Table of Contents

Filtration by Vacuum

The vacuum or suction arrangement shown has four openings and hence four filtrations can be made at the same time. If less than this number are ample for the work to be done, the table may be shortened accordingly. In an iron and steel laboratory, where many samples of pig iron are analyzed for silicon, sulphur, etc., four will not be found too many, as one of them may be needed for a reductor and the rest will be kept in use for filtering off graphite, etc., from the solution of the pig iron. Since three or four filtrations can usually be carried out as rapidly as one, it will save time to provide means for making this number simultaneously.

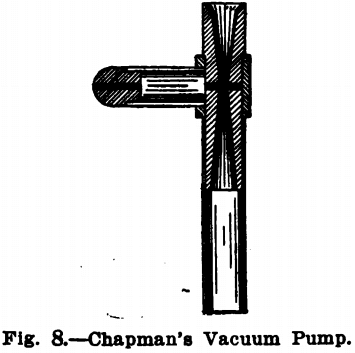

Vacuum Pump

The form of vacuum pump, filter pump or aspirator shown in the illustration is that of Chapman. This pump is small but effective. Figure 8 shows the details of its construction. It is made in three sizes. A No. 2 pump will be of ample capacity to take care of four filtrations and the smallest size, No. 1, will furnish vacuum for one or two filtrations. It can be obtained with a threaded coupling to fit a threaded faucet or with a smooth coupling for a plain faucet. The former is much to be preferred and is essential if the water pressure to be used is great. The threaded coupling has a milled ring around it so the pump can be readily removed from the faucet for cleaning.

This is sometimes necessary, as it often becomes stopped up with sticks, leaves and other trash in the water. The greater water pressure which is at hand the more perfect vacuum can be obtained. A fair suction will be secured, however, from a head of water such as would result from a tank placed on the laboratory roof. Another form of air pump is that of Richards. This also is very efficient and is made in two sizes. Still another form has a vacuum gauge attached, but these cost considerably more. If it is desired to measure the vacuum, it may be done by means of a long U tube, about 30 inches high, half full of mercury. One end of this is attached to the pump and the vacuum is measured by the difference between the levels of the mercury in the two limbs of the tube. If wished this mercury tube may be fastened to the wall behind the sink table and permanently attached to one of the openings of the vacuum line.

to the wall behind the sink table and permanently attached to one of the openings of the vacuum line.

As these little pumps are somewhat apt to let water pass back into the air line, if the water supply is suddenly cut off or the pump clogs, it is safest to place a trap between the pump and the air line. This may be merely a pint bottle provided with a double perforated stopper, through one of whose holes a piece of glass tubing passes nearly to the bottom of the bottle and through the other of whose holes a shorter piece of tubing reaches just below the stopper. A more durable form of trap is made of a piece of pipe 3 inches in diameter and 6 inches long capped at both ends to form a small drum. Two pieces of ¼-inch pipe are fitted into this, one reaching nearly to the bottom of the drum and the other just inside the cap. The long pipe or tubing connects with the pump and the short one with the air line. This latter joint if the drum is used should be made by a threaded pipe fitting, and the connection between the drum and the pump by a piece of heavy walled rubber tube, as shown in Fig. 7, to facilitate disconnecting the pump for cleaning.

Where a powerful suction is required and there is only a light head of water, these filter pumps may be operated by steam or compressed air. Schutte & Koerting Co., Philadelphia, Pa., make a very powerful filter pump to be operated by steam which they call the “Universal Steam Jet Laboratory Exhauster.” This with vacuum gauge attached is listed by the manufacturers at $10.00. It requires for operation a volume of steam equivalent to an evaporation of 12 pounds of water per hour. When there is a head of water available, however, the writer knows of nothing better for filtrations by suction than the Chapman filter pump first mentioned.

