Table of Contents

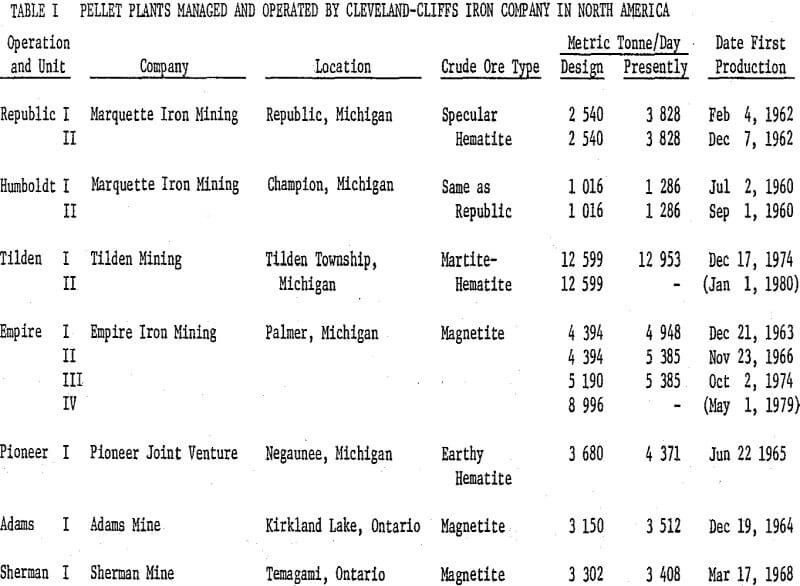

This paper describes some of the latest improvements that have been incorporated or planned by the Cleveland-Cliffs Iron Company to reduce operating costs and improve pellet quality. The Cleveland-Cliffs Iron Company operates and manages mining, beneficiation, and pelletizing operations in Michigan, Canada, and Western Australia.

Operating/Maintenance Cost Savings

Cleveland-Cliffs Iron Company, in December, 1976, embarked on an extensive test program utilizing various intensive mixing devices in an attempt to reduce present bentonite consumption in the pelletizing operations while maintaining pellet quality. Bentonite mixing devices tested at the LKAB straight-grate plant at Malmberget, Sweden reportedly have resulted in decreases in bentonite consumption.

The dual horizontal compartment-type mixer contains two muller wheels and two plows which rotate from a center shaft. Muller wheels at a controlled pressure agitate the mix through a special kneading, smearing, spatulate action. Two plows sweep the mix to an air operated bottom discharge door. Capacities range from 7.1 metric tonne/ hour (7 long ton/hour) to 508 metric tonne/hour (500 long ton/hour).

In testing the pellet plant feed materials from each of the operations, the first test series included firing of fresh plant green balls in the pot-grate and batch rotary kiln in order to avoid green ball degradation. The second test series included balling of the plant concentrate-bentonite mix in the laboratory continuous balling circuit followed by pot-grate and kiln firing.

Changes in pellet plant materials or operations that have proven to lower costs or are in the process of being evaluated are as follows:

- The use of self-lubricating urethane seals for reciprocating conveyor rams has quadrupled the seal life compared to conventional packing materials.

- A nitriding hard surfacing process for reciprocating conveyor rams has eliminated problems of chrome chipping and flaking that were experienced with the standard chrome type rams. Flamehardened 4150 steel is being considered as another alternative to the nitriding surfacing process.

Huck bolting of grate plate castings rather than the standard bolt and nut arrangement has drastically reduced the number of missing castings. Huck bolting of two piece grate plate castings maintains better top surface alignment, reduces casting losses in the stripper area and reduces the number of bent thru rods.

Conversion of one piece nodular iron to two piece (upper half stainless steel, lower half nodular iron) was a major cost savings improvement. One piece castings would oxidize (burn out) and distort.

Flame hardening of the lower base shoe has increased casting life to approximately seven years for one CCI operation. Thus ingress leakage into the drying and preheat furnaces from underneath the base shoe is minimal resulting in fuel and power savings.

Energy Requirements

The Pioneer Pellet Plant’s annular cooler was automated through the plant computer (DDC control) in 1976. No manual operator adjustments are necessary during start-ups, normal operation or shut-down periods. Benefits of the control system include improved cooling of pellets, prolonged discharge conveyor belt life and recuperation of more heat from the primary cooling zone. Data analysis indicates that automation of the cooler accounted for a 15% reduction in fuel consumption.

Preheat windbox temperature is utilized to balance the kiln-off- gas flow and recoup system gas flow. Tempering louver type dampers in each preheat cyclone exhaust manifold bleed in tempering air necessary to maintain 1A and 1B preheat fans to their maximum design limit of 427°C (800°F) .

Improved Pellet Quality

The Cleveland-Cliffs Research and Development group initiated an extensive test program in September, 1972 to determine if a grate roll feeder system would benefit the pelletizing operations. A test program utilizing a laboratory pilot test unit commenced on September 29, 1972. Testing was conducted utilizing green ball products from a number of CCI operations. Results of the testwork indicated that a grate feed with a minus 6.35 mm (¼ inch) content of 0.35% is an achievable goal with proper balling and roll feeder operation.

A roll feeder system was installed after the wide feed belt on Republic Unit II in April, 1975. A fines collecting belt, running perpendicular to the grate centerline, was installed between the roll feeder and traveling grate machine.

Even though no cost savings have been precisely determined, other benefits have occurred due to the installation of the roll feeder system. Increased life of fan wear liners, decreased chunk handling which correlates with reduced shell consumption, lower regrind mill maintenance and longer grate casting life, are side benefits that have been realized due to the roll feeder system.

Environmental Standards

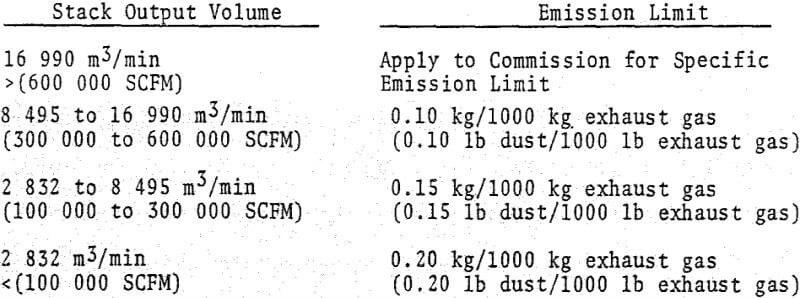

The Air Pollution Control Commission of the Department of Natural Resources of the State of Michigan has established the following particulate stack emission limits: