Table of Contents

The working of gold alluvial deposits by dredging has from all times been a popular form of mining, not only from the simplicity of its operations, but also, in its more primitive stages, from the possibility of carrying it on without large capital, without skilled labour, expensive plant, long terms of preparatory work, or, in fact, any other requisite than a shovel, a dish, and a stout pair of arms. It is possibly one of the oldest industries, and probably, also, it has been one of the most profitable.

In the Australian States the happy days of rich alluvial deposits, when gold was to be had for the shovelling, are now almost over. The lust for gold has caused almost every corner of the world to be ransacked, and the more easily-earned wealth to be exhausted: for the most part there remain now those deposits only which are too poor to be profitably worked by means of the implements and methods of old times. But, though the deposits have become poorer, the keen inventiveness of man has devised means whereby such large quantities can be treated at a cost so low that he can still make a profit out of them. In this article, out of the many means devised, three only will be referred to: hydraulic sluicing, bucket dredging, and hydraulic dredging.

All alluvial mining may be divided into three principal operations:

- the breaking down and conveying of the ground to where it is to be treated for the recovery of the metallic values;

- the treatment of the material for the recovery of those values; and,

- the removal of the worthless material or tailings.

In all mining the object is to effect these three processes for the least expenditure of money commensurate with the highest degree of efficiency. In mining solid rock the first two processes, the breaking down and crushing of the material, and the saving of metallic values, are both fairly expensive items. The first may cost from one to thirty shillings a ton, the second likewise, and this would be a prohibitive cost where the material is worth perhaps as many pence only. But here the great advantage of working an alluvial deposit is apparent. Nature has already broken down the material, and not only has it effected the first process, but it has largely helped in the second by both disintegrating the material and, to a great extent, concentrating the values. The first process can therefore be effected comparatively cheaply, and the second is reduced to its simplest form; in the third only does any difficulty present itself, or the cost become comparable with the same item in mining solid rock. For breaking down material, provided it is soft enough, no process is cheaper or better than by means of water under pressure. There is no cheaper method either for conveying large quantities over considerable distances; and the eliminating of metallic values by its means is one of the commonest in mining. Therefore all three of the above processes can be effected by one agent, the only requisite being that it should be obtainable in sufficient quantities, and, for the first process, under sufficient pressure. How cheaply work can be done by this means may be appreciated from the fact that material has been treated for as low as one penny per cubic yard, even basalt and cemented drift has been broken down and removed by it for considerably less than what it would cost to remove by other means. But it is not always possible to either obtain or use water under pressure for treating alluvial deposits, or it may not be possible to effect all of the three above-mentioned processes by its means. If water is not obtainable under pressure, if the material is so situated that the water cannot be used against it, or if it is so situated that after the water has been used to break down, convey, and treat the material, it cannot itself escape from the workings, some other means must be employed, and this has caused the differentiation of the methods of treatment into the three above- mentioned: hydraulic sluicing, bucket dredging, and hydraulic dredging.

The term hydraulic sluicing is confined to that method in which the breaking, the conveying and treatment of the material, and the removal of the tailings is done by water only. It is suitable only where the water can be obtained in sufficient quantity and under sufficient pressure to break down and remove the material, and also, if necessary, to work some kind of hydraulic elevator to remove the tailings. In hydraulic dredging the material is broken down and conveyed to the place of treatment by water, but the tailings and the water are elevated for removal by steam. Usually the material and water are elevated before treatment. This is not a necessity, but merely for convenience. The term “ dredge ” has been applied because the elevating machinery is placed on a pontoon, and so can be floated from one position to another, but the machinery serves one purpose only—that is, to lift the material and water to a height sufficient to flow away by gravity. In some few cases, where water under pressure is obtainable in no other way, another pump is installed, by means of which water for sluicing is pumped against the face, but the primary purpose of the plant is to elevate the water and material.

In bucket dredging, on the other hand, all three processes are done by means of machinery. The material is broken down by means of powerful steel buckets; it is conveyed to the place of treatment by the same buckets; the water for treatment is pumped up by means of a centrifugal pump, and the tailings are generally removed by means of a mechanical conveyor.

