Kyanite ore deposits occur in the Southeastern United States. The ore reserves in this area are estimated at about 100 million tons having an average grade range from 10 to 30 percent kyanite. The Graves Mountain kyanite-quartz rock ore deposit consists of a prominent ridge about 1 mile long and 300 to 400 feet high. The kyanitie-quartz rock forms large and irregular lenticular bodies about 300 to 400 feet wide and 1,800 feet long. The ore reserves for this particular deposit have been calculated as 10 million tons of kyanite-quartz rock.

Kyanite and mullite (converted kyanite) arc principally used by the glass and metallurgical industries, and to a minor extent mullite is used by the ceramic, chemical, and electrical industries.

Heavy liquid had been used for a long time as a laboratory tool in studying the separation of mineral mixtures. Preliminary tests on this kyanite ore revealed that it was suited for heavy liquid cyclone beneficiation using pure tetrabromoethane. During recent years industrial application of the heavy liquid cyclone separation method has been sought as a mineral beneficiation process. The Bureau of Mines has conducted heavy liquid cyclone separation tests of mineral mixtures to determine the separating efficiency of fluid cyclones in which several variables were studied.

The purpose of this Bureau of Mines investigation was to produce a high-grade kyanite concentrate by heavy liquid cyclone separation and to continue the study of tetrabromoethane removal from cyclone products by steam stripping, detergent scrubbing, and a combination steam stripping-detergent scrubbing. The study of steam stripping and detergent scrubbing is important not only for the removal of the toxic contaminants from the products before sale, but also to achieve an optimum recovery of the high-cost heavy liquid.

Description of Heavy Liquid

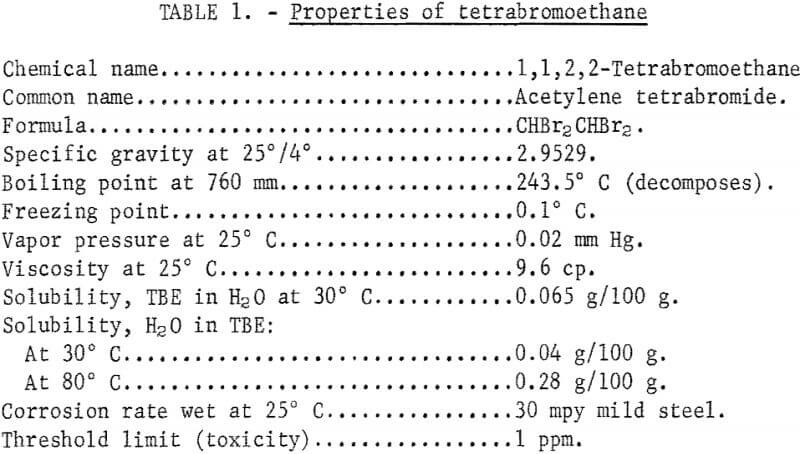

Pure tetrabromoethane (TBE), also known as acetylene tetrabromide (ATB), is colorless, nonflammable, relatively stable, and immiscible with water, and has a specific gravity of 2.96. The properties of 1,1,2,2-tetrabromoethane are given in table 1.

Tetrabromoethane is toxic and hazardous; consequently heavy liquid separation should be made under an adequate ventilation system. Exhaust ventilation, in the heavy liquid pilot plant, was furnished by two 8,000-cfm blowers. Each single equipment unit in the operation was hooded, and a minimum airflow of 100 cfm per equipment unit was maintained.

Precaution was also taken in removing the possible accumulation of heavy TBE vapors at floor level. Additional floor ducts were installed to insure air movement in those regions.

Environmental monitoring consisted of volumetric air sampling on silica gel, with determination of total bromine by X-ray fluorescence procedure, and

results were reported as ppm TBE in air. During pilot plant runs air samples were taken every hour. This ventilation system successfully-kept TBE vapors below a 1-ppm threshold limit.

