Table of Contents

Drying System Design

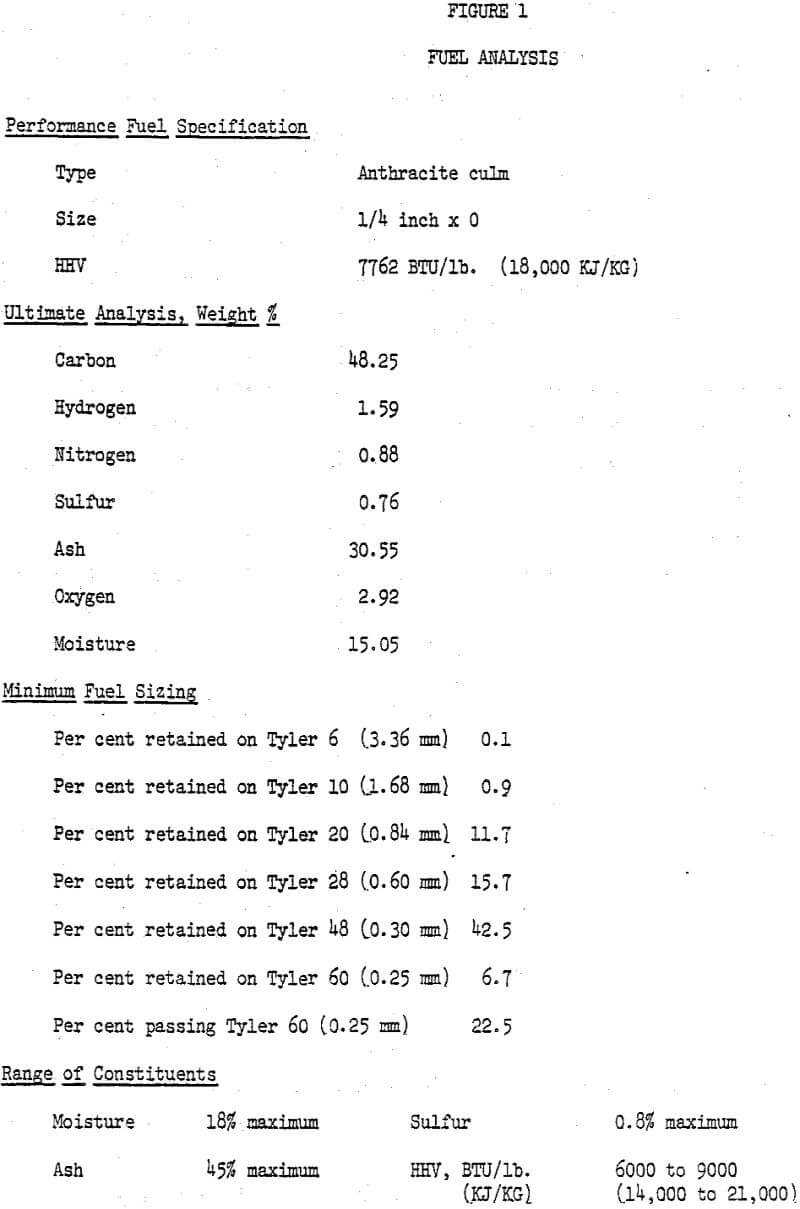

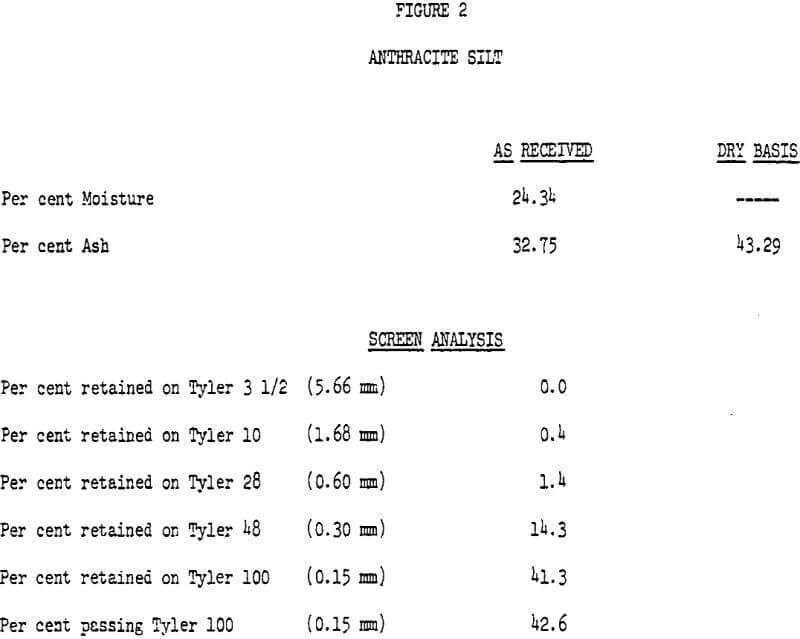

The fluid bed dryer has been designed for the specific requirements of drying a 6 mm x 0 (¼” x 0) feedstock of anthracite culm and occasional intermittent feeds of anthracite silt. The feed moisutre of the culm ranges between 16 and 18 per cent by weight and is approximately 24 per cent for the silt. The dry product moisture requirement for both the culm, and silt is 6 per cent by weight. See Figures 1 and 2 for a more detailed description of the culm and silt feed characteristics.

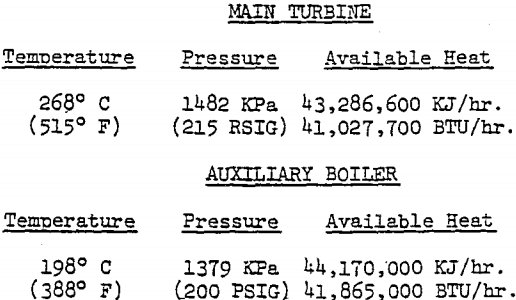

The dryer will utilize 22,725 Kg/hr. (50,000 lbs./hr.) of main turbine extraction steam or auxiliary boiler steam to fulfill the system heat requirements. The steam quality and heat available for each condition is shown below.

