Table of Contents

Placer Sampling

One of the most difficult tasks associated with placer mining is the sampling of the deposit. More placer projects have failed due to inaccurate assessment of the reserves than to any other reason. Within the realm of placers, those containing valuable minerals with a high unit Value are more difficult to sample than those with larger bulk, lower unit value minerals. Some items to consider when sampling a placer deposit are as follows:

A) A relatively large size sample is needed for accurate valuation of the ground being tested. Placers are composed of many sizes of gravel which makes a representative sample difficult to obtain.

B) When sampling placers for high unit value minerals such as gold, any error in mineral content of the sample will be magnified in the calculation of reserves.

C) Values are usually erratically distributed within the gravel mass. Therefore, some placers with a more uniform value distribution may be adequately assessed with a minimum number of samples while a deposit with a highly erratic distribution of values may not be adequately sampled regardless of how many samples are taken.

D) The investigation of a placer deposit should be made by, or be under the direction of, a person experienced in the art of placer sampling.

E) During a sampling program, items that must be observed and noted in addition to the sample size and valuable mineral content should include boulder size and number, clay content, bedrock conditions, water, frozen ground, false bedrock, and any other physical characteristics that would affect mining of the deposit.

Sampling Programs

The steps to be followed in approaching a placer sampling program are outlined below:

I. Reconnaissance

A. Check status of land ownership

B. Physical characteristics of area

C. Research mining history of the area

II. Choosing a Sampling Method

A. Existing exposures

B. Hand dug pits or shafts

C. Backhoe trenches

D. Bulldozer trenches

E. Other maching dug pits or shafts

F. Churn drill holes

G. Other drilling methods

H. Bulk samples

III. Special Problems Associated with Placer Sampling

A. Large rocks and boulders

B. Erratic high values

C. Uncased holes

D. Small diameter holes

E. Salting

IV. Sample Processing or Washing

A. Sample washing

B. Sample washing equipment

V. Data Processing

A. Record keeping

B. Reporting values

C. Splitting samples

D. Assay procedures

VI. Reserve Estimation and Placer Valuation

A. Block method

B. Triangle method

C. Polygonal method

D. Cross section method

E. Method of diamonds

VII. Conclusion

A. Summarize results of the investigation

Sampling Methods

The sampling methods outlined above vary from simple grab samples on existing exposures to sophisticated drilling methods such as churn drilling. In this section, the various methods are discussed briefly and the applicability of each is indicated:

A) Existing Exposures – If existing exposures are available, they can be tested for potentially valuable minerals by taking a grab sample and panning the sample. Advantages of taking samples from surface exposures are the low cost and the speed at which the samples can be taken. The disadvantages are that you can only sample what is on the surface and no quantitative information can be produced.

B) Hand Dug Excavations – These may be pits, trenches, or shafts and are suited to dry, shallow ground. This method of sampling is not used in the United States much today due to the high cost of labor but it can be effectively used in remote parts of the world where trained labor is not available or general labor is relatively cheap. The method provides a good bulk sample and is often used to verify drilling results by sinking a shaft over a drill hole. Bedrock values and characteristics can also be accurately determined when the excavations are sunk to bedrock.

C) Backhoe Trenches – Backhoes are a very versatile piece of equipment for sampling relatively shallow, up to about 20 feet deep, deposits. Backhoes are mobile, fast, can dig fairly hard ground, and are inexpensive as compared to hand dug excavations. Once a trench is opened up, channel samples are taken by hand or by using the backhoe or a bulk sample can be made with all of the material from the excavation. For backhoe sampling programs, the ground must be fairly dry and stable. Care must be taken when using a backhoe or any mechanical equipment to keep all fuel and lubricants away from the sample material as sample contamination can result causing the fine gold to float thereby reducing the value of the sample.

D) Bulldozer Trenches – Bulldozers are best suited to work in ground where trenches are to be dug 10 feet deep or less and are in dry, stable ground. The greatest advantage of prospecting placers with a large bulldozer trench is that the trenches permit good visual inspection of the ground. Other advantages and disadvantages are similar to those associated with the backhoe trenches.