Description of Sample

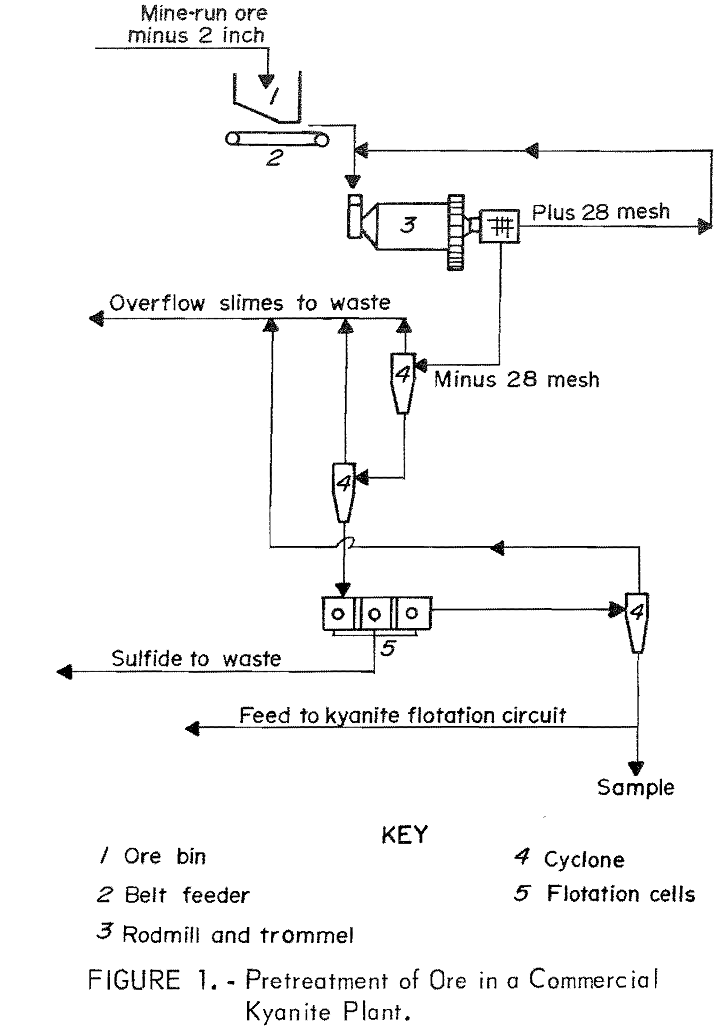

A 3-ton sample of minus 28-mesh kyanite ore was received from Aluminum Silicates, Inc., Graves Mountain, Ga. This sample was obtained after it had been ground, deslimed, and the sulfide content removed by flotation. Figure 1 shows schematically this stage of the ore treatment in the commercial plant operation.

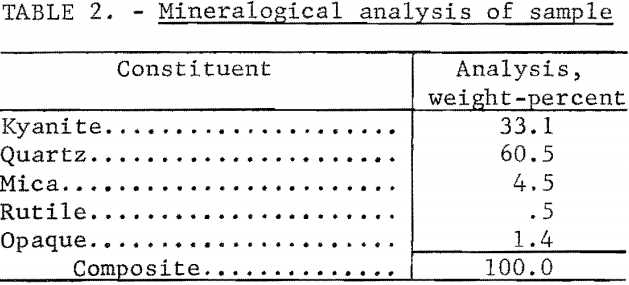

Petrographic examination of the sample showed that very little kyanite locking occurred in the coarse-mesh fractions. Table 2 shows the mineralogical constituents and analysis of the sample. Laboratory centrifuge sink-float methods were used to determine the percent kyanite through-out the report.

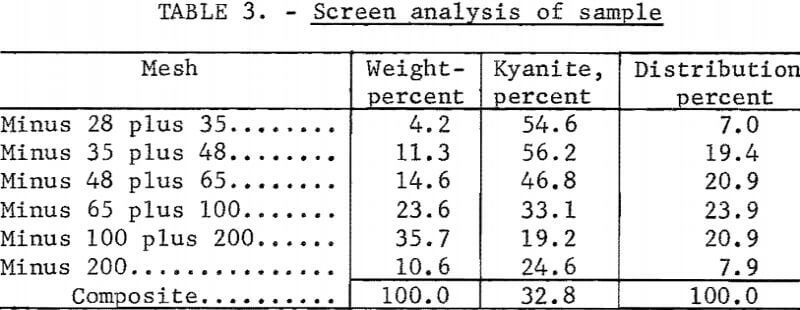

A screen analysis of a representative portion of the sample proved that the kyanite concentrated in the coarser screen sizes. Results of the screen analysis are given in table 3.

