Mill liner design is an important factor in grinding. Testing and selection of the optimum liner profile for a given set of mill operating conditions can improve mill capacity, liner life, and liner wear rate.

In testing four mill liner profiles for 13′ x 12′ overflow ball mills. Climax found that an improved design increased mill tonnage by 3 tons per hour while reducing finish grind by 1.7% + 100 mesh, reduced liner wear rate, and almost doubled liner life.

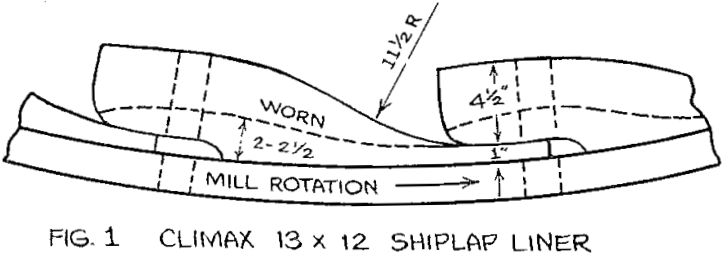

During a 5-year test series, four liner contours were tested in Climax’s 13′ x 12′ overflow primary ball mills. The original liners for these mills were a shiplap design.

The shiplap design is actually an interrupted single wave with the trailing half-wave eliminated. This allows radii of valley and peak to double within a given liner width. Such designs are noted for low lift and the spinning and rolling effect they produce in grinding balls.

The shiplap liner profile changes during its life and eventually approximates a very mild sinusoidal single wave pattern, wearing down until there is very little wave to produce lifting.

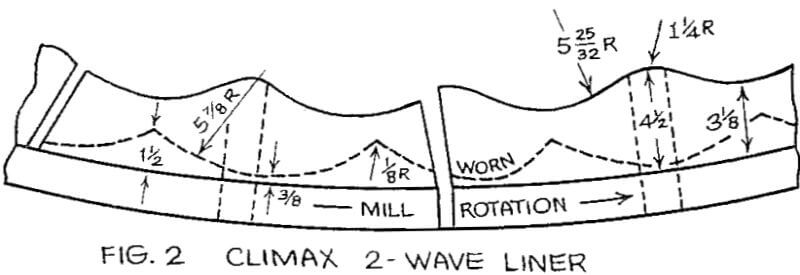

The excellent performance of the Climax Triple Wave liner in 9′ x 8′ and 9′ x 9′ grate discharge ball mills operating at 76% of critical speed suggested that a scaled-up version of that design might do well in 13′ x 12′ overflow mills too.

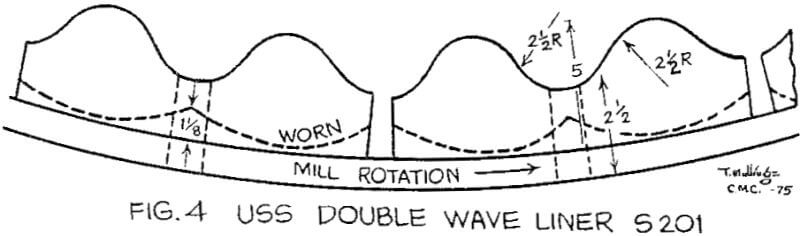

The new Climax Double Wave Design became standard in our 13′ x 12′ mills in 1967 after initial trials showed it to outgrind and out-last the old shiplap liner. Liner life increased by about 500 hours and metal wear rate was 18% less for the new Double Wave Liner.

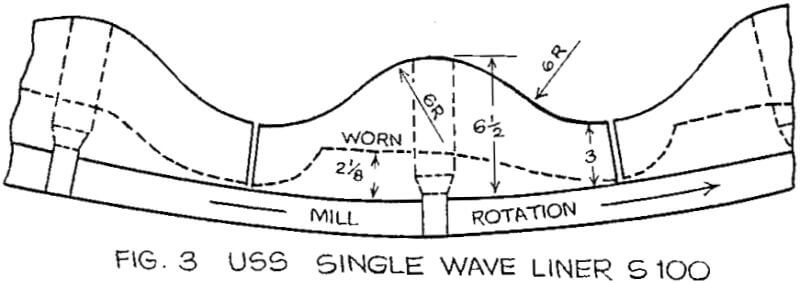

The S-100 single wave liner produced better tonnage than previous designs, with reduced grind size, during the first third of its life. But as wave tops wore down, a profile similar to the shiplap contour developed and grinding ability diminished. Over their 18-month life, the S-100 liners produced average tonnage at required grind about equal to that produced by Climax Double Wave liners. Because of greater thickness and harder alloy they lasted longer with lower metal wear rate.

Tonnage and grind were very good during the first 8 months of operation because of the higher, more abrupt profile which gave improved ball lift. During the next 12 months, profile was nearly identical to that of the Climax Double Wave design and the liners produced comparable tonnage. During the last 3 months, this design, worn thinner than Climax liners, extended the large-volume, high-capacity period of especially improved grinding we experience when Climax Double Wave Liners are worn thin, mill volume is maximum, and the mill turns at the highest per cent of critical speed.