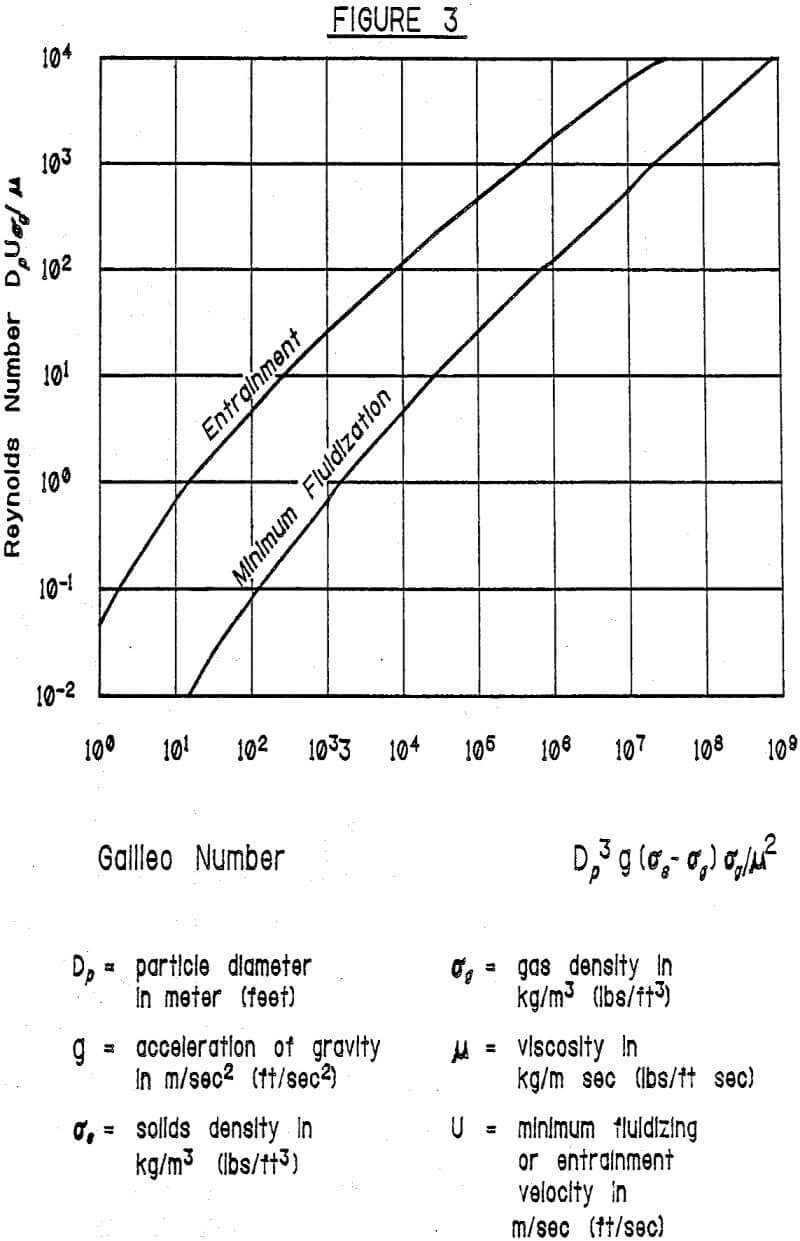

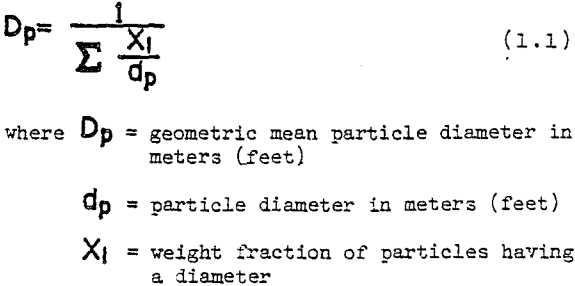

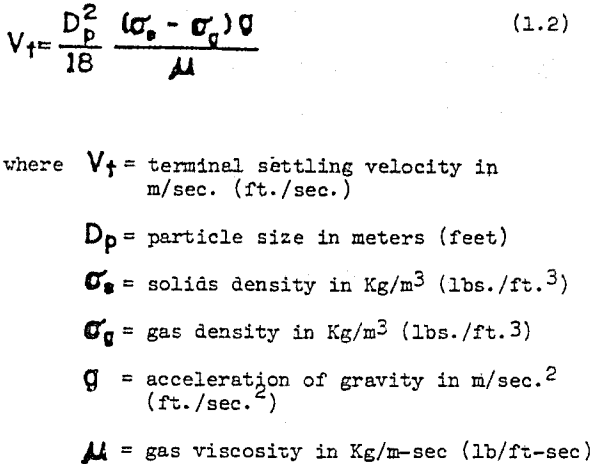

Fluidization velocities are generally selected for material feedstocks having a narrow range of particle sizes and for practical purposes, the mean geometric particle diameter, as calculated in equation 1.1, is typically used.

