Pelletization is the unit operation of agglomerating moist particulate materials by tumbling in horizontal rotating drums or inclined discs. Pelletization has extended the life of iron ore industry by enabling the treatment of low grade iron ores which are available in large reserves through out the world. Iron ore pelletization is a two step process consisting of pellet production in balling circuits and pellet induration in straight-grate or grate-kiln systems. Extensive applied research and plant scale testing have been directed to understanding and improving the induration process and pellet quality.

Experimental investigations were performed in a 9″ diameter by 6″ length balling drum fitted with three lifter bars and a scraper. The drum rotational speed was maintained at 40 rpm which corresponds to 46% of the critical speed. The drum assembly was enclosed in a humidified chamber so as to minimize the loss of moisture from the agglomerating charge.

Moist feed for the experiments was prepared by mixing desired quantities of water and binder (0.5 percent by weight of Wyoming bentonite) with the dry concentrate and then nibbing the moist mix through a 6 mesh screen. This feed was stored in sealed plastic containers for further use. Seed pellets were produced by pelletizing a 350 g batch of moist feed for 200 rev and sieving the agglomerated product in the size range of 4.75 mm to 9.50 mm. During this test program, we have not changed any of the properties of the seed pellets.

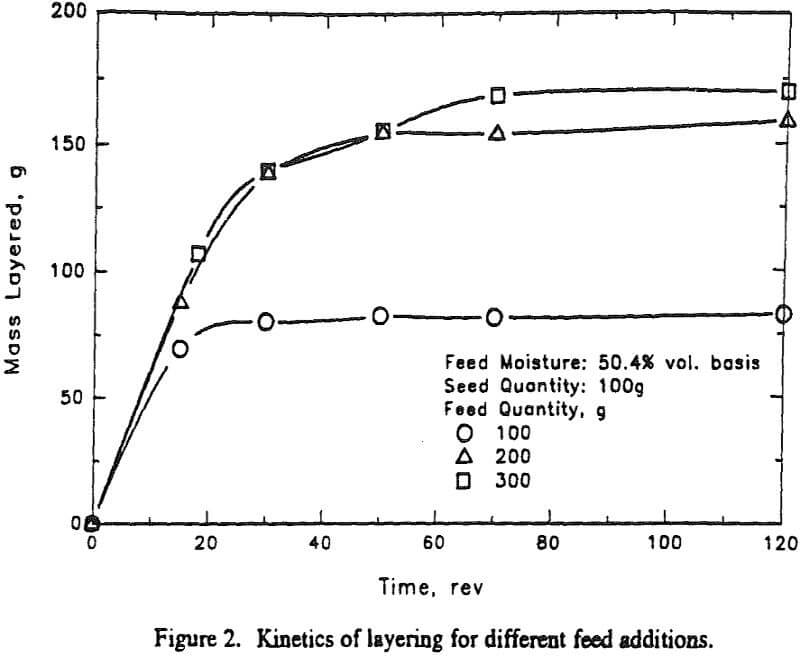

The three experiments were conducted with the addition of feed (with fixed feed moisture) with the same moisture. The rate of layering is fast in the beginning and then it decreases continuously until it becomes zero. No further growth by layering takes place after approximately 40 rev. Also, amount of feed that is layered increases with an increase in initial feed quantity.

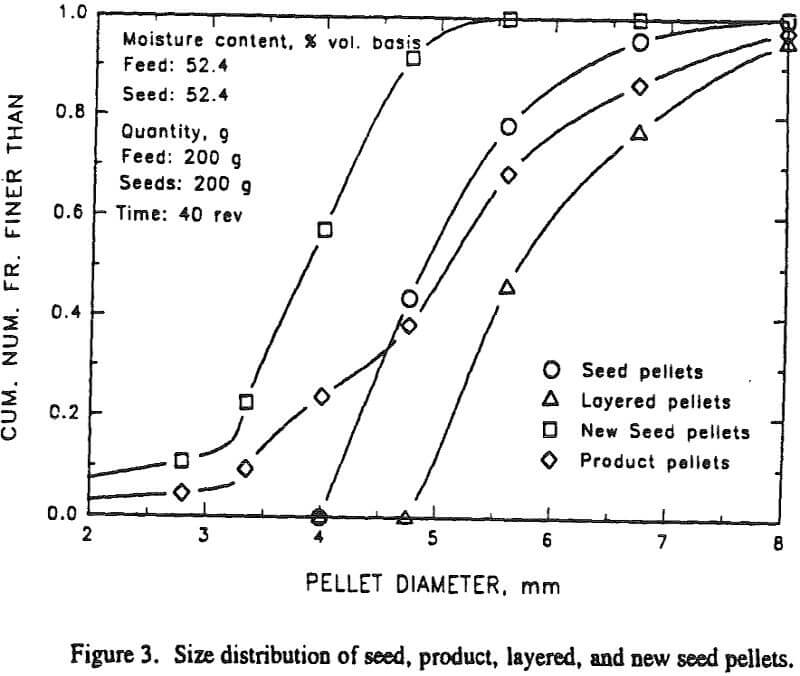

It can be seen that the product pellets constitute pellets of sizes both smaller and larger than the original seeds. The smaller pellets result due to the generation of new seeds and the larger pellets are the consequence of the layering type of growth of the original seeds. The individual distributions for the new seeds and layered pellets were obtained from the product pellet size distribution using a simple mathematical computation.

Following are several important observations that were made from the present study.

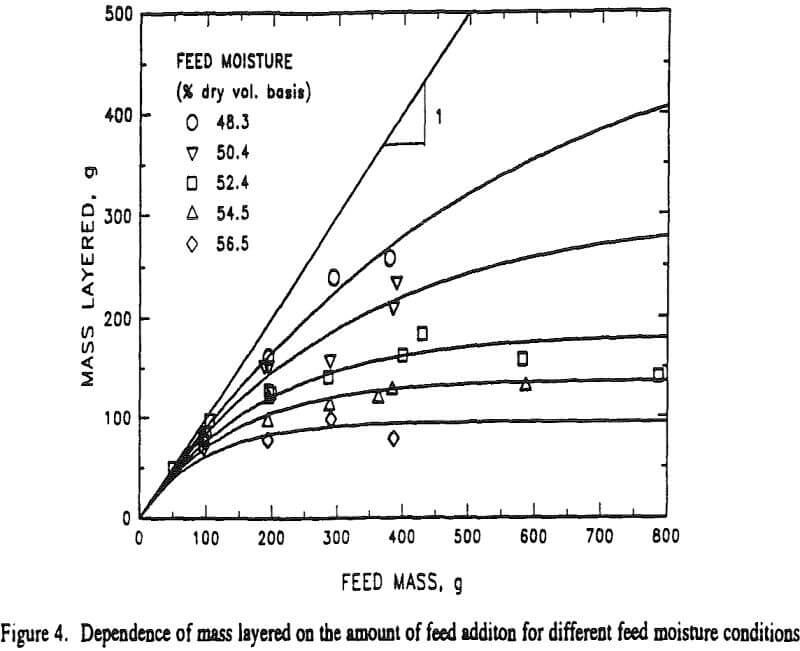

- Layering and new seed generation occur together under almost all conditions, except for the cases of low feed addition and low feed moisture.

- The partition of added feed between layering and new seed generation can be predicted by a relatively simple relationship.

- High feed moisture conditions favor high generation of new seeds.