Study of the behaviour of an ore during concentration by flotation process starts, in general, with a series of tests in laboratory cells. Given the discontinuous nature of these tests, the information obtained by such a study is somewhat limited. It has long been recognized that laboratory test results are not always reproducible in pilot plant tests and subsequently, the pilot plant results do not always predict plant performance. The differences are often blamed on batch vs continuous operations, grinding media, size distribution, aging (oxidation), water quality, equipment, operator’s skills, etc.

Following some preliminary test work that substantiated the feasibility of the project, the design, construction and testing of the various components of the mini pilot plant began in earnest.

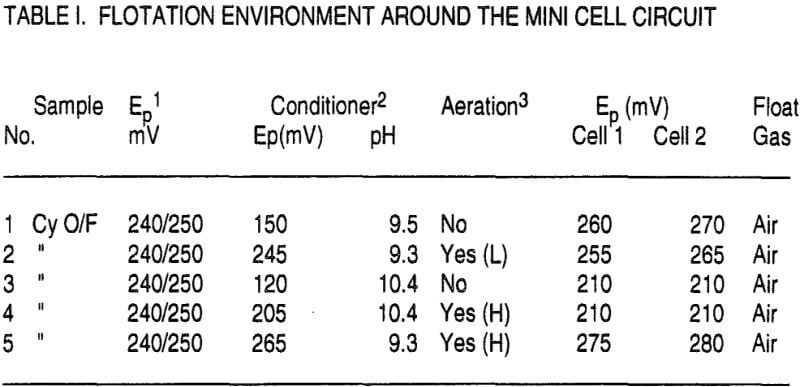

The feed and discharge ports are set at opposite ends of the cell and in the turbulent zone. Flotation air or gas is introduced through a hollow agitator shaft. A needle valve and a flow meter control and monitor the air flow. A pulsed water spray, controlled by a timer, is used to maintain a plug-free froth flow with practically no dilution.

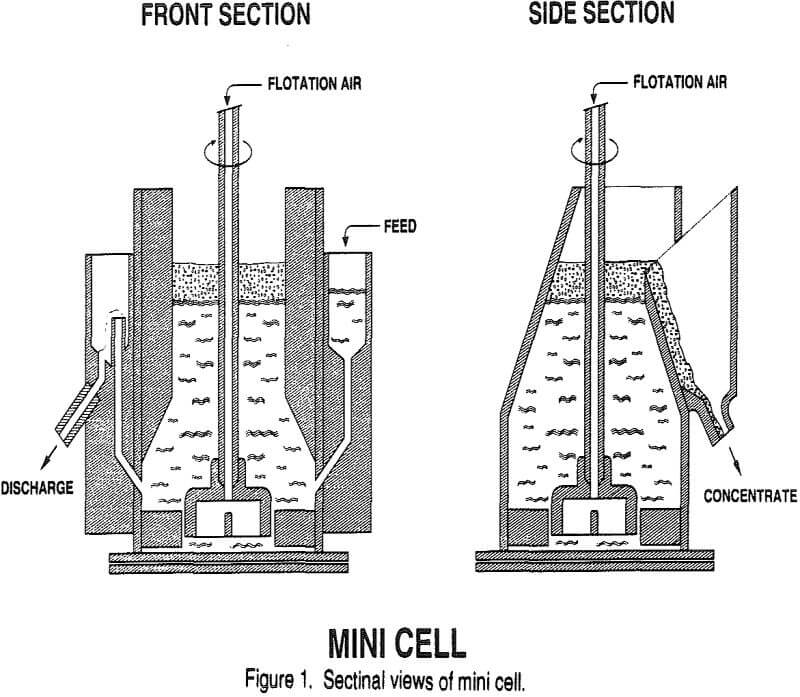

The feeder is essentially an agitated vessel with an inlet, outlet and overflow. The pulp inlet port is positioned at the level of the impeller ( one inch from the bottom).

