Microwave Digestion Systems (MWD) were popularized by the US Bureau of Mines (USBM) back in the early 1980’s. The USBM published a series of papers on the topic and discussed the advantages of the system. Basically MWD is used to replace the traditional hotplate or digestion block digestion systems employed for sample digestions. This system results in a significant savings in time and expense over traditional methods of sample dissolution and is ideal for preparing solutions for analysis by atomic absorption, inductive coupled plasma or other analytical methods.

Trace metal analysis by AAS or ICP requires that the sample be in liquid state before introducing into the system. Obviously, some samples come in liquid form such as mine water or leach solutions which require little or no sample treatment prior to analysis. However, samples can also be complex matrices such as oils, ores, concentrates, tailings, soils, coal, etc. such samples are extracted using acid digestions for removal of metals prior to analysis. The objective is to have complete decomposition of the solid matrix while preventing loss or contamination of the analytes within a safe to use system.

Wet chemical digestions utilize various mineral acids such as HNO3, HCl, HF, H2SO4, HClO4 or combinations of such acids. Digestions can be carried out in either open system under atmospheric pressure or under elevated temperature using microwave digestions.

The basic process is that solid samples and an acid mixture are placed in sealed polymer vessels (or other suitable materials). The vessel contents are heated using microwaves, digested for a period of several minutes.

Conventional wet sample digestions of solid samples are typically carried out in vessels containing the sample and large volume of acids. The mixture is heated inside a fume hood for relatively long periods using hot plate or a digestion block. The heating is stopped when the analyst feels that digestion is complete. In contrast microwave digestion offers digestions of both inorganic and organic matrices under controlled conditions.

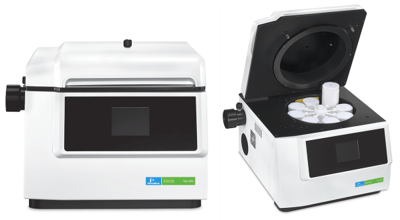

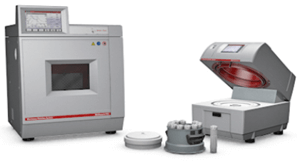

These systems have progressed to the point where purpose-built microwave systems are now available to allow for the system to be easily adopted by any number of laboratory types.

Perkin Elmer Titan System

Anton Paar – Multiwave 7000

Microwave digestion systems offer several distinct advantages over traditional digestions:

- Time saving. Simultaneous heating of 8 – 12 samples is possible and reaction times are typically less than 10 minutes in comparison to 1-2 hours or more for open digestions.

- Higher reaction temperatures. The time required for a digestion is dependent on temperature. Open digestions are limited to the boiling points of the acids used whereas closed digestion systems can be operated at higher temperatures of 250 – 300C.

- Lower acid consumption. Acid usages is lower in microwave digestion.

- More complete digestions. Microwave digestion systems offer greater extraction efficiency whereas in open system digestion extraction can be incomplete depending on discretion of the analyst.

- Safer. No exposure of analyst to acid fumes as compared open digestions.

- Lower loss of volatile elements. Loss of volatile elements such as Hg or Pb can take place in open digestion whereas in closed system digestions loss of volatile elements is prevented.

- Less potential for contamination. A greater risk of contamination from external sources exists in open digestion.

There is a potential disadvantage for closed microwave digestion systems in that there is a risk of explosion and cracking of the digestion tubes due to the buildup of pressure with increasing temperature. However, most modern microwave systems have built in sensors for both temperature and pressure. The microwave power is automatically controlled or shut-off when pressure reaches the maximum limit.

The choice of closed microwave systems really depends on the throughput of the lab and the cost associated with the system. High productivity automated labs should really consider microwave systems. The benefits of a standardized system tend to improve the accuracy and reliability of the assays.