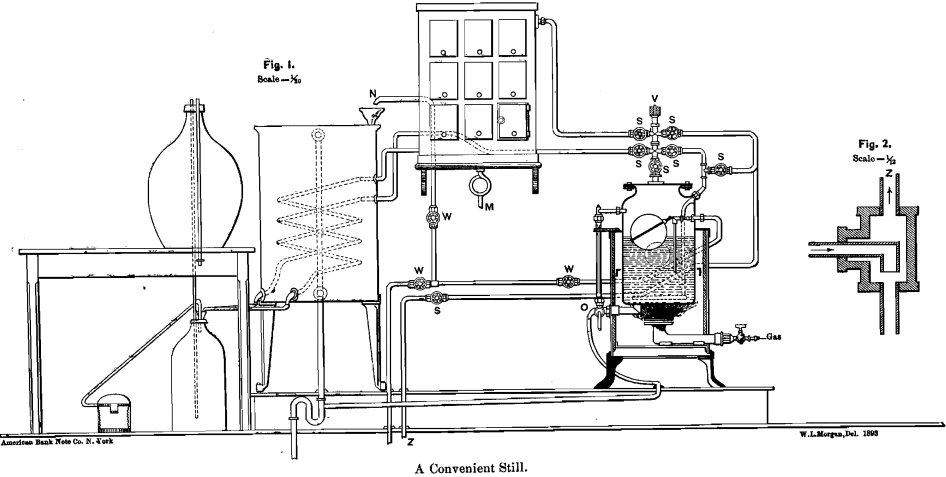

In the use of the apparatus purchased for the new chemical laboratories of the university, no piece has given us more satisfaction, or has been a greater success, than a new still which is the subject of this paper. In the designing of this still I had two definite objects in view ; one, the utilizing of steam from the large 60 horse-power boiler used in heating the building, and the other, a provision for making distilled water with gas, when steam from the heating-plant was not available. The still is encased in wrought-iron, with a lining of asbestos, and is provided with a float which automatically regulates the flow of water from the supply-pipe. It was made for me by G. J. Murrle, Pforzheim, Germany, and was imported by Messrs. Eimer & Amend, of New York City. It is a beautiful piece of apparatus, and the workmanship is excellent in every detail. The essential parts of this apparatus will be understood by consulting the accompanying figures, but a few words of explanation may be appropriate. The still has a capacity of seven gallons, and is made of heavy copper, tin-lined. It has a water-gauge showing the height of the water in the still, also an exit for steam, and safety-valve, V; inlet for steam through a coiled perforated block-tin pipe; also an outlet, O, for cleaning out the still ; and there is also a heavy

disc gas-burner. There is a conveniently arranged drying-oven and a large condenser, carrying two block-tin worms, one direct from the still, the other from the oven, both delivering water to a carboy resting on the floor. When steam is taken from the large boiler, provision is made, by an arrangement seen in Fig. 2, located at Z, beneath the floor, to cleanse the steam, before it reaches the still, from the water mechanically carried into the pipes. The water returns to the boiler, while the steam passes to the still. By the arrangement of the steam-valves, S, it is possible to deliver the steam to the empty still, where it is again washed, and may then be passed either to the oven or direct to the condenser or to both. Or the steam from the boiler may be taken direct to the oven or to the condenser or to both. When a small quantity of steam is admitted to the still, most of the distilled water is condensed in the oven and is caught in a copper tin-lined vessel underneath, through the valve, M, a part passing to the condenser, and then to the glass vessel, from which it may be forced to the carboy above. When there is no steam in the large boiler, gas is used, the water being kept in the still at a constant level by the automatic arrangement before mentioned and seen in the sketch. In this case the steam may be passed to the drying oven or to the condenser direct or to both, as heretofore mentioned. In the case of gas alone, the still has a capacity of about 26 gallons of distilled water per day, while with steam from the boiler, at a pressure of 5 pounds, I have made distilled water at the rate of 112 gallons per day. A convenient system of piping has been arranged for supplying water to the still and condenser, to the latter at N, and under control of valves, W, as seen in the sketch. The still and condenser are both connected with the waste, and may be emptied and cleaned when necessary. Other details of this apparatus are shown in the drawings. As I have used this still constantly for a year, and fully appreciate its merits and good points, I have no hesitation in recommending the design to those who may wish a still for the purposes for which this one is used.

disc gas-burner. There is a conveniently arranged drying-oven and a large condenser, carrying two block-tin worms, one direct from the still, the other from the oven, both delivering water to a carboy resting on the floor. When steam is taken from the large boiler, provision is made, by an arrangement seen in Fig. 2, located at Z, beneath the floor, to cleanse the steam, before it reaches the still, from the water mechanically carried into the pipes. The water returns to the boiler, while the steam passes to the still. By the arrangement of the steam-valves, S, it is possible to deliver the steam to the empty still, where it is again washed, and may then be passed either to the oven or direct to the condenser or to both. Or the steam from the boiler may be taken direct to the oven or to the condenser or to both. When a small quantity of steam is admitted to the still, most of the distilled water is condensed in the oven and is caught in a copper tin-lined vessel underneath, through the valve, M, a part passing to the condenser, and then to the glass vessel, from which it may be forced to the carboy above. When there is no steam in the large boiler, gas is used, the water being kept in the still at a constant level by the automatic arrangement before mentioned and seen in the sketch. In this case the steam may be passed to the drying oven or to the condenser direct or to both, as heretofore mentioned. In the case of gas alone, the still has a capacity of about 26 gallons of distilled water per day, while with steam from the boiler, at a pressure of 5 pounds, I have made distilled water at the rate of 112 gallons per day. A convenient system of piping has been arranged for supplying water to the still and condenser, to the latter at N, and under control of valves, W, as seen in the sketch. The still and condenser are both connected with the waste, and may be emptied and cleaned when necessary. Other details of this apparatus are shown in the drawings. As I have used this still constantly for a year, and fully appreciate its merits and good points, I have no hesitation in recommending the design to those who may wish a still for the purposes for which this one is used.