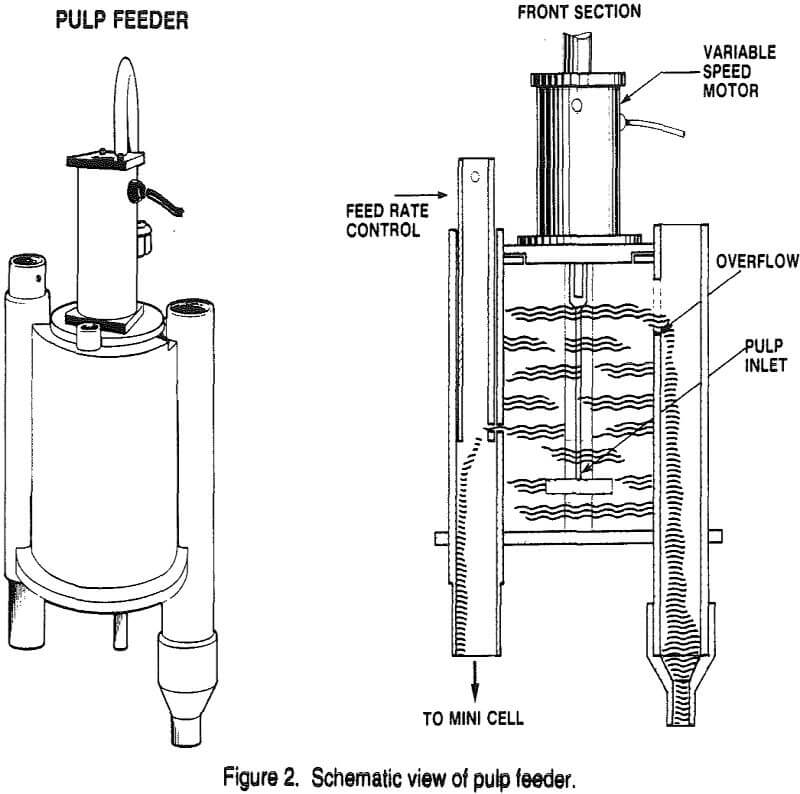

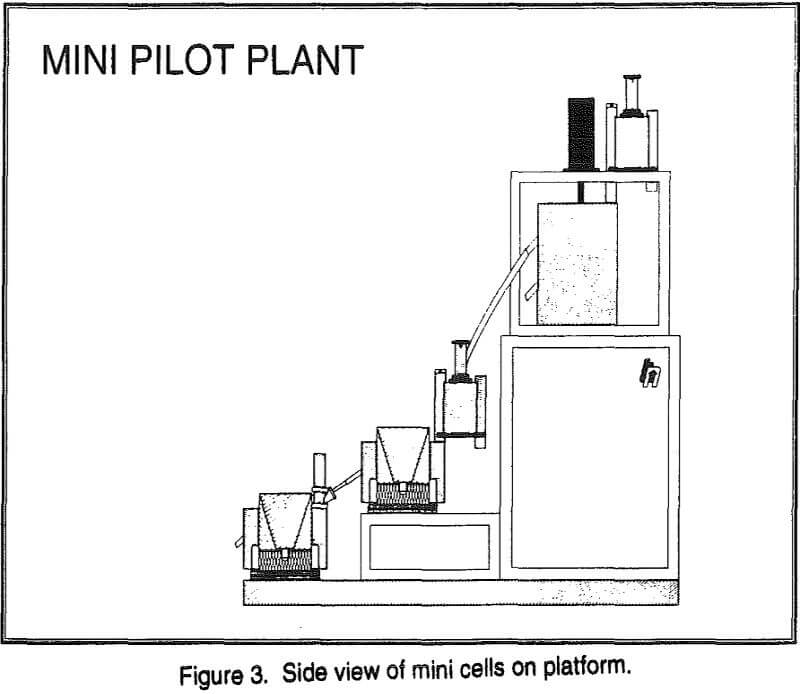

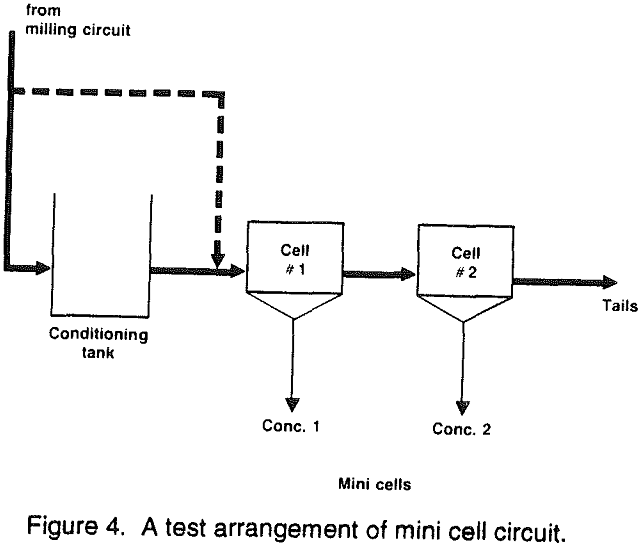

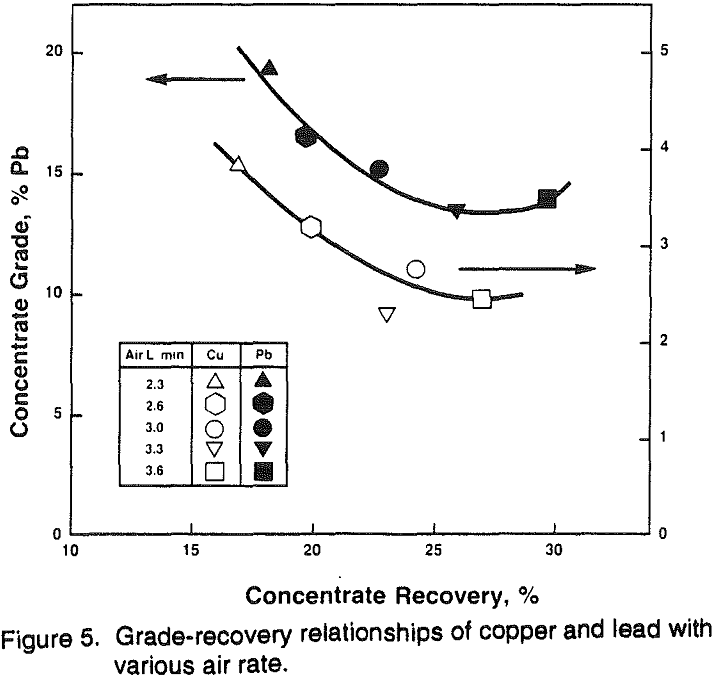

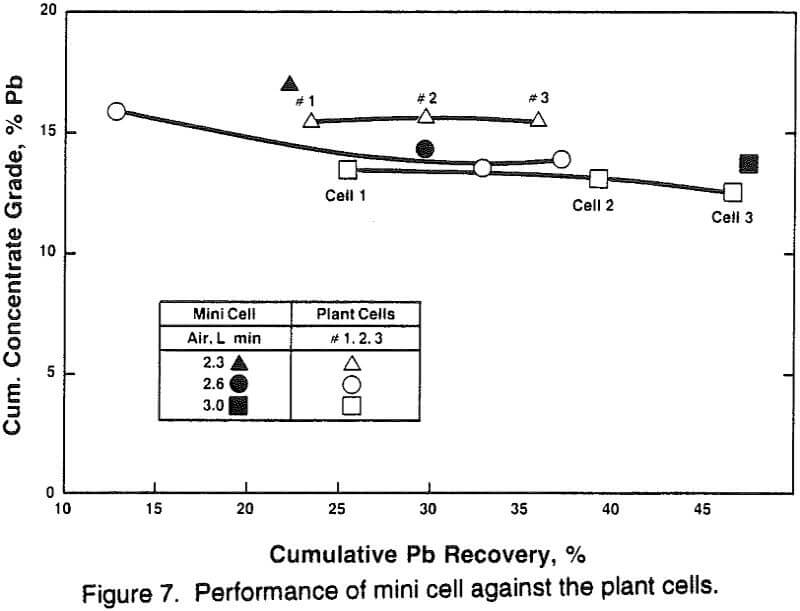

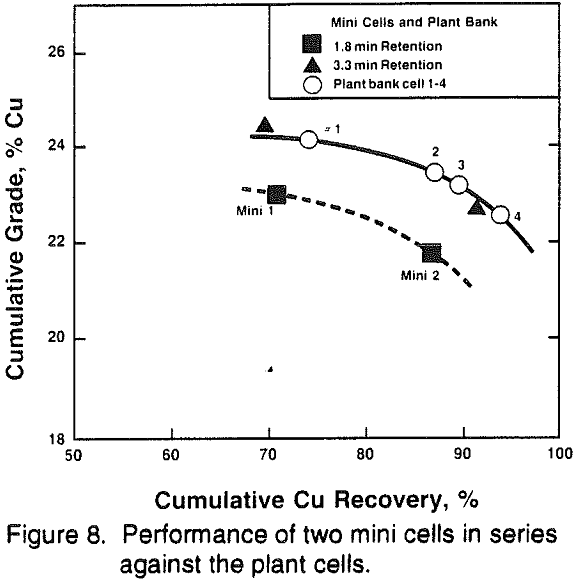

The mini cell pilot plant was tested in parallel with plant circuits at a number of milling operations to examine the feasibility of several