Technology improvements in copper mining operations have been the key factor for increasing productivity. Beyond dump leaching, the industry will increasingly use various heap leach techniques in SX-EW operations in the coming years in order to optimize recovery and maintain low production costs. They include:

- Finer comminution followed by agglomeration.

- Finer comminution followed by coarse size separation for coarse heap leaching and agitation leaching of fines.

- Bioleaching of sulfide ores.

- Thin layer leaching and/or thin layer-bacterial leaching.

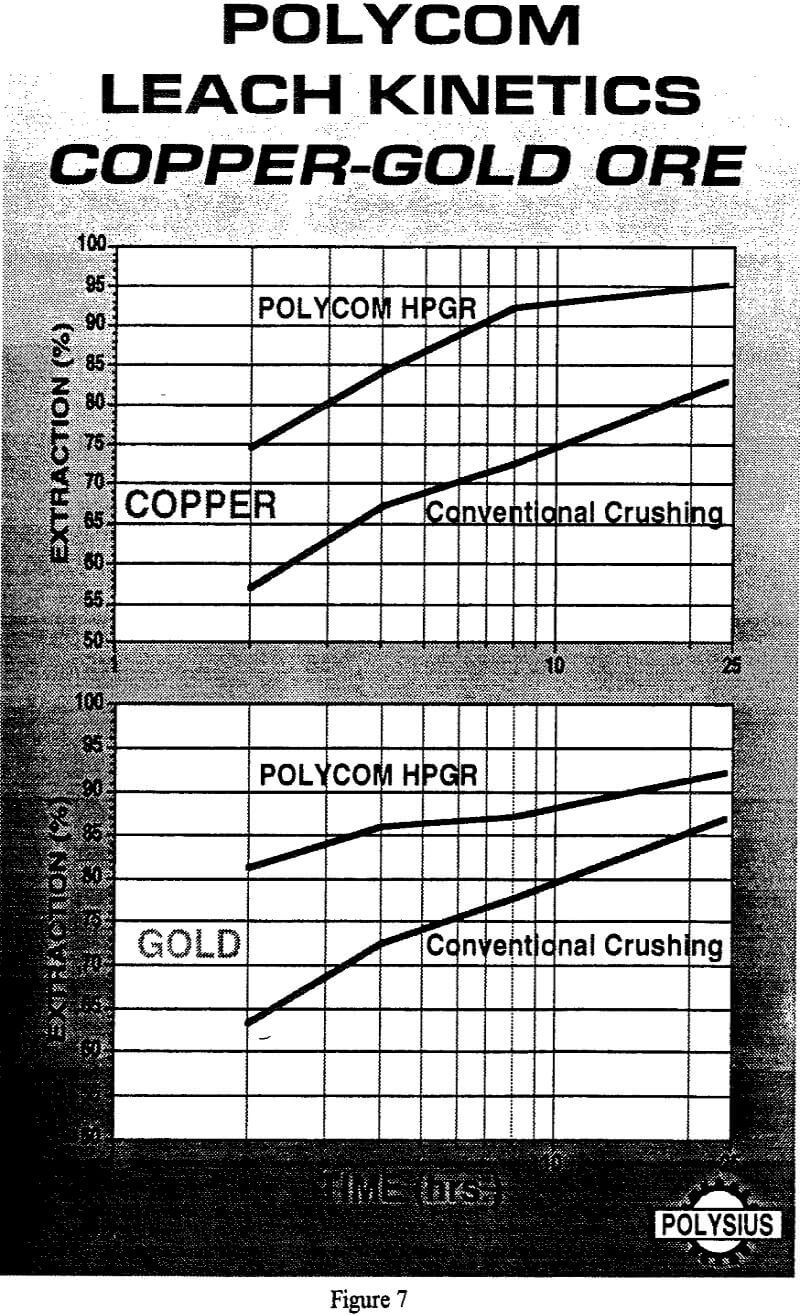

Thin layer (TL) leach techniques are increasingly used in SX-EW operations. HPGR treatment has several advantages over conventional crashing for optimization of TL or thin layer-bacterial (TLB) leaching:

- Better liberation of copper minerals.

- An option for a coarse size separation for un-agglomerated TL heap leaching and agitation leaching of the fine HPGR product.

- Fracturing of coarse chalcopyrite or secondary sulfides for enhanced TLB leaching.

