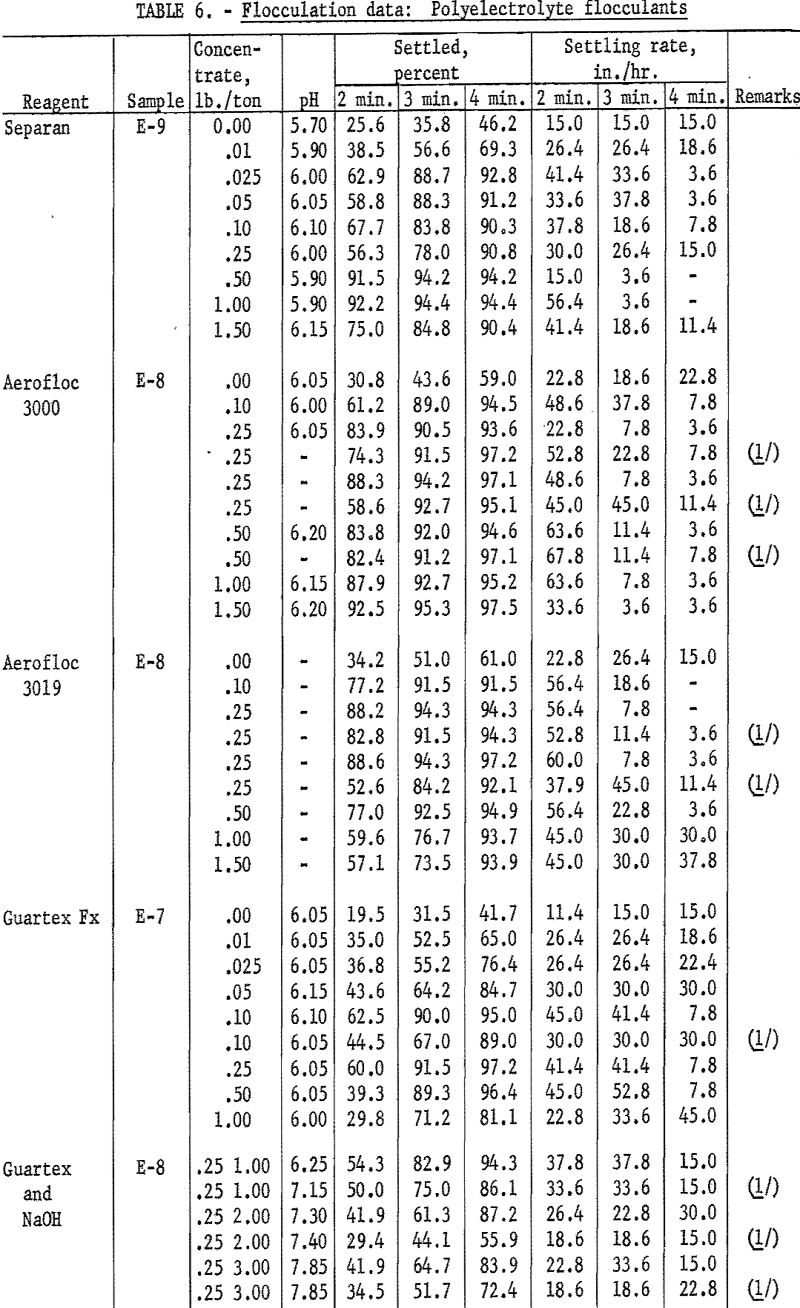

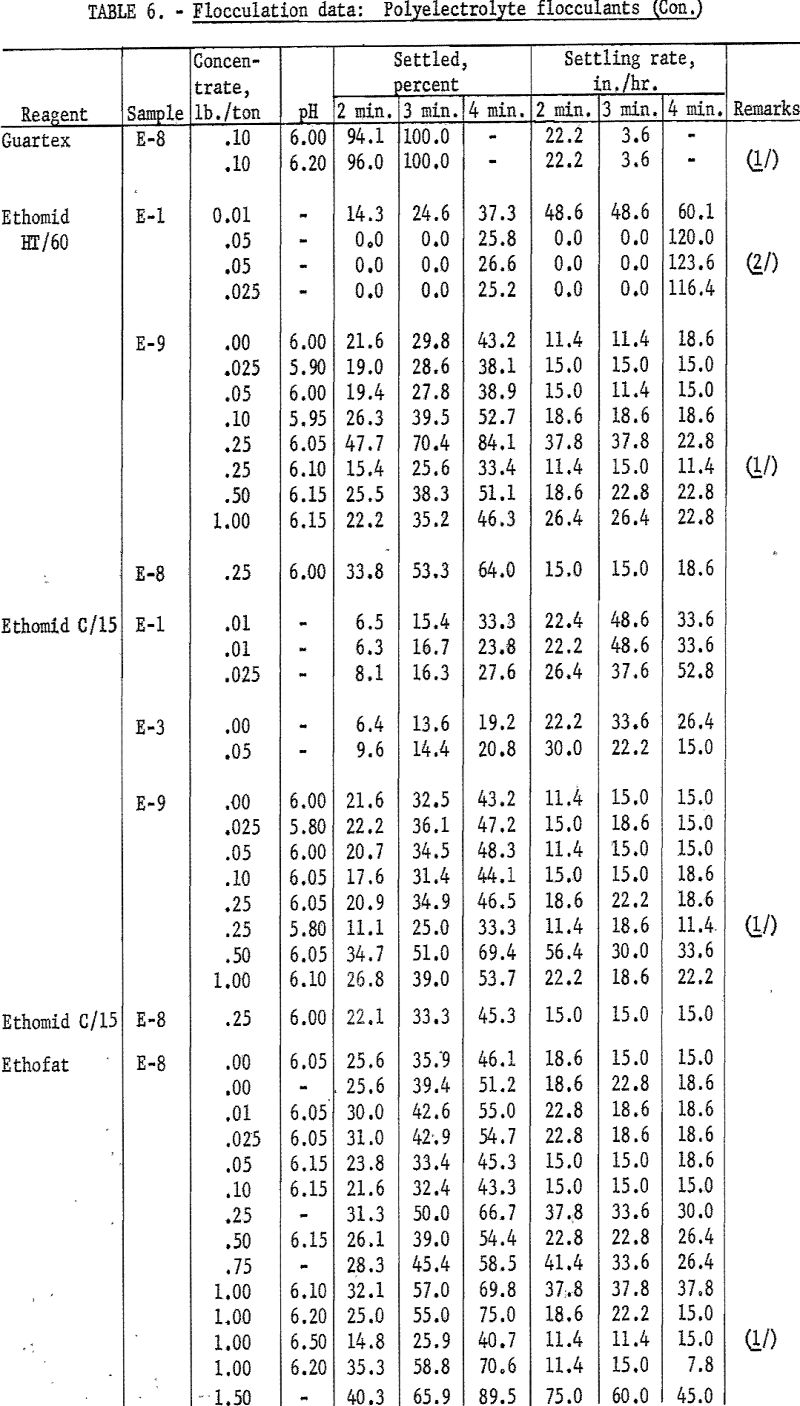

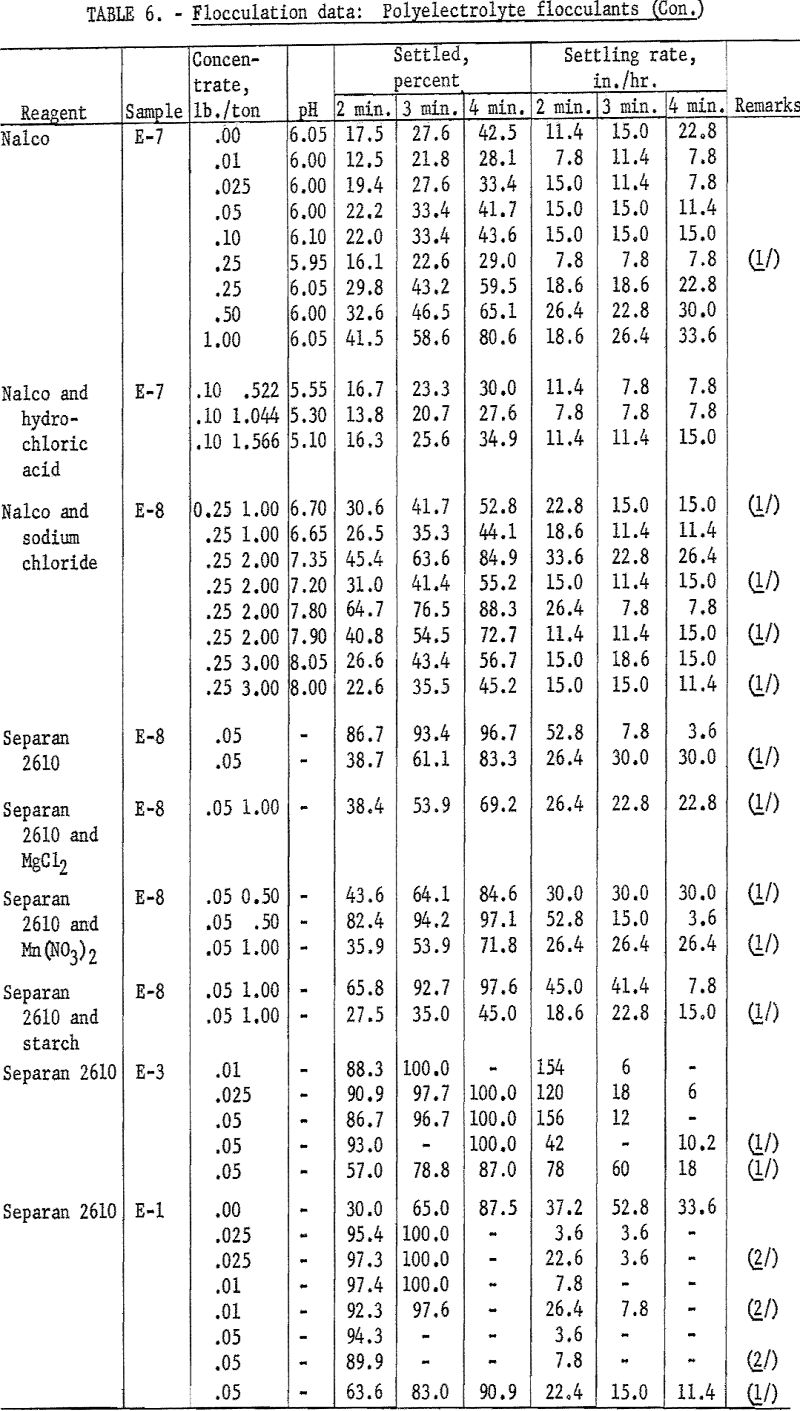

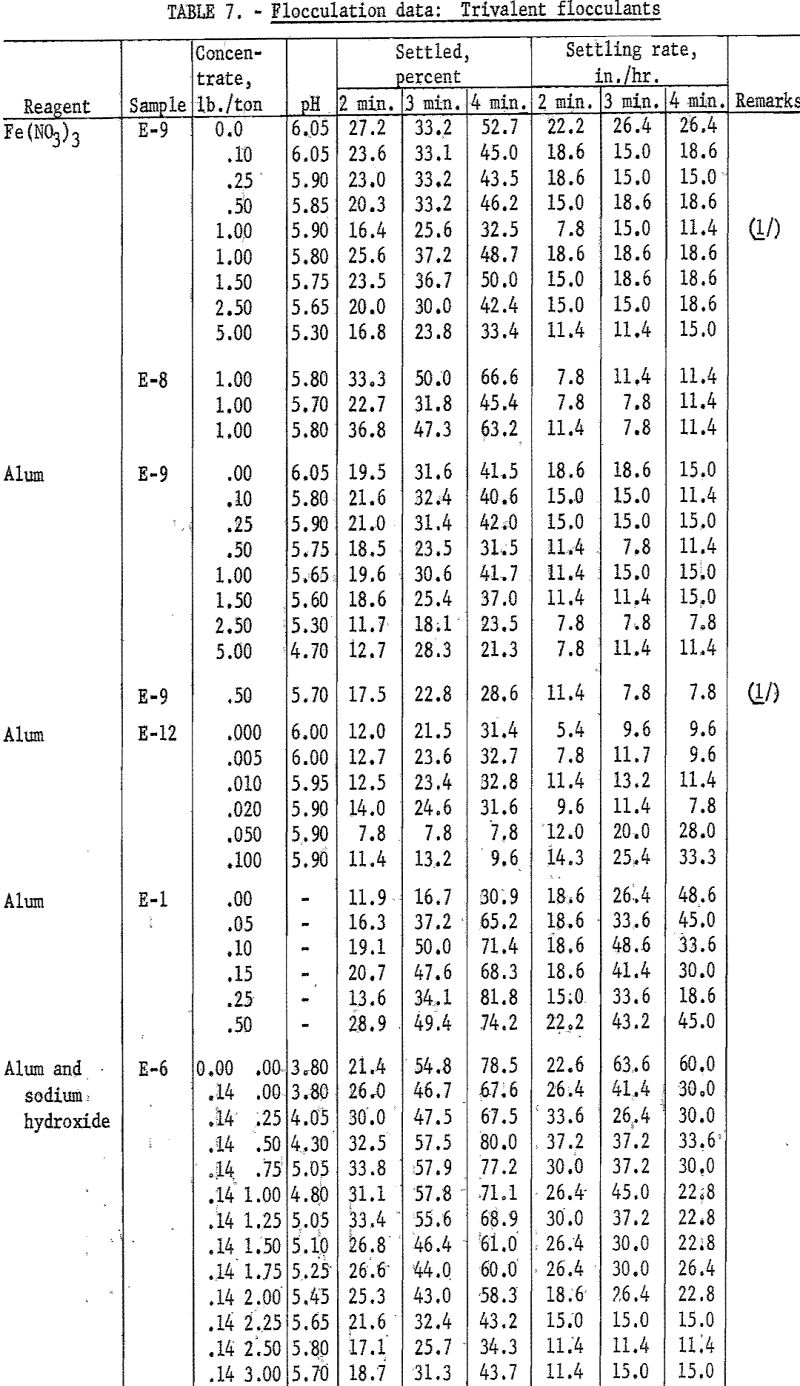

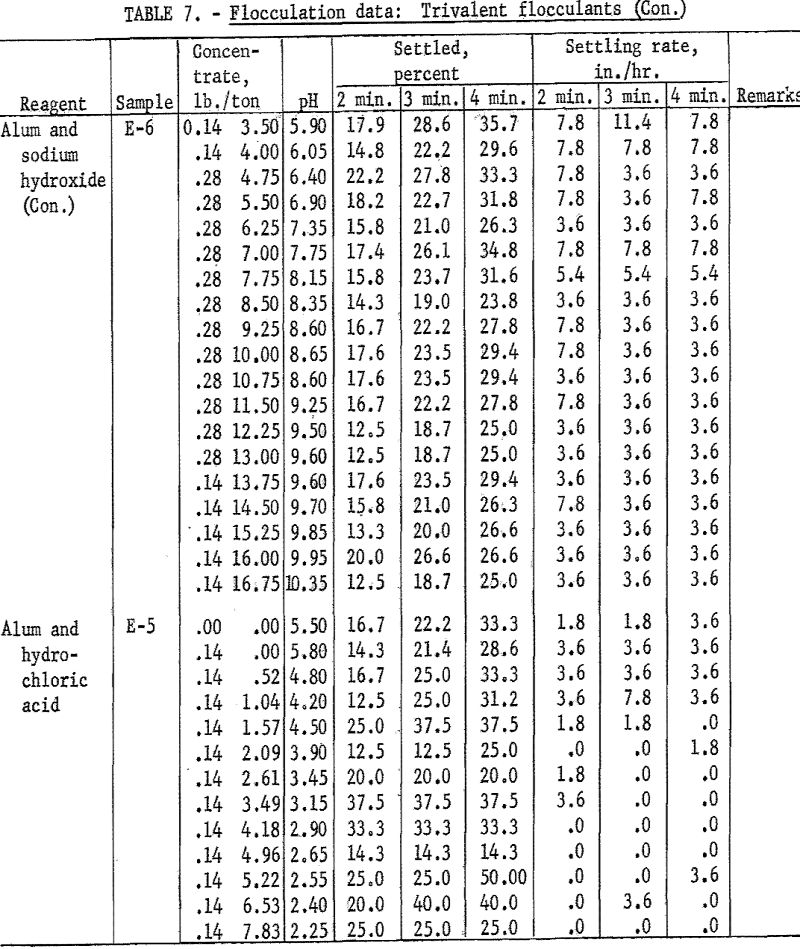

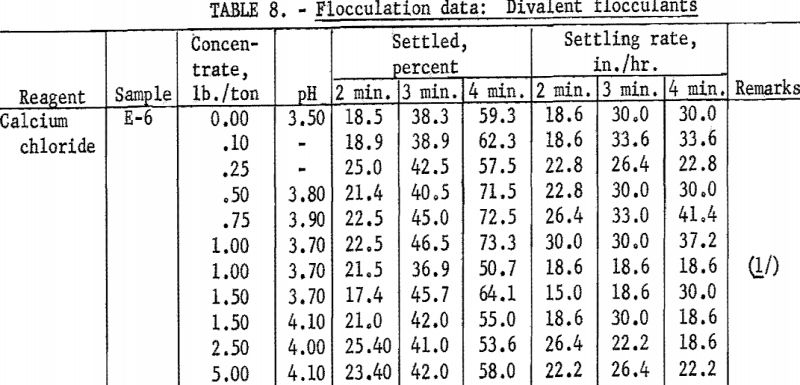

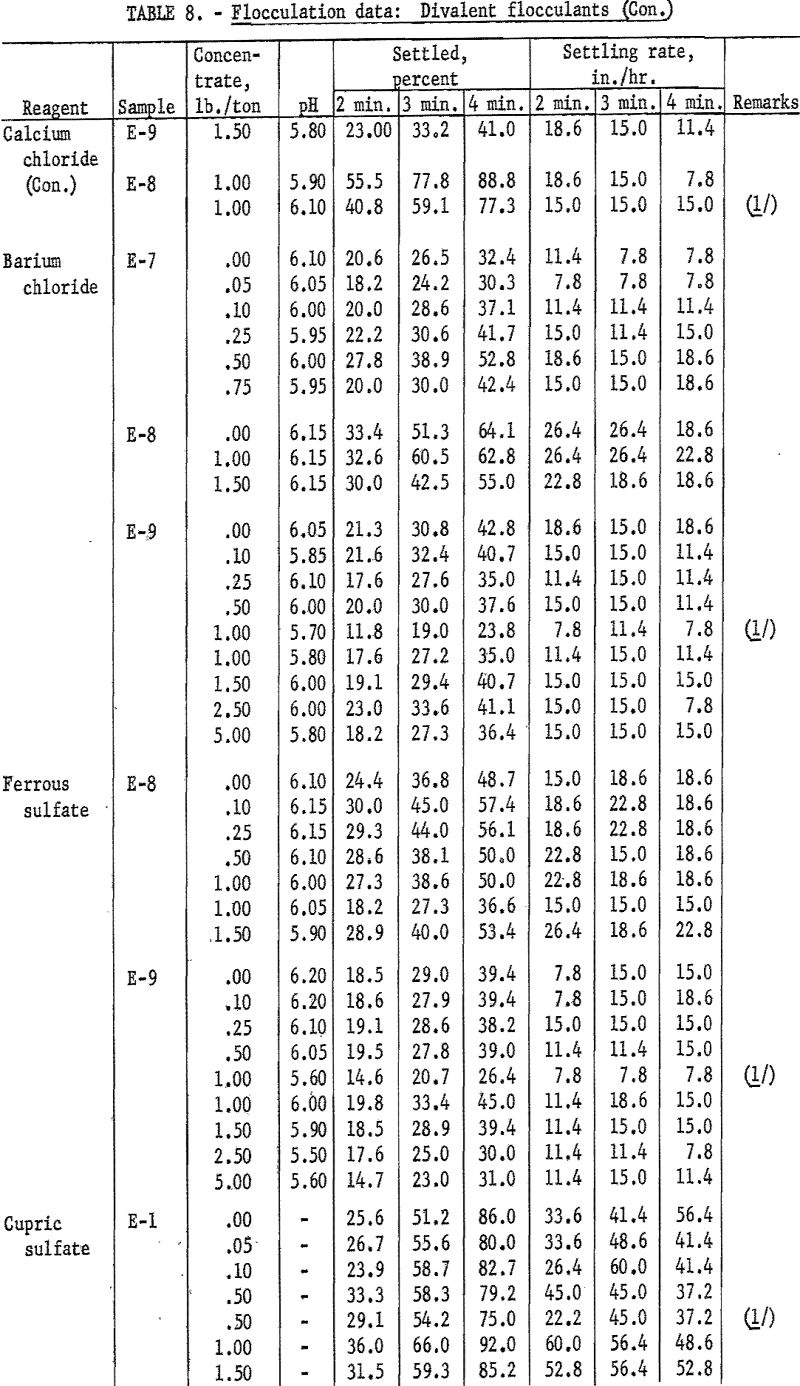

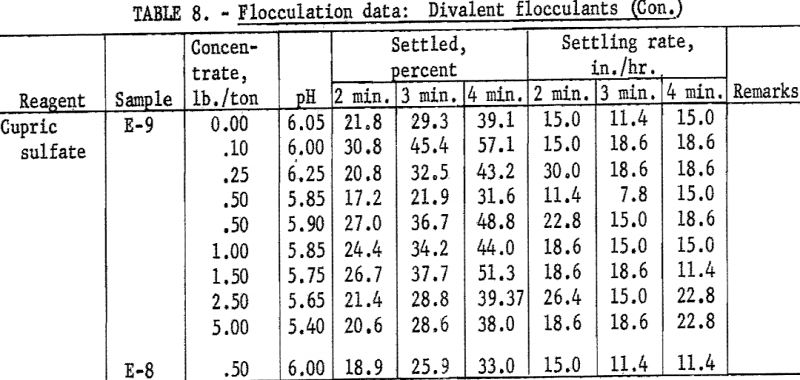

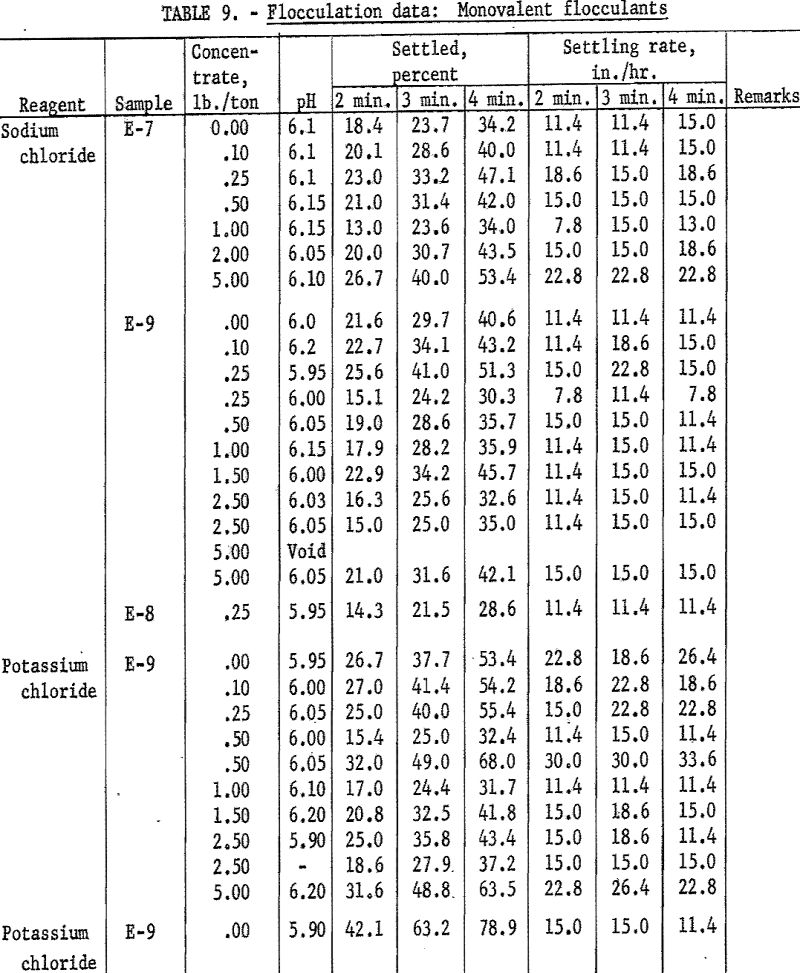