Dryer Operation and Control

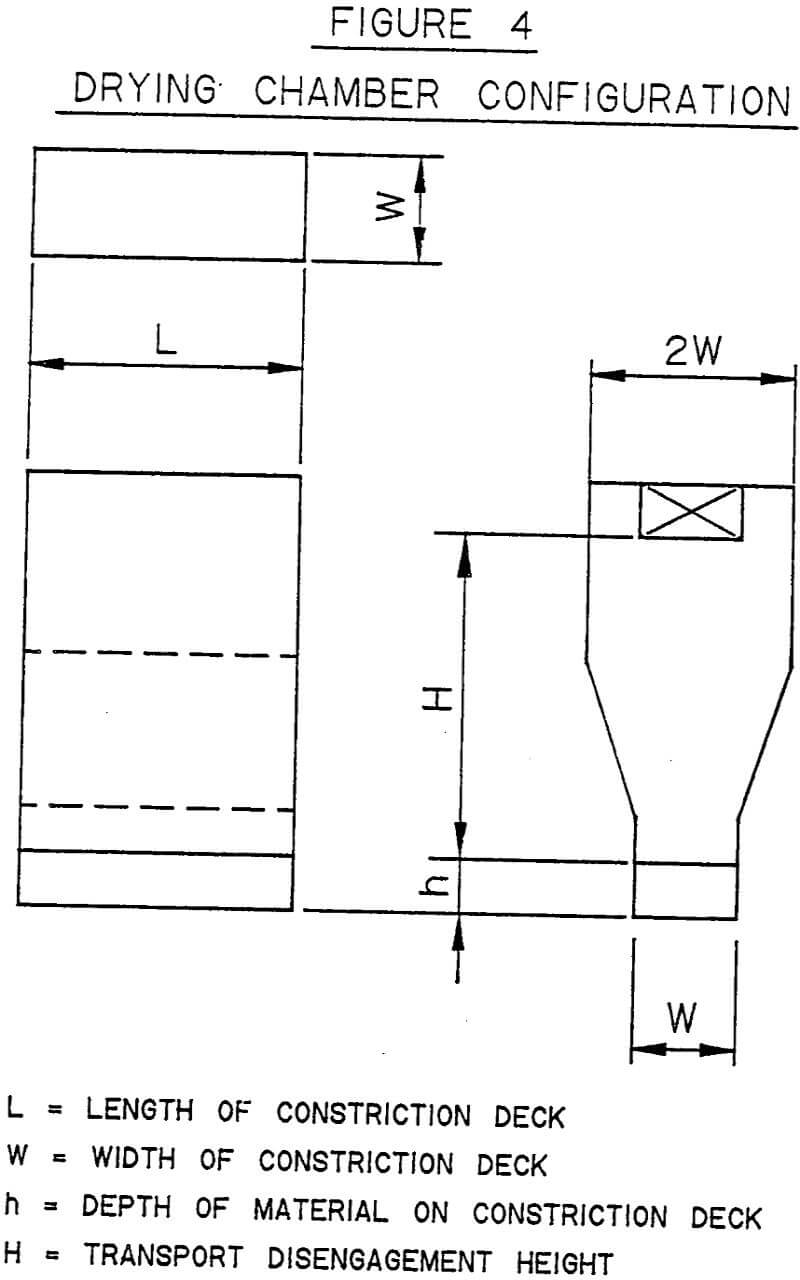

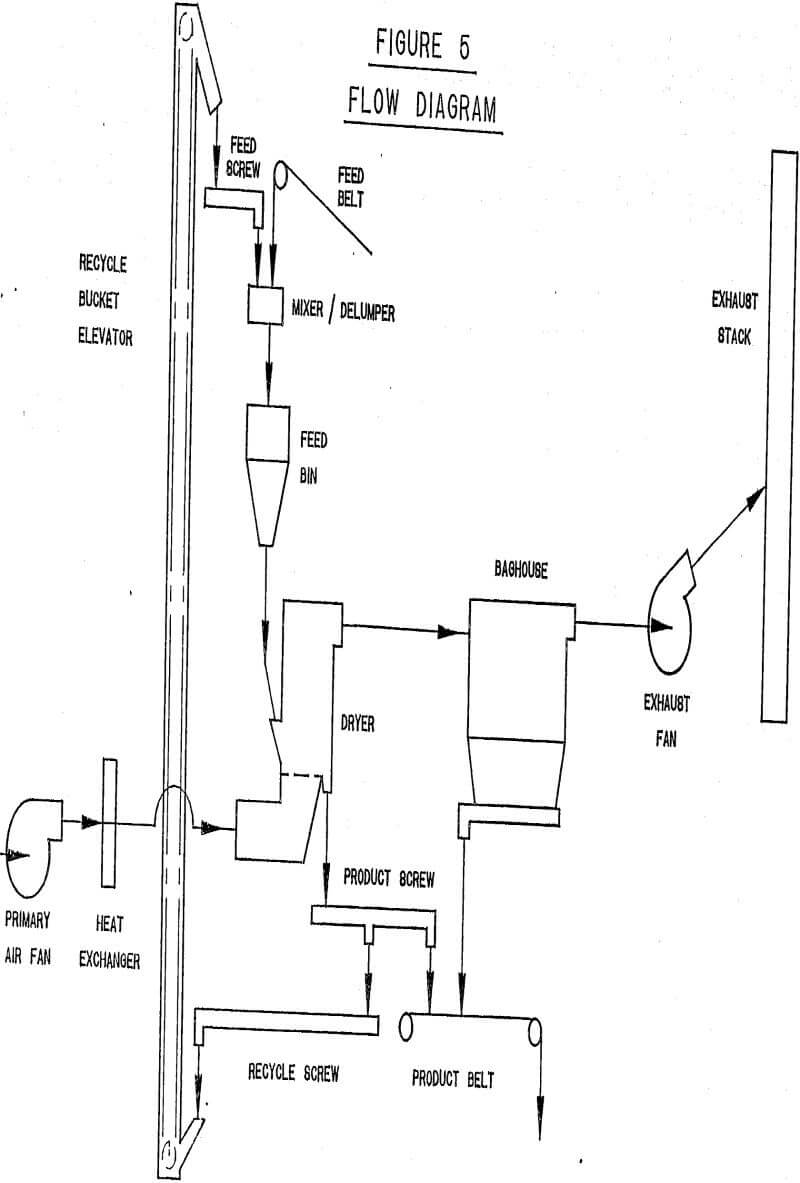

The dryer is a combination positive-negative type system and is shown in Figure 5. Ambient air is introduced through a steam heat exchanger by the primary air fan where it is heated to a temperature of approximately 185° C (365° F). The hot gases then flow through the hot gas duct and pass through the constriction deck. The function of the constriction deck is to provide an even destricution of heat and uniform fluidization of the solids. A secondary heat exchangers in the form of fintube heaters, is located in an area just above the constriction deck. The purpose of the fintubes is to reheat the moisture laden gas stream and provide direct heat transfer to the bed of solids.