E) Other Machine Dug Excavations – Other machine dug excavations consist of shafts or pits which are dug using powered equipment such as large augers, bucket drills, or clamshell-type excavators. Digging shafts with the aid of powered equipment requires experienced operators and suitable machine access. Dry, stable ground is also needed for successful sampling operations when digging shafts and pits.

- Augers – Augers for sampling placers can vary from small hand-held posthole size machines up to very large truck-mounted machines. Augers are relatively inexpensive to operate and can provide large volume samples. The disadvantages of using augers are their inability to penetrate ground with boulders, gold sorting may occur with spiral type augers, and their inability to perform in water saturated ground.

- Bucket or Clamshell Type Excavators – These machines are usually quite large in size and allow one to take a fairly large bulk sample. The advantages of using this equipment are its ability to allow one to visually inspect bedrock, by using caissons to hold the hole open, and the capability to obtain a fairly accurate sample volume. The disadvantages are the need for good access for the large equipment and a fairly slow digging speed.

F. Churn Drills – Churn drilling is used in deep or wet ground where sampling by pits, trenches, or shafts is not feasible. The churn drill utilizes a heavy casing with a drive shoe at the bottom, a chisel shaped bit, and a vacuum type sand pump for removing the sample from the hole. There are three main types of churn drills which are differentiated by their size: the hand-held “Ward”, the light “Hillman” or Airplane”, and the heavy “Bucyrus-Erie” or “Keystone” drills. The advantages and dis¬advantages of using churn drills for sampling placer deposits are as follows:

Advantages:

- Sample is very reliable

- Equipment is fairly portable

- Few mechanical problems are encountered

- Technical data and interpretative information available

Disadvantages:

- Very slow penetration rate

- Large boulders create many problems

- Problems from “running” ground

- Requires skilled operator and careful drilling techniques

- Fairly small sample size

- The larger equipment requires good access

The churn drill is a tried and proven process for sampling placer deposits. Abundant information exists on both the process and method of sampling. Due to the churn drill’s reputation for producing reliable sampling results it is still the most popular method of sampling deep placer ground in use today.

G. Other Drilling Methods – Due to the slowness and high cost associated with churn drills, other drilling methods are being tested for placer sampling. Some of the other types of drills are the reverse-circulation, hammer and rotary; the vibratory; and the resonant or sonic drill. Details of each drill type are as follows:

- Reverse-Circulation – With a reverse-circulation drill, the sample cuttings are blown up the inner section of a double walled pipe. This method of cuttings removal reduces the chances of sample contamination as compared to conventional drilling techniques which force the drill cuttings out between the drill pipe and the surrounding wall rock. The advantages of using the reverse-circulation drill are high penetration rates at a fairly low cost per foot, its ability to penetrate boulders, and the ability to drill fairly deep deposits.

The main disadvantages are the need for good equipment access and the sample may not be representative of the actual material being sampled due to sorting. The use of a combination of churn and reverse-circulation equipment would give the operator the advantage of both speed and reliability. A correction factor will be necessary in most cases for the reverse-circulation drilling results. - Vibratory Drills – Vibratory drills have been tried recently for sampling placer deposits. The vibratory drills developed to date are quite portable, very fast in fine grained materials, and a fairly undisturbed core is obtained. The disadvantages are the small sample size, blockage in the core barrel, inability to penetrate boulders, and clay reduces the penetration rate.

- Resonant or Sonic Drills — These drills have also been developed fairly recently and the technology associated with this drilling method is still being tested. Advantages of the resonant drill are its ability to penetrate boulders, it is relatively fast, the sample is generally undisturbed, and the method has good depth penetration. The disadvantages are the need for good equipment access, fairly high operating costs, core may be lost if vibration is used to extract the rods, and the method can only be used in fairly competent ground.

H. Bulk Samples – Wherever possible, bulk samples should be taken in placer deposits having an extremely erratic value distribution such as in deposits where the valuable mineral is found as widely spaced nuggets. Bulk samples are also needed for pilot plant test work. Any time a sample volume is measured, it must be carefully converted to bank volume. Especially in pits and reverse-circulation drill holes, variations in the swell factor can cause anomalies in the estimated grade exceeding 2 times the standard deviation.

