I was requested to write an article on Longwall Mining a short time ago; however, the time has been so short that I have not had time to prepare an article as I would like to have presented it to this body. In writing this article it has not been my intention in making comparison of various mines, to favor one or discredit the other. I hope it will be considered in that light.

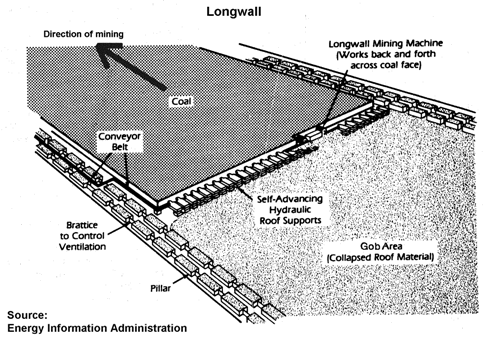

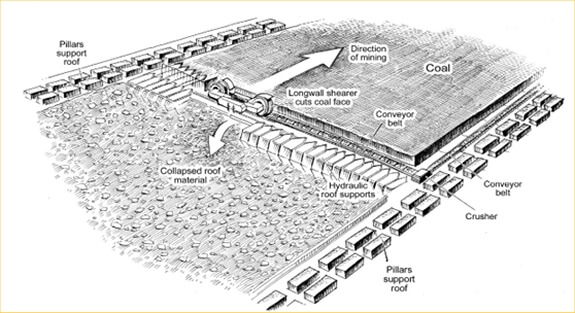

The coal mining industry as I have seen it in the past, at present and in the future. In years gone by large tracts of coal land could be obtained at a very small cost, and as yet coal land may be purchased at a reasonable price in this country, but I believe the time is near at hand when the methods of mining will have to be changed greatly in this country. Many changes have taken place in the last few years, some of them have been forced by law, others by the coal operators themselves, after being convinced that the changes made were for their own benefit. During my 20 years in the mines I have seen thousands and thousands of tons of coal lost that could have been saved if proper methods of mining had been used. The Room and Pillar system of mining coal is none too good at its best; a certain per cent of the coal is always lost, yet it is about the only system that can be used under certain conditions, but where the Longwall system can be used I believe it is the best system yet introduced. If the Longwall system is used there is no coal lost. You get it all as you advance with the workings. Some coal operators object to the Longwall system for several reasons, and most of the reasons they advance are not founded on facts. For instance some of them claim it is too expensive. I will admit that the cost per ton is a little higher in Longwall than it is in Room and Pillar as a rule for the amount of coal mined, but after the Room and Pillar mine is finished as a rule there are thousands of tons of good coal lost, for the simple reason that it cannot be mined at a profit. In many cases if the same mine had been operated on the Longwall system every ton of saleable coal could have been mined at a fair profit, and in the long run would have netted the owner much more money than it did under the Room and Pillar system. The Longwall system has been in operation many years in Europe and especially Great Britain, and is the most approved of systems in many countries at the present time. Millions of tons of coal have been saved by its use in those countries. It is claimed that the Armour Packing Company loses nothing but the squeal of the hog when it is killed, and doesn’t allow it to squeal much. Why lose coal if the Longwall system of mining will save it ?

The Longwall mine is far more easy to ventilate than the Room and Pillar mine; the air has a much less distance to travel for the same amount of working face in Longwall than it has in the Room and Pillar.

