Table of Contents

Primary underground coal transportation systems, such as conveyor belts, rail haulage, and mechanical hoists, have numerous inherent safety hazards. During the period 1990 to 1992, 12% of all the reported 31,266 accidents that occurred at underground coal mines were associated with powered haulage, and 52% of all haulage accidents, including surface areas of underground mines, were directly related to conveyor belts (MSHA, 1994).

The U.S. Bureau of Mines (USBM) initiated a research program to eliminate safety hazards associated with primary haulage equipment through design of safer, highly productive systems that have potential for replacing many of these existing systems. The balanced air-lift hydrohoist (ALH) was selected among several innovative coal haulage systems as having the most potential for improved safety, flexibility, and efficiency.

The balanced ALH is based on the concept that vertical pipeline flow can be generated by injecting compressed air into one column of a two-column U-shaped hydraulic pipeline. The fluid density is reduced in the air-water column, creating a pressure differential between the two columns. This pressure differential results in an upward flow of the air-water column within the “riser pipe,” and a corresponding downward flow of the water-only column within the “downcomer pipe.” When coal is introduced into the upward flowing column, a coal hoist is created. Coal is ideally suited to an ALH, as coal is relatively light and normally hydrophobic, i.e., it tends to repel water and attract air. The coal is hoisted primarily by water flow, assisted by air flow. If the balanced ALH system is combined with state-of-the-art horizontal pipeline transport technology for coarse-sized materials, a replacement coal haulage system is created.

Previous applications of airlifts to hoist slurry mixtures at mines include removal of cuttings from large-diameter rotary-drilled shafts (Friant, 1988) and hoisting coal from hydraulic mines in the Donbass Coalfield, Ukraine (Mills, 1978). These applications do not use a downcomer pipe, but utilize a large reservoir of water that fills a shaft or large sump and continuously supplies water to the riser pipeline. Airlifts were also used during the period 1960 to 1980 to hoist manganese nodules from the ocean floor. The ocean served as a reservoir, and the airlift provided the required water displacement, with

resulting upward movement in the riser pipe, to hoist an ocean bed slurry.

Hydraulic hoisting of 8-cm or less, run-of-mine coal with centrifugal pumps was proven a feasible technology in the United States with the Consolidation Coal Company “Loveridge Coarse Coal Slurry System” (Alexander and Shaw, 1984). Over 2 million tons of coal during the period 1980 to 1983 were vertically hoisted 270 m in a steel pipe mounted in a borehole at the Loveridge Mine and transported an additional 3.9 km overland to a preparation plant. The system proved to be safe and required relatively little maintenance. However, additional quantities of very fine-sized coal were generated as the slurry passed through a series of 13 centrifugal pumps that lifted the slurry and transported it to the preparation plant. It is more difficult to remove unwanted moisture from fine-sized coal than coarse-sized coal, which resulted in increased coal preparation costs.

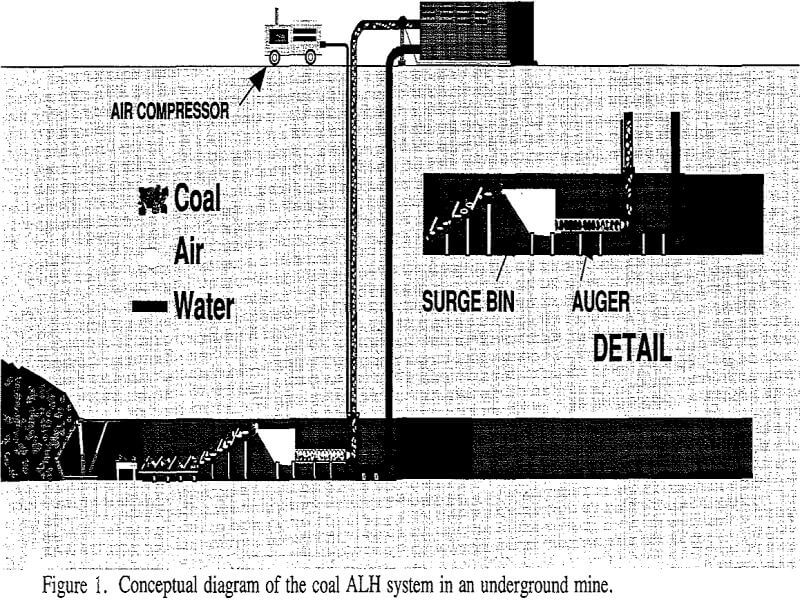

The system envisioned for coal mines is to locate the ALH in a main or submain entry near several continuous miner or longwall sections. Figure 1 shows a conceptual diagram of the coal ALH system, where two holes are drilled from the surface to the mine level, and steel pipe is installed in each hole. A horizontal pipe connecting the two vertical pipes underground completes the U-tube design. Relatively dry, broken, run-of-mine coal is injected into the bottom of the riser pipe and transported to the surface in the air-water medium. Alternately, similar vertical piping can be installed in an existing shaft, and coal could be injected into an interconnected underground horizontal pipeline some distance away from the shaft. An airlift or hydraulic pumping on the upstream side of the injector would provide a hydraulic velocity of about 3 m/s to transport coal out of the mine. Since the coal does not pass through any pumps while it is lifted to the surface, size degradation in the ALH is relatively minor. Air can be injected at various locations in the riser pipe, and the air compressor could be installed on the surface for safety and ease of maintenance. The three-phase mixture would be discharged into a storage tank on the surface where the air separates from the coal slurry. At this point, the coal slurry may be transported overland in a lower-pressure pipeline with positive displacement pumps to a cleaning plant or dried on-site with a mobile preparation plant.

