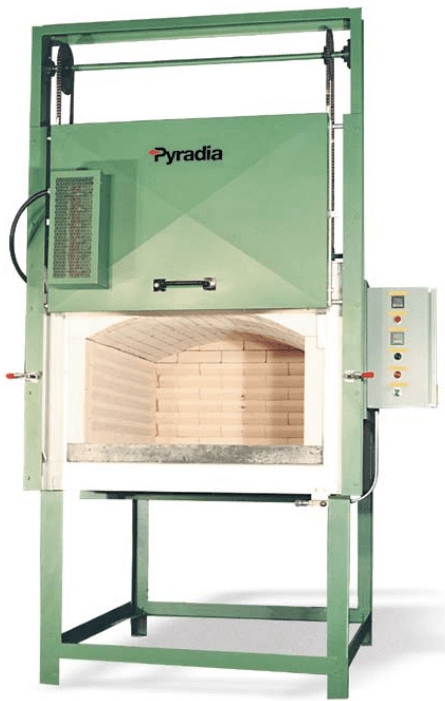

Our heavy-duty box furnaces are designed for an intensive and continuous use. Equipped with a ramp to set point digital indicating controller, our high temperature furnaces allow you to reach and accurately maintain the desired temperature. In order to minimize the heat up and cool down times, our furnaces are insulated with the best refractory bricks. The temperature control accuracy and the quality of the insulation of our furnaces enable you to achieve maximum performance and efficiency.

Our heavy-duty box furnaces are designed for an intensive and continuous use. Equipped with a ramp to set point digital indicating controller, our high temperature furnaces allow you to reach and accurately maintain the desired temperature. In order to minimize the heat up and cool down times, our furnaces are insulated with the best refractory bricks. The temperature control accuracy and the quality of the insulation of our furnaces enable you to achieve maximum performance and efficiency.

- Heavy-Duty 2300°F Furnaces/1260°C

- General Heat Treating

- Annealing

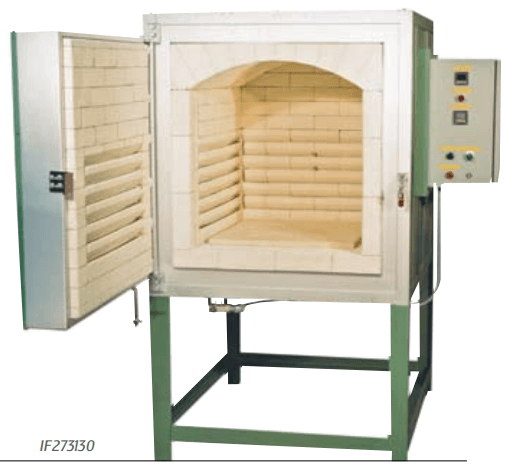

- HardeningThis is our high temperature industrial batch furnace. It looks like our tabletop furnaces for their interior design but offer higher continuous temperatures.

Let’s talk about one of our heavy-duty industrial box furnaces. These furnaces are ruggedly constructed, heavy-duty, designed with high power ratings for production heat treating, processing heavy loads. A common Model is 54 inches high, 24 inches wide, 36 inches in length. We construct our models with angle iron frame, lined with a 10 and 12-gauge sheet metal. The front face plates are nice and thick. These are heavy-duty models.

The inside of the furnace is designed with heating elements on the side walls, door and backwall. On our even larger models, we put heating elements in the floor of the chamber. Our heating elements, again, use a heavy-gauge coil mount heating element, 10, 11, 12 gauge wide. The wires are held in place which are removable. If you do need to replace a heating element, slide out the plate, we will send you a new plate, slide in the new plate, you’re backed up and going. You do not have to change any of the insulation in order to replace a heating element. The chamber is lined with a 4.5 inch layer of fibrate backed up with a 2.5 inch layer of mineral wall. This provides a great heat storage and keeps the outside shell temperature low.

The floor of the chamber is lined with hearth plates to protect the floor insulation and supports the workload. A heating element is located in the floor of the chamber on the larger heating elements, on larger furnaces as well. A microswitch shuts off the power to the heating elements when the door is open. This particular customer wanted a double pivot door. On our larger furnaces, we usually provide a vertical lift door which can be a manual or an air-operated type door. All of our furnaces are standards equipped with digital temperature controls. We do provide additional options such as programmers, timers, recorders and other types of door arrangements.

Bringing your heat treating in-house will help save on our minimum life charges for your commercial heat treater, saves on your turnaround time, helps you gain better control over your product in-shop as well as the quality of your product. The return on investment will be surprisingly quick.

| We also designs and manufactures metal melting furnaces, heat treating furnaces, drop bottom solution ovens, walk-in ovens and cabinet ovens. ISO 9001 – 2000 certification guarantees the quality of our products. |  |

GUARANTEE

All heavy-duty furnaces carry a one year guarantee. |

Temperatures up to 2 300°F/1 260°C

Our heavy-duty furnaces offer remarkable performance, long service life and ease of operation. A variety of options enable you to customize our heavy-duty furnaces to meet your process specifications.

- LONG-LASTING AND EFFICIENT, OUR HEAVY-DUTY FURNACES CAN BE USED IN A VARIETY OF PROCESSES.

HEATING ELEMENTS THIS INDUSTRIAL BOX FURNACE

The specially designed grooves optimise heat transfer and fully support heating elements for maximum life expectancy. The open coil FeCrAl heating elements are easily accessible for replacement.

BOX FURNACE FEATURES

|

BOX FURNACE OPTIONS

|

|

INDUSTRIAL BOX FURNACE FEATURES

- QUALITY INSULATION: we use the same kind of “grooved bricks” as in the tabletop furnace. Starting inside the furnace, you will find the 4½’’ thick low-density refractory bricks (rated 2,600°F) backed by the 2½” fibreboard (mineral fibre rated 1,900°F) followed by the internal casing.

- AUTOTUNING TEMPERATURE CONTROLLER our standard controller is a Omron model E5CK. Autotuning is the automatic calculation and entering of the control parameters (PID) into memory. The customer has to enter the value for the type of autotuning he needs to run on in his particular application based on overshoot tolerances and the precision of the PID parameters needed. The Omron model E5CK offers a ±0.3% precision (ramp to set point, 1/16 DIN).

- HI-LIMIT OVERSHOOT PROTECTION: this device will shut the furnace when the preset temperature is exceeded. A reset button has to be pressed by the operator in order to get the furnace to heat up again. Our standard is Omron model E5CN-FR.

- HEATING ELEMENTS: grooved bricks optimize heat transfer and make maintenance much easier. FeCrAl heating elements are located into the groove of the bricks (but not moulded into the brick) and can be replaced without taking any bricks out. By being in the brick groove, radiant heat from the element is lowered, which offers a better temperature uniformity. Plus, the elements are protected from any contact that can occur during the furnace loading. This kind of design also allows the operator to replace just a few bricks when required.

- AUTOMATIC DOOR SWITCH automatically shuts off the power to the elements as door is opened and restores it as door is closed.

- HEAVY-DUTY CONSTRUCTION: we use ¼” structural angle frame with HRS.

- HEARTH PLATE is made of Cordierite and included with every furnace if furnace is not designed with a castable floor design.

- STANDARD VOLTAGES: 460/3/60 or 575/3/60 but we can meet any requirements your customer might have (exception: only 230/3/60 or 230/1/60 are available for model IF141413).

OPTIONS AVAILABLE ON OUR BOX FURNACES

- PROGRAMMABLE CONTROLLER: our standard model is Omron E5AK-T (¼ DIN) (8 programs – 16 segments).

- STEEL AND ALLOY TRAYS: we offer custom made products based on customer’s requirements (weight and size of the parts to be loaded in the oven). Our furnace comes with a standard Cordierite plate at the bottom.

- CHIMNEY: this is not a forced exhaust but a vent.

- NiCr HEATING ELEMENTS at no extra charge. These elements are usually used for corrosive applications.

- INERT GAS ARRANGEMENT: we modify our standard design to accommodate controlled atmospheres.

- CASTABLE FLOOR: usually for applications for heavy work piece.

Note: this is our standard design. We can adapt standard models to accommodate your customer’s requirements.

BOX FURNACE HEATING ELEMENT

What makes for a good Industrial Box Furnace design? Well, actually there are several factors: thick wall of insulation, strong KW ratings, good door seal, accurate temperature control. All of these are important, however we feel the backbone to a good electric furnace are the heating elements.

We use heavy-gauge wires, typically 10, 11, 12 gauge wires combined with a loading of less than 10 Watts per square inch. We coil the wire with the right spacing and the right OD to form a stable, self-supporting wire. In addition, we use high-grade iron-chrome-aluminum wire. All of these features add up to longer element life and a better value for your investment.

We mount our wires in removable holders, forming 4 banks of heating along the wall surfaces, resulting in better temperature uniformity in the work chamber which delivers better heating and a better finish, and a better, more consistent hardness across the surface of your part. Replacing a heating element is easy. Slide the old plate out and you can slide the new plate with the wires right back in. You do not have to touch or remove the insulation to replace an element assembly.

Other furnace brands, with the wires grooved into the brick use a very thin gauge wire coiled to a small OD with a wide spacing. The wires are actually pinned or nailed into the brick. The brick breaks, ultimately leading to expensive chamber relining and downtime. We inventory our wire, we coil our own heating elements. We have developed over the years hundreds of heating element designs specifically for each chamber size, voltage supply and temperature rating. When a heating element is needed, we can usually ship a replacement assembly in 1-2 days.

So, when considering the purchase of a new furnace, compare the heating element design very carefully. What heating element would you rather have in your furnace?