As a rule it is not difficult to decide which of the three methods is most suitable. Where water can be obtained in sufficient quantity and under sufficient pressure, and where sufficient grade can be obtained for it to remove the material, both before and after treatment, and sufficient area obtained on which to dump the tailings, hydraulic sluicing would certainly be used, provided the three conditions could be obtained at a cost commensurate with the value of the deposit. The most important condition, and the one most usually overlooked, is the disposal of the tailings. There must be area enough to dump not only as great a quantity of material as the deposit contains, but also to allow for a considerable increase in bulk over the material in situ—an increase that may be as much as one-third of the amount. To obtain this area may necessitate the construction of a long and expensive race, the driving of a costly tunnel, or the installation of an expensive pumping plant, and the costs of all these must be balanced against the probable value of the material. As the rate at which the material can be removed and treated, provided the sluice box can be made proportionate in size, depends in a direct ratio on the steepness of the grade down which the water flows, the dumping area must not be obtained at the expense of the rate of treatment if the latter is such that it becomes unprofitable. It must also be ascertained whether the race can be brought in at such a level that it can treat the material at the bottom of the deposit, or, if not, whether it will pay to lift this material. If the material has to be lifted, due consideration must be given to methods of elevating it. If water is cheap and plentiful, jet elevators might be used; the wear and tear is small, and they need no attention. On the other hand, as a pump they are most inefficient, and, if water is expensive, it would be well to use it in some more efficient way. If water is not in sufficient quantity to allow of its being used for pumping, some other motive power would have to be used, and a choice made between belt transmission and electrical transmission. If it were necessary to move the plant often, probably the method of hydraulic dredging would be followed; but due consideration would, of course, be given as to whether it were better to move the plant by water or by rail, or whether it were better to have boilers, engine, and pump on the one pontoon, or to have the machinery on a fixed site and transmit the power by electricity. These questions must be decided for each particular locality. Bucket dredges can work material at a very, low cost, but their use is limited. They can be used for certain lifts only, and the surface on which the deposit lies must be of a favourable character. It is doubtful also whether they can work a deposit as efficiently as either of the two other methods, and it is probable that there is always some loss in metallic values. The information on this point is meagre and unsatisfactory, and only one case is known to the writer where a fairly satisfactory comparison could be made, the same deposit being worked at the same time by hydraulic sluicing with jet elevator and a bucket dredge. The evidence was entirely in favour of the first method, both in cost and efficiency; but due regard must be given to the fact that the conditions might not have been exactly identical; that, although the same deposit was worked, there may have been some local difference both in the quality of the material and its value, and there was also no independent standard of comparison.

The method of working having been decided on, the next step would be to arrive at some idea as to the value of the deposit, and whether it would yield a profit.

Bucket Dredging

Having now discussed most of the salient points in regard to hydraulic sluicing, we will pass on to the next important method, the working of deposits by means of bucket dredges.

New Zealand lays claim to being the first country where the bucket dredge was applied to gold-saving, M‘Queen having built the first one in 1882. Specially favourable conditions in the rivers of Otago may account for the rapid rise of this great industry, which is now carried on in many rivers all over the world. The rivers of Otago, N.Z., were rich in gold-bearing gravels, and from the earliest days of the colony efforts were made to obtain the gold.

That which lay on the banks was soon won, and when the rivers were low some of that in the bed also. The richness of the gravels in the bottom of the rivers was early known, and all sorts of contrivances to get it were discussed; projects were seriously entertained of diverting some of the rivers, but the cost and difficulties being recognized, less heroic measures were tried, such, as spoon dredges and diving bells, but nothing came of them until the invention of the modern bucket dredge, which has done so much to win gold from places hitherto unworkable.

In gold dredging the material is broken down by heavy steel buckets driven through it by machinery; the buckets also elevate it to a place where the metals can be saved. The metal-saving equipment is an adaptation of the ordinary principles to particular circumstances, and the waste material is removed by water, or by means of some form of elevator.

