Table of Contents

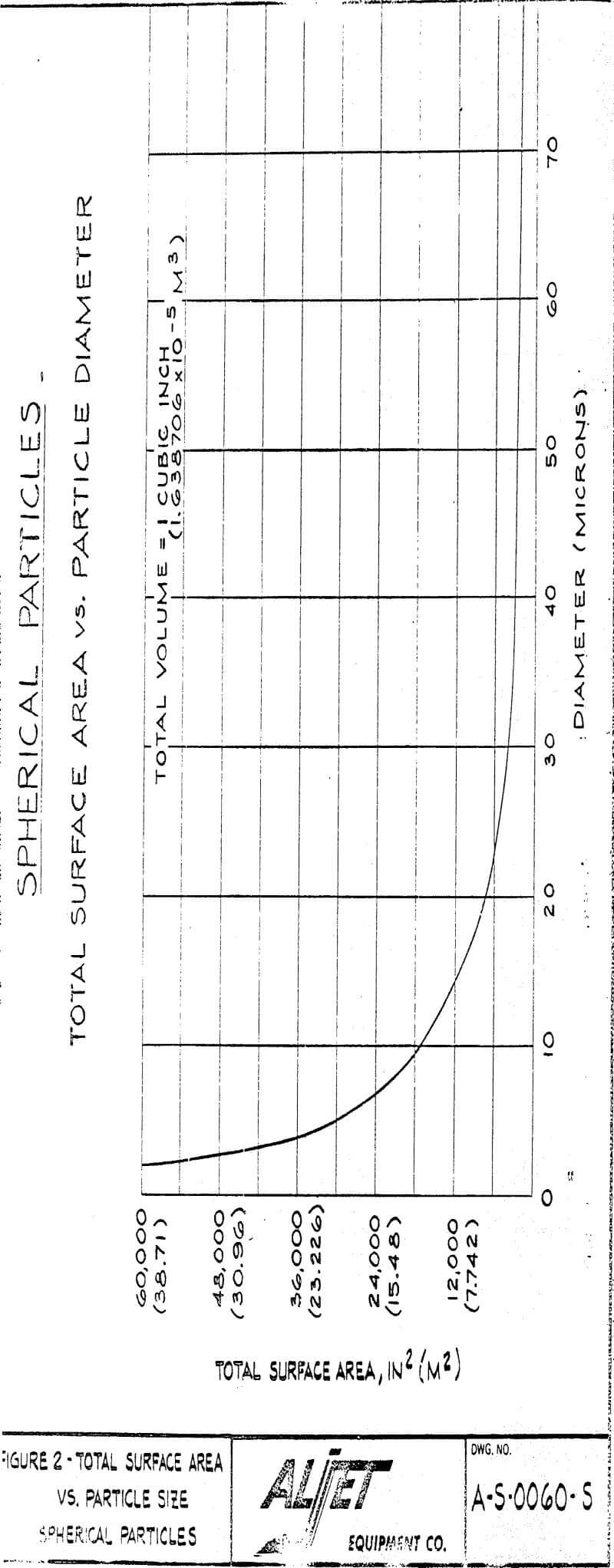

High pressure fluid energy grinding, or jet milling, is a versatile method of continuously fracturing solids into fine particles to gain substantial increases in exposed surface area.

Applications in the minerals industries include calcium carbonate, talc, barytes, mica, diatamaceous earth, bauxite, rutile, coal, kaolin, sepiolite, diamonds, etc.