https://www.youtube.com/watch?v=bXORrVmxwbM

The faces are the airways in Longwall workings, and that one feature alone is a great advantage. First, better air is circulated along the face to the miner, enabling him to perform a better day’s work with better assurance of his health. In gaseous mines the gas is more easily controlled, the faces being the airways, the velocity and quantity of air can easily be adjusted to dilute, render harmless and carry away all explosive gas, powder smoke and other gases met with in mines, with the use of much less brattice than is required in Room and Pillar mines. The air having to travel a much less distance in Longwall workings there is less rubbing surface and less resistance, therefore a lesser horsepower is required to furnish ventilation, therefore less power expense. The cost of timber is more in Longwall workings than it is in most of the Room and Pillar mines if the price of coal lost under the Room and Pillar system is ignored. But I know of some cases where enough coal is lost to have paid for enough timber to have worked out the mine under the Longwall system. Some coal operators I know of have attempted to change from the Room and Pillar system to the Longwall system of mining and failed to make a success of it. Some of them failed because the man they employed to make the change did not understand the Longwall system of mining. Others have failed because the officials higher up would not furnish the money to reopen the faces after the first big squeeze that most always takes place when Longwall workings are first opened up. Some of these officials refused to furnish the money because they did not understand the Longwall system themselves and feared it would not be a success if put into operation. The Colorado Fuel and Iron Company is at present operating four mines in Fremont county, Colorado, on the Longwall system; three of them have been in operation for many years. I commenced work in the Fremont mine as a timber-man two and a half years ago; later on I was employed as night foreman for seven months. I then went digging coal for a few months, and then I laid track for seven months. I am at present employed as fire boss at the Emerald mine, which is also operated by the Colorado Fuel & Iron Company, on the Longwall system. During the time I was employed at the Fremont mine, I had a good chance to study the Longwall system. In some parts of the mine the roof is very bad. Other portions of the mine there is a good, hard sandstone roof, but the bottom is of a soft nature all over the mine. This soft bottom heaves up and is the cause of the track having to be graded often in some portions of the mine. It gives the most trouble where the roof is of heavy sandstone, but as the workings advance the roof and sides are brushed for height and width, and roads graded where required and far enough back from the working faces for settled conditions to prevail. The roadways stand fairly well the cost of upkeep being reasonable. When I first commenced work at the Fremont mine I noticed that many cribs were used, and the use of these cribs was to some extent to blame for the high cost of timber per ton of coal mined. It has been proved by actual tests made through the co-operation of the mine officials and the men, that cribs are not of much use and the use of them has been discouraged, except in cases of emergency.

In turning rooms, dips and cutoffs, where it is slate roof and in most cases none too good, one crib is used on the corner where the roof is sandstone, the use of cribs is being done away with altogether. Packs of dirt and road walls built from the rock and slate blasted down when brushing is far better than cribs, the dirt packs and walls give as the weight settles on them, and does not break the roof at the working face as do cribs where they are built too solid. If cribs must be used for safety at the face they should be left open and removed when dirt is at hand to fill in the space. In Longwall workings the spaces should be kept as even as possible. Corners should never be allowed to lag behind. Wherever corners are allowed to get behind, the squeeze settles on them and the face tightens for some distance around them. Very often corners left on for some time causes bad falls of roof; where the bottom is soft it heaves up also and makes the work difficult to remove the coal and falls. The system of timbering in Longwall workings differs somewhat from Room and Pillar. In Longwall you have the side squeeze to contend with. In my opinion it is best when placing sets of timbers to place blocks of wood at each end of the collars. When the squeeze comes on from the sides the collars sink into these blocks of wood before breaking, and last much longer than without them. Also soft blocks of wood should be placed under each leg and the legs will last longer still if some loose dirt is left under the blocks so placed.

In my opinion when turning the levels off from the slopes of drifts, they should not be turned too far apart. Three hundred feet should be the limit of face between levels, for where more than six or seven rooms are turned between levels, the cost of upkeep of the cutoffs is too great. The cutoffs usually stand fairly well until the first four or five rooms are finished, but if more rooms are still to be worked the cutoffs usually have to be rebrushed at a considerable expense for the small amount of coal still to be mined front the other rooms still unfinished. Dips should not be driven for to turn more than two rooms off them. I don’t believe in pulling coal up hill any more than is necessary. All haulage ways should be driven on a slight grade favoring the loaded cars going out the partings if possible to do so. I believe that the gun and shaft is better and safer than the tail chain in Longwall workings. Where the gun and shaft is used the mules can usually stop the cars when falls happen on the entries, which makes the work of driving safer for both man and mule.