Dredges are now made so strong that there is little in the way of river alluvium that they cannot work, although due regard must be given as to what the dredge can do profitably. In hard material the chances of breaking links or buckets are minimized by the use of the friction gear, but even with all contrivances and precautions breakages are frequent, causing expense and loss of time, and telling seriously against profitable working.

The conveyance of the material to the metal-saving equipment is limited in distance by the length of the ladder, and in quantity by the capacity and rate of delivery of the buckets. Dredges are now made to lift material from 40 feet below water level, and there are cases where banks 40 feet above water level have been successfully attacked, but usually banks of 15 to 20 feet are deemed high enough. High banks are not safe to work, except under careful and skilled supervision, and deep deposits require high elevators with large, powerful, and expensive dredges.

The buckets have been made with as large a capacity as 7½ cubic feet, but when deciding this question due regard must be given to the quantity of material it is desirable to treat, and the metal-saving equipment must be made large in proportion. The kind of material to be treated must be ascertained beforehand, and the question whether it is desirable to treat large quantities or not must be decided by an expert. Very rich wash, especially of a clayey nature, cannot be put over the tables in large quantities without risk of losing gold; on the other hand, loose, gravelly wash, poor in value, can be put through as fast as possible.

Care must be taken to differentiate between the nominal and actual capacities of buckets. The former is the amount which would be obtained if the bucket came up full with the ladder lying at 45 degrees, or at its maximum dredging depth, and the buckets emptying at their rated speed—say, 12 a minute. But the buckets seldom come up full, especially in shallow water with the ladder lying at a flat angle; a few large stones also make very bad stowage ; hard, cemented ground is very difficult to get into, and stiff clay very difficult to get out of the buckets, and all these things tend so much to reduce the nominal capacity that 25 per cent, is often little enough to allow for reduction.

It must be remembered also that the buckets load themselves, and do not have the material loaded into them, and in this lies one of the weaknesses of the bucket dredge, for it is undoubtedly a fact that, however good the winch man, and however favourable the bottom may be, all the gold is not taken up. In a strong current the disturbance of the ground causes material to be washed past the buckets; shoes of ground are left between two consecutive outs; hard, uptilted slates, with the gold in the crevices, or hard bottoms with cracks and pot-holes cannot be cleaned up properly; large boulders lying about make the proposition almost prohibitive ; and in fact nothing but a soft bottom into which the buckets can dig is entirely favourable for this kind of work. The real reason why most of the dredges in Otago, N.Z., have been so successful over ventures in other parts, appears to be that most of the bottoms there are soft and easily worked.

The metal-saving equipment is simple, and the principle employed the same as in hydraulic sluicing.

In many dredges the stone and gravel over a certain size are screened out by means of a revolving screen, and do not pass over the tables, but go straight to the elevators. The fine material is passed over tables set athwartship, or into sluice boxes running fore and aft. Both these methods have their advocates, but it seems probable that of the two the tables are the best.

When discussing metal-saving in hydraulic sluicing, the necessity was shown of keeping an even feed of material into the boxes. It was shown that in gold-saving an increase of material, without a proportionate increase of water, would tend to cover the ripples with sand and prevent them doing their duty, and would raise the grade of the plane down which water and material flows, increasing the velocity, which would tend to remove the gold. In tin-saving, ripples are not used in the same way as with gold, but raising the grade of the plane down which the material flows would also tend very materially to lose the tin.

This tendency would be greatly increased in a short box unless the same amount of surface be gained by widening it.

To make the matter clear it should be stated that lowering the slope at which the box is set will act in the same way as putting in too much feed. If the slope is flat the material will not go away as fast as if the box were set at a steeper slope, consequently the sand will pile up at the head of the box till it makes a grade at which it will go away, unless it runs over the sides of the box, in which case work must be stopped.