If disposal of waste rock on the surface is environmentally unacceptable, it is conceivable that waste materials could be returned periodically to the mine with the ALH. When coal is not being hoisted, waste rock can be sent back to the mine level through ALH piping and hydraulically stowed underground. Mine tailings would be mixed with water or foam and pumped from the cleaning plant to the downcomer pipe, through additional horizontal piping underground, and discharged into a gob area.

When operating parameters are optimized, including initial air bubble size, method of air injection, and level of air-water solids mixing, the ALH can provide an efficient hoisting system. Sizeable hydraulic flow rates are created in a balanced ALH with compressed air generated from a standard commercial-size air compressor, and the hydraulic flow rate created is infinitely adjustable depending on the flow rate of injected air. The U-tube airlift can be supplemented with a pump on the upstream side of the coal injector to increase the hydraulic flow rate in the pipeline; however, this will also increase the hydraulic pressure at the point of coal injection, thus increasing the force required to inject coal into the moving water stream.

Pilot-Scale Model Description

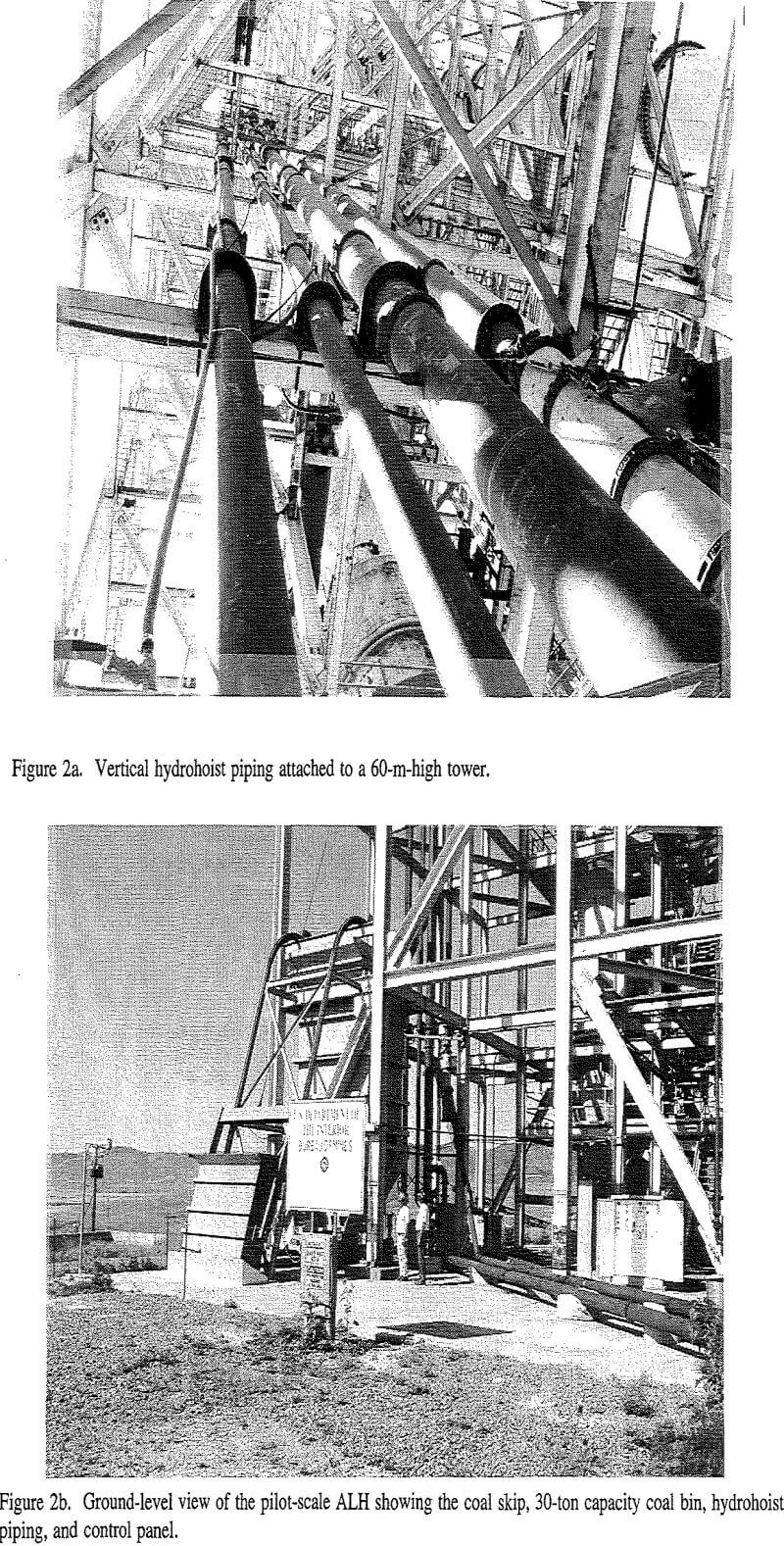

After obtaining favorable results from bench-scale model research (Lindahl and Faddick, 1991), it was determined that a 50-m-high pilot-scale model of a coal ALH should be constructed using an existing 60-m-high tower located 32 km northwest of Denver. Pictures of the completed model are shown in figures 2-a and 2-b. The model is currently providing data to define the basic performance and operational characteristics of a coal ALH before it is tested in an active underground mine. Construction of the pilot-scale model was completed in July 1992, with the first successful model test performed in July 1993.