Description of Continuous Operation

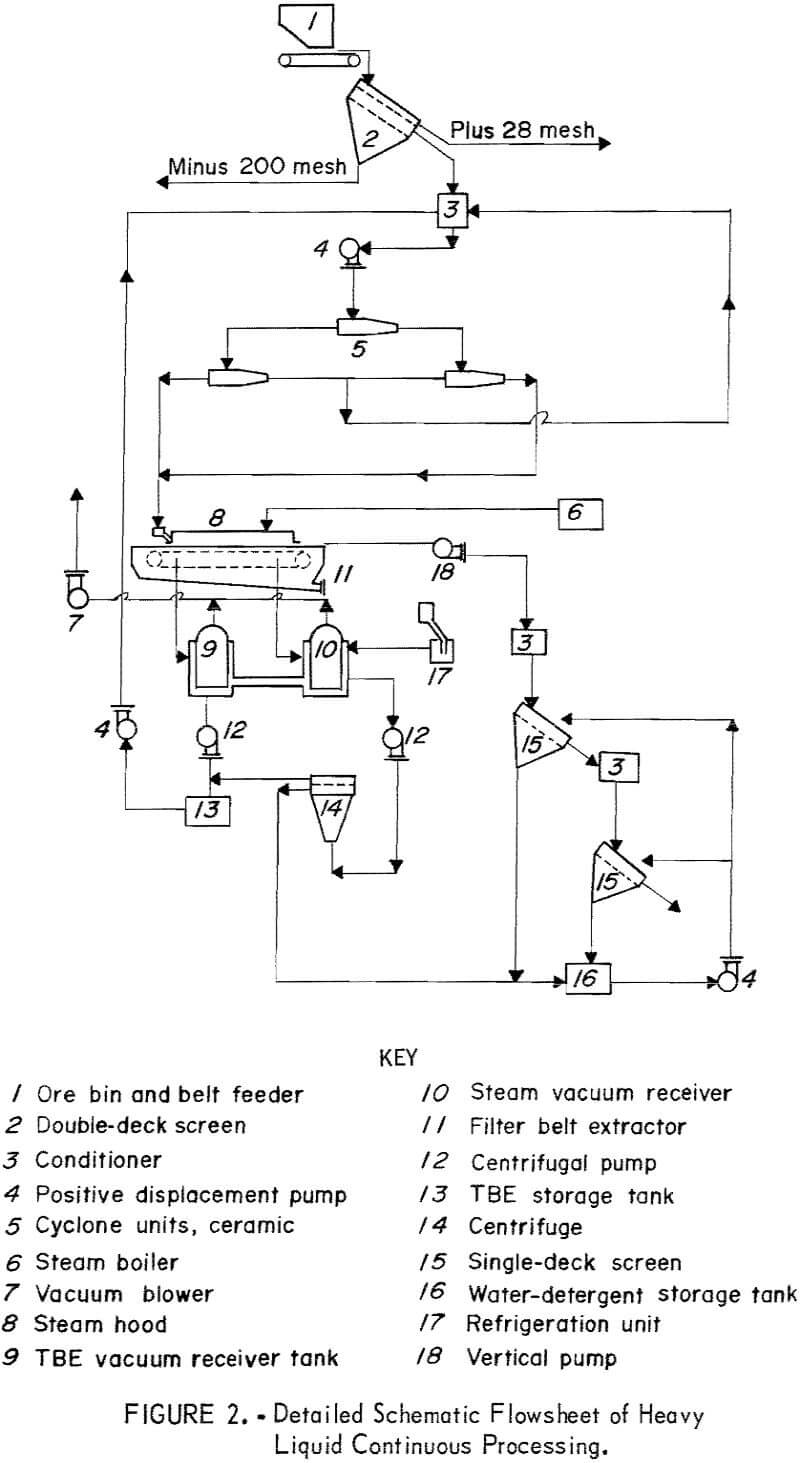

The pilot plant circuit is shown in figure 2. The pretreated kyanite ore was stored in an ore bin and withdrawn by a belt feeder to a double-deck screen. The first deck screen was used to remove any tramp 28-mesh oversize material which might plug the cyclone units, while the second deck screen was used to discard a portion of the 200-mesh undersize particles which represented about 2.0 percent of the feed weight. The minus 28- plus 200-mesh ore was conditioned with the required amount of heavy liquid and pumped to the three-stage cyclone unit. The middling from the three-stage separation was recycled by gravity to the conditioner.