From what has been said above, it seems that tables placed athwartship should not be so liable to a change of grade as long sluice boxes running fore and aft. If the buckets come up heavily loaded, the bow is depressed, therefore in a fore and aft sluice box the grade is flattened just when, a greater quantity of material coming up, it should be made steeper. The material will therefore pile up at the head of the box if the water is not increased. If the water is increased, and for any reason the weight at the bow is lessened, the grade rises and the material is scoured out—gold and all. A dredge is in constant movement in two directions, the bow constantly dipping and rising, and the dredge surging against its headlines. These movements, though relatively small, are of great influence in a long sluice box, where the variation of the grade by even a very small amount would be detrimental to its efficiency as a metal-saver. With wide tables placed athwartship a depression or elevation of the bow does not alter the grade of the table, but by depressing one side tends to send the sand and water to that side.

However, as the width of even a fairly wide table, say 20 feet, is relatively small compared to the length of a dredge, this depression is not great, and is further minimized by the custom of dividing the tables into compartments. The same remarks apply to the metal- saving equipment of a tin dredge, except that, because of the smaller specific gravity of tin ore, fewer liberties can be taken with it. Tin, also, is such a bulky metal that the relatively small area that can be devoted to its saving in the limited space available on a dredge must necessitate constant clean-ups, which must entail a heavy expense. The question for investors must always be whether or not the tin or gold can be saved in sufficient quantity to pay them back their invested capital with profit, not whether an indefinite amount only can be saved.

The last stage of the operation is the conveying away of the refuse material after it has been treated. In a swift current it can be allowed to run away over the stern; the current will carry it far enough away to prevent it causing trouble. But in a sluggish river or in a paddock the tailings must be stacked. This is usually done by means of a bucket elevator, though belt and other elevators are used. The material will take up more room than it did in the bank, so that an elevator proportionate to the total depth of the deposit must be provided. If the depth of the deposit is great a very long elevator must be provided, and this is one of the factors limiting the capabilities of a dredge. Material loosely deposited lies with a very long slope, and must be deposited so far back that it will not slip down among the buckets again.

In regard to the dredges, the machinery and boilers should be of the highest class to work efficiently with the poor fuel and bad water that is generally used. The buckets and links should be of the best material and make, otherwise constant breakages from the rough usage will tell heavily on the cost sheet. All dredges should have watertight compartments, for want of which numbers of dredges have gone to the bottom.

The cheapness of bucket dredging lies partly in the small amount of labour required, seven men being the usual crew, and partly in the small amount of power necessary, 20-horse power being enough for a large dredge. Of the seven men, every one of them should be competent, else the efficiency is greatly diminished. As a large dredge takes about the same number of men as a small one, the expenses do not, for this item, rise in proportion to the material treated. Many dredges claim to work between 1¼d. and 2d. per cubic yard, but it is difficult to find out whether this includes amortization charges. In the hypothetical case to be stated later on, the cost, including amortization, works out in both cases at very little over 2d. per cubic yard, and, excluding amortization, at 1.83d. per cubic yard, which is certainly very cheap working.

Centrifugal pumps for lifting the material instead of buckets have not, so far as the author knows, proved a success. A very large increase in the power is required to lift the water, which is necessary in the pump, but detrimental on the tables.

When going in for a dredging property, the first thing is to ascertain its value. In paddock dredging this can be done by boring or shaft-sinking, and at the same time the depth of the deposit, the character of the wash and of the bottom can be ascertained, all of which are points which the designer of the dredge must know.

In a river, prospecting up till now has proved very unsatisfactory, and most river ventures have been little better than a gamble. A small, powerful dredging plant, to be taken to pieces and moved from claim to claim, might meet the case. Sinking cylinders by air locks has been proposed, but both methods are expensive, and generally dredging properties are not rich enough to stand expensive prospecting.

Let us take a hypothetical case, which for convenience shall be a paddock dredge, where the values and extent of material can be ascertained.

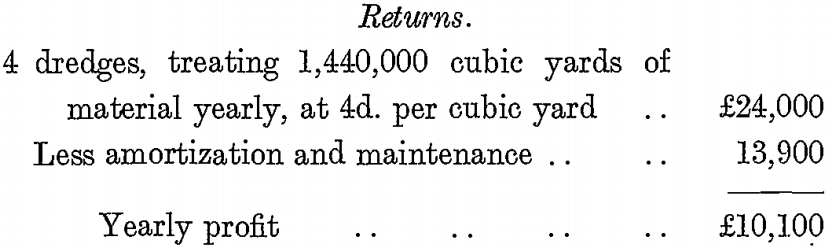

Say the proposition is of 400 acres, the average depth is 24 feet, and for which £10 per acre is paid. The contents are 15,488,000 cubic yards, which, say, average two grains of gold, worth 4d., per cubic yard, or £258,000 total value.

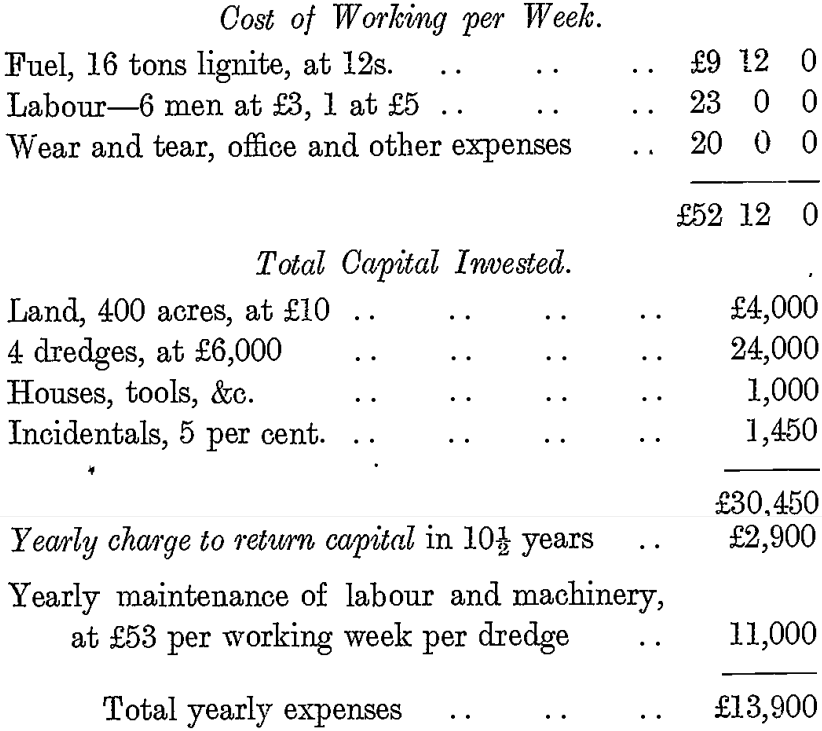

The dredge has buckets of, say, 3¾ cubic feet, delivering 12 to the minute; allowing them to deliver 60 per cent, of the nominal rating, the amount treated is 60 cubic yards an hour. Allowing a dredging week of 120 hours, we get 280 working days of 24 hours each in the year. This gives 360,000 cubic yards treated a year, which, at the above value, returns £6,000, and at this rate the deposit would be worked out in 43 years.

It is advisable in all mining ventures to work out the deposit as quickly as possible, in order to obtain the interest on the values lying in the ground. Let us say, then, that four dredges are put on instead of one; the deposit would then be worked out in about 10½- years.

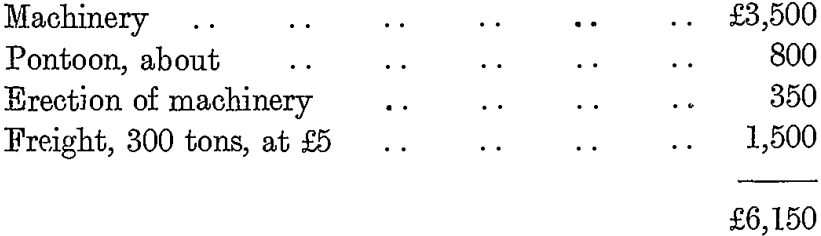

The cost of a dredge, with buckets of 3¾- cubic feet capacity, to dredge to a depth of 25 feet, and elevate the tailings 20 feet above water level, would be—

In the above capital charges, no account has been taken of the amount spent in boring surveys, flotation expenses, &c., but all these should be included.

