Table of Contents

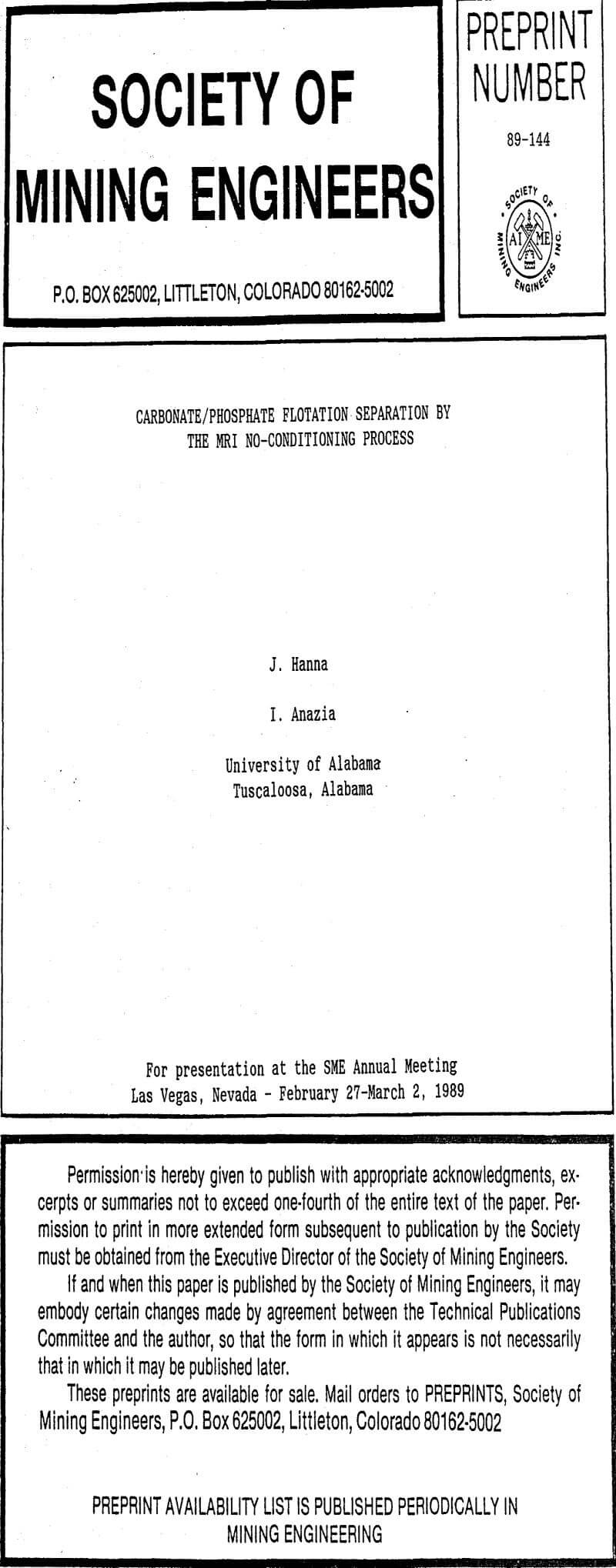

Tests to study the effect of collectors and pH were randomly conducted on the phosphate matrix, using a 2k full factorial design for collector screening and process optimization. Star points needed to estimate non-linear factor responses were included in the optimization test series and in some reagent screening tests. For the fatty acids, the two collector levels tested were 0.75 kg/t and 2.25 kg/t with 1.5 kg/t as centerpoint. The pH levels tested were 4.5 and 6.5, with 5.5 as centerpoint for the fatty acid tests, while for the fatty acid salts, the pH levels tested were 3.5 and 5.5, with 4.5 as a centerpoint.

The response variable used in the statistical evaluation of test data, which represented the MgO separation efficiency (MgO S.E.), was related to the grade and recovery of the carbonate froth product, as follows:

MgO S.E. = RCf – RPf

where: RCf = MgO recovery in the carbonate froth; and RPf = P2O5 recovery in the carbonate froth

Collector Screening

The 2² test designs, for the collector screening tests, are shown in Table 1 together with the MgO S.E. responses. Statistically generated response surfaces from these data are presented in Figures 4, 5 and 6 for tall oil, oleic acid and OA-5, respectively. Preliminary testing indicated that collector selectivity for carbonate flotation was negligible in case of the WRG soap and, therefore, this collector was not tested in a factorial.

Figures 4 and 5 indicate that the two fatty acid collectors gave similar responses, however, oleic acid was less sensitive to pH variations and was more effective than tall oil. Oleic acid gave the highest MgO S.E. of more than 54% at pH 5.5 and collector dosage of 1.5 kg/t. The results with OA-5 (Figure 6) were not as good, and they indicate that more data (at starpoints) would be needed to delineate other regions of curvature. The results of OA- 5 flotation suggest that optimum carbonate flotation would be obtained at a pH range of 3-3.5. It would be difficult to maintain the pulp pH at this low level without using excessive acid, therefore, further testing with OA-5 was discontinued.

