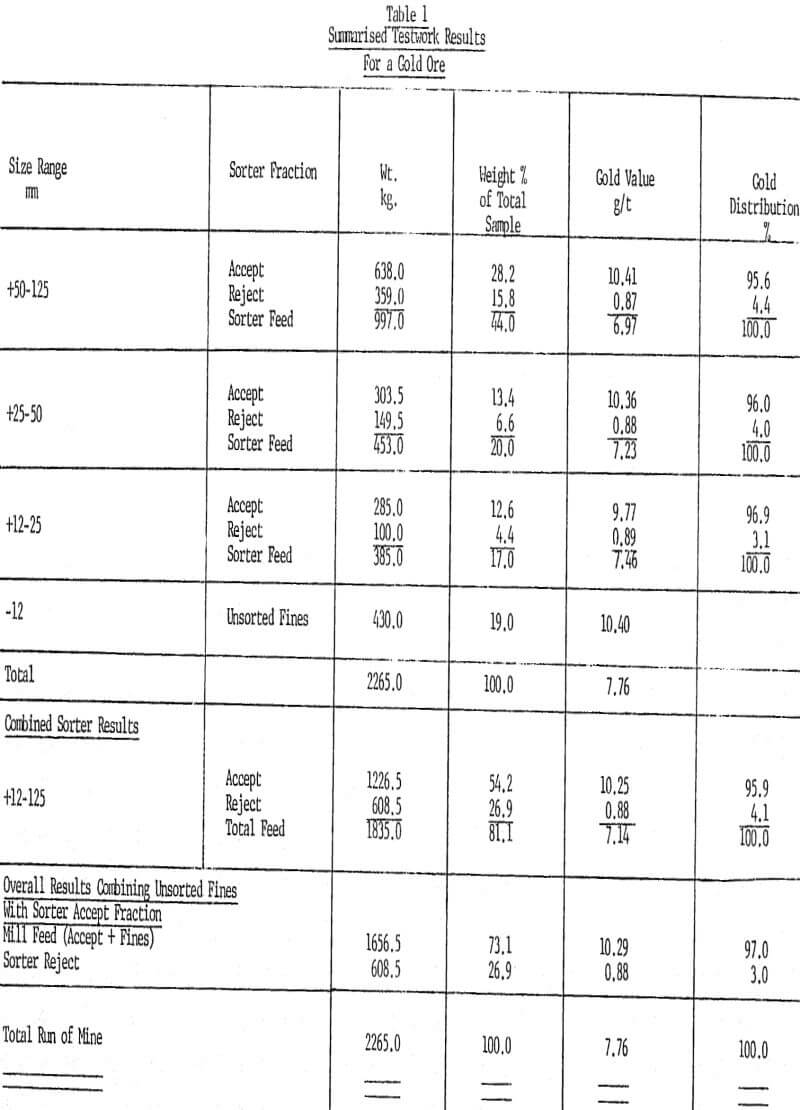

The primary objective of ore sorting is the separation of mineralized ore from waste or low-grade material, early in the concentration cycle. The concept of applying automated ore sorting techniques has been recognized for same years, but limitations in technology has meant that, until recently, manual sorting was the oily practical sorting technique available.