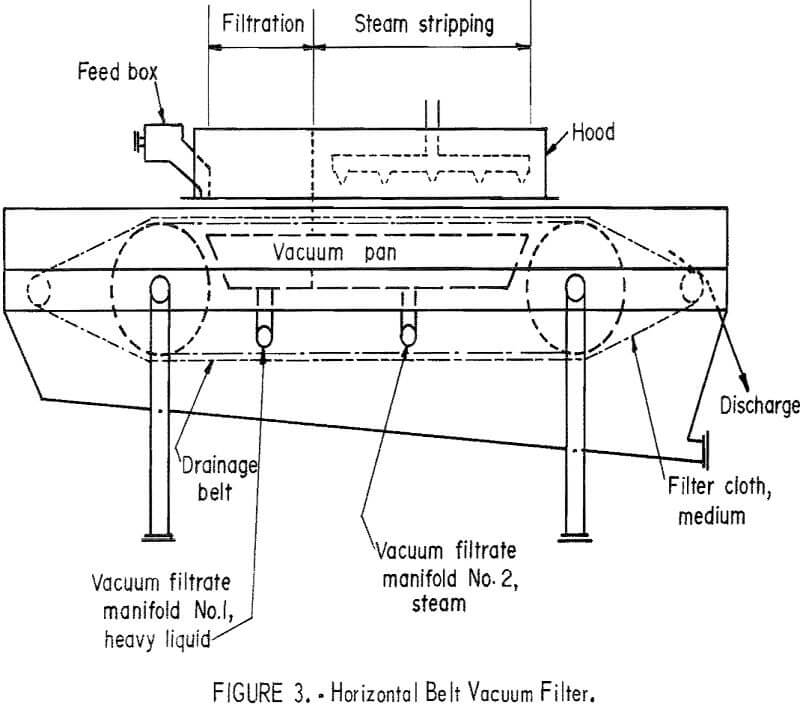

The cyclone products were discharged onto a horizontal belt vacuum filter, in which the material travels on a continuous filter cloth and rubber drainage belt across a stationary vacuum pan. The vacuum (2.5 inches of mercury) was applied over 6.5 feet of the belt length. The first 20 inches of length was applied for heavy liquid filtration, and the remaining 58 inches was applied for steam stripping. A schematic drawing of the horizontal belt vacuum filter is shown in figure 3. An orifice plate and a recording meter were used to measure steam consumption. A stainless steel hood was tightly installed to the filter assembly, to contain the steam over the filter cake and minimize steam losses. The filtered heavy liquid was pumped to the storage tank. The steam, water, and heavy liquid were pulled through the filter vacuum system into a condenser tank from which the water-heavy liquid emulsion was pumped to a liquid-liquid centrifuge for separation of the heavy liquid.

The combined cyclone products, after filtration and steam stripping, were discharged into a vertical pump where hot water and detergent solution were added. The ore pulp was scrubbed in a conditioner for 5 minutes and then dewatered over a screen. The screen oversize product (ore) was repulped with hot water and detergent solution, scrubbed for another 5 minutes, and again dewatered. The detergent-water-heavy liquid emulsion undersize of both screens was also pumped to the liquid-liquid centrifuge for recovery of the heavy liquid. The heavy liquid discharge from the centrifuge was recycled to the storage tank, and the water-detergent solution was recycled to the screen sprays.