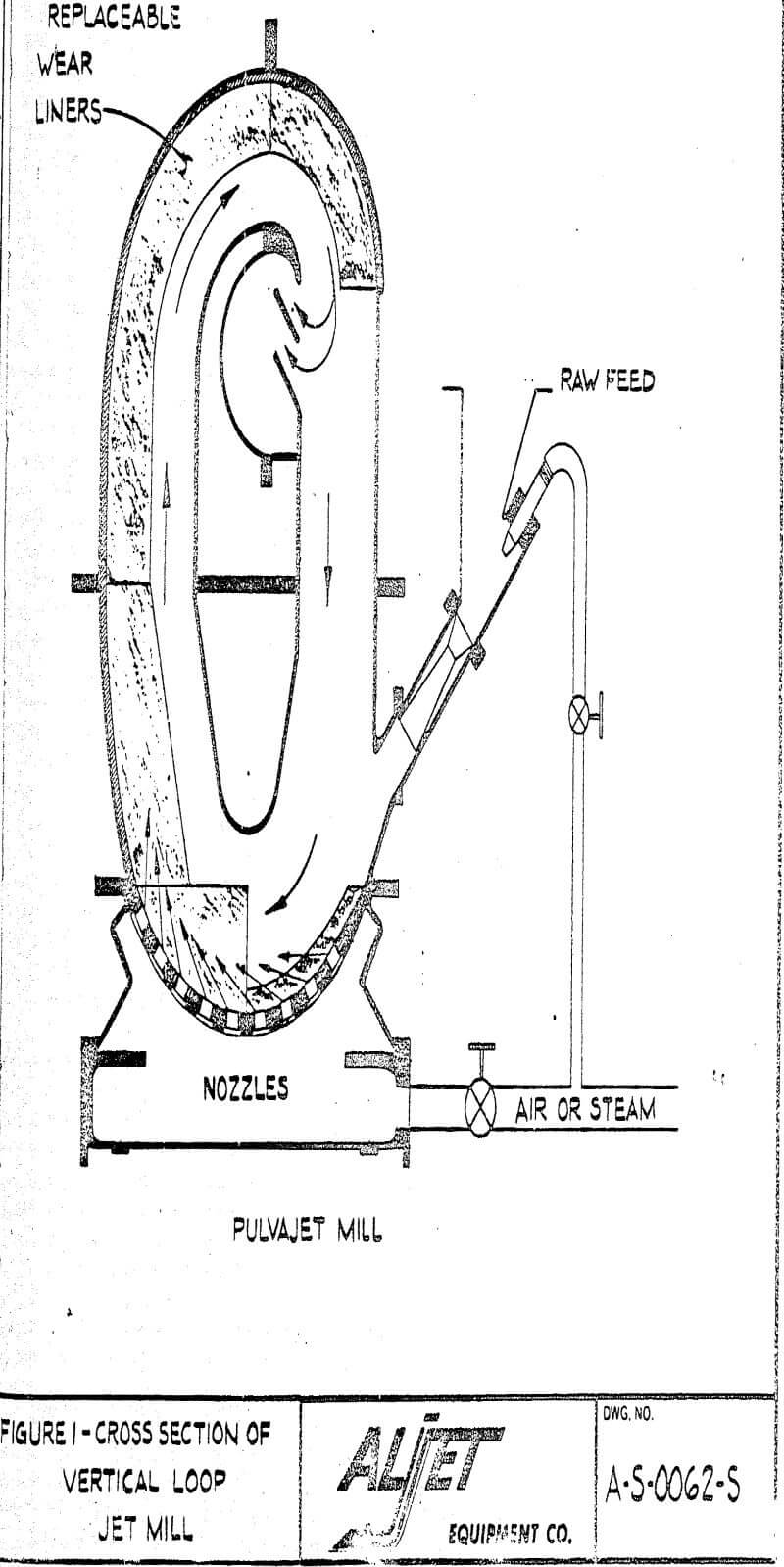

The underlying principle of all jet action fluid energy mills is to induce particles to collide with each other at high velocity causing one or both to fracture into smaller particles. Multiple collisions enhance the reduction process and, therefore, multiple jet arrangements are normally incorporated in the mill design.

The motive elastic fluid is normally air at up to 100 psig (6.9 Bars) or steam at up to 300 psig (20.7 Bars). Inert compressed gases such as nitrogen or carbon dioxide can be used under certain circumstances involving volatile materials.

Total Concept Size Reduction Systems

Although it is possible to introduce large section feed into a jet mill, it is generally undesireable to do so. Such practice can lead to high rates of abrasive wear, and be an energy intensive mode of operation.