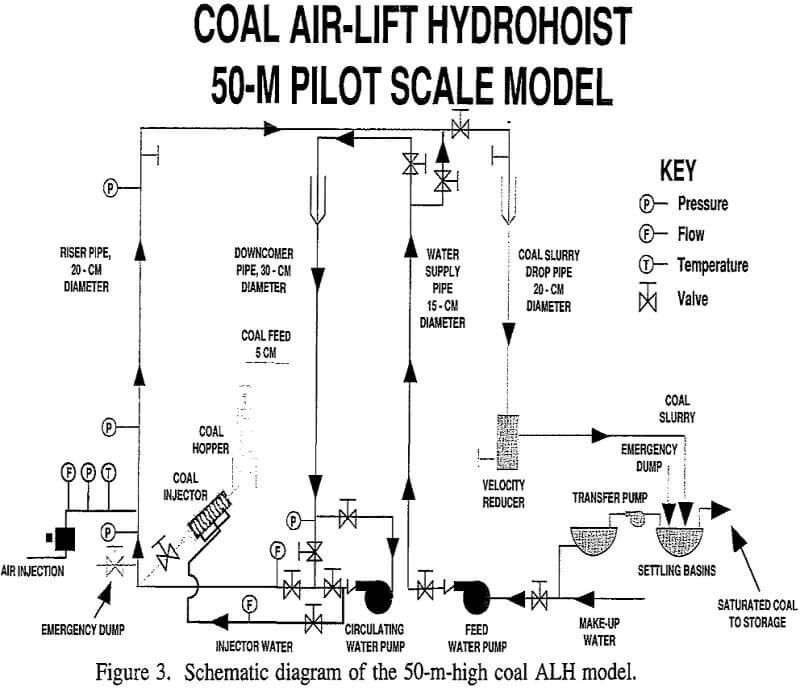

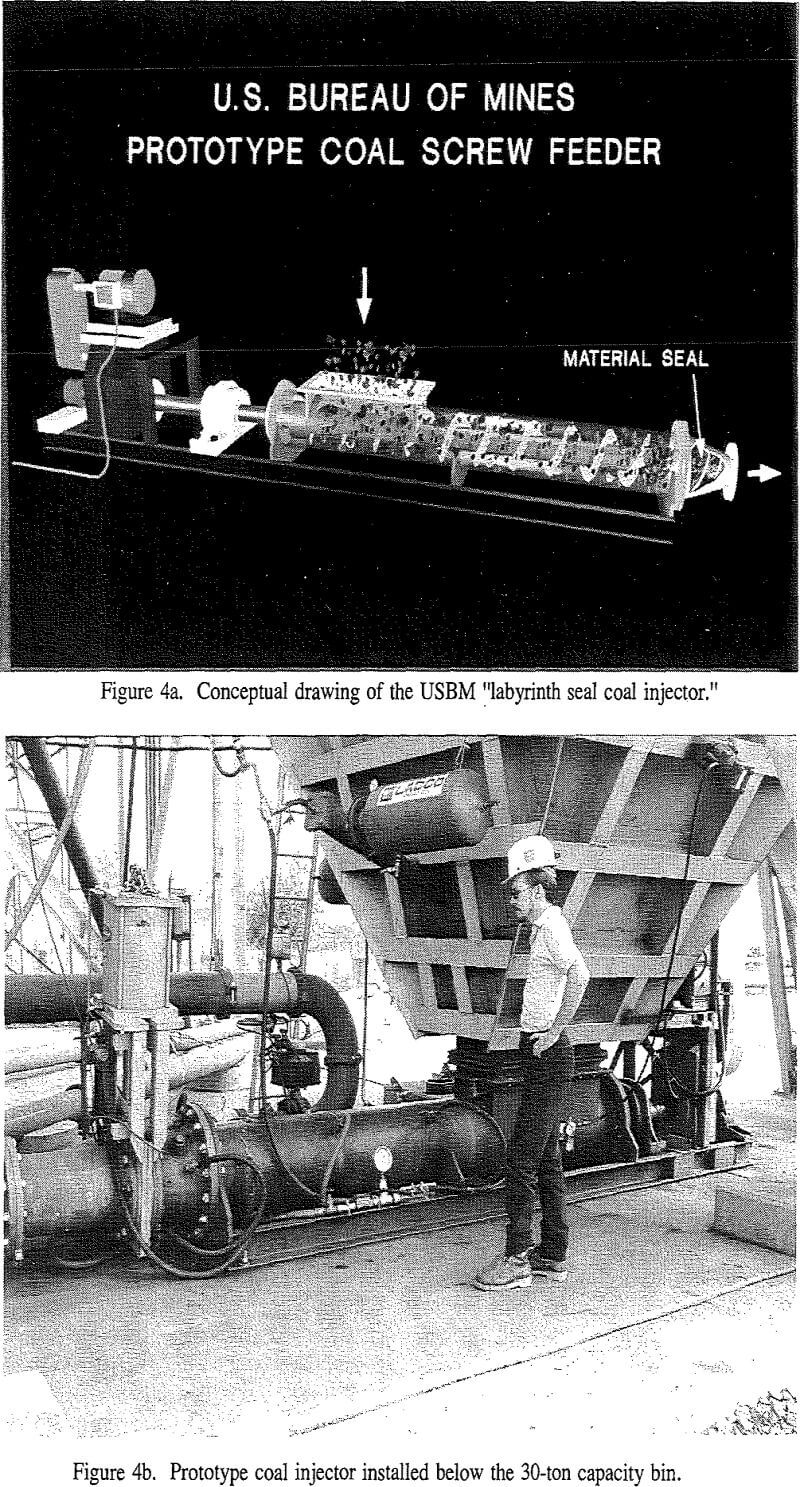

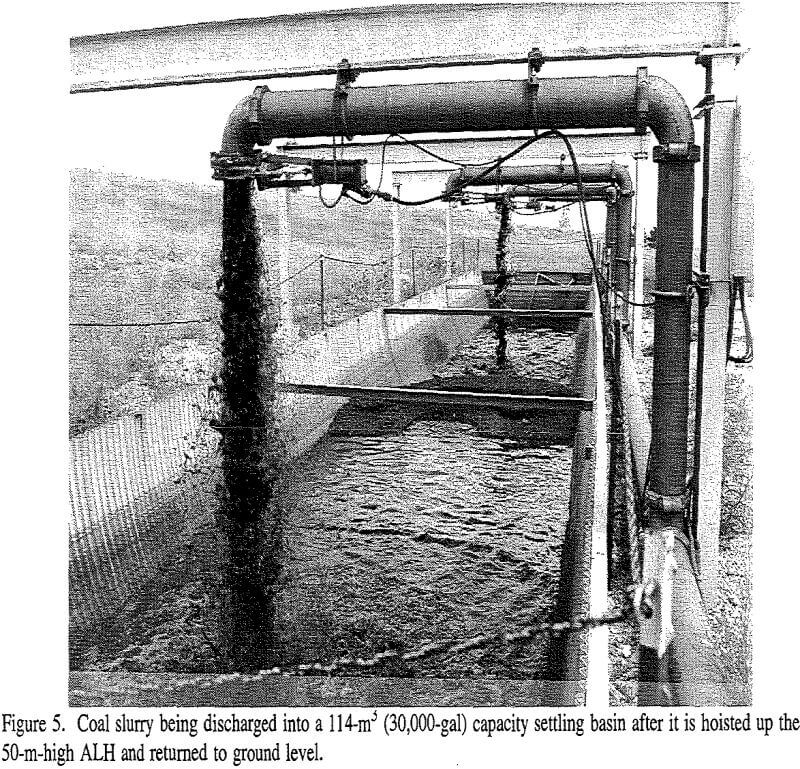

The pilot-scale model is designed to hoist 25 metric tons of 5-cm or less run-of-mine coal in a U-tube pipeline during a 15-minute test run, with an equivalent output of 100 tph. A schematic diagram of the model is shown in figure 3. Test batches of coal are first loaded into a 30-ton-capacity bin using a 3-m³ skip that is lifted by a 5-ton hoist mounted at the top of the tower. A 40- cm-diam prototype screw feeder installed at the bottom of the bin continuously injects coal into the ALH, as shown in figures 4a and 4b. The feeder, called the “labyrinth-seal coal injector,” receives gravity-fed coal from the bin at atmospheric pressure, continuously compacts coal within the feeder to form a hydraulic seal, and discharges it into a moving pressurized stream of water. A cylindrical air-sparger having the same internal diameter as the 20-cm riser pipe injects 480 kPa (70 psi) air through a porous insert into the water stream, creating very fine-sized air bubbles. Coal is hoisted 50-m high in the air-water mixture to the ninth level of the tower, returns to ground level in a slurry drop pipe, and is discharged into a 113 m³ (30,000 gal) settling basin. Coal slurry discharge is shown in figure 5. Water is then pumped back to the supply basin, after nearly all the coal separates out by gravity, and is reused. The USBM has filed two patent applications, one on the overall coal ALH system and one on the labyrinth seal coal injector.

Dynamic operation of the ALH model is achieved at a maximum water flow rate of 3.6 m³/min (1,000 gpm) and water velocity of 2.0 m/sec (6.4 ft/s) through proper flow control of water, air, and slurry. Slurry flow in the riser pipe is limited by the rate that feed water can be lifted to the top of the tower by a 56 kW (75 hp) pump, as the airlift can easily outperform the feed water pump. A consistent level of water is maintained in the 30-cm- diam downcomer pipe during airlift operations by controlling water flow into the pipe based on continuous monitoring of a slurry pressure sensor at the bottom of the downcomer, as described by Miller (1995). This

system delivers hydrohoist water at a continuous pressure and flow rate to a mixing chamber at the bottom of the U-tube where coal is mixed with transport water and injected into the riser pipe. The downcomer and slurry drop pipes are open at the top of the tower; both pipe stacks have a large 60-cm-diam, 6-m-long pipe section at the top to provide atmospheric venting. Air separates from the coal slurry at the top of the tower as it discharges out of the riser pipe into the large-diameter slurry drop pipe.

