Stringent environmental regulations, which have limited the use of sludge ponds, coupled with the economic incentive to clean more coal or to add fine coal cleaning additions to existing preparation plants have increased the use of static thickeners in preparation plants. The Lamella Gravity Settler, sometimes designated Lamella Thickener, is a shallow depth sedimentation device which has been applied in a variety of industrial process and wastewater control projects in place of the conventional raked thickeners.

Theory and Design

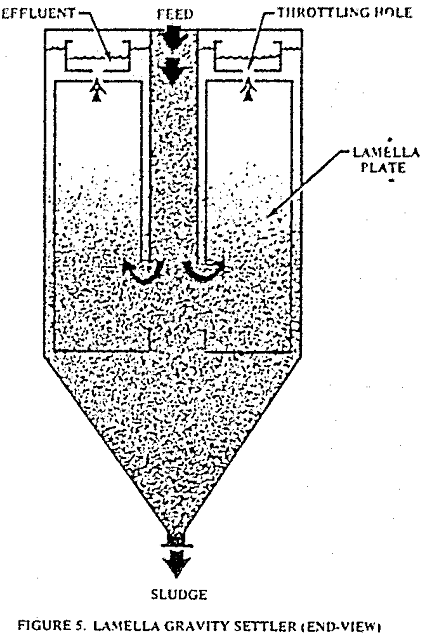

The Lamella Thickener is an inclined, shallow depth sedimentation device. It performs the same function as a conventional Thickener, but it occupies only a fraction of the space.

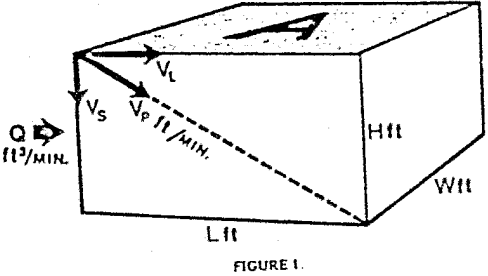

For an initial understanding of the Lamella Thickener, it is best to restrict the initial discussion to suspensions in which the particles exhibit “free settling.” This phenomenon occurs when the concentration of particles is low enough that the individual particles or flocs settle independently of one another and follow Stokes’ Law. At higher concentrations, the settling particles interfere with each other, and “hindered settling, ” which is characterized by a clearly defined interface between the suspension and the clarified liquid, is encountered.

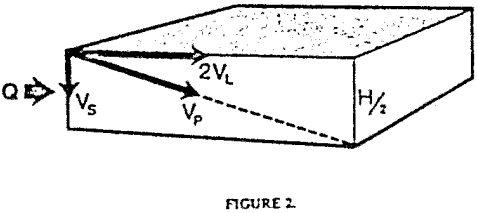

The shallow depth sedimentation device is impractical since it is difficult to remove sludge from the plates. Either the space between the plates must be large enough to accommodate mechanical scrapers or the unit must be shut down periodically and backflushed. Both systems are used occasionally for special applications, but in general they are impractical for coal processing applications.

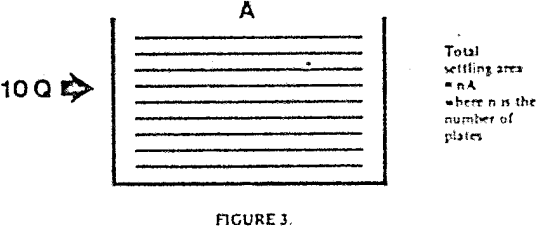

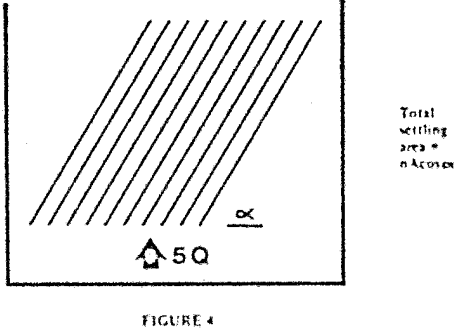

For a more general solution to these problems, the plates are inclined so the sludge will be self draining. The total settling area is derived as above, but the plate area must be multiplied by the cosine of the angle to correctly determine the capacity and overflow rate. (Thus only the projected area of each plate on a horizontal plane is “counted.”). In this example, the total settling area is 10A cos. 60° = 5A and the capacity of the unit is 5Q.