HPGR “Split-Use” Copper Leaching

During current heap leach operations, large amounts of copper (i.e. 20 to 50%) may be left in the heaps. Unfortunately, the concept of “deslimed” heap leaching has not received much attention yet. The reasons for this reluctance may be related to limitations of conventional crashing circuits in terms of throughput, energy-efficiency and leach increases. The availability of high pressure grinding rolls may enable mining companies to re-focus their attention on this concept.

The characteristic of a HPGR “Split-Use” is to subject the HPGR product to a size classification followed by heap leaching of coarse, unagglomerated ore and agitated leach of the fine HPGR product. Alternatively, the HPGR products can be agglomerated for heap or thin layer leach.

The objectives and benefits of the HPGR “Split-Use” are:

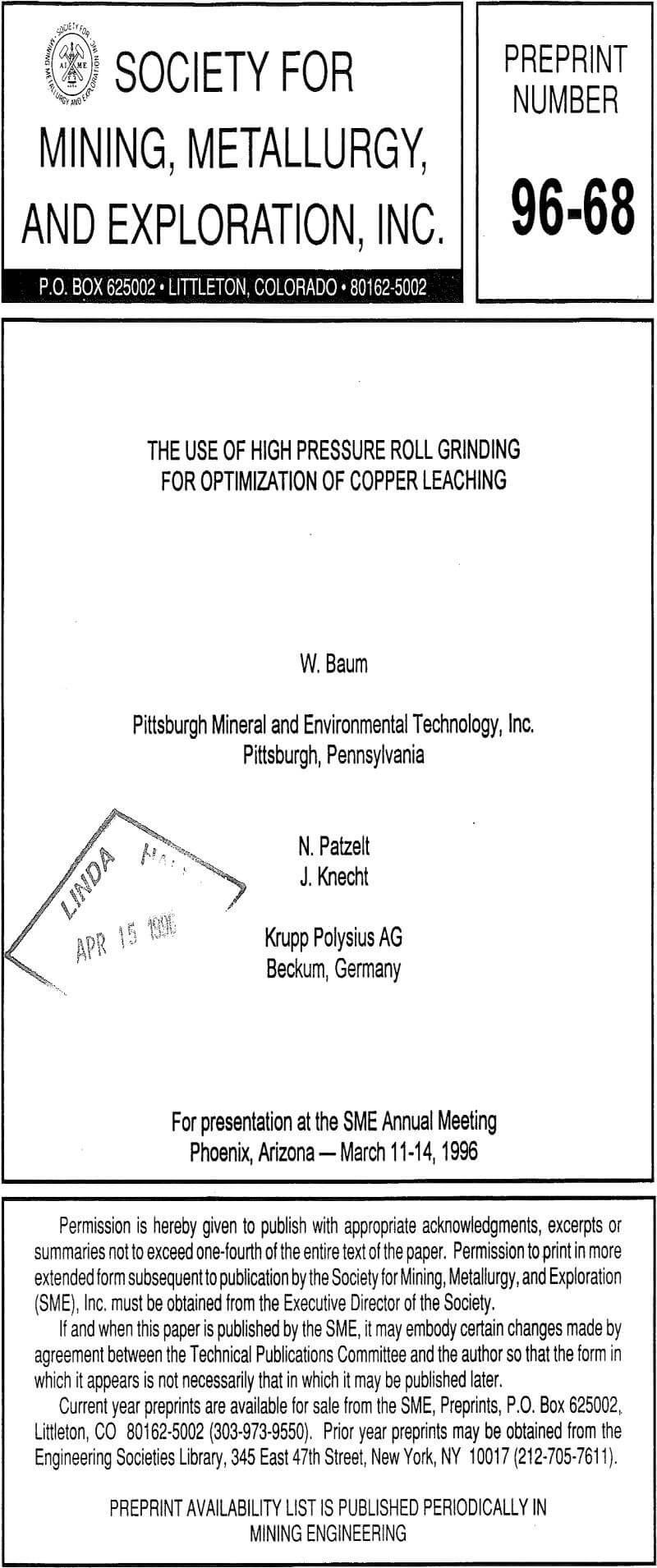

- Increase of overall copper recovery by 5 to 20%.

- Capability of treating low-grade and/or semi- refractory copper ores.

- Capability of energy-efficient throughput increases.

- Eliminating the need for agglomeration and problems of poor-quality agglomerates.

- Reduction of leach cycles.

- Significant increases in permeability of coarse heap feed.

- Minimization of ponding, channeling and comp action.

- Increasing of oxygen availability, solution flow, solution penetration and bacterial access.

- Removal of preg-robbing/borrowing slimes from the heap.

- Increase of copper extraction for the HPGR fine product to over 90%.