The small ball mills and rake classifiers in the London concentrator were replaced by one large ball mill and one hydraulic classifier. This new ball mill was designed oversize so that it could be operated at slower than normal speed. The proper operating conditions were established and the results published.

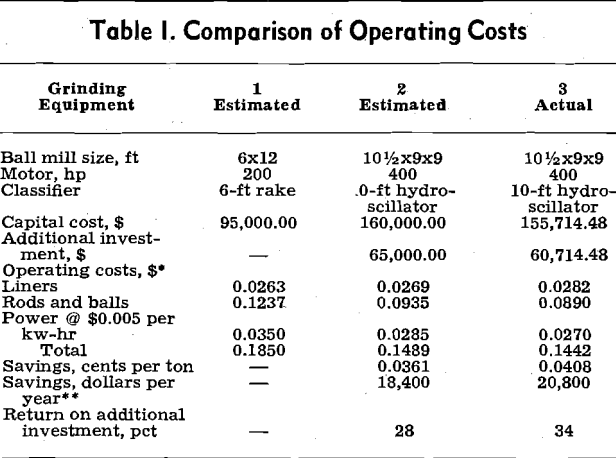

In 1953 this study was reopened when plans were made to increase the Isabella mill output from 1150 to 1500 tpd. At this time the grinding circuit consisted of a 6×12 rod mill followed by a 6×12 ball mill in closed circuit with a 6-ft rake classifier. Another 6×12 ball mill and 6-ft rake classifier would have been sufficient equipment and would have been the simplest and cheapest installation. However, this would have offered no improvement in grinding efficiency or operating cost. If, on the other hand, the grinding operation could be converted to the London practice by installation of one large 10½x9x9 tricone mill and a 10-ft hydroscillator, lower operating costs would justify the additional investment.

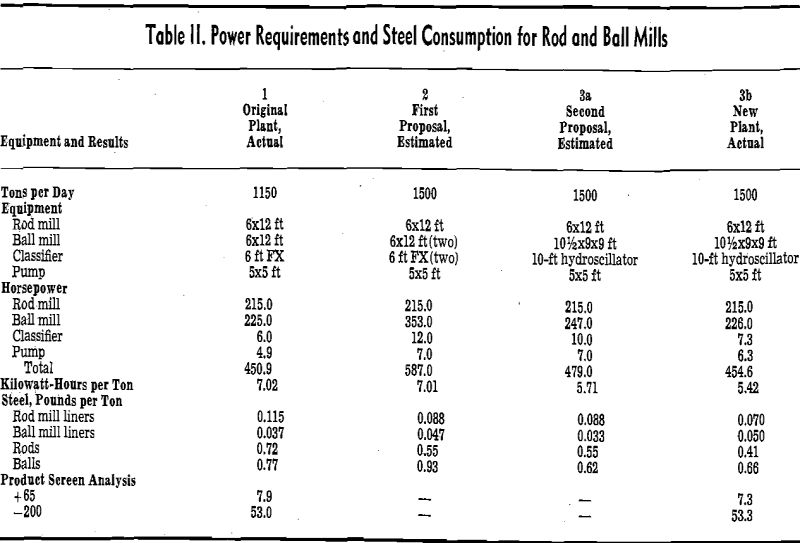

Rod Mill: Grinding data on the Isabella 6×12 rod mill are presented in Table III, Columns 1 and 3 are from the plant records on 1150 and 1500 tpd respectively. Column 2, giving the estimated performance for the rod mill on 1500 tpd, predicts that the efficiency of the rod mill will improve on the higher tonnage. Later a study of the Isabella plant data proved that this prediction was correct, because this rod mill on 1500 tpd was calculated to be 13 pct more efficient than it was on 1150 tpd.

Since the Isabella results were so close to the estimate they prove further that this grinding practice is sound. It is the writers belief that the rod mill, ball mill, and classifier are components of this efficient grinding circuit. The rod mill controls the size of its product at —8 mesh. Therefore the ball mill has no oversize material and it is possible to use 1-in. grinding balls.