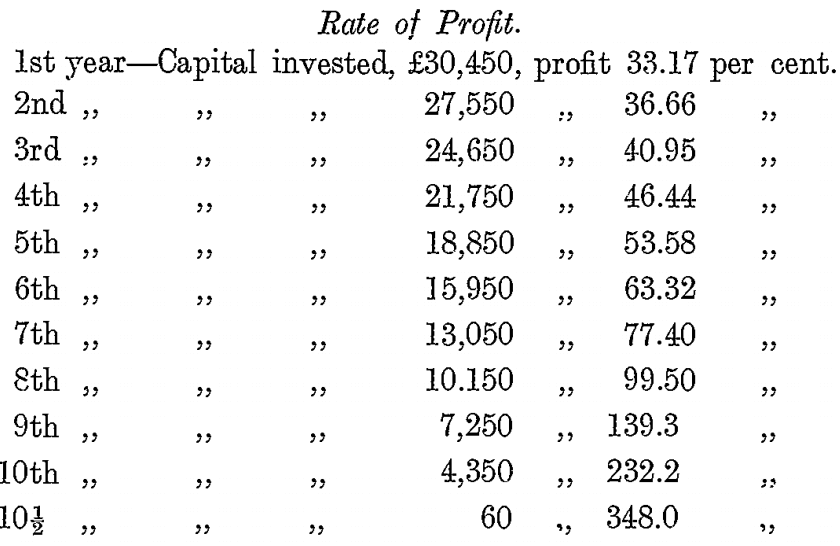

The policy of putting on four dredges to work out the material in one-fourth of the time is justified by calculating how much will be gained in interest by so doing. The calculations are too long to set forth in detail. It will suffice to say that the profit is considered to be invested yearly, as it is won, at 5 per cent, compound interest, and is reckoned as the difference between the amount won yearly and the working expenses, the first two or three years’ profit being deducted to pay back the capital invested, together with the interest at 5 per cent, while so invested.

With four dredges the property would be worked out in 10½ years, returning in that time, after paying back the capital, together with all working costs, a clear profit of £102,568; and this invested yearly as it is won would bring in £19,556 in interest.

With one dredge, under the same conditions and during the same time, only £21,084 is returned as clear profit; and this invested yearly as it is won, would return £3,651 in interest.

If the single dredge worked the whole property out in 43 years, the yearly profit, invested as it is won, would at the end of that time return £241,673 in interest; but the investment of £102,568 won by the four dredges in 10½ years, together with its interest of £19,556 for a further term of 32½ years, would return £462,342 in interest, a gain of £220,669, which shows that in every respect the saving of time in working out the property quickly is advantageous.

In conclusion it may be said that, if the conditions are favourable, bucket dredging is cheap, both in first cost and in working expenses. It is a mistake to think, however, that it will be successful under any conditions. The adverse effect of a bad river bottom has already been pointed out, also the losses that may occur from the stirring up of the material, especially in a fast-flowing river. If this is true for gold, it is doubly or trebly so for tin, especially for fine tin, where the loss may reach a very high proportion. Logs and boulders increase the lost time and the working expenses in proportion to their quantity, and in any dredge with a long sluice box the depression of the bow caused in lifting them must have a detrimental effect on the metal-saving, and it cannot be sufficiently emphasized that although this liberty may be taken in gold-dredging, it cannot be taken in tin-dredging.

The conditions in gold-saving and in tin-saving are so different that it is probable that those managing tin dredges have yet a great deal of experience to gain, one of the most serious being to avoid the losses caused by the movements of the sluice box. However, no doubt this difficulty will be overcome as others have been, and due credit must be given to those who undertake to unravel this problem. The construction of metal-saving dredges is so recent an industry that only a few makers have the experience necessary to meet all the difficulties that are incidental to this form of dredging only, and when ordering a dredge recourse should be had to experienced makers, even if the price, either for the dredge itself or for extra freight, is higher. Few dredging propositions are rich, enough to afford a cheap dredge.