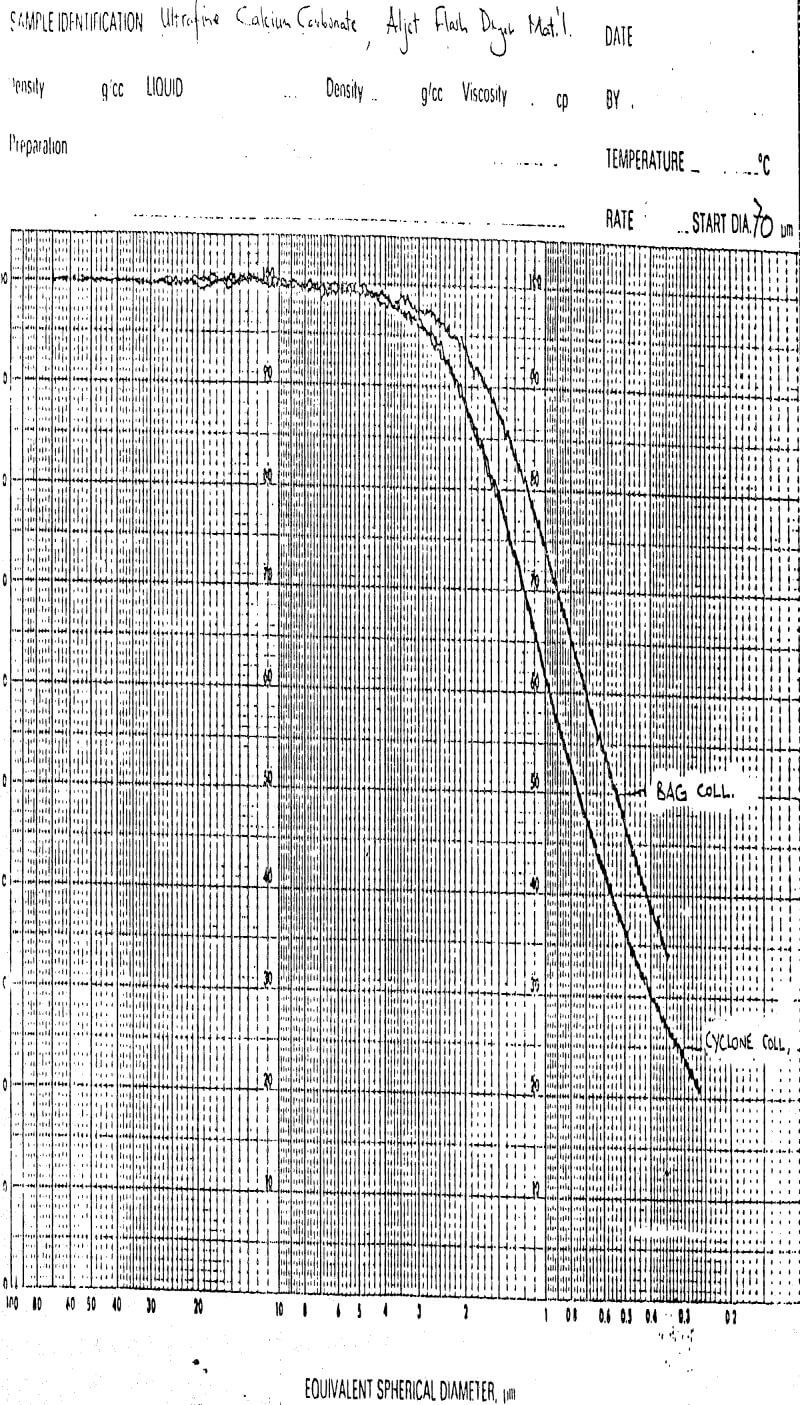

This leads us to define jet milling techniques as being aimed at the “fine end” of the total size reduction spectrum, generally with finished product having a median particle size of less than 5 microns.

Thus it is common practice to prepare jet mill feed by pre-crushing or mechanically milling cc a suitable level take advantage of the most economic operating levels of both size reduction techniques.