Special Problems Associated With Placer Sampling

Due to the physical nature of placer deposits, a mixture of material ranging from large boulders to sand, the nature of the valuable mineral contained in the deposit, and medium to high unit value minerals erratically distributed within the deposit, placers are extremely difficult to sample. As mentioned previously, more placer mines have failed due to improper sampling than due to any other cause. Some of the special problems associated with placer sampling are listed below:

A. Large Rocks and Boulders – When sampling placers, there is a tendency to bypass areas containing many boulders or to sample the easily collected finer material around the boulders. In many cases, this is essentially salting the sample since the valuable minerals in a placer deposit usually occur in the finer material.

The most direct solution to sampling areas containing boulders would be to take samples large enough to contain a representative portion of the boulders to give accurate value estimates. Since it is not physically possible to take large enough samples to include the boulders in most-sampling situations, how does one consider the effect of boulders without including them in the sample? The most common solution is to visually estimate the volume and insert a correction factor into the end sample volume calculations.

B. Erratic High Values – The methods used for estimating the value of placer ground rely on the assumption that the value found in a particular sample extends halfway to the next sample. While evaluation of ground having a general low or fairly uniform average of values can be done using the standard reserve estimating methods, erratic high value samples in a deposit cause problems.

Methods for adjusting erratic high values so an over-evaluation of the ground does not occur includes re-sampling erratic areas and using the lower value determined or determining what the highest reasonable value should be and then keeping all sample value within that limit.

C. Uncased Holes – The use of uncased drill holes should be discouraged in placer sampling, especially in sampling ground with a high unit value mineral. If uncased holes are used, there is a tendency to unintentionally salt the sample and get over-valued sample results. This problem arises due to the fact that without casing, an excess of material can get into a sample without knowing where, within the hole, the material came from.

An exception to always casing drill holes is when drilling frozen ground. If the ground being sampled is well frozen, casing is usually not used.

D) Small Diameter Holes – Due to the large “nugget effect” associated with sampling ground containing high unit value minerals, the use of small diameter drill holes is not recommended for sampling deposits for gold, platinum, etc. When sampling deposits which have fine grained material and contain low unit value minerals, small (5 cm diameter) holes may be used.

E) Salting – Salting of samples can occur intentionally or unintentionally. Intentional salting is the deliberate addition of valuable mineral to a sample. Unintentional or innocent salting is usually the result of careless or improper working procedures. No matter how salting occurs, the results can mean the failure of a project after many thousands or even millions of dollars have been spent bringing a property into production.

Sample Processing or Washing

Sample Washing

Once a sample has been taken from a placer deposit, it must be washed to separate the valuable mineral from the waste material. The valuable mineral thus separated is then weighed to determine the value of the ground being tested. Most washing devices use some type of riffled surface to retain the heavy minerals as the lighter waste material is washed away. In dry washers, a current of air floats away the lighter material while leaving the heavy minerals behind.

No production equipment designed for the recovery of heavy minerals actually recovers 100% of the mineral. Because of this, it is important to select a washing system which will indicate the commercially recoverable mineral content of a sample. Other essential features of a sample washing system are:

- Low initial cost

- Easy maintenance

- Easy transport and setup

- Will accept a wide range of material sizes

- Will efficiently wash the sample

- Efficiently uses available water

- Good mineral recovery

- Can be cleaned easily and quickly

- Will be reliable and give meaningful results

There are many sample washing devices available from the simple miner’s pan to more complicated mechanical devices such as a “Denver Gold Saver”. All of the systems that will be discussed in the following sections have been tried and proven over the years as effective sample washing systems.

Sample Washing Equipment

- Miner’s Pan – The old fashioned gold pan is still the most widely used device for washing small placer samples. The pan is well suited for washing small samples but is not well suited for handling samples over 30 pounds or if samples are taken very frequently.

- Sluice Box – A sluice box is generally defined as an elongated wood or metal trough equipped with traverse riffles through which alluvial material is washed to recover the heavy minerals. Sluice boxes are sometimes, but erroneously, called “long tom”.

The function of riffles in a sluice box is to retard the movement of heavy minerals allowing them to settle while the lighter material flows on through the sluice. Carpeting is often used under the riffles to increase the recovery of fine gold. In some operations, mercury is placed in the riffles to enhance gold recovery. - Rockers – A rocker is a short, sluice-like trough with curved traverse supports which permit it to be rocked from side to side. A flow of water, aided by the rocking motion, carries the material down the trough where the heavy minerals are trapped by riffles.

