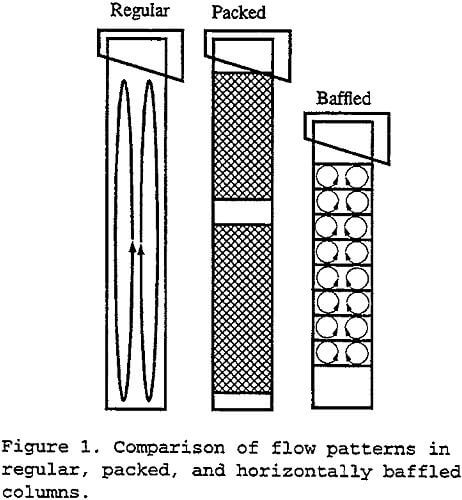

The separating efficiency of a flotation column is largely limited by the degree of backmixing of tailings into the froth zone, and its recovery is limited by the degree of short-circuiting of feed to the tailings. Current columns are typically made very tall, on the order of 30-40 feet, in order to limit the effects of backmixing and short-circuiting. These effects can also be reduced in a much shorter column, provided that the flow in the column approaches plug-flow.

Experimental Procedures

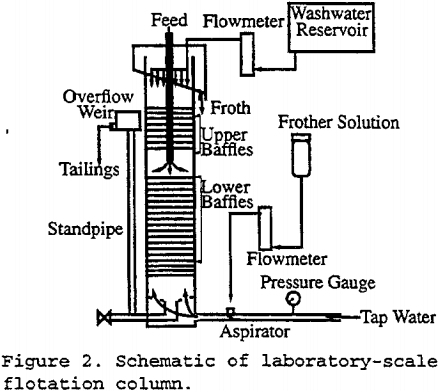

The column used was a modified Deister Flotaire column, 7.6 cm in diameter and 1.83 meters tall. This is significantly shorter than is typical for laboratory columns of this diameter, which are more commonly 4-5 meters tall. The short column was used so that its height/diameter ratio would be more similar to that of plant-scale columns, and so it would show a similar degree of axial mixing.

The baffles were of two types: three baffles which bolted into place, at heights above the tailings outlet of 0.3, 0.9, and 1.2 meters; and a larger number of adjustable baffles which were threaded onto support rods with a spacing of 3.5 centimeters, and held in place by the bolt-in baffles. All of the baffles had 29% open area.

Solids Free Tracer Tests

Column feed was prepared by grinding 900 grams of the stage-crushed coal in 1500 ml distilled water in a 20.3 cm diameter rod mill for 45 minutes. The assay and size distribution of the rod-milled coal was as follows: 13.5% ash; 3.41% total sulfur; 12100 BTU/lb; 80% passing 40 micrometers, 10% passing 4.5 micrometers.

After grinding, each 900 gram lot was filtered, and divided into three 250 gram flotation charges and a 150 gram head sample. The coal was found to be poorly floatable with only 2 fuel oil as a collector, and so a mixture of 80% 2 fuel oil and 20% Dow M210 froth conditioner was used. The froth conditioner is an agent which improves the wetting of oxidized coals by neutral oils, and therefore reduces the collector requirements for 1 flotation of these coals.

For each test, a flotation charge was repulped to 1600 ml with water, and conditioned by shaking vigorously in a stoppered Erlenmeyer flask with the desired reagents and the tracer dye for one minute. The flowrates in the column were adjusted to the desired level, after which the tailings valve was closed to begin filling the column, and the timer was started.

Experimental Results and Discussion

All of these tests were conducted with at least one upper baffle and two lower baffles, to prevent the operating instability which was seen in the solids-free tracer test with no baffles. These tests show that adding baffles to the column improved the grade-recovery performance markedly. The best results were reproducibly obtained with the complete set of 8 upper baffles and 18 lower baffles, which showed a markedly higher grade with little loss of recovery. The complete set of baffles reduced the ultimate recovery by only a few percent, which is compensated for by the increase in froth grade.

This shows that entrainment is reduced by the baffles, which accounts for the improvement in the froth grade. The best results are when the complete set of baffles is installed. The addition of lower baffles increases the residence time in the column, which is the same effect as was seen in the solids-free tracer tests. The effect of the upper baffles was to change the total amount of tracer that reached the tails at all, but they did not affect the residence time.