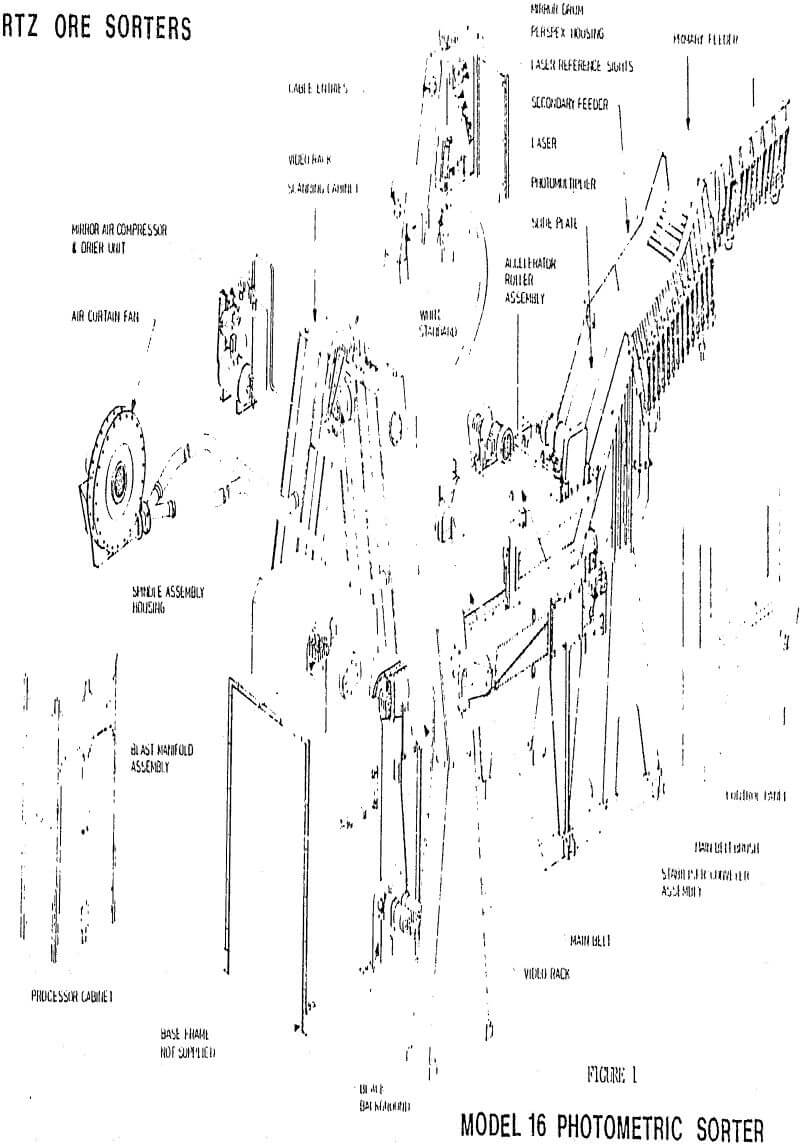

The Model 16 Sorter

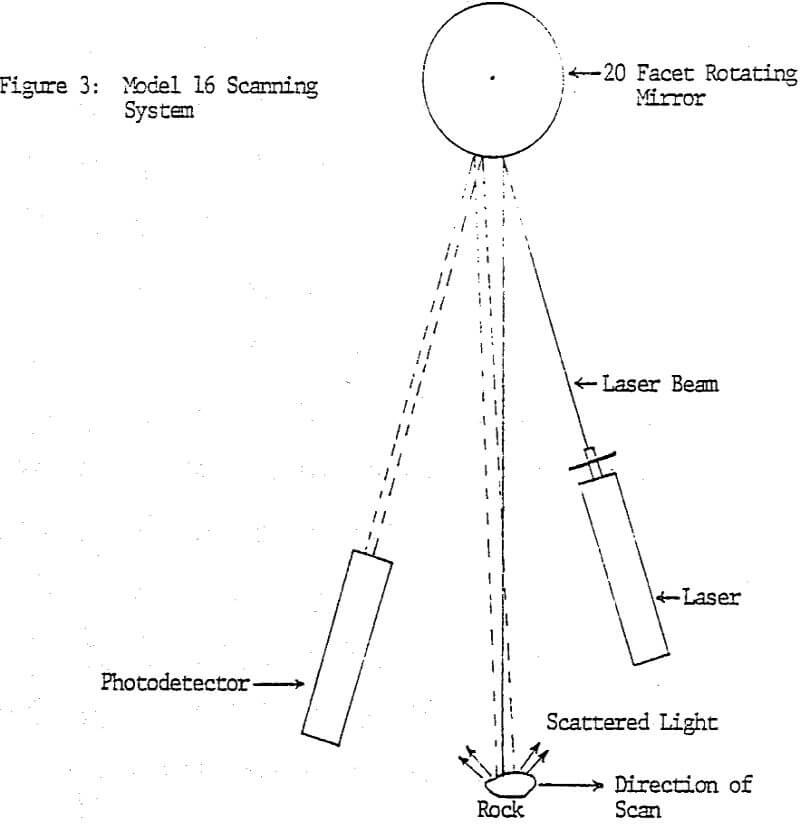

The Model 16 is a high capacity random stream sorter designed to sort particles at sizes from 10 to 150 mm. The principle of operation of the machine is to measure the light reflectance characteristics of each and every particle, and as a result is suitable for processing a wide range of minerals that show a reliable and consistent optical difference between ore and waste.