Rockers have been used almost unanimously for washing samples by the dredging industry. A rocker requires less water than a sluice and is capable of recoverying very fine gold. They are easily constructed in the field and quickly cleaned of concentrate. - Dry Washers – Dry washers are used in arid regions where water is scarce and a “cry” recovery plant is proposed for production. The dry washer uses a bellows to blow air up through a sluice box with a porous bottom causing the lighter material to progress down the sluice while the heavy minerals are trapped behind the riffles. In order for a dry washer to work efficiency, the feed must be very dry. Damp, sticky material cannot be processed until it is dried.

- Other Hashing Equipment – In addition to the previously discussed washing equipment which have been used since the early years of placer mining, there are two other types of washing machines which have come into use relatively recently.

The “Denver Gold Saver”, and other comparable machines, utilizes a revolving trommel screen to separate the coarse and fine materials with the fines going to a shaking riffle for separation of the heavy minerals. The advantages of the “Gold Saver” type of system is its ability to process relatively large samples and to recover fine gold.

A second machine which has been used for about the last 40 years is the mechanical pan. Once the coarse material in a sample is screened from the fines a mechanical panning device can collect the heavy minerals. As the name implies, the equipment is designed to duplicate hand panning.

Data Processing

Record Keeping

Accurate, systematic records must be kept for proper placer evaluation. As an example, data that must be recorded on a log sheet when churn drilling a placer gold deposit includes the following:

- Name of property

- Location

- Date

- Drill hole line number

- Hole number

- Hole collar elevation

- Time (time of day is given for each bailing. A summary of time consumed in drilling, pulling, moving, repairs, and delays is also given)

- Depth of the drive shoe for each sample interval

- Depth of pumping for each drive or sample interval

- Total hole depth

- Core rise in the pipe for each drive

- Core left in the pipe after pumping, i.e., the plug thickness

- The length of core removed

- Volume bucket measurement

- Classification of colors (count the number of No. 1, 2, and 3 colors)

- Estimate the gold weight based on the color count

- Formation (note the visible physical characteristics of the formation being drilled)

- Depth and nature of overburden

- Labor used

- Depth of the pay gravel

- Depth to bedrock

- Nature of bedrock

- Thickness of pay zone

- Size distribution of pay gravel

- Diameter of the drive shoe

- Theoretical volume of material removed

- Measured volume of material removed

- Weight of gold recovered in milligrams

- Fineness of gold

- Drive shoe constant used in calculations

- Value in cents per cubic yard

- Price of gold used in calculations

- Signature of the driller, panner, and helper

It is essential that detailed records are kept as they will be used to determine the value of the deposit as well as to determine its mineability. Information included in the drill logs will also be used in selecting a mining method.

Reporting Values

In the United States, the volume of placer material is always reported as bank cubic yards. The value of ground in gold placers is reported in cents per cubic yard as well as in milligrams of gold per cubic yard. The fineness of gold and the price used in the value determination are also reported. Minerals other than precious metals are reported in pounds per cubic yard, percent, or the particular unit customarily used for the commodity in question.

Splitting Samples

When a gold or other high unit value mineral sample is taken, it should never be split or reduced prior to assay determination. Any attempt to divide a sample to reduce its volume will yield erratic assay results. When dealing with fine size placer minerals having a low unit value, a reduction of the sample size by mixing and splitting is an acceptable procedure.

Assay Procedures

At this point, the procedures for determining the value of a sample needs to be discussed. The only correct way to determine the amount of valuable mineral in a placer sample is by weighing. After the volume of the total sample taken has been determined, the amount of valuable mineral in the sample is measured by weighing. After the sample volume and valuable mineral quantity has been determined, a value can then be placed on the ground represented by that sample.

It should be noted that placer samples should never be fire or AA assayed. The only time fire assaying is acceptable is to determine the fineness of the gold.

