The transportation of mine products incurs a cost which can have a significant bearing on the competitive position of the manufactured product. Clearly, the engineer who is responsible for selecting a mode of transport must base his decision, at least in large measure, on economic comparisons. And today, the engineer usually finds that he has to choose between several modes, including slurry pipelines. Several design variables affect the total transportation cost. The amount of preparation that is required to make the solid material into a satisfactory slurry is an important factor.

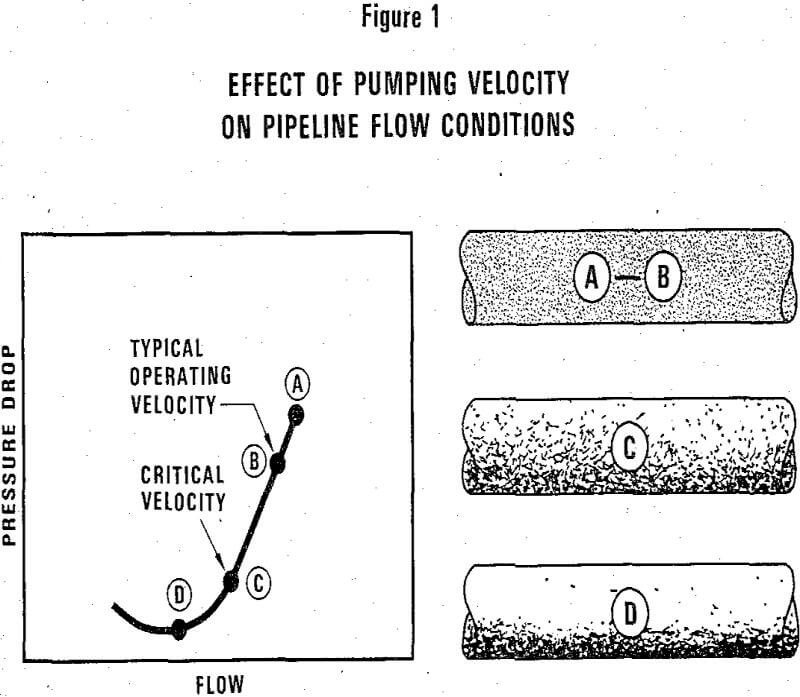

Pumping velocity is another critical variable in slurry pipelining. Next figure illustrates the general relationship between pressure drop and rate of flow; it also illustrates the concept of critical velocity. The straight portion of the curve, between Points “A” and “C”, encompasses the velocity range at which the solid material is suspended in the carrying liquid. However, as the velocity is decreased from Point “A”, the uniformity of suspension gradually decreases. This decrease continues until, at Point “C”, part of the solids are being conveyed along the bottom of the pipe. At Point “D”, a bed of solids has formed. The so-called critical velocity, below which the bed of solids begins to form, lies between Points “C” and “D”; the exact location depends on which definition of critical velocity is used.

The capital cost estimate is the basis for the annual capital charges. Although these charges depend on a number of variables, including local ad valorem tax rates, depreciation schedules, interest rates, debt/equity ratios, and return on equity; for the purpose of the initial economic evaluation, a 15 percent annual rate was assumed for the capital charges.

The operating costs consist of two major elements. In one element, the costs for operating and maintenance labor, maintenance supplies, and for corrosion inhibitor may be lumped together.

In establishing the operating cost, it has been assumed that all stations have been automated. Except for the master station, where one operator per shift is available to run the system, the booster slave stations assume only the presence of a day-man for routine maintenance and inspection.

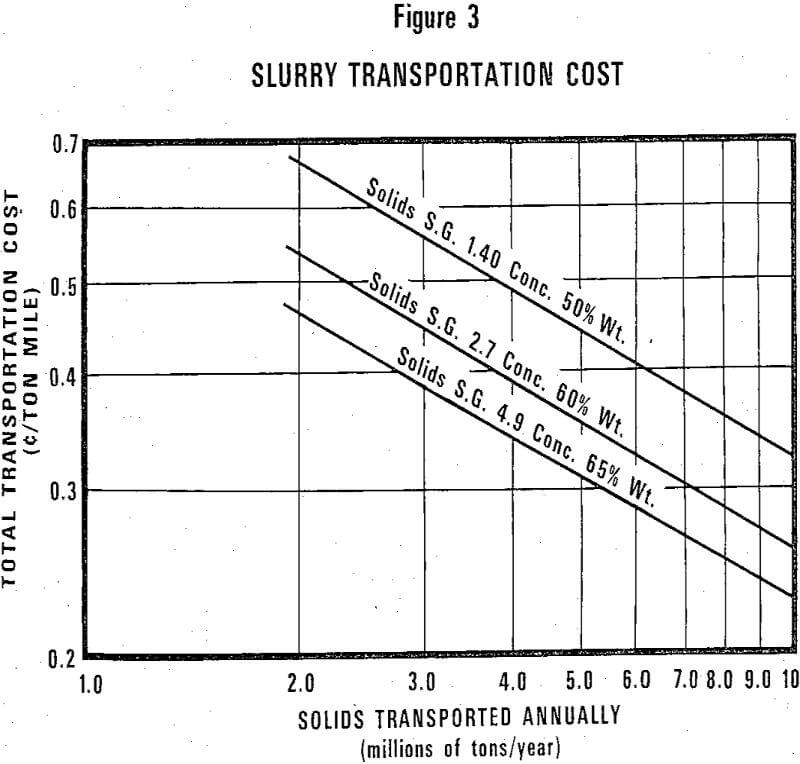

The total transportation cost is summarized. An estimate can be made on the basis of only two variables; the specific gravity of the solid material in question and the quantity of slurry pumped per year.