The labyrinth seal coal injector is the primary component of the pilot-scale model that required significant development before successful performance was achieved. This unit is capable of continuously transporting broken coal from a hopper at atmospheric pressure into a hydraulic pipeline at a significantly higher pressure without flow disruption. It includes a 37 kW motor that rotates a variable pitch screw, feeding coal at speeds up to 60 rpm. A variable speed motor controller is used to control the screw rotational speed, which can be programmed to optimize performance. Water is injected into the screw feeder housing at up to 10 locations to reduce the frictional forces at coal-steel interfaces within the injector. This water is obtained from process water in the downcomer pipe, pressure- boosted by 270 kPa (30 psi), and delivered through a 5- cm-diam hose to each 2-cm-diam water injection port mounted on the screw housing. A rotating shaft with several perpendicular steel bars, powered by a 0.75 kW motor, is mounted in the coal bin just above the intake area of the injector; continuous operation of this unit improved coal flow into the screw and reduced coal bridging inside the bin.

Test Observations

The ALH system proved to be a reliable system for hoisting coal-water slurries in more than 50 individual test runs, and required relatively little maintenance. Some fluctuations in downcomer and riser pipe fluid levels were observed due to air compressor cycling and slurry weight changes in the riser pipe. These fluctuations occurred primarily at startup and can be controlled with proper operation of air and water flow controls. The air sparger was mounted in the horizontal pipeline immediately upstream of the coal injector and also in the riser pipeline immediately downstream of the injector. The airlift operated successfully with the sparger in both locations when little coal was injected. However, most tests were conducted with the sparger in the riser pipe, since it appeared that a small portion of the air escaped into the downcomer pipe, even when using a check valve upstream of the sparger.

The prototype labyrinth seal coal injector was successful at feeding Western Colorado run-of-mine coal, having a specific gravity of 1.37 and less than 1% refuse, into the ALH at production rates up to 40 metric tph; work is currently in progress to increase production to 50 tph by increasing the rotational speed to about 60 rpm. In addition, the labyrinth seal injector successfully injected a mixture of 50% coal and 50% hard shale into the ALH at the rate of 40 tph during a preliminary test run. When the screw feeder was filled with compacted coal, a complete hydraulic seal was maintained during transport operations. Hydraulic seal failures did occur, caused primarily by a restriction of coal flowing from the bin to the screw feeder intake. However, coal was capable of forming a hydraulic seal within the injector and withstanding a hydraulic pressure of 480 kPa (70

psi) even when feed coal in the bin was submerged under water. Coal compacted easily inside the injector and the large bin, particularly with a high percentage of moisture and fines. Therefore, a consistent flow of coal into the injector was essential to maintain the hydraulic seal during model operation. Reliable operation of the prototype injector was eventually achieved, and it appears that continuous operation for very long periods is possible for coal with similar moisture and size characteristics.

It was observed that if the intake side of the screw feeder became sufficiently wet, the screw would rotate with compacted coal adhering to the screw flights, referred to as the “log effect,” and the coal feed rate to the ALH was substantially reduced. This problem could be eliminated by using two co-rotating, intermeshed screws instead of a single screw, with other components of the injector remaining essentially the same. A twin screw feeder should provide a forward thrust of coal or other materials from the feeder into a pipeline with significant hydraulic pressure, and would enable abrasive mined materials to be initially wetted to minimize friction and resulting wear of the screw rotor(s) and housing.

Adjustments in the quantity of water injected into the screw were required, depending on the initial moisture content and percentage of fines in the coal. If water injection ports on the screw feeder housing were shut or clogged with compacted coal, friction from dry coal within the screw feeder became excessive, and the screw feeder would jam. Initial test results indicated that the injector achieved maximum productivity when a thick slurry of coal and water was created at the discharge side of the injector containing approximately 20% to 50% water, by weight. Coal with a high percentage of fines required a greater percentage of injection water for lubrication, with the injector discharge approximately 50% water, by weight. As the rotational speed of the screw was increased, additional injection water was added closer to the intake side of the screw feeder to prevent excessive coal compaction and reduce friction between coal and screw housing interface. Additional injection water was required in proportion to the volume of coal injected to maintain continuous feeding of coal into the ALH. Effective management of the length and position of the material seal was essential for successful operation of the single screw injector.

It was observed that the quantity of air required to hoist water or coal slurry increases substantially as the differential height between the discharge out of the riser pipe and the height of the water column in the downcomer pipe increases. When this differential height increases to 20% or more of the total height of the ALH, the system is no longer considered to be “balanced.” No other data are known that relate the required air volume to lifting height for different slurry densities and specific gravity of solids in a balanced ALH with large diameter piping. Significant additional research will be required to accurately assess the performance of the ALH for various lifting heights and slurry mixtures.

Data Analysis

Several hours of model performance data were obtained, and a preliminary data analysis was made. The model performed successfully in the ranges of 1.1 to 3.7 standard m³/min (40 to 140 scfm) air flow, 0.93 to 3.2 m³/min (260 to 900 gpm) water flow, and a coal screw feeder rotational speed of 12 to 45 rpm. Initial data indicated the coal injection rate is almost directly proportional to the screw feeder rotational speed, providing a proper flow of relatively dry coal feed into the injector is maintained. Some variations occurred, possibly due to increased slippage of material within the screw at higher rotational speeds.

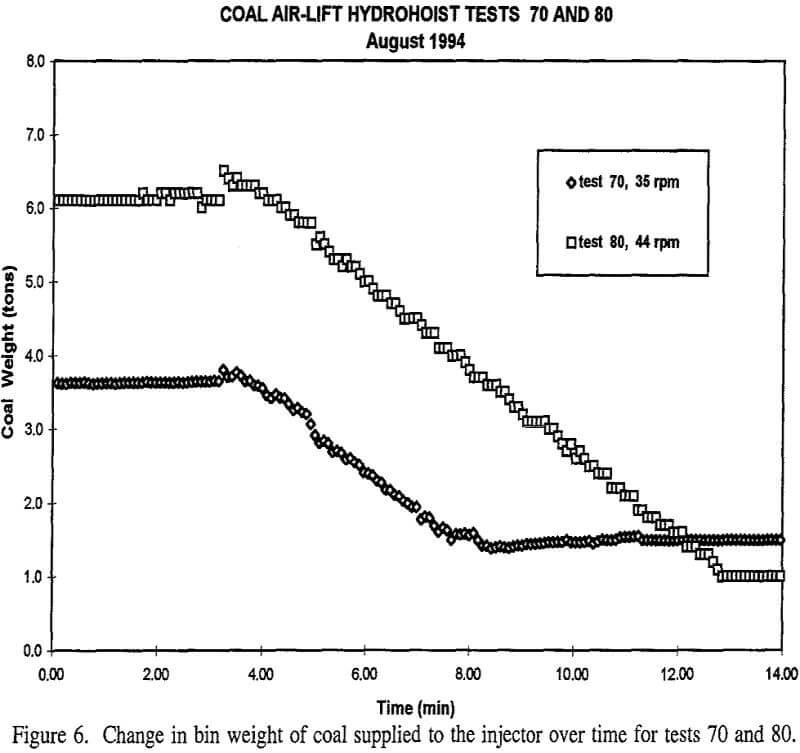

Figure 6 shows a graph of the change over time in coal weight, measured by bin load cells, for two typical tests when coal was injected and hoisted in the ALH. In test 70, 2.3 metric tons were hoisted during a 5-min period at an average production rate of 27.6 tph and a peak production rate of 31.6 tph. A maximum screw feeder rotational speed of 35 rpm was maintained for approximately 2.6 min of test 70. In test 80, 5.35 metric tons were hoisted during a 9.7-min test at an average production rate of 33.1 tph and a peak production rate of 37.7 tph. A maximum screw feeder rotational speed of 44 rpm was maintained for approximately 7.5 min of test 80. Tests were relatively short due to the cost of purchasing and handling coal and the limited supply of process water. The pilot-scale ALH model appeared to be capable of hoisting coal at the 100 tph design production rate, with the exception of the prototype screw feeder which is undersized and not expected to achieve a throughput of more than 50 tph.

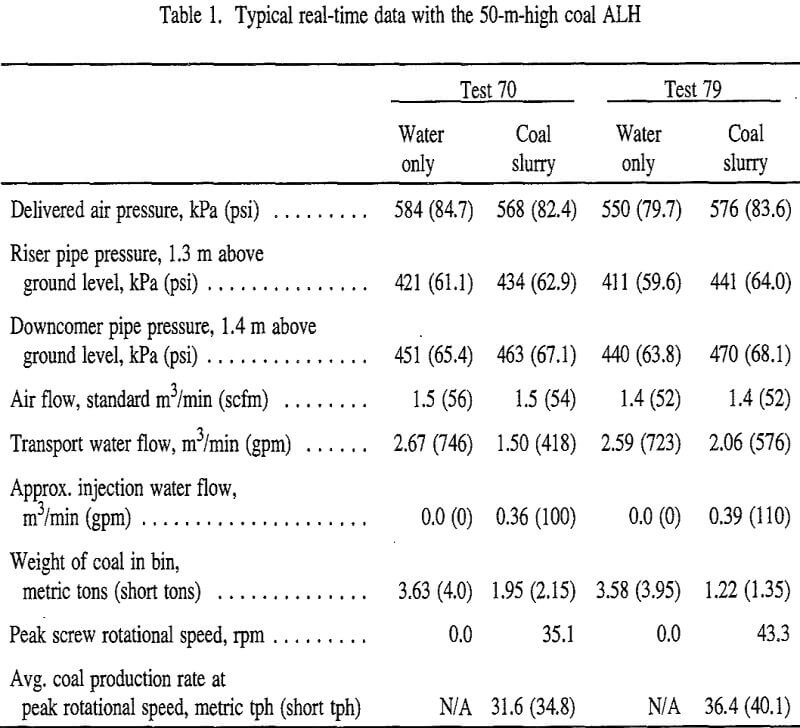

Table 1 shows typical real-time data recorded at approximately 8 sec time intervals with a data logger and a PC computer for two test runs, test 70 and test 79. “Water only” data are given immediately prior to coal injection, and “Coal slurry” data are given during coal hoisting. Using the data from test 70, the transport water velocity immediately upstream of the coal injector is calculated as 0.813 m/sec, with a volume of 1.5 m³/min water travelling through the 20-cm-diam pipe. Coal is saturated with additional water in the injector to form a thick slurry of 48% coal and 52% water, by volume. This thick slurry is then discharged at a rate of 0.69 m³/min into a 30-cm diam. pipe where it is mixed with the transport water and delivered to the riser pipe. After transport water was mixed with this thick coal slurry, the mixture entering the riser pipe in test 79 contained 14.6% coal, by volume, and 85.4% water. It is difficult to determine velocities of air, water, and coal in the riser pipe since each phase of the three-phase flow is travelling at a different speed; large-coal particles travel more slowly than fine-coal particles, and air constantly expands as the pressure decreases during upward travel in the pipe. The “aggregate” coal-water slurry velocity entering the riser pipe is approximately 1.18 m/sec at a flow rate of 2.19 m /min. Assuming air is an ideal gas, the expansion ratio for air discharged out the top of the pipe compared to air injected into the bottom of the riser pipe is 5.9:1. Using test 70 coal slurry data given in table 1, the riser pipe is estimated to contain an average of 16% air, 13.8% coal, and 71.2% water, by volume, with most of the air volume concentrated in the upper part of the pipe.

Test 80 was conducted using the same screw feeder

rotational speed as test 79, but the air flow was increased by 20% and the water level in the downcomer pipe was lowered by 4 m in test 80 compared to test 79. The increased differential height between the downcomer pipe water level and the riser pipe slurry discharge level significantly reduced the flow of transport water entering the riser pipe to one-third the water volume compared with test 79, reduced the riser pipe “aggregate” slurry velocity, and increased coal-water slurry concentration to 35% coal, by volume. The flow of transport water into the riser pipe became intermittent, although the water flow rate into the coal injector was consistent. Further increase of the differential height between dowcomer and riser pipe levels without additional air injected into the riser could result in a pipeline blockage.

The volumetric percentages of air, water, and coal in the riser pipe varied considerably depending on the flow rates selected. Coal-water slurries ranged, by weight, from 10% coal to 90% water, up to a maximum of 35% coal to 65% water, and were hoisted with air flows of 1.1 to 2.7 standard m³/min (40 to 100 scfm). Air flows were increased in proportion to the increased weight of the slurry mixture in the riser pipe to maintain a consistent flow. Slurry flow out of the riser pipe approached the characteristics of “slug flow,” or cyclical flow, as the total weight of the air-water-coal mixture in the riser pipe approached the weight of the water in the downcomer pipe. If the weight of the two columns reaches equilibrium, no additional transport water is delivered to the bottom of the ALH until the mixture in the riser pipe is lightened with additional air.

A preliminary test was conducted with a mixture of 50% coal and 50% rock, by volume, to simulate balanced air-lift hydrohoisting of run-of-mine coal with a high percentage of rock. The rock was a hard shale with a specific gravity ranging from 2.0 to 2.7. The coal-rock mixture, 5-cm or less, was injected and hoisted at a rate of 40 tph using an airflow of 2.0 standard m³/min (75 scfm). Additional tests with coal-rock mixtures and pure rock are planned to define the performance of the ALH with high-density mined materials.

Application of an ALH in Underground Coal Mines

Primary advantages of the ALH include its flexibility and compact design, which can be incorporated into an existing coal mine without requiring a separate, dedicated haulage entry. Safety hazards eliminated with an ALH include coal float dust, methane generation, and open, moving parts associated with belt and rail haulage. The ALH has relatively low capital and operating costs, low maintenance, and the flexibility required to integrate with existing mine layouts and coal haulage systems. In addition, it could operate as a primary haulage system or as a supplemental system transporting a product from a specific area of the mine. If operated as a supplemental system, the ALH could be activated with little preparation and used during peak production periods when the existing haulage capacity is inadequate. It could be installed in remote areas of the mine and appears capable of hoisting coal-rock mixtures created in areas where roof or floor rock is taken.

Although the balanced ALH system has not yet been tested in an underground coal mine, a number of beneficial changes could occur if it is used as a primary haulage system. Coal is totally enclosed in a hydraulic pipeline, which greatly reduces the potential for liberating coal dust and methane into the atmosphere. By eliminating a separate entry for belt or rail haulage, traffic congestion can be reduced in existing mines, and new mines can reduce the number of main and submain entries by one. This could result in more coal production from high-extraction areas of the mine, since main entries normally have a lower extraction ratio, thus increasing the overall mine productivity. If a fire occurs in the face area, the ALH system will provide an immediate source of pressurized water to fight the fire. In the event that miners are trapped underground, large- diameter hydrohoist pipes could be opened on the surface and at an emergency dump valve opened underground to provide direct communication to the surface, additional ventilation, and a possible escapeway.

It is expected that the ALH would be mounted in two boreholes or an existing shaft to transport the production from several nearby sections. A labyrinth seal coal injector sized for a typical continuous mining section is relatively compact and can be located with a mobile coal breaker and surge bin close to the face area. High-production sections would probably use two or three injectors rather than one large injector, since the working height is limited, and one injector may be periodically shut down for maintenance. There is no known production limitation for the ALH system, and production from the most productive longwall section in the United States could conceivably be hoisted in a 76- cm- (30-in-) diam. piping.

The primary disadvantage of the ALH is that moisture will be added to the coal that can lower its BTU value. The increase in moisture content is proportional to the addition of fines generated through mining and handling coal. Since grinding and pulverizing actions to coal are minimized with an ALH compared to centrifugal pumping, the additional moisture added to the final product should be relatively low. However, underground breakage of coal is required to achieve a top size no more than one-fourth the diameter of the transport pipeline. Water is normally removed from coal in a cleaning plant through screening, gravity separation, filtration, and thermal drying. The ALH system will probably not find application in mines that currently do not have a plant to wash coal. Pipeline blockages may occur due to the presence of tramp materials, loss of power, water, or air flow, or excessive solids concentration in the pipeline. However, proper engineering design can minimize these occurrences and provide for rapid cleanout of the pipeline if a plug occurs.

Two potential safety hazards of the ALH system have been identified, which appear to be controllable through proper design and regular inspection. Failure of the coal seal in the injector is a potential safety hazard, and the injector must be designed to protect mining personnel from a possible backflow of slurry through the intake side of the injector. The ALH should be designed with automatic valves that immediately close with any sudden drop in hydraulic pressure to protect mining personnel from a large discharge of water or coal slurry. Pipe wear due to abrasive materials travelling through a pipeline is another area for concern, since breakage of the pipeline is a safety hazard. Wear rates of vertical slurry pipe are significantly lower than wear rates of horizontal slurry pipe, estimated at one-third or less, and wear rates can be greatly reduced through application of state-of-the-art wear-resistant materials.

Initial results from the pilot-scale model indicate the coal ALH would be a cost-effective alternative to conventional hoisting systems. A preliminary cost analysis was performed by the Bureau of Mines Office of Process Evaluation, with the operating cost of a coal ALH estimated in 1992 dollars at $0.93 per metric ton compared to $1.21 per ton for a mechanical hoisting system. The capital cost for a coal ALH installed in a 182-m-deep mine with a continuous mining section was estimated at $1,453,000 compared to an estimated capital cost of $2,889,000 for a mechanical hoist. Hydrohoist capital costs include essential hydrohoist components, borehole and excavation, feeder breaker, and additional dewatering circuit for an existing preparation plant. The mechanical hoist includes a hoist and headframe, mine shaft, and hoist building. Based on pilot-scale model data, a 224 kW (300 hp) air compressor is proposed for injecting air at the bottom of a 35-cm-diam riser pipe to hoist a 25% by volume coal slurry. The resulting transport water velocity in the U-tube pipeline is estimated at 3.7 m/sec. By scaling up pilot-scale test results, 16.1 standard m3/min (600 scfm) of air should be adequate to hoist 435 metric tph (480 short tph) coal in this commercial-scale example of a balanced ALH.

Potential applications for the coal ALH are numerous, but a possible initial commercial application for this technology is to install a system in a mine that currently is experiencing insufficient hoisting capacity. Coal could be initially screened underground to separate out coarse- sized material for transport in an existing skip hoist and transport fine-sized raw coal through the ALH system. Another feasible application for a coal ALH would be to install the system in a mine that is currently producing multiple products created from different mining machines or sections. Coal-rock mixtures created by continuous miners developing entries with increased vertical height could be transported through an ALH to the surface and overland to a coal cleaning plant. Coal production from a longwall section that is mining entirely within the coal seam could be transported by an existing belt conveyor directly to the coal tipple, thus bypassing the cleaning plant. The USBM is currently seeking mines or underground construction projects that are interested in a commercial-scale test of this alternative hoisting system.

Other Mining Applications

The ALH appears to have a wide range of applications for transporting mined materials from underground excavations other than underground coal mines. Surface coal mines that transport coal from a deep pit may consider the ALH as an alternative method for transporting coal up a very steep incline. The ALH appears capable of hoisting virtually any mined material that is properly sized for the selected pipe diameter, providing the hydraulic velocity is sufficient to lift the heaviest particle to be hoisted and a suitable injector is available. Work is currently in progress to test mixtures of coal, shale, and sandstone having specific gravities up to 3.0 using the 50-m-high model. The labyrinth seal coal injector may require modification to successfully inject some mined materials that have physical properties largely different from coal, but the concept appears feasible if sufficient material fines are available to form a hydraulic seal. Tunnel boring machines could transport muck directly to the surface through ALH systems installed at intervals along the tunnel and relieve congestion underground due to a long conveyor system. The ALH may also be feasible for hoisting cuttings from large-diameter blind-drilled or up-reamed shafts. Nonmetallic minerals mined underground that may be applicable to the ALH system include trona, a sodium bicarbonate, and potash, a salt. Since raw trona ore is currently purified on the surface by dissolving it in water, it could be crushed underground, injected into a pressurized pipe with a screw feeder, and dissolved during transport to the surface in an ALH.

Conclusions

The U.S. Bureau of Mines has developed, tested, and applied for patents on a method of injecting and hoisting coal and other mined materials with a labyrinth seal injector and a balanced U-tube airlift system that appears to be commercially viable and safer than existing transport methods. Compared to present coal haulage systems, the ALH system should be much safer, and potential hazards associated with an ALH can be controlled through engineering design and regular equipment inspections. Based on a preliminary cost analysis, the ALH system has approximately a 25% lower operating cost than a comparable mechanical hoist and a capital cost of about 50% the cost of a comparable mechanical hoist. The ALH has numerous potential applications in coal and other mining industries for hoisting a wide range of materials. However, additional research is required to accurately assess the performance of the ALH for various lift heights, slurry specific gravities, and material characteristics.

Pilot-scale tests have demonstrated that coal can be continuously hoisted at production rates of 40 tph with the balanced ALH system using air flow rates ranging from 1.1 to 2.7 standard m³/min (40 to 100 scfm) as the primary motive force. Slurries with a maximum of 35% coal by volume were hoisted up a 20-cm-diam pipeline using the balanced ALH system. The existing pilot-scale ALH model should be capable of hoisting 100 tph coal, which is currently limited by the size of the injector. The single screw labyrinth seal injector continuously injected coal into 480 kPa (70 psi) water in more than 50 tests, and a hydraulic seal of compacted coal was maintained in the rotating screw even when the feed material in the bin was entirely submerged in water. However, the single screw injector required a relatively dry feed with a consistent size range to achieve full performance. An injector with two co-rotating screws is recommended to improve productivity, eliminate feed material adhesion to screw flights, and provide positive material displacement when injecting against significant hydraulic pressures.