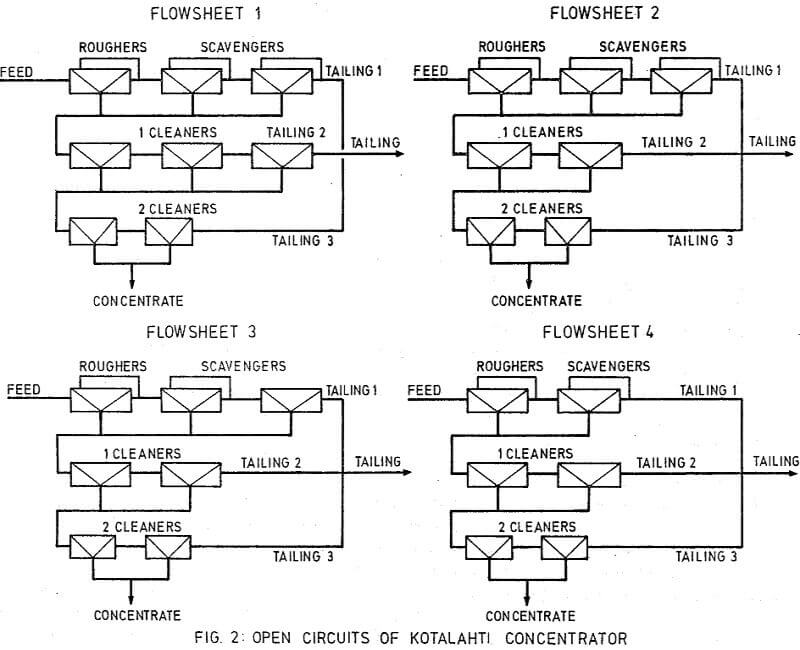

The use of open circuit flotation is common practice in porphyry copper ore concentrators and Australian copper concentrators and its use in other than copper concentrators is minimal a completely open flotation circuit is not used and it is general practice to have recirculation within the cleaner flotation stage.

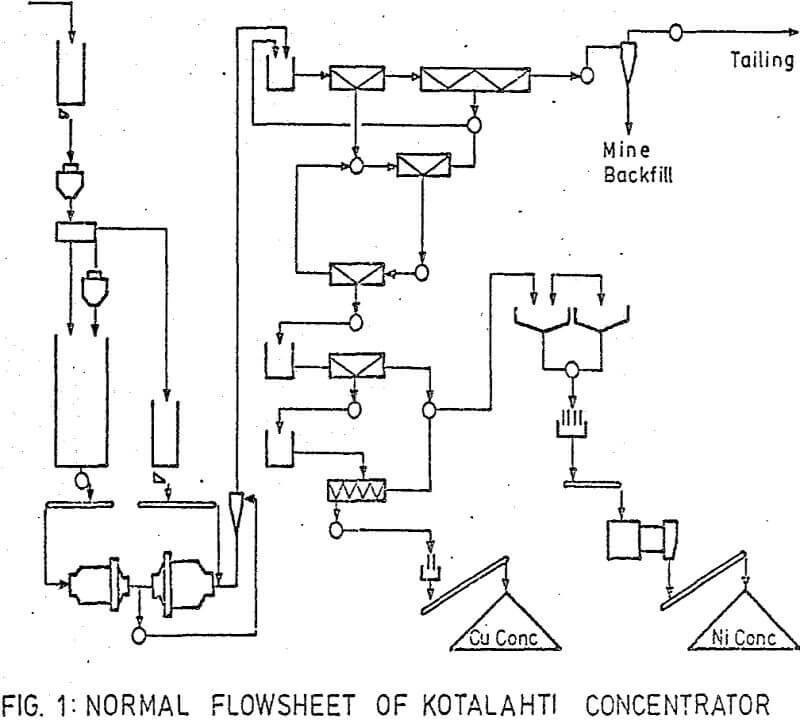

The Kotalahti Concentrator. The recovered minerals are pentlandite, chalcopyrite and pyrrhotite which have average ore assays of Ni 0.7% and Cu 0.25%. The annual mine capacity is 450 000 tons of ore and the concentrator produces 50 000 tons of 6% Ni concentrate and 3 000 tons of approximately 30% Cu concentrate annually.

The flotation stage is divided into two main, parts; bulk flotation of sulphide minerals and the separation of the nickel and copper concentrates from the bulk concentrate. The bulk flotation process is operated at a low pH value. Chemicals used in the process are KEX as a collector, Finnish raw pine oil as a frother, and sulphuric acid to activate pyrrhotite and to depress insoluble silica minerals. Lime and dextrine are the chemicals used in separation flotation. The principle of separation is based upon the flotation of chalcopyrite and the depressing of nickel bearing minerals.

The process tests were carried out on the bulk flotation stage to determine the effects of cell volume and various types of flotation circuits on flotation results.

In the open circuit test run the main interest centered on the Ni % of the tailings. The test was carried out such that a maximum amount of concentrate was extracted by varying the amount of flotation air and the pulp level in the cells. During this test the Ni % in the tailings was found to be lower than that during normal operation but a poorer quality concentrate in regard to the percentage of insolubles was also evident.

In this test the Ni % of the concentrate and the insolubles % were closely recorded while the chemical feed points were changed. During the test a steady concentrate feed was maintained.

During the test on low tailings the color of the concentrate in the final cells was noted to be grey and this is due to the fact that the foam is low in sulphide content and there is a tendency for the silicates to rise to the surface. A large concentrate quantity causes problems with the separation flotation and the subsequent drying.

Throughout the open circuit tests the pulp level in the rougher conditioners remained rather stable, whilst circulating loads during normal closed circuit operation cause pronounced fluctuations in the pulp level.