The dryer is equipped with a 140 ton surge bin and a feed roll that is utilized to deliver the wet solids across one end of the constriction deck. A bed of solids will fluidize across the deck and discharge through three automatically controlled discharge valves into the dry product screw conveyor. Fine solids that become entrained in the gas stream will exit the drying chamber and will be drawn into the baghouse by negative pressure induced by an exhaust fan. The fine solids collected in the baghouse will drop through the hopper section and into a screw conveyor where it is transported to a belt conveyor and combined with the coarse product.

Undergrate Temperature Control

The temperature in the hot gas duct is measured and transmitted to an indicating controller adjusted at a predetermined setpoint. This device controls the flow rate of steam into the steam heat exchanger and thus the temperature of the hot gases entering the drying chamber. It also accepts a remote setpoint override in the event that the exhaust temperature cannot be controlled as previously stated.

The dryer is also equipped with an auxiliary panel for an emergency spray system that is centrally located in the system. The drying chamber and baghouse are each provided with an emergency spray system. Thermocouples are strategically located in each area to detect high temperature conditions due to fires. The auxiliary panel is equipped with temperature alarm relays and solenoid valves for the control of water sprays inside the drying chamber and the baghouse plenum.

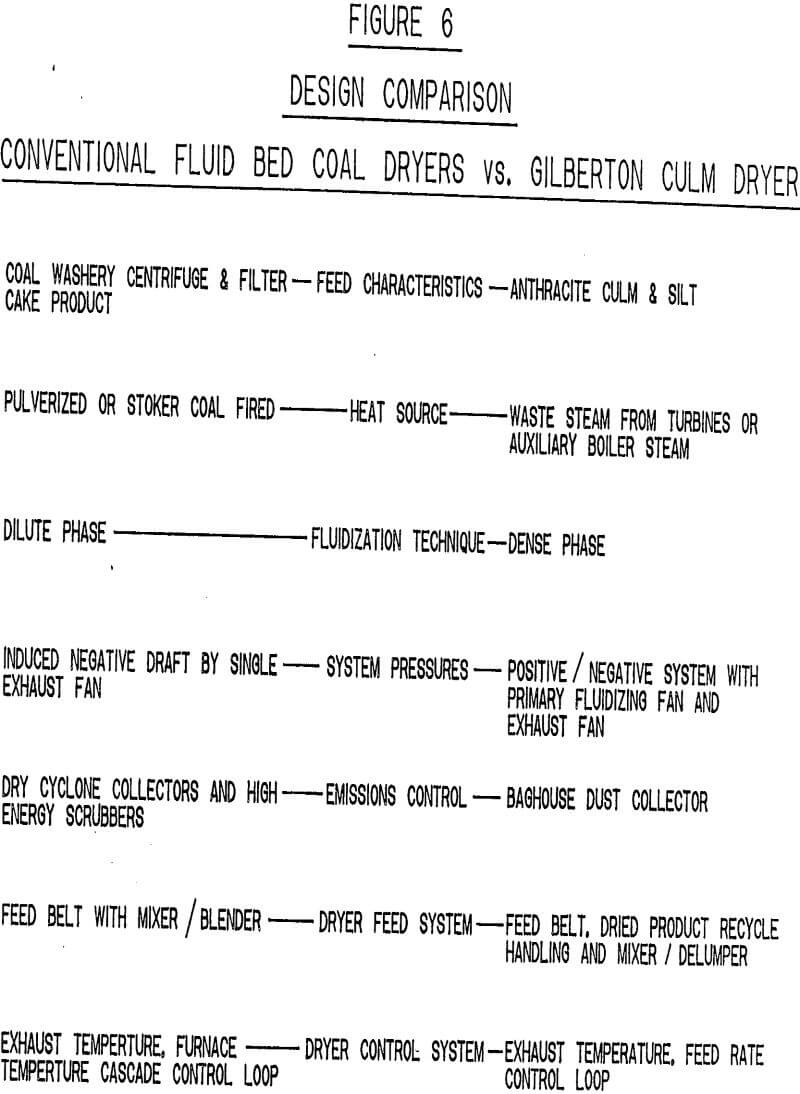

Design Comparison to Conventional Fluid Bed Coal Dryers

The Gilberton culm dryer utilizes a different type of system design than is typically exhibited in bituminous coal dryer installations. The differences evolved from an analysis of the material feed characteristics. Through the analysis, the following, was determined:

- The size distribution of the material showed a much finer material than is normally handled in bituminous coal dryers,

- The moisture content of the material is significantly higher than typical feedstocks of bituminous coals,

- The material had tendancies to agglomerate. The agglomeration is attributed to the high moisture and ash content,

- For feed moistures in excess of 18 per cent it would be necessary to recycle a portion of the dried product in order to enhance the flowability of the material through the system.