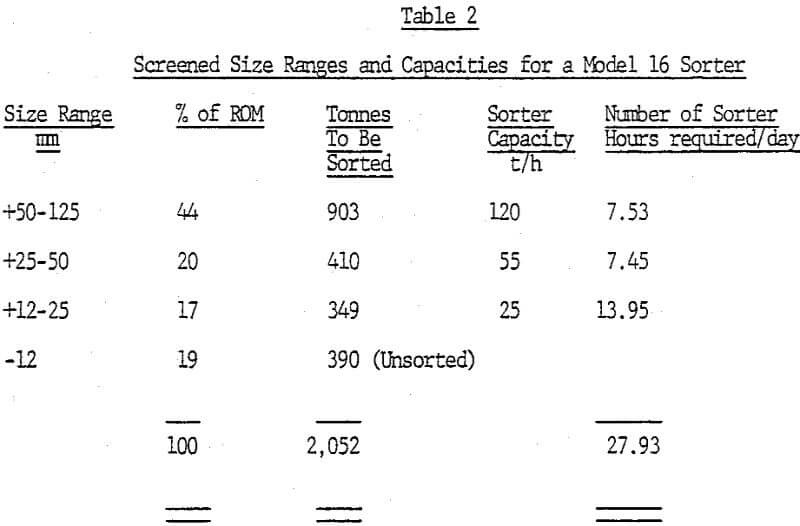

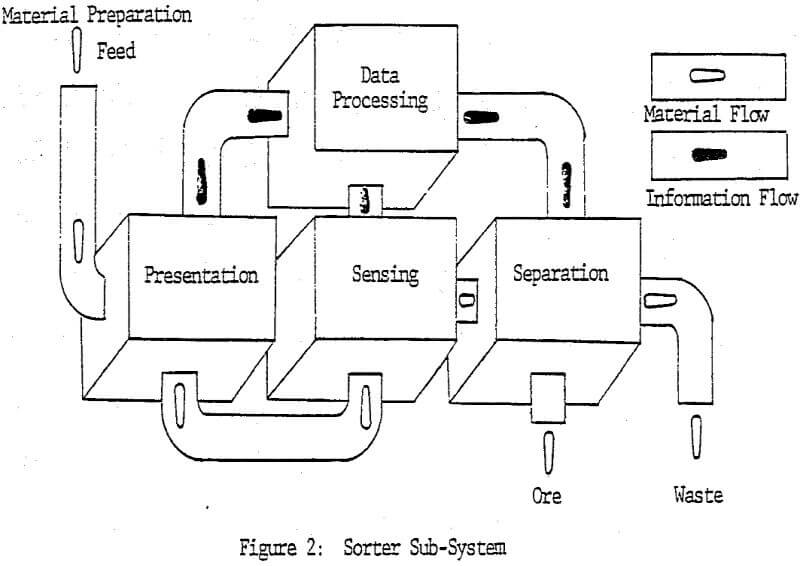

A prerequisite for efficient sorting is the preparation of the feed material. Run of mine feed is screened to prepare it such that the maximum to minimum particle size ratio is approximately 3:1, and where permissible, the material is washed to remove fines and enhance light reflectance properties.

The rock feed system is of vital importance in any sorter, as presentation to the scanner and separator must be such that these sub-systems can perform efficiently. This requires that the rocks are spaced, so that there is no inter-particle interference, and that they are effectively stabilized so that at any instant after scanning all rocks are actually located where the processor believes them to be.

The system, is designed with a scanning speed of 2000 scans per second, and allows a scan every 2 mm for a rock presentation speed of 4 meters/second. This ensures high resolution at high capacity.

The Separation System

The separation system deflects rocks from their free-flight trajectory using high-pressure air blasts. The system comprises a manifold containing high-speed solenoid air valves, each of which is independently operable and responds to signals from the processor. These electronic signals cause the appropriate valves in the manifold to open in such a way that the air blast is tailored to match the shape and position of individual rocks in the stream. The selected rocks, diverted from their free-flight trajectory, and the unblasted rocks divert into two distinct streams of rock that are physically separated by a splitter plate. The separated rocks are directed via two chutes to ore and waste conveyors.

Applications

Model 16 Photometric Sorters have been installed at mines in various locations round the world to process many different minerals, including gold reef, magnesite, wolframite in quartz, copper/silver in quartz, phosphate, limestone, wollastonite, talc and spodumene. In addition many other mineral types such as quartz gravel, dolomite, gypsum, flourspar, feldspar, asbestos, oil shale, and base metals have been successfully tested for sorting feasibility.

Benefits of Ore Sorting

These benefits include:

- Savings in Capital and Operating Costs: Smaller milling and treatment facilities, with a substantial reduction in both capital and operation costs, can be constructed as a result of the rejection of low-grade or barren material after crushing.

- Increased Production: Some established mines having the capability to increase mining rates are unable to do so owing to limitations in the capacity of their treatment plants. Ore sorting allows operations such as these to increase mining rates, with a subsequent overall increase in metal production, without a major expansion of the existing facilities.

- Development of Low-grade Deposits: Marginal low-grade, and even previously unexploitable deposits subjected to ore sorting can be upgraded to produce a feed of sufficiently high grade for economic processing.

- Flexibility in Mining Operations: In deposits where mineralization occurs in narrow veins and high dilution occurs during mining, ore sorting can be used to provide a high grade fraction carrying little waste. This means that not only can costly selective mining be relaxed but also a controlled material grade can be fed to the milling plant.

- Product Grading: In mines where product value is determined by a particular characteristic (eg. colour), ore sorting can be used to generate several products of different sales values. This increases overall product sales revenue.

Determining Operating Cost Increases

There are several increases in direct operating costs that are associated with installing ore sorters and these must be offset against revenue increases:

The cost of mining the additional ore required to maintain existing milling rates.

The cost of crushing the additional ore to a size range suitable for ore sorting.

The cost of preparing all crushed product for sorting.

The cost of ore sorting.

The cost of disposing of sorter reject material.