design features and operating parameters. Pulp from the plant cell was used as feed to the mini cell, and the feed rate was controlled by adjusting the feed slot gate. Weir type overflow discharge was used on the tailings end. Impeller speed and froth level were kept constant at 780 rpm and 1.0 inch, respectively.

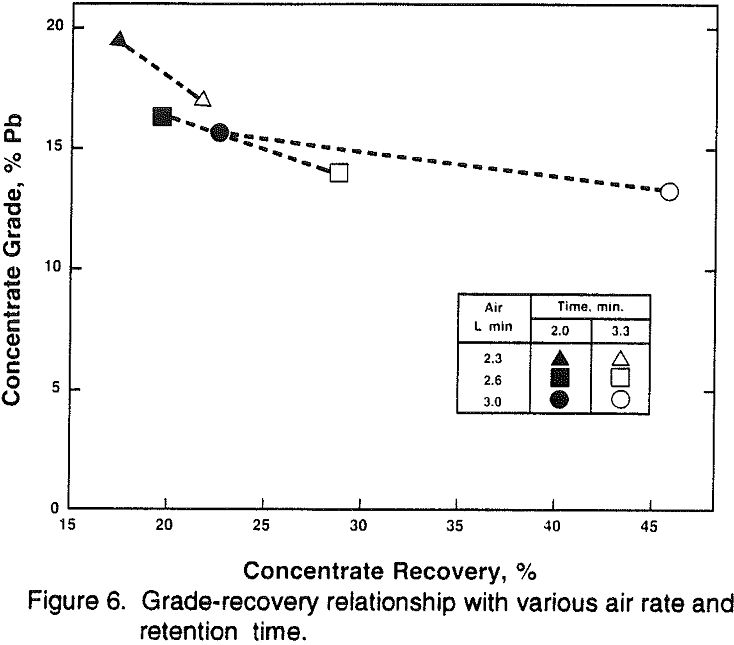

Relationships between the air rate and retention time (feed rate) on the metallurgy are shown in figure 6. At low air rate, the recovery was not affected significantly by the retention time. However, the recovery changed over 20% units when the air rate was increased from 2.3 to 3.0 L/min. Although the concentrate grade was reduced, the increased air supply produced more usable bubbles floating mineral grains as noted above.