It is not practicable to use mechanical haulage at or near the face of Longwall workings on account of falls and the tracks heaving up, but some distance back from the faces where settled conditions prevail, haulage, motors, tail works or other mechanical, haulings may be used the same as in Room and Pillar mines.

Having discussed the Longwall system under good and bad top and bottom under deep cover, I will now discuss the system under bad top and hard sandstone bottom and shallow cover which is the case at the Emerald mine where I am now employed. Under the conditions mentioned the bottom does not heave up. The top being slate and in most parts of the mine of a soft nature and in some places wet, it is hard to hold. To hold this top the gobs must be kept well filled and packed tight up near the face, and good walls maintained along the roadways. In my opinion solid or filled cribs should not be used at the face as they check the squeeze too quickly and the top breaks around them and at the faces. Where good road walls are built and the gobs well filled with dirt and rock, the roofs bend and settles down slowly and does not break so often at the working face. The water under these conditions should be kept well drained off and not be allowed to run through the gobs. Wherever water is permitted to run through the new gobs, it softens them and bad squeezes and, falls are the results.

If the bottom is soft it heaves badly on the roadways. In any Longwall mine where there is much water, all entries and roadways should be driven on a pitch great enough to permit fair drainage on the working face if possible to do so, so as to keep the faces dry for the miner. In low seams of coal the miner must do a great deal of his work on his knees along the face. There is no objection to the system of Longwall that is in use in some parts of the country. In my opinion the distance between rooms at the face is too great in many places, which is a disadvantage to both the miner and the company. Wherever distance between rooms is more than 50 feet it is altogether too far for the miner to shovel the coal to the car. Forty feet from center to center of roadways at the face makes the best work, although it isn’t always practicable to keep 40 foot centers, 50 feet should be the limit. If the dirt cannot be gobbed it should be loaded out and bogged elsewhere if needed or hauled outside to. the dumps. I don’t know of anything that will make a miner quit or get discouraged quicker than to shovel coal three or four times for nothing along the face before it can load it into the car. Where the distance is too great between rooms, the rooms last too long and have to be rebrushed for height so as to get the cars in and out. Also corners get left on between the roadways. The squeeze settles on these corners and the roof breaks at the face. The coal tightens, falls block the airways at the face, gas accumulates and is sometimes difficult to remove. The miner loses his work until the place is cleared of gas and made, safe, for every additional time the miner has to shovel the coal, his output is lessened; also his wages. The operators profit is also less. Mr. Boss, wherever you have a miner shovelling coal three or four times just imagine yourself working in that place, and in my opinion, if good judgment is used, you will lessen the distance by turning another room or otherwise. The average man will cooperate with you if you don’t forget the golden rule altogether, and co-operate a little with him. The day of the bulldozing boss is past. The average man does not fear the boss or the loss of his job, but as a rule he will play fair with you if you are fair with him. Of course there are exceptions on both sides; but in my experience I have found that little misunderstandings are the cause of most trouble between the bosses and men. If grievances are threshed out as soon as discovered, they seldom amount to much.

Another objection to the Longwall system of mining in some parts of the country is that the rooms are driven too great a distance before being cut off by the cutoffs, and again I must stand by the miner; 200 feet is too far for the miner to have to push the cars from the switch to the face, and as a rule either the roof has settled down too low for the mules to go to the face and pull the loaded cars, that causes the miner to have to push the cars both ways. Also in many places the bottom heaves up and makes the pushing of cars difficult. I believe that rooms driven a distance of about 150 feet would give the best results under most conditions in Longwall mining. Rooms driven a distance of 200 feet often have to be rebrushed or the roads graded. Rooms driven 150 feet would seldom, if ever, have to be rebrushed or the roads graded.