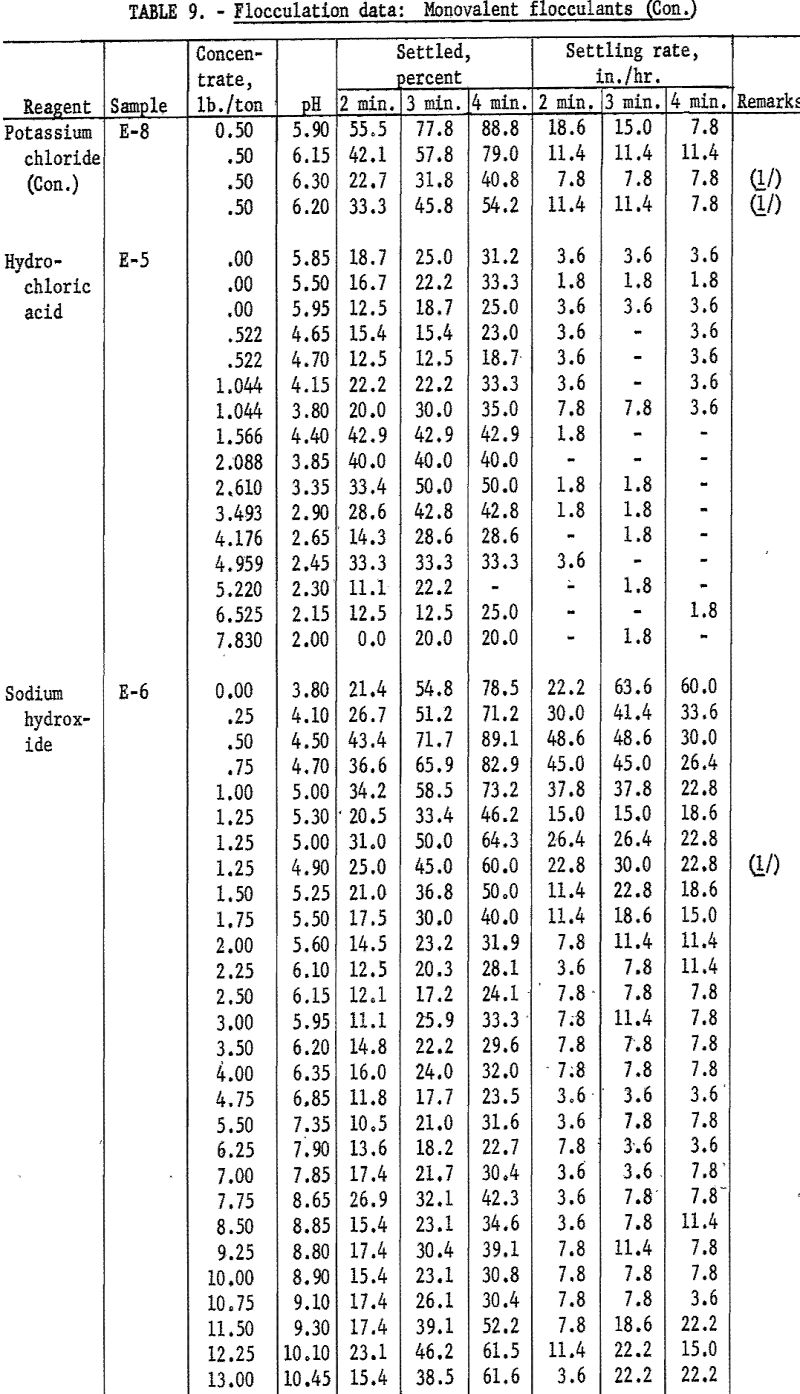

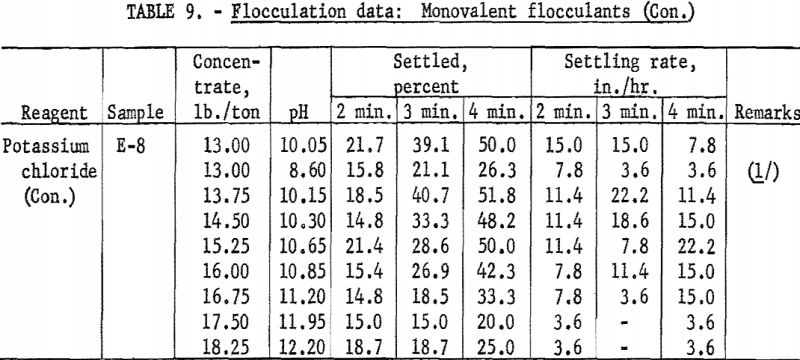

The comparisons of settling rates of pulps flocculated by polyelectrolytes were those of Separan 2610, Aerofloc 3000, Aerofloc 3019, and Ethofat, respectively. Others are included in table 6 in the appendix. The actions of other flocculants are shown in tables 7, 8, and 9 in the appendix.