Hydraulic Dredging

The third important method of working alluvial deposits is that known as hydraulic dredging. This method has been evolved for working those deposits that have no escape for either water or material, both having to be elevated. This method contains no modification in the method of breaking down the material, nor in the treatment of it for saving the metallic values; both these processes are carried on by the ordinary methods employed in hydraulic sluicing.

To elevate the water and material to a height sufficient to effect- their removal by gravity, a jet elevator up till now has been generally used; but, the want of sufficient water for this purpose has led, in Victoria and elsewhere, to the installation of centrifugal pumps driven by steam, and the necessity of continually moving these plants as the work recedes from them has led to their being placed on pontoons, whereby they can be floated from one situation to another.

The comparative merits of jet elevators and steam-driven centrifugal pumps will not be discussed here, depending as they do on so many local circumstances. Centrifugal pumps are certainly the more efficient of the two, and have by this time been so improved that they can not only stand the rough tear and wear of mining work, but can efficiently lift the water and material to a considerable height. At present 60 feet is the most economical height, but lifts of 70 and 80 feet are common. For lifts over 80 feet, for continuous work, it is cheaper to build another dredge and lift in two stages.

It is probable, in view of the great improvements that have been, affected lately in this class of pump, that its use will be largely extended, and that in many mines where jet elevators would, formerly have been used the water employed for power will be much more efficiently employed by this means, the power being developed by some form of water wheel, either direct or belt- coupled or transmitting its energy electrically.

The chief distinction of hydraulic dredging is that the elevating plant is not a fixture. The boilers and machinery are on a pontoon, and, when necessity arises, the excavation can be filled with water, the plant easily moved to its new site, the water pumped out, and work resumed. While working, the pontoon rests on the dry ground, and is in no sense a dredge, as the term is commonly used.

The material is generally elevated into a sluice box and there treated, but there is nothing to prevent the material being put through a sluice box in the paddock, and the tailings only elevated, if circumstances warrant such a proceeding.

It has been claimed for these plants that they have been made to pay on two grains of gold—about 4d.—per cubic yard; some even, claim to make 1½- grains, or 3d., pay; and costs under 4d. are claimed by several plants in Victoria. In a plant with which the writer is personally acquainted, and which is equipped with the most up-to-date engine and pump, the cost of a horse-power per annum, reduced to a standard of 280 days of 24 hours, is £15 8s. for 250 I.H.P. The cost per day is therefore £13 14s., which is equal to a cost of 2.3d. per cubic yard for 60 cubic yards, 1.9d. for 70 cubic yards, and 1.4d. for 80 cubic yards moved per hour.

Though many Victorian plants claim to move on an average more than 60 cubic yards an hour—some even have claimed to move over 100—60 may be taken as a good average in any material other than loamy soil; if, therefore, to the 2.3d. we add the cost of sluicing the material to the pump, say even at a cost of 2d., which is a low average, the cost is over 4d., and to this must be added the amortization and interest on the plant, head and tail races, pipes, nozzles, &c., together with a profit suitable for a mining risk. It is doubtful, therefore, whether anything less than 6d. a cubic yard will pay.

It must also be remembered that a certain amount of time is lost at frequent intervals according as the deposit is deep or shallow, wide or narrow, during which the excavation has to be filled with water, the plant moved, and the water pumped out, with all its expenses.

All that has been said about prospecting, estimates of cost, and metal-saving, when describing the other two methods, applies to this one, and need not be repeated.