When seeking multiplication of surface area by ultrafine grinding the economics of a combined mechanical and jet milling approach can be demonstrated.

General Design and Application Considerations

In considering the application of jet milling techniques, there are several basic material characteristics and final product requirements which should be considered, typically:

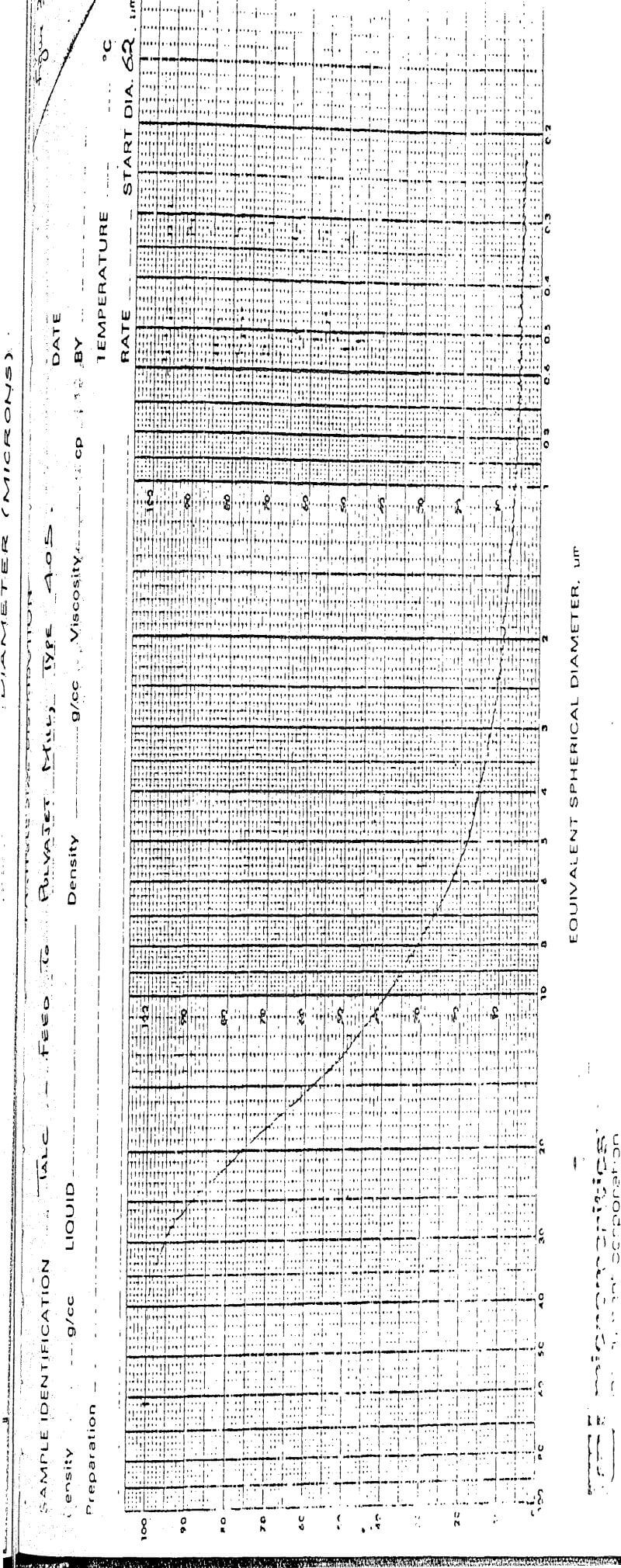

- Feed and product particle size distribution.

- Particle shape.

- Friability/elasticity.

- Abrasiveness/hardness.

- Melting/softening point.

- Purity requirements.

- Moisture in feed and product.

- Safety considerations, particularly pertaining to toxicity or flammability.

- Multiple process requirements – i.e. blending and coating.

As previously established, jet milling is aimed at the generation of fine particles, and feed preparation is generally more economically carried out by an upstream mechanical milling device.