Reserve Estimation And Placer Valuation

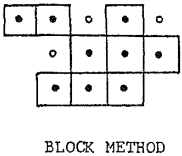

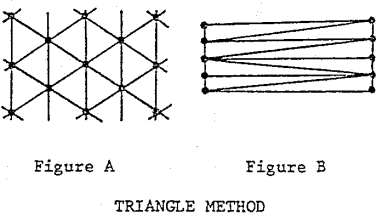

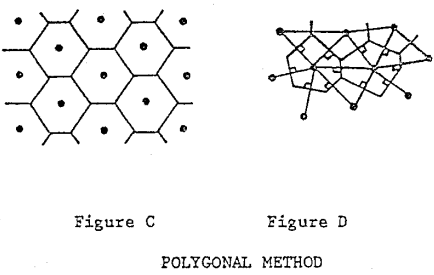

After samples have been collected, washed, and assayed, reserves for a deposit can be estimated. There are many placer reserve estimation methods available. Some of these methods are the block, triangle, polygonal, cross sections, and diamonds. The figures below graphically demonstrate these methods:

The value using the block method is calculated as follows:

- Find the volume of each block, length x width x depth.

- Multiply the volume by the value per cubic yard in each block.

- Find the sum of all the weighted values to obtain the total value.

- Find the average grade by dividing the total in Step 3 by the total volume to obtain the value per cubic yard.

If Figure A is used, then the method of calculating the value of the Section is as follows:

- The volume equals the average of depth of the three drill holes times the area of the triangle.

- The average gold content is equal to the gold value of each of the three holes times the depth of each of the holes divided by the sum of the depths of the three holes.

- Total volume equals the summation of values in Step 3.

- Total gold content equals the total volume in Step 3 times the average from Step 2.

- The average grade equals the value in Step 4 divided by the value in Step 3.

Figure B is used when the pay streak is parallel to the long dimension of the triangles. The method of finding the value is the same as Figure A.

Either method may be used in finding the value using polygons. There may be need either for regular or irregular drill spacing. Figure C is for regular polygons and is calculated as follows:

- The total volume equals the sum of the volumes of the individual polygons. Find the volume of the polygons by multiplying the area of the polygon times the depth of the drill hole.

- Total gold content equals the sum of the grades of each hole times the volume of each polygon.

- Average grade equals the value in Step 2 divided by the value in Step 1.

The volume (area) of each irregular polygon in Figure D may be found by using a planimeter or by dividing the polygon into regular triangles and rectangles.

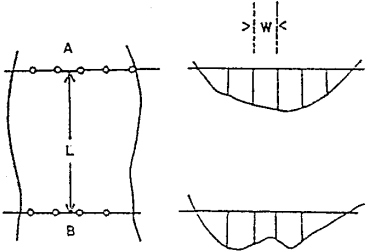

Cross Section Method

This method is very similar to that of the triangle and may be used as a check:

- Area of a cross section (A) is the average of the depths of the boreholes (di + dj/2) times the distance between the boreholes (W).

- The total volume is ½ the sum of the areas of all individual sections A and B times the distance between the traverse (L).

- The total gold content is the sum of the gold contents of each section. The gold content of a section is the volume of the section times the value of the drill hole.

- The average grade is the value in Step 3 divided by the value in Step 2.

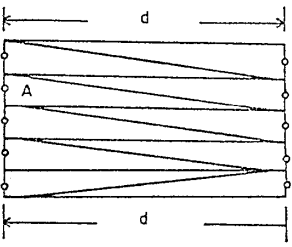

Method of Diamonds

The method of diamonds is much the same as that of triangles. The drill hole is located at the center of the diamond and apexes midway between drill holes on adjacent lines. This method is best used for regularly spaced holes. The total yardage is equal to the sum of all diamonds which may be treated as right triangles for all practical purposes:

- Total volume equals the area of each diamond (A) times the depth of each hole through the pay zone.

- Total gold value equals the sum of the gold value in each hole times the volume of each diamond.

- To find the value per cubic yard, divide the value in Step 2 by the value in Step 1.

Conclusions

There are many ways to sample and methods to calculate the value of a placer deposit. It is important to remember to use care in sampling and find the method that best suits the type of occurrence that is being sampled. Also, use the ore reserve calculation method that best typifies the configuration of the deposit and mode of deposition.