I recently made a partial inspection of the Rockvale mine which is another property of the Colorado Fuel & Iron Company. In going through the mine I noticed that many cribs were being used. The gobs in many places were not well filled, and after seeing these conditions I was informed that considerable rock was being loaded and hauled outside to the dumps. When travelling the faces I discovered that many corners were left on. The squeeze had settled on these corners, the coal was hard and the faces blocked by falls. In one part of the mine a coal cutting machine had been installed to undermine the coal. It is my belief that if the faces were straightened out they would have no need of a machine. The coal would bury the machine if they tried to use it. I also noticed that no blocks were being used under the legs of timbers set on the roadways or at the ends of the collars to help protect them from side squeeze. In my opinion the cost of timber per ton of coal mined was more than double the cost in the Fremont mine. Both mines are working the same seam of coal on conditions a good deal the same. If anything, Rockvale has the best natural conditions for Longwall workings. The high cost of timber is plain to me; the first place where no blocks are used under the legs or at the ends of collars, the timbers don’t last so long; second, too much expensive spruce timber was being used at or near the face. Cheaper light timber would serve the same purpose; and third, too many useless cribs were used on the gobs not well filled.

In Longwall workings small pit cars give the best service; big cars require that the roadways be maintained at too great a width and height and makes the cost of upkeep too expensive. Big cars usually have to be taken to and from the face by the driver, and cannot be taken into low and narrow places that have been finished and used as a gob car. About a ton car gives the best service. Usually a few night shift men are required to brush, clean and grade roads where the Longwall system is in operation, and to gob the rock and do repair work that cannot be done while the mine is in operation; I have discussed the system of Longwall mining advancing. I will now take up the Longwall mining retreating.

Under the latter system thicker seams of coal may be mined with much less danger, as the haulage, roads and airways are first driven to the boundary line and then the face is opened up. Under this system the gobs do not have-to-be kept well filled or tightly packed. The worked out portions can be allowed to cave in a good deal the same as when drawing pillars when under the Room and Pillar system. While in the Longwall system advancing if the gobs are not kept well filled in gaseous mines, there is often danger lurking within the gobs, on account of accumulations of gas and always the danger of squeeze on the roadways. In the system of Longwall retreating, if the faces are kept about even between levels the squeeze will be fairly good at the face whether the gobs are well filled or not, and a good deal of the dangers are left behind as the faces retreat back toward the slopes or shaft under the Longwall system retreating, that are a menace in other systems of mining. In my opinion the best natural conditions for Longwall mining advancing, is in seams of coal ranging from four and one-half feet to five and one-half feet in thickness. If the coal is clean and no dirt is present at the top or bottom to fill the gobs, dirt may be hauled in from the outside However, where there is enough dirt or rock coming with the coal to fill the gobs it is an advantage. Dirty seams of coal can often be operated at a fair profit on either of the above systems mentioned, that would not pay at all under the room and pillar system. Wherever the seam of coal pitches at from three per cent to five per cent it is about the best pitch for Longwall workings, whether dry or wet, as it offers a good grade for haulage and drainage. Although the Longwall system, in my opinion, is practicable in seams of coal laying level and up to a pitch of 40 degrees, or even greater. Under the Longwall system a considerable amount of timber used can often be saved and used over again in various ways. The props and sprags used at the face can be saved by the miners in many instances and used over again, while the broken timber on the roadways can often be saved by the company men and used up in building cribs, making cap pieces, wedges, etc. And now, in conclusion, allow me to say a few words to the operator himself.

In saying what I have said and am going to say, it has not been my intention to criticise or find fault with the ideas of any one, neither do I ask any one to believe as I do or do as I say. Just consider what I say for what it is worth, Co-operation of officials and the men in the the employ of any company will pave the way to a better understanding, more friendly relations, greater efficiency in industry and in the end larger returns will be obtained for all concerned in both money and friendship. To have the confidence and good will of your employees is worth a lot to any employer. It is my belief that if the coal operators throughout the country would give to each of the mine employes a short yearly vacation and arrange for part of the vacation to be spent in visiting other mines so that they would see what the other-fellow is doing, and have a general exchange of ideas, better methods of mining would result, and would not cost as much as does the sending of so-called efficiency experts to the mines to inspect them and make recommendations to the mine officials. The advice given by these so-called experts is often not well taken by mine officials, who are on the job all the time, and in most cases better acquainted with conditions than their advisors. Co-operation will work wonders.