Optimization of Collector Dose, pH and Pulp Solids

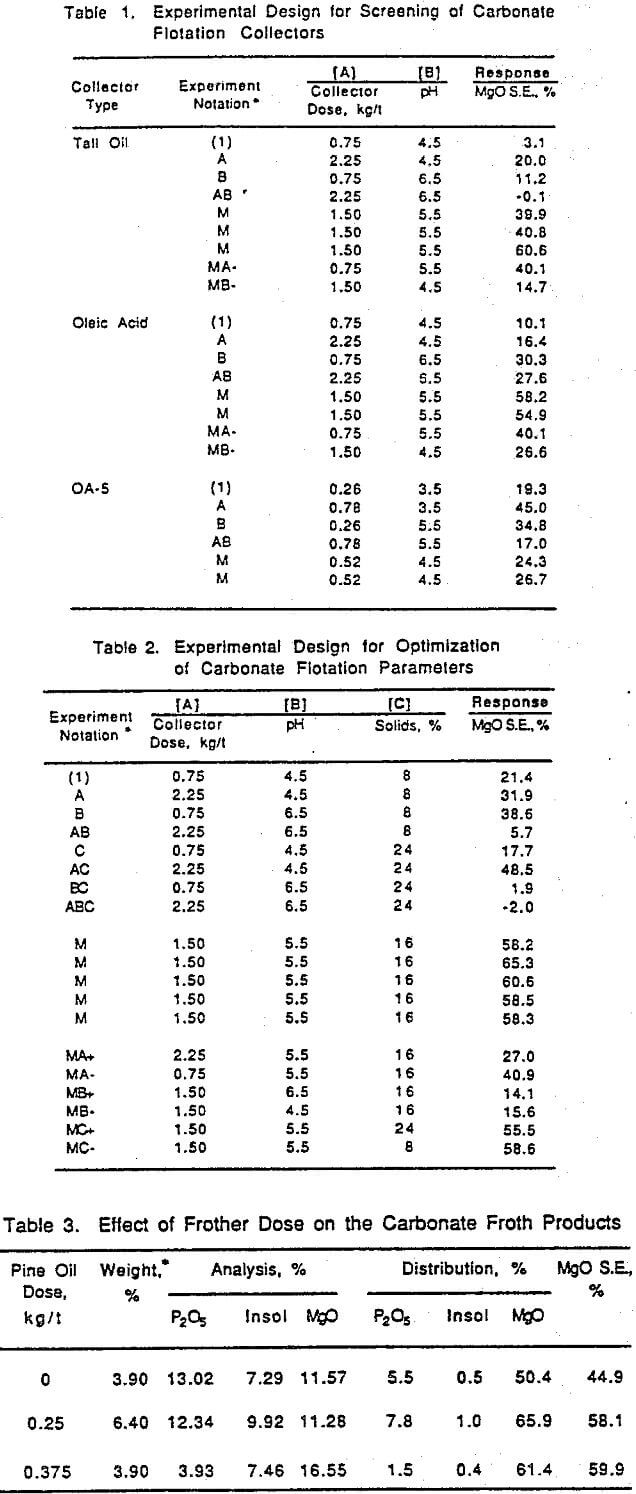

Oleic acid was selected for further test work involving a three-factor two-level (2³) full factorial design to optimize the carbonate flotation step. The factors included in the design and the factor levels tested are given in Table 2. Also, included in Table 2 are the Mgo-S.E. for the 19 experiments conducted. Statistical analysis of the data indicated that pH and collector dose factors and cross factors had predominant effects on MgO S.E. compared to the effect of pulp solids.

Effect of Collector Conditioning

The effect of conditioning the pulp with the oleic acid collector prior to aeration was studied under conditions stated above—pH 5.5, 1.5 kg/t oleic acid and 16% pulp solids. Conditioning times shown are the totals for the 3-stage collector additions, i.e., 3 minute conditioning time entailed a one minute conditioning after each collector addition.

As shown in Figure 8, collector conditioning had a deleterious effect on the selectivity of the carbonate/phosphate separation. Figure 9 shows that even at “zero” conditioning time the dolomite content in the froth decreased while the apatite increased after each addition of the collector. Under this condition, the pulp was unavoidably agitated (conditioned) for about 3 minutes during the froth skimming. The amounts of phosphate material reporting to the carbonate froth increased with conditioning time. This confirmed the merit of not conditioning the pulp with the collector prior to carbonate flotation.

Effect of Frother Dosage

Tests were conducted to study the effect, on carbonate flotation, of increasing pine oil frother additions.Flotation without a frother also was possible, indicating that the oleic acid collector had a considerable frothing property even at a pH as low as 5.5.

Effect of Type of pH Modifier

The data indicate that the type of acid used played a significant role in determining the MgO S.E. in the carbonate froth. The use of these pH modifiers resulted in the removal of about 76% of the total Mgo in the feed as carbonate froth.