- To participate in the 911Metallurgist Forums, be sure to JOIN & LOGIN

- Use Add New Topic to ask a New Question/Discussion about Flotation.

- OR Select a Topic that Interests you.

- Use Add Reply = to Reply/Participate in a Topic/Discussion (most frequent).

Using Add Reply allows you to Attach Images or PDF files and provide a more complete input. - Use Add Comment = to comment on someone else’s Reply in an already active Topic/Discussion.

How to improve copper & gold recovery to copper concentrate (6 replies and 3 comments)

What is your head grade %Cu %Fe Au g/t and other elements you have? What is your primary grind P80?

What are your tailings assay? Can you post a flowsheet here? Have you done any tests? Can you post the results/conditions here?

It sounds like you need to go back to the basics and determine a grind-recovery curve and a grade-recovery curve, all of which can be done fairly quickly in the lab. Run three lab flotation tests at different grind targets to quantify the sensitivity to grind. Once you think you have determined the "best" grind, then do the same with reagents, primarily collector and pH (lime), usually the impact of frother cannot be measured in the lab, i.e. as long as you have enough froth to float, then you can't do much better than that.

My guess is that the problem is pyrite, and guys have spent their lives trying to develop an ultimate pyrite depression scheme. Sometimes cyanide works, and sometimes it doesn't. Sometimes some highly specific copper collector works, sometimes it doesn't. Sometimes using shorter chain xanthates works, sometimes it doesn't.

The key is to get back to basics - determine the best grind (remember this is a balance between recovery and grinding horsepower), and the best combination of reagents in the lab. As part of the program you should take a sample of your rougher concentrate and look at it under a microscope - if there is a lot of pyrite is it liberated or associated with the copper minerals. If it is the former then there are opportunities to optimize flotation. If it is the latter then you need to look at finer grinding.

I'm sure there are dozen of other things to consider, and the 911 met team can help, but don't make flotation any more complicated than it needs to be. I hope this helps.

Best Regards

Andrew

Saddam,

seriously: 0.04% Cu tails on a 2% head? You wonder why the low 18- 20%Cu?

What reagent suite are you using (dosages)?

What is you Au/gold content in tailings? Please describe your flowsheet. Plant tonnage? Regrind? Give us details if you really want help.

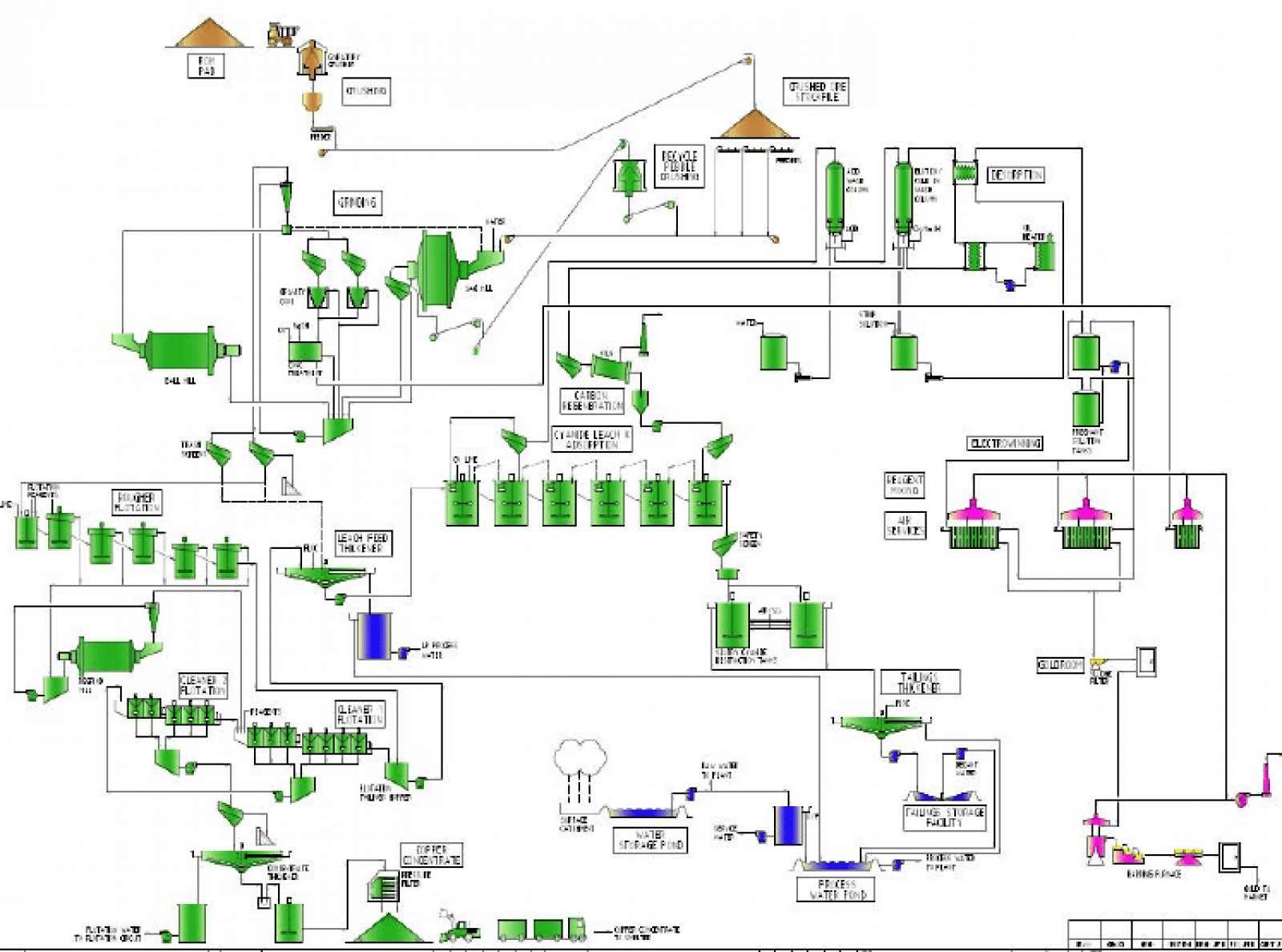

The flows sheet of the plant has been attached.

https://www.911metallurgist.com/blog/saddams-copper-gold-flowsheet

Hello Saddam, yes please give use details. It appears you are pulling much too hard. We need to know how you are doing it. What chemicals, dosages, % mass pull rate, plant details. The more info you give us, the better we can guide you.

Do you have photos of the plant froth? Videos?

What frother? MIBC, Dow, Pine Oil? Glycol?

What pHs are you running at?

What is you Au/gold content in tailings?

Your PAX, what strength are you mixing it at 10, 15 or 20%?

500 ml/min: are you certain?

What is the %Fe in your copper conc?

Your reagent dosages do not make sense to me...

I have been given a project on optimization of copper concentrate grade so as to improve copper and gold recovery. I need help on the main factors which I have to consider in my project. The targeted copper concentrate grade at the plant is 18- 20%Cu, but currently the target is not achieved. The plant ore is chalcopyrite.