Experimental Results

Semi-continuous Tests

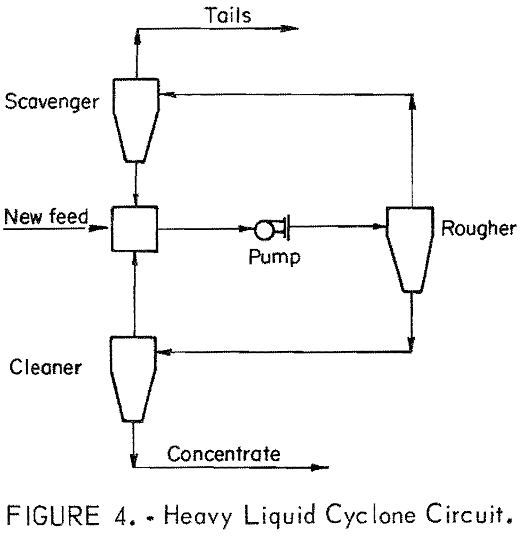

A series of tests, at a set feed density of 10 percent solids, was made to examine the beneficiation of kyanite in a semieontinuous one-stage and three-stage heavy liquid separation (HLS) cyclone unit, and to determine the influence of cyclone feed pressure upon kyanite grade and recovery. The ½-inch cyclones were fitted with a 0.12-inch vortex finder and a 0.09-inch apex disk opening, according to experience gained on concentration of spodumene ore. A schematic representation of the heavy liquid cyclone circuit used, in both the semicontinuous tests and the pilot plant, is shown in figure 4.

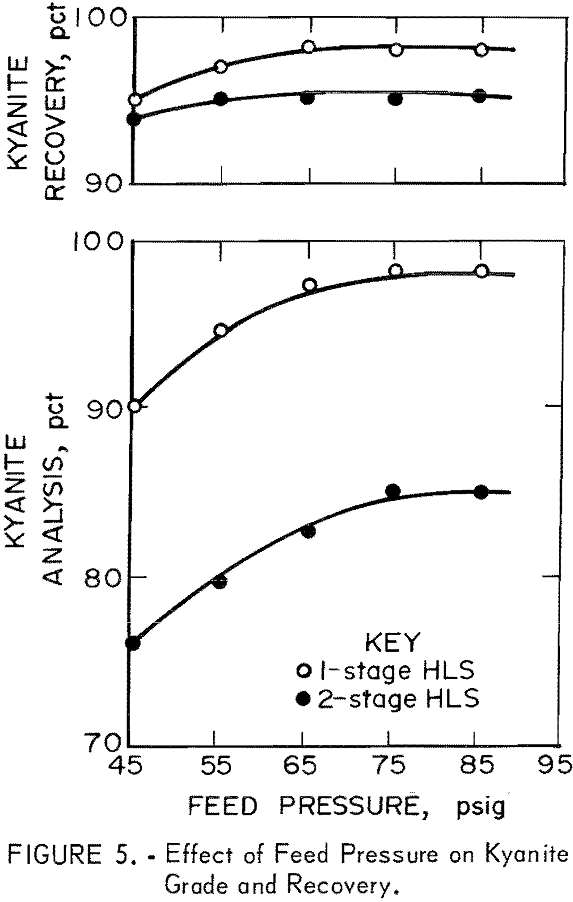

Results of these tests in which the feed pressure was varied from 45 to 85 psig are presented graphically in figure 5. The change of feed pressure between 45 and 55 psig increased the kyanite recovery from 94.0 to only 95.0 percent in the one-stage HLS cyclone circuit, and as the cyclone pressure was further increased to 85 psig, the recovery remained constant. In the three- stage HLS cyclone circuit the change of feed pressure between 45 and 65 psig increased the recovery by 3 percent, from 95.0 to 98.0 percent, then remained constant.

Pressure had a greater influence on concentrate grade, in both cases. In the three-stage HLS, changing pressure from 45 to 75 psig caused an increase in the kyanite grade from 90,0 to a maximum value of 98.0 percent, after which

pressure had practically no effect. In the one-stage HLS, this maximum grade was also reached at 75 psig, but was only 85.0 percent kyanite. The three-stage circuit produced the highest grade and recovery.

Continuous Tests

Based on the semi continuous results, a series of pilot plant test runs was carried out to determine the grade and recovery that could be obtained in a continuous test with a circulating load. Another purpose of this investigation was to continue studying the removal of tetrabromoethane from pilot plant products, applying the combined steam stripping-detergent scrubbing removal method.