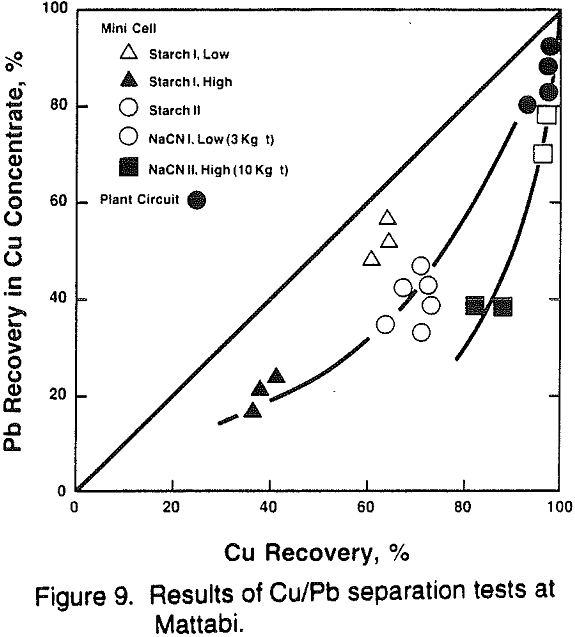

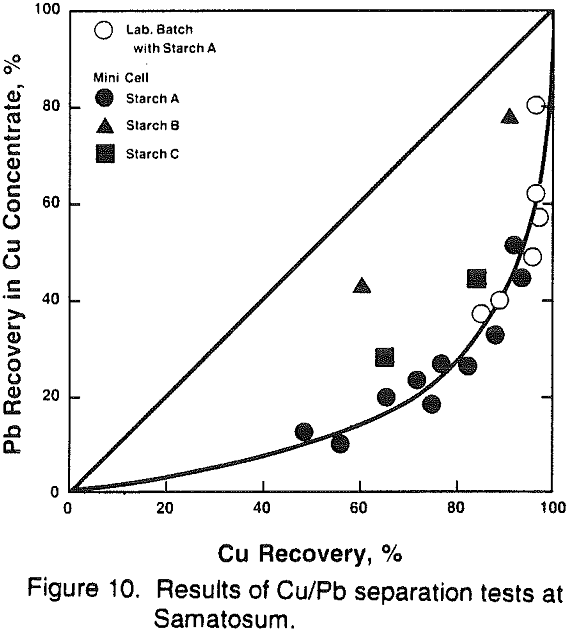

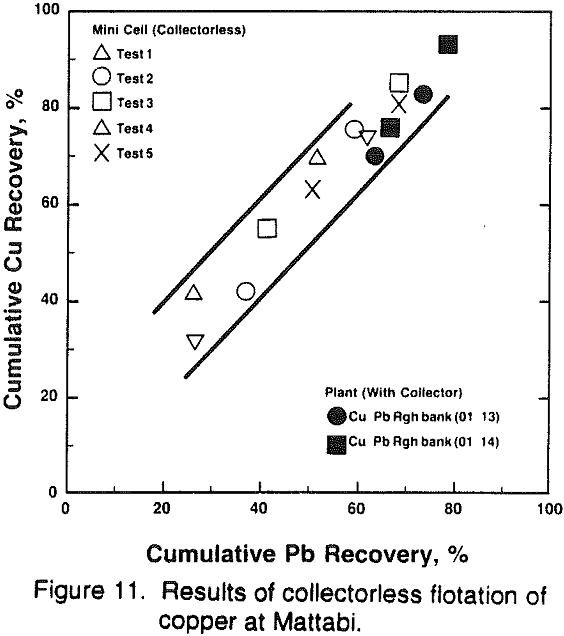

Flotation of some sulphide minerals without the use of conventional collectors is widely recognized. The requirement seems to be related to the degree of oxidation. The phenomena has been termed “collectorless” or “self-induced” flotation. One of the minerals most responsive to collectorless flotation is chalcopyrite, while pyrite and sphalerite show little response and galena shows intermediate response. Experience in laboratory and plant scale tests at Mattabi confirmed the collectorless bulk Cu/Pb flotation.