Most earth minerals can be considered to be friable in the context of jet milling. That is, they will display fracture upon impact. This is, of course, in considerable contrast to elastic materials such as polymer and organic fibrous materials which display resilience upon impact. Even so, minor changes in friability characteristics can significantly alter energy consumption and the resultant particle size, even between ostensibly similar materials.

Jet Mill Feeding Considerations

The grinding zone of a jet mill is in extreme turbulence, resulting in eddying and backwashing of gases at the feed injection point. Placing the entire collection system and mill volume under a suction pressure, by use of an exhaust fan, does not ensure that local positive pressure conditions at the entry point will not exist, at least on an intermittent basis. Therefore, to assure feed consistency, and eliminate the possibility of backwash ‘dusting’, it is normal to use a positive pressure raw feed delivery system into the mill body.

Traditionally, a venturi feed injector, using pushing fluid tapped directly from the nozzle supply header, has been used. This generally consumes from 20% to 40% of total motive fluid going into the mill and thus is a significant energy consumption consideration.

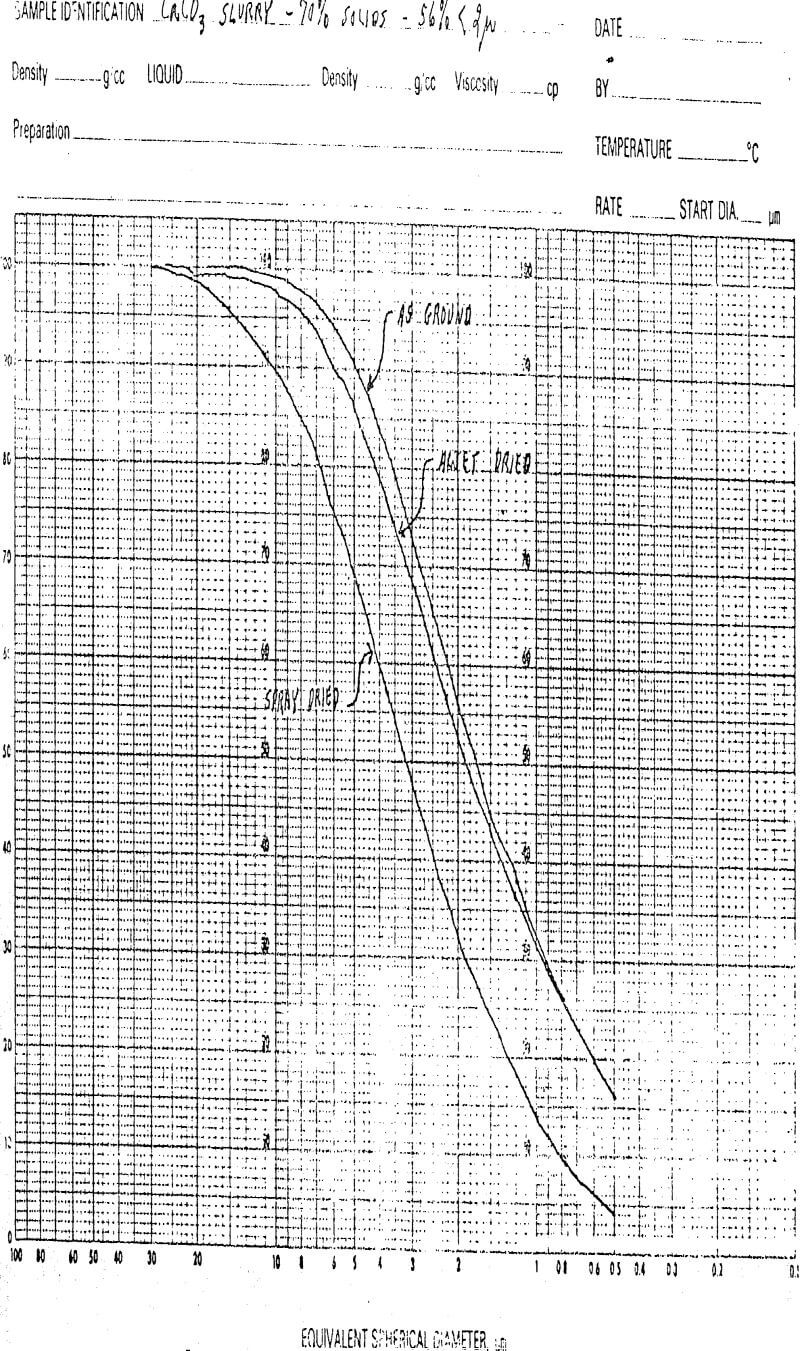

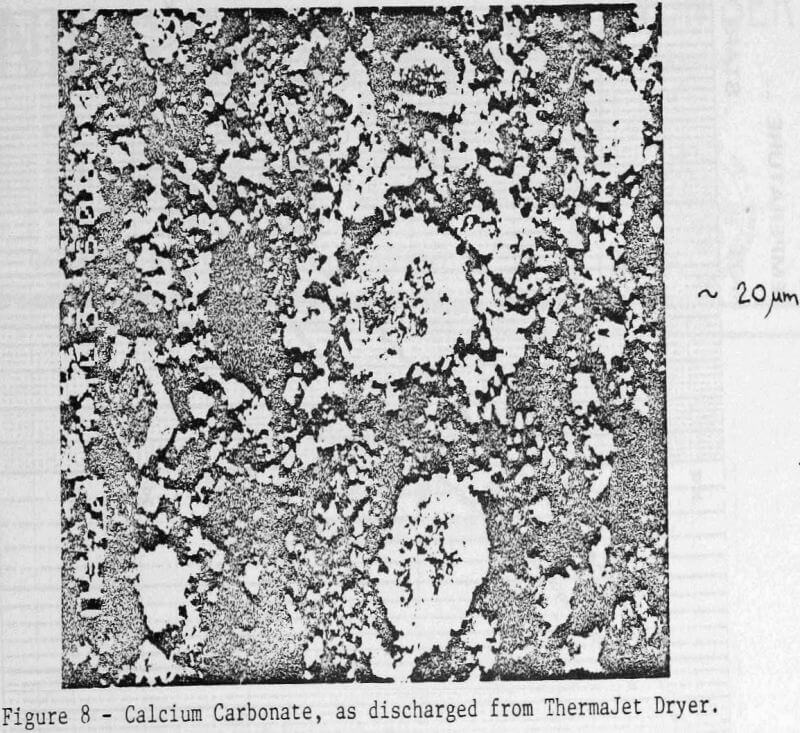

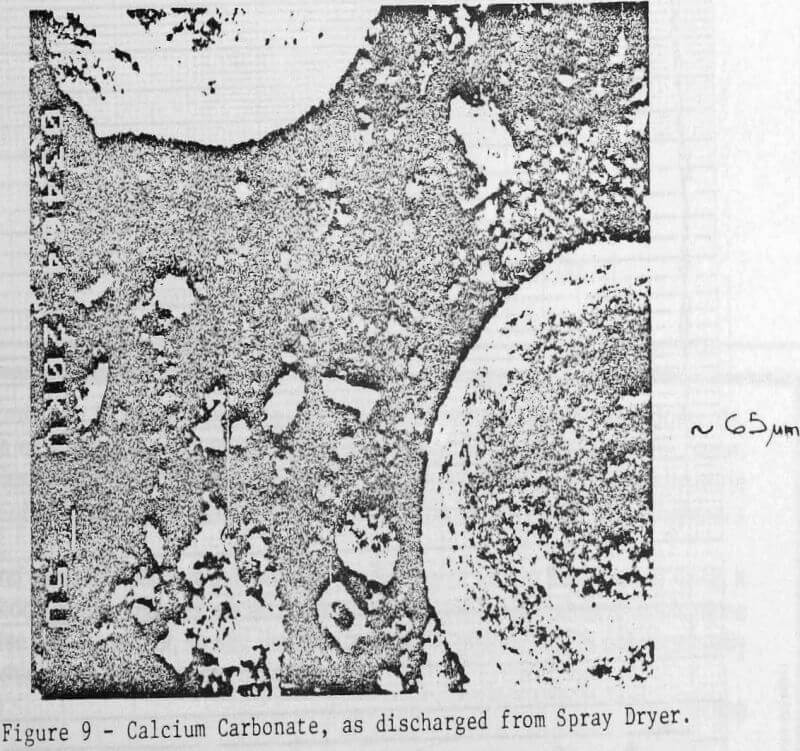

In those instances where wet processing is deemed necessary either for product beneficiation or comminution purposes, one of the major considerations becomes one of regenerating with fidelity the discrete mono-particle size distribution in the final dry product.