All polyelectrolytes yielded pronounced reductions in slime thickness as determined visually. No slime developed for Separan 2610 and Aerofloc 3000. Complete mingling of the slimes into the mass of flocculated pulp occurred when Separan 2610 was the flocculant.

Settling rates for alum and ferric nitrate, two trivalent flocculants, are shown in table 7 in the appendix. Both alum and ferric nitrate are commercial flocculants of extremely wide industrial application. As a result of the widespread use of these flocculants, much data have been accumulated. The reagents were of low effectiveness in the normal range of concentrations used in this study, however.

Calcium chloride, barium chloride, ferrous sulfate, and cupric sulfate were the divalent flocculants studied. Only calcium chloride appeared to be potentially favorable (table 8 in appendix).

Of the several monovalent flocculants investigated (table 9), sodium and potassium chlorides were most effective in concentrations between 0.10 and 0.50 pounds per ton of solids. Their effectiveness decreased rapidly for concentrations greater than 0.50 pounds. Neither was very promising as a practical flocculant.

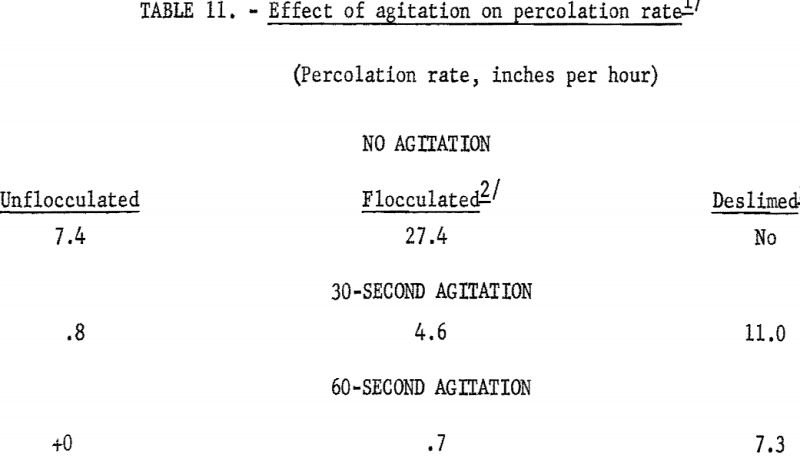

Effects of Flocculation and Agitation on Pulp Behavior

To test the effect of simulated-pipeline degradation on percolation rates, the rates were measured on one group of unagitated, unflocculated and flocculated E-3 tailings. Percolation rates were measured on a second group of unflocculated, flocculated, and deslimed flocculated tailings agitated 30 seconds in a Waring blender. The same procedure was followed for the third group for a 60-second agitation. Separan 2610 was the flocculation reagent.

To simulate desliming by classification, slimes were siphoned from the percolation column, leaving only clean sand for subsequent percolation tests. In all three cases, substantial increases in percolation rates accompanied flocculation, although the increases were considerably less than for removal of slimes.

Since this agitation was somewhat analogous to pipeline degradation, the deleterious effects of extended turbulent transportation are indicated.