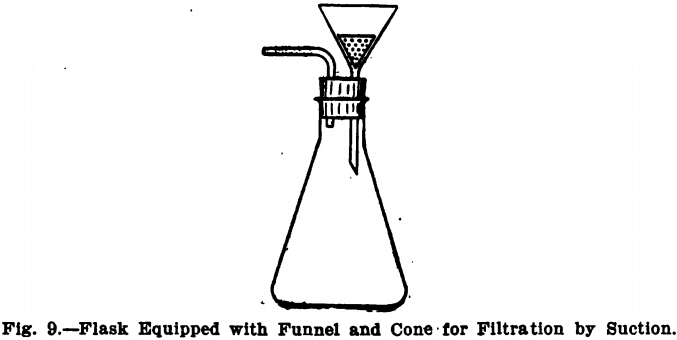

Method of Using Vacuum for Filtering

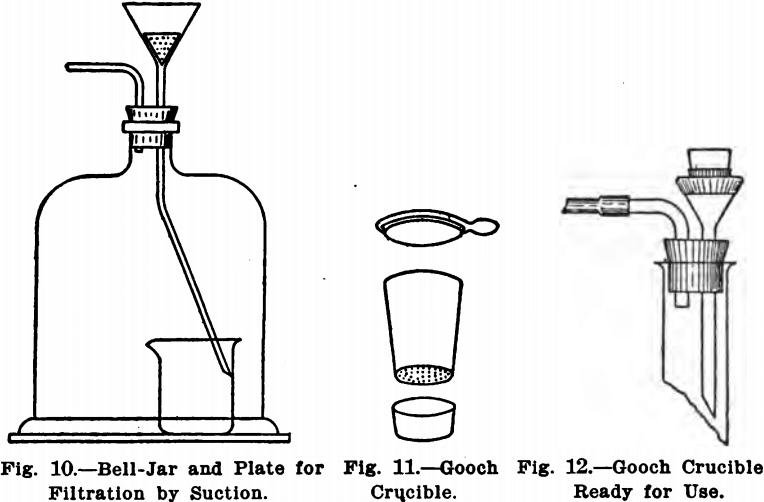

For use with these pumps in filtering nothing is more serviceable than a thick walled Erlenmeyer flask fitted with a two-hole rubber stopper. A 6o° short, thin-stemmed funnel, of exact angle, passes through one hole of the stopper and a piece of glass tubing bent at right angles through the other, reaching just below the stopper. A perforated platinum cone fits in the funnel and prevents the filter paper from being torn by the suction. Figure 9 shows the completed apparatus. A special form of Erlenmeyer flask can be obtained, having a tube inserted in the neck and made of very heavy glass, at a slightly increased cost. This is, however, but little more convenient and indeed has some disadvantages over the simpler form. In using Erlenmeyer flasks, the filtrate has often to be transferred to a beaker. In order to obviate this the bell-jar and ground glass plate shown in Fig. 10 can be used. For filtering barium sulphate the Gooch crucible is very useful. This requires suction and consists of a flat bottomed perforated crucible provided with a cap, see Fig. 11. The perforated crucible is placed in one end of a piece of soft rubber tubing of a large bore, the other end of which is stretched over a small funnel passing into the Erlenmeyer flask, through a rubber stopper, see Fig. 12. The method of using is as follows: Pour a little prepared asbestos (purified by washing with hot concentrated hydrochloric acid) suspended in water into the crucible and attach the suction to

the flask. The asbestos at once forms a thick felt over the bottom of the crucible, which by using the suction may be readily washed with water. After washing, suck as dry as possible with the pump. Remove from the funnel, detach any pieces of asbestos that may be on the outside of the bottom of the crucible, cap, ignite and weigh. Remove the cap, attach to the funnel as before, apply the suction and pour the liquid to be filtered through the crucible, wash cap, dry, if necessary, ignite and weigh as before. The Gooch crucible is made of either porcelain or platinum; those of the former material have no cap, and are made either with a permanent bottom, or with a movable porcelain or platinum plate, which rests on a small border, in place of a bottom.

When the filtrates are to be discarded and many filtrations are made every day, such as silicon in pig iron, it will be found more convenient to filter into a large bottle, instead of a small flask, doing away with the necessity of emptying the receiver after each filtration.

Water Stills & Extractors

The left end of the table shown in the cut is reserved for distillations and is accordingly provided with gas as well as water. Where many distillations or extractions have to be made, however, a larger table may be found necessary. Figure 13 shows a compact still for nitrogen determinations, which will allow of six distillations being carried on at once, and which will fit this table space nicely. Stutzer’s apparatus for extractions is also very compact and is used in the German agricultural experiment station at Bonn. It will take care of six extractions. Both forms are made by Messrs. E. H. Sargent & Co., of Chicago.

Stutzer’s apparatus for extractions is also very compact and is used in the German agricultural experiment station at Bonn. It will take care of six extractions. Both forms are made by Messrs. E. H. Sargent & Co., of Chicago.

The cooling water from the condensers runs down into a waste pipe, which is brought up flush with the top of the desk, behind the drawers, and which connects with the drain pipe of the sink, as shown in Fig. 7.

Where extractions have to be frequently made with ill smelling liquids, such as carbon bisulphide, it is well to either partition this end of the table off to form a hood or else to extend the water and waste line into the hood. Where extractions are made with very volatile or inflammable liquids, it is safest to do the heating with electric stoves. Several forms of these will be mentioned later on.