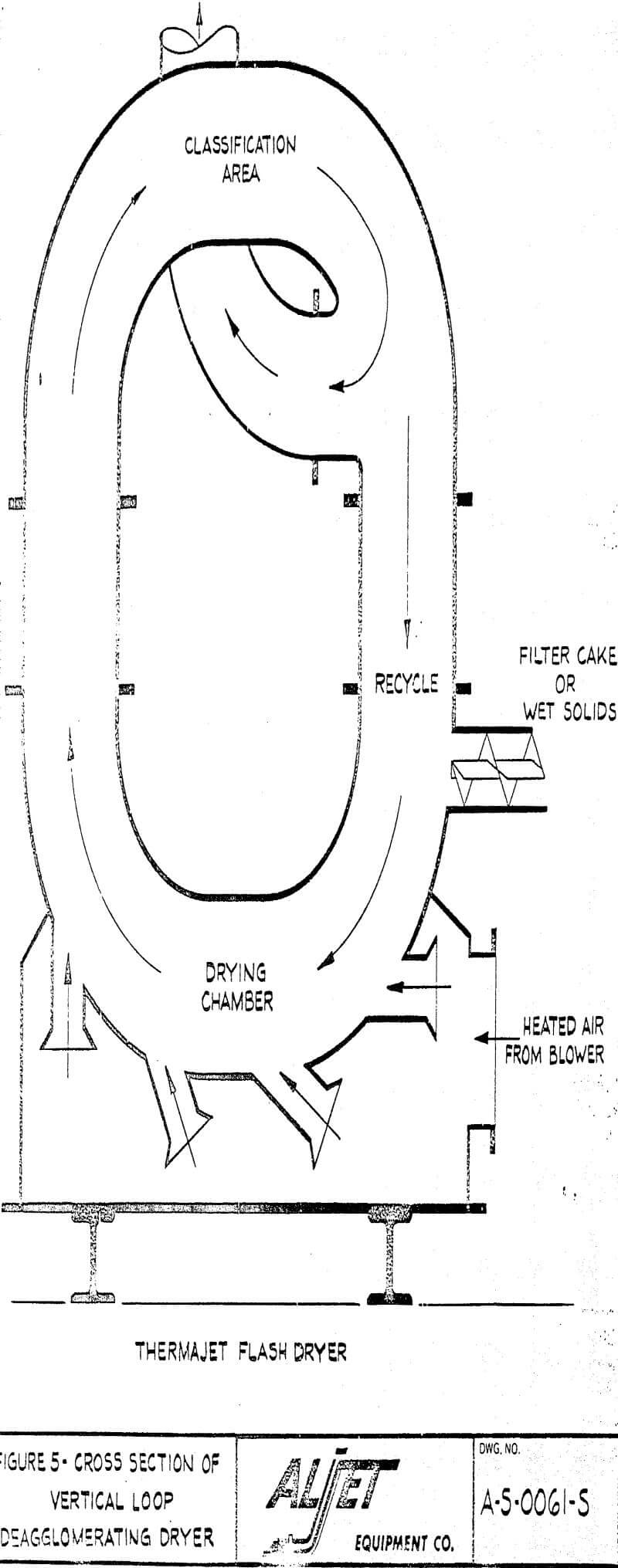

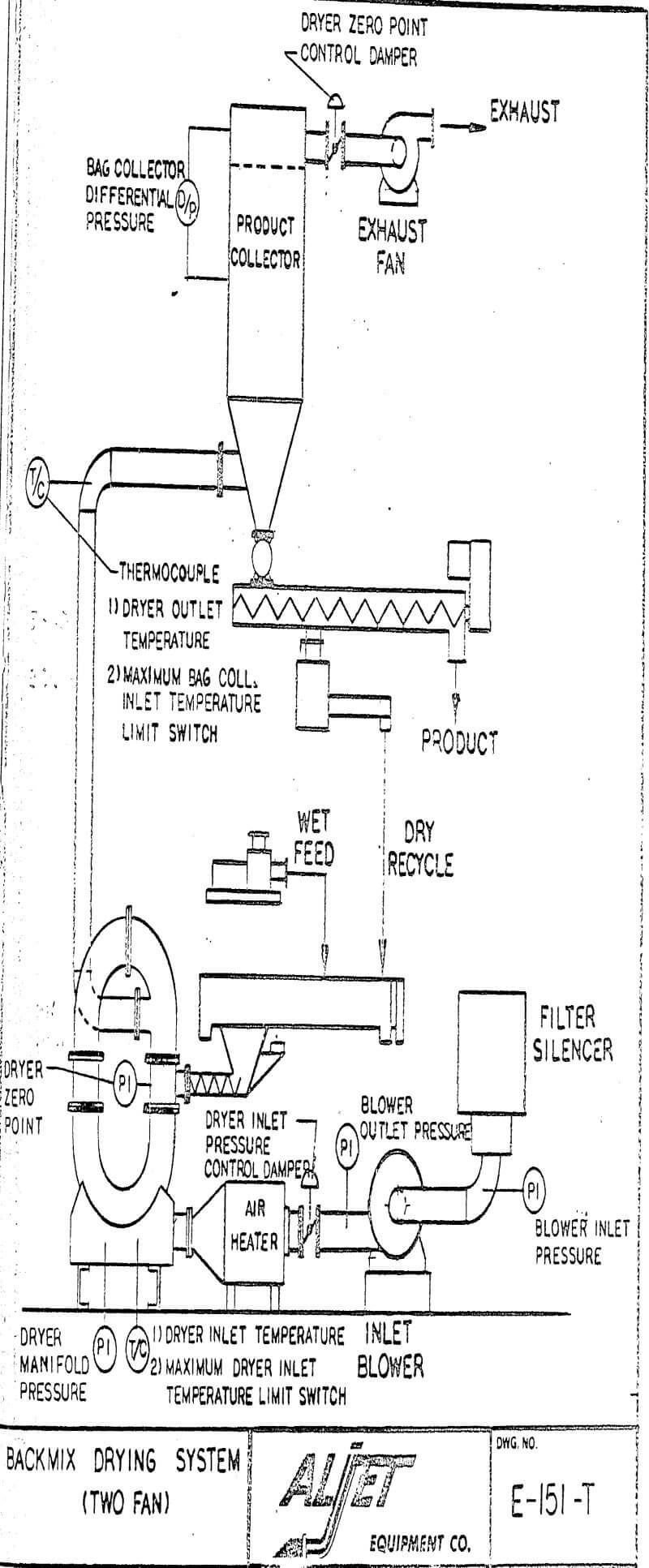

Recent advances in mechanical dewatering systems have brought into commercial reality the continuous processing of slurries into hardcake capable of being delumped and directly fed into the ThermaJet type dryer and immediately picked up by the recirculating gases.

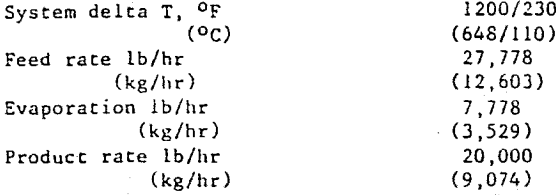

Operational parameters for a typical system to generate 20,000 lbs/hour (9074 kg/hour) are as follows: