The writer has been unable to find much information relative to tests made to determine the effect of forging on the specific density of steel. The opinion, however, among men engaged in the business, seems to be that forging greatly compresses or consolidates the steel. While such is doubtless the case with spongy or porous steel, the following experiments indicate that there can be little or no change in the density with steel initially free from cavities:

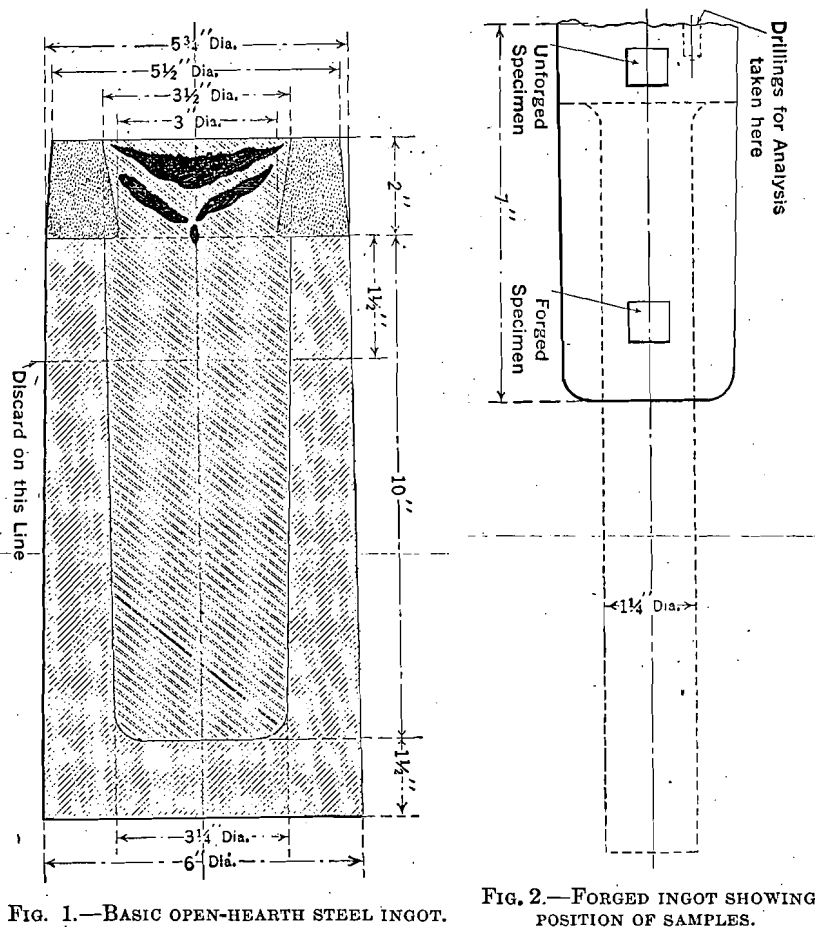

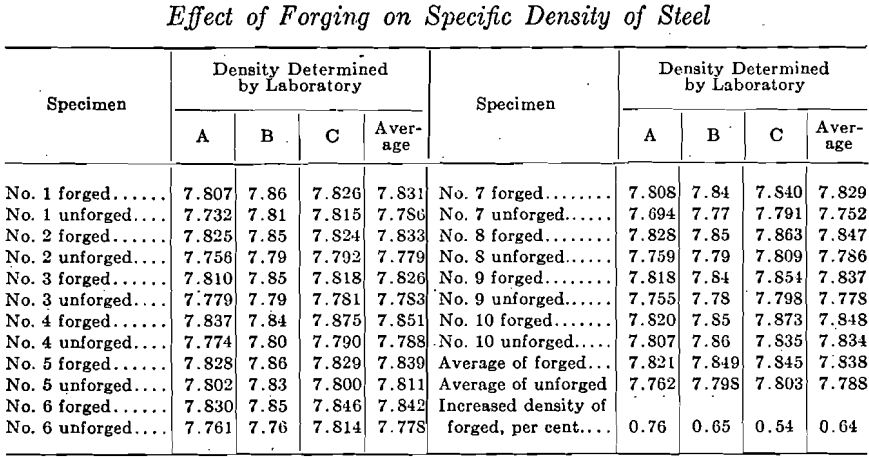

Ten ingots of basic open-hearth steel cast as shown in Fig. 1 were used in the experiments. All the specimens were 0.53 carbon with all other elements the same, the analysis being determined from drillings taken midway between the center and outside of the upper end, as shown in Fig. 2. The specimens were selected from over one thousand ingots so that the tests could be comparative for the work done in forging only, but no two of the ingots were cast in the same heat. Each ingot remained in the mold approximately 30 min., when it was removed and air-cooled. About 12 hr. later, when the temperature had been reduced to approximately that of the surrounding atmosphere, the head was discarded and the ingot heated in an oil furnace to approximately 2250° F. (1235° C). Approximately 1 min. was required to forge under the steam hammer to 1¼ in- (31.75 mm.), rough diameter, as shown by the dotted lines in Fig. 2. All ingots were allowed to air-cool after forging. Cylinders ½ in. (17.7 mm.) in diameter and ½ in. high were then turned from the forged and unforged parts of the ingots and numbered. The ten pairs of specimens were submitted to Louis E. Endsley, Professor of Railway Mechanical Engineering, University of Pittsburgh; A. N. Talbot, Professor of Applied Mechanics, University of Illinois; L. Z. Slater, chief chemist, Scullin Steel Co., St. Louis, Mo. No information was furnished as to which specimens were forged or unforged and each laboratory used the same specimens, submitting the average of three independent determinations, a tabulation of which is shown in the accompanying table in which the laboratories are designated by the letters A, B, and C. While there is considerable difference in the individual determinations for a number of the specimens, the averages for both the forged and unforged specimens are very close. The determinations of each laboratory indicate that the forged is the denser of each pair with the single exception of “B’s” determinations for No. 10. Assuming that all cavities, however small, were completely closed, the

average results indicate that only 0.64 per cent, of the sectional area of the original ingot consisted of cavities.

The ratio of volume to superficial area is so great with an ingot of the size used that it is doubtful whether the ingot can properly solidify without the formation of microscopic cavities. Undoubtedly, with large ingots where the ratio of volume to superficial area is smaller than with the ingots used, the percentage of increase in specific density of the forged specimens would be reduced to a negligible value, if not wholly eliminated.

Related: Best Blacksmith Hammer