The Lamella Thickener design successfully overcomes these limitations. Uniform flow distribution is obtained by taking a small pressure drop (2-4 inches of water) at the discharge of each plate. Sludge reentrainment is avoided by having separate “doors” for the feed, effluent, and sludge.

A typical Lamella Thickener plate is usually two feet wide by ten feet long, is spaced two inches from adjacent plates, and is inclined at an angle of 45 or 55 degrees. The ten foot plate length is divided into two sections, one above and one below the feed point. The section above is called “clarification area” and the section below the feed point is called “thickening area. ”

Full Scale Installations

Based upon both the laboratory settling tests and the series of pilot Lamella tests, initial full scale design parameters were formulated. Employing a surface loading rate of 0.5 gpm/ft² (1.25 m/h), a Lamella overflow of less than 500 parts per million suspended solids and an underflow of at least 25-30% (by weight) was predicted. Subsequent full scale installations were sold, designed, and are currently operating based on these parameters.

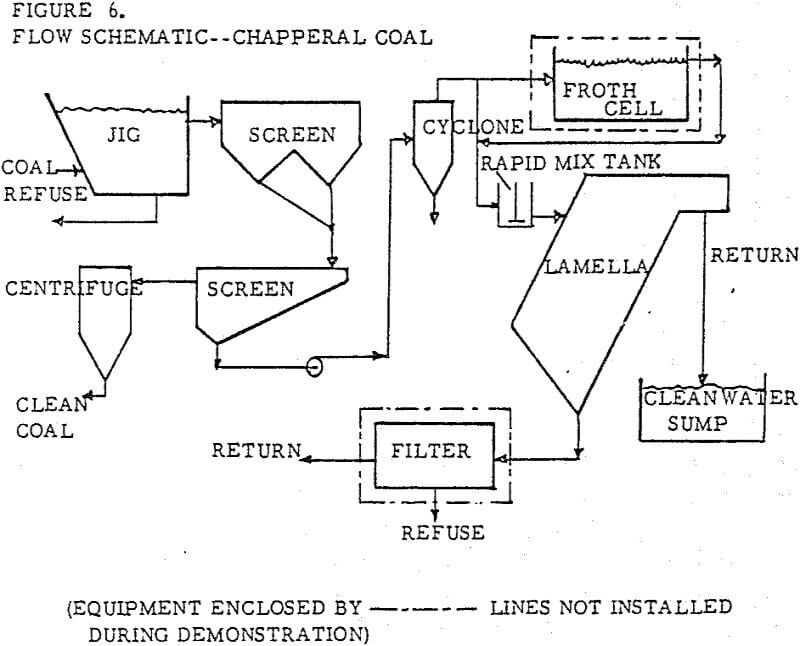

The first two full scale Lamella Thickeners were purchased by Chapperal Coal Company in Pikeville, Kentucky and were installed in September, 1975. They provided the first demonstration site for full scale operation of a Lamella Thickener in Coal Washwater.

The units were designed to handle froth cell tailings with the Lamella Thickener overflow returned to the jig washer and the Lamella underflow pumped to a disc filter. During the initial operation, froth cells and disc filter were not installed and the units operated on a temporary basis with feed from refuse cyclones and with the underflow pumped to a pond.

During the initial phases of operation on both conventionally and continuously mined coal, the Lamella feed solids averaged 8 – 12% (versus 5% design) because the froth cells were not in operation. The influent rate was 1500-1600 gpm. No operational problems were experienced with the Lamella and successful operation continued even during periods of plant upsets (such as very high ash content raw coal and several cyclone pluggages).

Mary Helen Coal Company, Belfry, Kentucky, installed and started up another Lamella Thickener in August, 1976. Coal is cleaned at Mary Helen using heavy media cyclones. Lamella feed consists of magnetic separator tailings and screen washwater. Design basis was an 850 gpm flow rate containing up to 10 wt% solids from continuously mined coal. Initial problems throughout the plant were attributed to very fine stock piled coal from the initial mine workings.