The question may arise in this kind of work whether a large pump or a small one is to be installed. Of course, the usual factor of particular conditions governing individual cases arises here as with other methods, but it may be as well to point out that not only is there a saving in labour, as practically the same number of men will operate a large plant as a small one, and a saving in fuel, as the consumption is generally less per horse-power for large engines than for small ones, but also the amount of material that can be put through the pump rises in a much greater proportion than the increase in diameter of the suction pipes. Thus, to state a simple case, if the diameter of the suction pipe is doubled, the moving power is increased sixteenfold, and a suction dredge that can lift 500 cubic yards an hour when its pipes are 20 inches in diameter can lift 16 times 500, or 8,000, cubic yards when its pipes are 40 inches in diameter. However, on the other hand, the wear in the pump varies more or less inversely as the quantity of material passing through it, and a large pump with a small amount of sand passing through it may prove very costly in repairs. Great care must also be exercised over the stoking of the boilers, and the fire grates may often have to be modified to suit the poor fuel generally available in the bush.

It may appear a truism to say that no unnecessary delays should be incurred, but dredges are often found idle while tail races are being reconstructed on another site, and every delay increases the cost per cubic yard.

The same point must be kept in view here as in hydraulic sluicing—that the amount of material treated depends on the grade of the races through which the material passes. As the face recedes from the plant, the grade as a rule becomes flatter, and the dredge should be moved as soon as the quantity of material becomes too low to yield a profit.

On the whole this method has proved an efficient one for dealing with deposits otherwise unworkable, but, being more expensive than either of the other two methods, careful and competent management is necessary.

It may be as well to mention another method, which has been extensively used in America, and has lately been introduced to Australia. This is the working of deposits by steam shovels, and is of use when water is so scarce that there is just enough to treat the metallic values, being often used over and over again. It is claimed in America that deposits can be worked for 6d. a cubic yard, and a great deal of gold has been won by this means at a profit.

But this method is slow, one-third to one-half of a cubic yard a minute being good work, and, except under special conditions, it can never be adopted as against the other methods described above.

It is held by many that the employment of a man capable of accurately measuring the quantity of material treated, or of accurately gauging the water used, is an unnecessary expense. It may not be possible for a mine to afford such a man; but, unless these two factors are known, no accurate idea can be formed, either of the efficiency of the power employed, or of the relative cost, consequently no idea can be formed whether the material is being treated at the cheapest rate possible. The accurate estimation of the quantity removed is perhaps beyond the technical knowledge of many men otherwise perfectly competent, but it is often possible to periodically employ someone who has the required knowledge. It is possible, through carelessness or incompetence, to vary very much from the truth in this matter, and much harm has been done by the statements, often perfectly sincere, published as to working costs and quantities removed. In all low grade propositions it is necessary to save every penny, and this can certainly not be done if no accurate measurements are made either of the ground moved or of the water used. The latter is as important as the former, and one perhaps in which most error is made. Where steam is used for power the same applies, and the engine should be frequently indicated to see if the maximum of power is being obtained for the minimum of cost. As a rule, with steam some care is taken to prevent waste of power, but water, being such a common object in nature, is apt to engender the idea that the waste of it is immaterial. A simple calculation would show that every cubic foot of it has a certain monetary value, and the continual loss of even a small value will soon allow it to grow into a large one.

The chief methods of working alluvial deposits have now been examined—unfortunately, in a very incomplete manner, and with no attempt at going into technical details. Many of the points raised could be elaborated into a paper of their own, and would be a welcome addition to the technical literature of mining. It will be understood that all the calculations are on hypothetical cases only, and all the pros and cons that crop up in actual cases are not dealt with. They are only meant to indicate the lines it is advisable to go on in an attempt to ascertain whether a venture is profitable or not. Such full information as is necessary to determine with certainty the value and probable profit of a mining venture is seldom forthcoming, and much depends on the caution and experience of the investigator.

Unfortunately, with human nature it is easier to say what will please than what will displease, and the restraining of that optimism and enthusiasm which seems to break out in most natures as soon as they come in touch with anything that has to do with the winning of the precious metals, and which is so disastrous to cool judgment, is a power given to but few. But in these days of low-grade propositions every penny has to be examined before it is spent, and the few hints given in the above paper may serve as a guide to those who, not in themselves versed in the technicalities of mining, have yet to safeguard the interests of the great body of investing shareholders.