The average pilot plant operational conditions for three separate tests were the following:

- A feed rate of 460 grams per minute.

- Cyclone feed density of 10.0 percent solids by weight.

- Cyclone pressure of 85 psig in rougher unit, 20 psig cleaner, and 25 psig in scavenger.

- Constant cyclone apex diameter and vortex finder opening at 0.12 and 0.09 inch, respectively.

- Filtration time of 2 minutes.

- Filtration cake thickness of ½ inch.

- Cyclone circulating load of 90 percent.

- Steam stripping time of 5 minutes.

- Steam temperature of 260° F.

- Scrubbing time of 3 minutes at 30 percent solids.

- Scrubbing water detergent temperature of 180° F.

- Detergent addition to each scrubbing stage of 10 pounds per ton of ore.

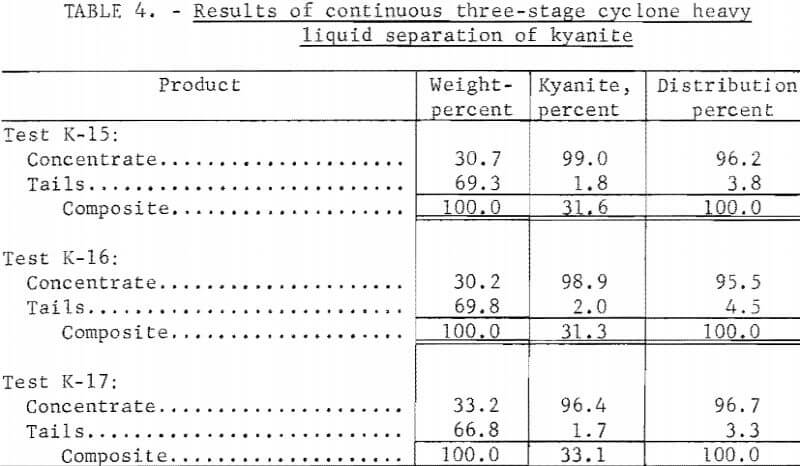

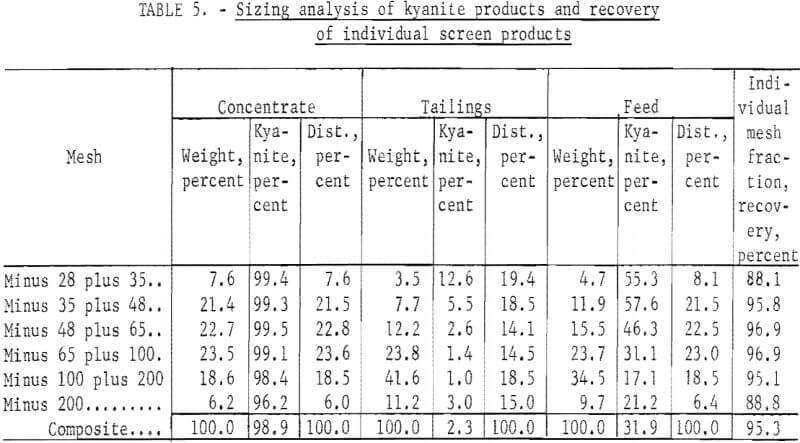

Results of three continuous pilot plant tests are presented in table 4. Sizing analyses of the concentrate and tailings are given in table 5. The semicontinuous three-stage cyclone test runs yield a 98.0-percent kyanite with a 97.8-percent recovery. The continuous pilot plant runs averaged about 98.0 percent kyanite with a mean recovery of about 96.0 percent.

Calculating the percent recovery of the individual mesh fractions (table 5) indicated that the best recoveries were obtained at the minus 35- plus 200-mesh range. The lowest recoveries were obtained at 35- and minus 200-mesh fractions.

