Table of Contents

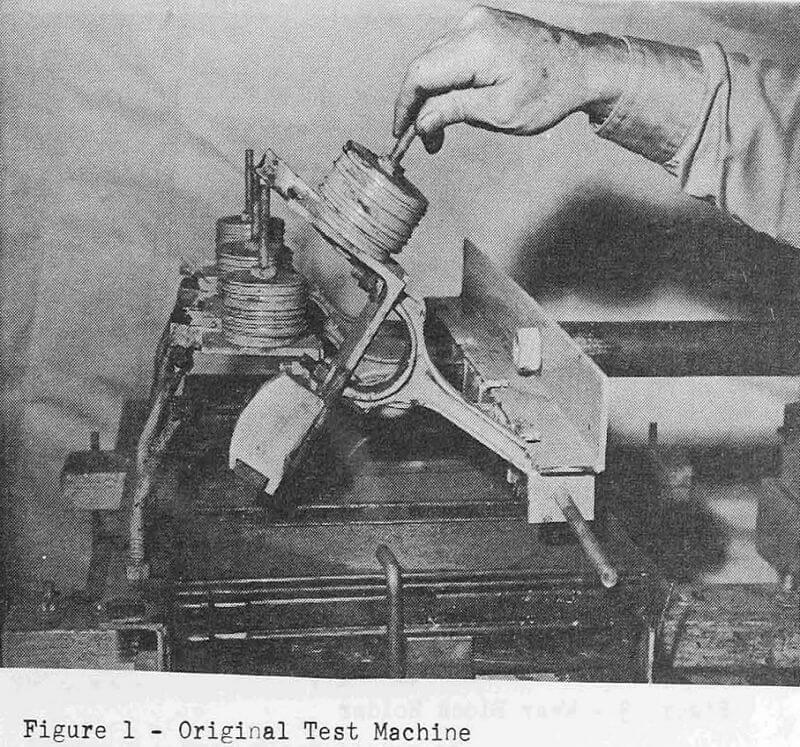

The development of a new means of measuring the relative abrasivity of a slurry came about by necessity in 1967 during a full scale loop test of a 560 H.P. reciprocating pump handling magnetite slurry. In order to evaluate the life of expendable fluid end parts, the question of the amount of attrition in a re-circulated slurry had to be considered.

Test Equipment

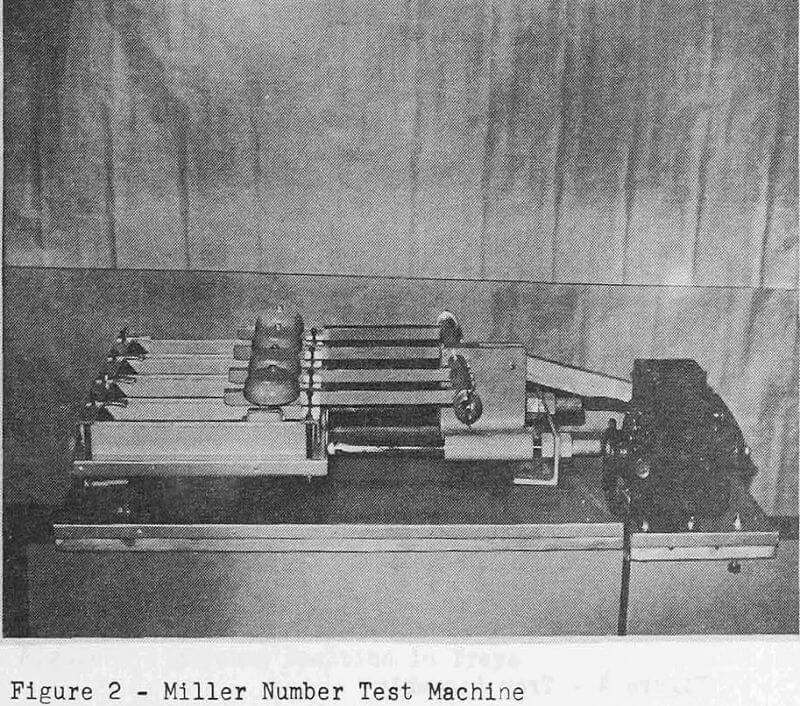

The device used to measure the relative abrasivity of various slurries consists in general of a standard ½” x 1″ metal wear block, driven at a rate of 48 strokes per minute, with a 200 mm stroke, riding in the bottom of a tray containing a 50% by weight slurry of the solids mixed in water. (Some tests are run in actual wet slurries as supplied.) A dead weight of five pounds is applied.

Standard procedures were adopted and a series of tests on available slurries and “pure” minerals were made. The test data was examined and it was noted that the abrasivity, or loss of metal wear block, was not the same for each incremental run, indicating a change of characteristics of the solid particles – apparently a “breaking down” due to the friability of the material. Therefore, this phenomena was taken into account and it was reasoned that the rate of metal loss early, in the test would be more indicative of the effect in passing through the pump for the first time.

Miller Number

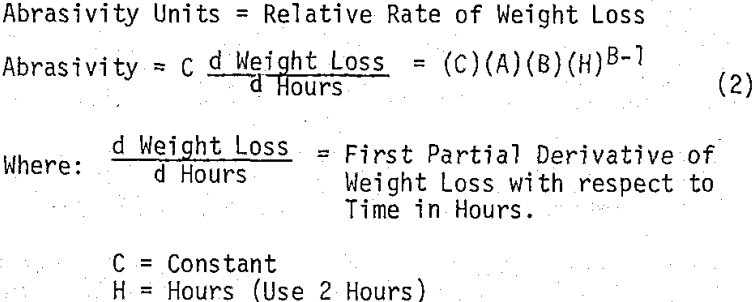

The Miller Number consists of two values. The first value is called abrasivity and represents the rate of weight loss from the metallic wear block. The second value is called attrition and represents the effect of slurry particle breakdown as measured by a loss of abrasivity as the test progresses. This value is minus (-) if there is a loss of abrasivity and plus (+) if there is a gain in abrasivity. F

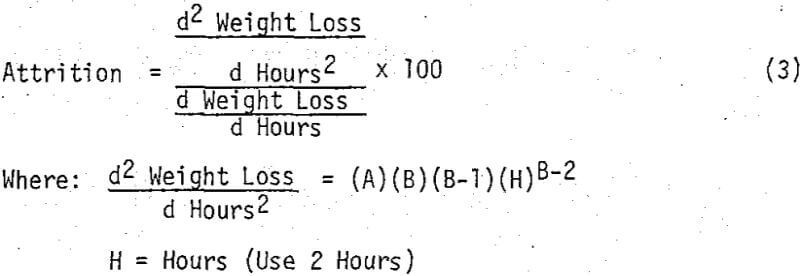

Calculations

The wear block weight loss data are curve-fitted to the equation

Weight Loss = (A) (Hours)B………………………………………………………(1)

Using the least-squares linear-taylor differential-correction technique, the values of A and B are determined for any one test. The above equation was selected because it best fits the past test data.

The abrasivity is calculated by evaluating the partial derivative of the above equation at two hours.

The derivative is evaluated at two hours to override the initial effect of wear block surface finish and to obtain the wear rate early in the test before attrition takes place. The constant (C) includes a factor to force the abrasivity of 220 mesh corundum to be approximately 1000 for comparison purposes.