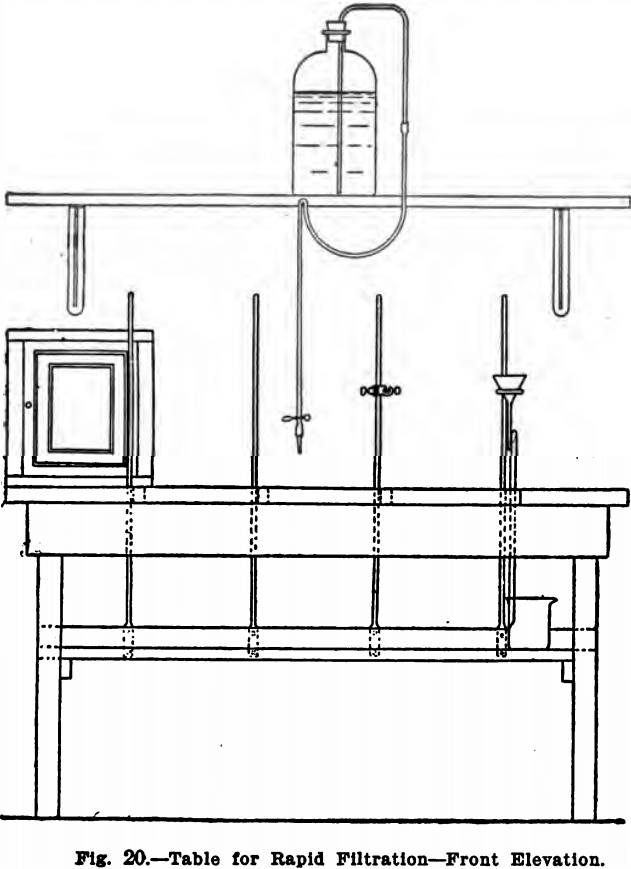

Table & Rapid Filtration Equipment

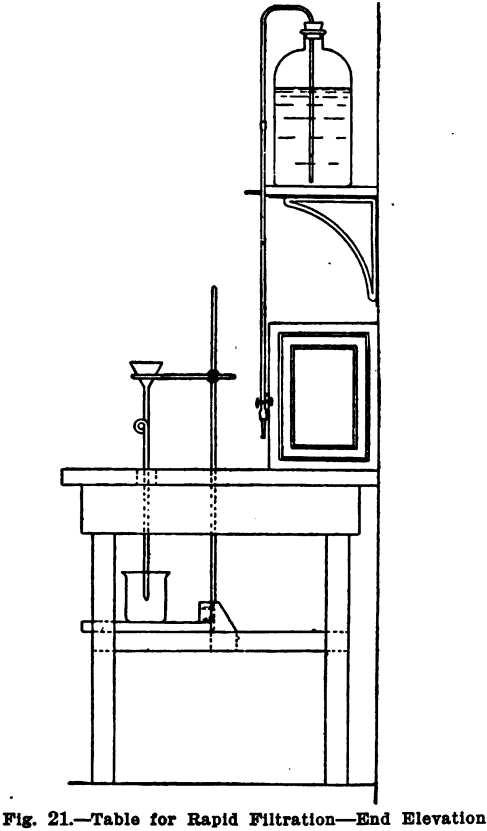

Figs. 20 and 21 show a table especially designed for the use of long stem funnels. It is merely an ordinary table, thirty inches high, provided with a shelf running the entire length across its front, eighteen inches below the top of

the table. The shelf is designed to hold the beakers which are to catch the filtrates. The funnels pass through slots, 1″ x 2″, in the table top and are held in the arrangement shown in the illustration. This consists of an iron rod, screwed fast to the lower shelf of the table and passing up through the top, twelve or sixteen

inches or even higher. The funnels themselves are held in glass triangles made of heavy glass rod, ¼” in diameter, which in turn are clamped to the rods, at any height desired, by means of right-angled clamps. These filter stands are very neat and are cleaner than the wooden ones. A piece of rubber tube should go around the glass triangle where it is gripped by the clamp. The funnel stems should be bent in a loop so as to keep them always full of liquid. Instead of making the bend, the tube may be merely drawn out slightly, reducing the diameter to about 1-16 inch. In order to have them fill rapidly it is essential that the filter paper be put in tight, so that no air can leak past. In connection with this table, the writer has used to advantage the device for washing precipitates shown in the cut. It consists merely of a bottle standing on a shelf, either fastened to the wall or supported from the table, provided with a siphon tube to which is attached a long flexible rubber tube terminating in a jet and closed by Mohr’s pinch-cock. This apparatus will be found very useful for washing such precipitates as magnesium pyrophosphate, phospho-molybdate, etc. The small cupboard at the back of the table is for filter papers. It may be dispensed with entirely and the japanned tin filter cases, sold by dealers in chemical apparatus, substituted. These latter hold five sizes of filter papers, ranging from 19 cm. down.

Wash Bottles

For covering the necks of wash bottles to be used for hot water, sheet cork will be found the neatest material. It is a good non-conductor of heat and does not flake off on the hands as does asbestos. It is usually sold in plates 8×4 inches and 1/8 inch thick. A piece of this is cut so as to cover the neck of the flask with about an inch lap. One end of this piece is then shaved with a sharp knife until it tapers to a thin edge, and the cork is placed in hot water to soak. It is then partly dried on a towel, and curled around the neck of the flask. Mucilage or glue is used to hold the two ends of the cork together, string being wrapped around until this dries, which can be hastened by boiling water in the flask.

Asbestos paper is much used for this purpose also. The author’s objection to it has always been that it flakes off on the hand and these flakes are liable to get into the filter paper or solution. Where asbestos is used, therefore, it is safest to cover this with cloth. The asbestos is wet and wrapped around the neck of the flask and partially dried. A strip of flannel or felt is then pasted around this so as to entirely cover the asbestos.