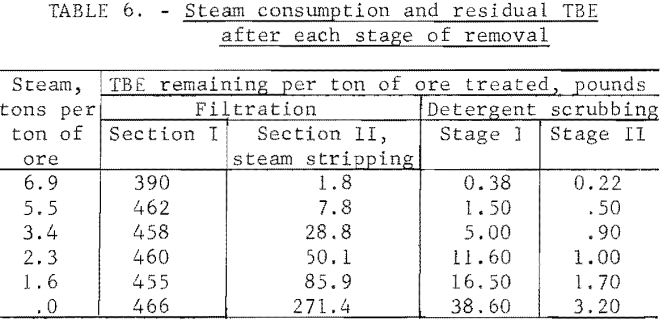

Tests for Removal of Heavy Liquid From Continuous Plant Products

In one series of tests the amount of steam used was progressively reduced from 6.9 tons to 0.0 ton per ton of ore. Samples were simultaneously taken from each stage of TBE removal, and comparative data were obtained. Initially 95 percent of the heavy liquid was recovered from the cyclone products in the filtration section of the belt vacuum filter. Results of steam consumption and the amount of TBE remaining after each stage of removal are shown in table 6. This data indicated that, using 6.9 tons of steam per ton of ore, the remaining heavy liquid was 1.8 pounds per ton of ore. By combining steam stripping, using 1.6 tons of steam per ton of ore, and two stages of detergent scrubbing, the residual TBE content was 1.7 pounds. The best result was accomplished with the highest steam consumption of 6.9 pounds per ton of ore and two stages of detergent scrubbing; the final product content of TBE was only 0.22 pound per ton of ore.

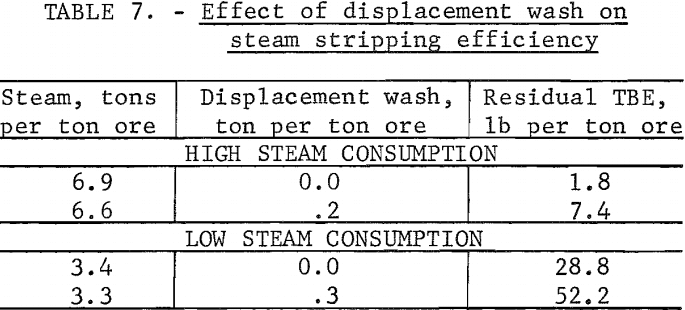

The addition of hot displacement wash before steam stripping was studied to determine its effect on TBE removal. The displacement wash consisted of three pressure sprays using recycle detergent solution. The wash solution was sprayed on the filtered cake immediately prior to the steam stripping section. Table 7 shows results with and without displacement wash at high and low steam consumption. Steam stripping with a consumption of 6.9 tons of steam per ton of ore, without displacement wash, gave a residual TBE of 1.8 pounds per ton of ore. However, the addition of 0.2 ton of recycle detergent solution at a temperature of 180° F raised the residual TBE to 7.4 pounds per ton of ore.

At lower steam consumption the addition of displacement wash revealed the same increasing trend on the residual amount of TBE.

Conclusions

- These series of continuous pilot plant runs on kyanite ore demonstrated that a 96.4- to 99.0-percent kyanite concentrate can be obtained with recoveries of 95.5 to 96.7 percent of the kyanite.

- The data showed that detergent scrubbing is not as efficient a method for removing heavy liquid from the ore as steam stripping. By using two stages of detergent scrubbing, without steam, the residual TBE was 3.2 pounds per ton of ore. However, by steam stripping using 6.9 tons of steam per ton of ore the residual TBE was only 1.8 pounds per ton of ore. A combination of the two methods is more efficient than either method alone. The lowest residual TBE, 0.22 pound per ton of ore, resulted from the highest steam consumption and two stages of detergent scrubbing. The investigation has demonstrated that approximately the same separation of the heavy liquid from the mineral could be achieved by steam stripping using 6.9 tons of steam per ton of ore, as by a combination of steam stripping using 1.6 tons of steam per ton of ore and two stages of detergent scrubbing in the removal of TBE operation.

- A displacement wash of the filtered cake adversely affected steam stripping efficiency of TBE removal. Residual TBE, after steam stripping, was 1.8 pounds per ton of ore without a displacement wash detergent solution. However, this residual TBE was raised to 7.4 pounds per ton of ore when 0.2 ton of recycle wash solution was used to wash down the filter cake.