Iron king mine, producing gold-silver-lead-zinc ore, is 10 miles east of Prescott, Ariz. At present the 1806 level is being developed. The echelon pattern of ore deposit continues at depth but is less pronounced, and the orebody is now more or less continuous over 2600 ft of strike length, with widths 5 ft to as high as 26 ft where overlapping of lenses occurs in one section of the mine.

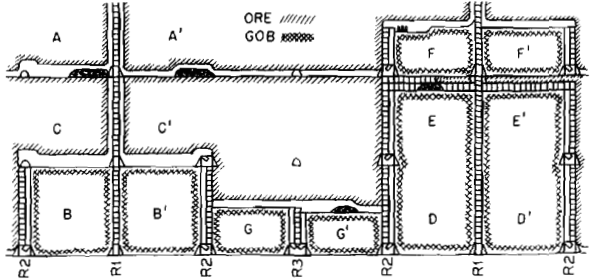

With favorable persistence of ore at depth, the three-compartment No. 6 hoisting shaft appeared inadequate to handle increased tonnage from greater depths, and in 1952, a four-compartment steel and concrete shaft was started. This is now at a depth of 1906 ft, and shaft pockets and loading cartridges are being installed on the 1806 level.

Level Development: An orebody 300 times as long as it is wide requires a lot of development work. Former practice consisted of driving a haulage drift about 30 ft from the ore in an andesitic footwall, a drift on the ore, and crosscuts from the haulage drift at 100-ft intervals. Crosscuts are about 90 ft long.

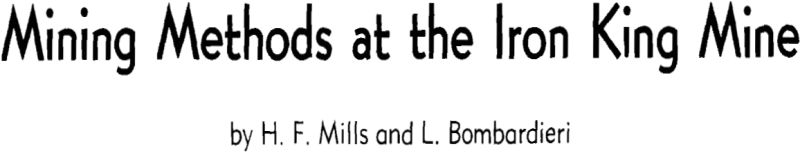

Stope Development: All crosscuts and raises are on 100-ft coordinates, see cut, p. 728. At intervals of 400 ft a three-compartment raise (R1) with stulled and lagged center manway is driven on ore to the level above. The back of the ore drift is then taken out to 16 ft above track level for the 100-ft stope length (A) on each side of this raise.

Haulage: Haulage drifts and crosscuts are 7×7 ft. Cars are rocker dump, of 25-cu ft capacity. Both Little Trammer and 4-ton locomotives are used, and trains consist of six cars of ore or ten cars of waste. Two locomotives per level service the loading and dumping of stope ore and waste fill.