The requirements for controlling air and stream pollution are a most timely subject for all concerned people. The coal industry has taken great measures to reduce both types of pollution.

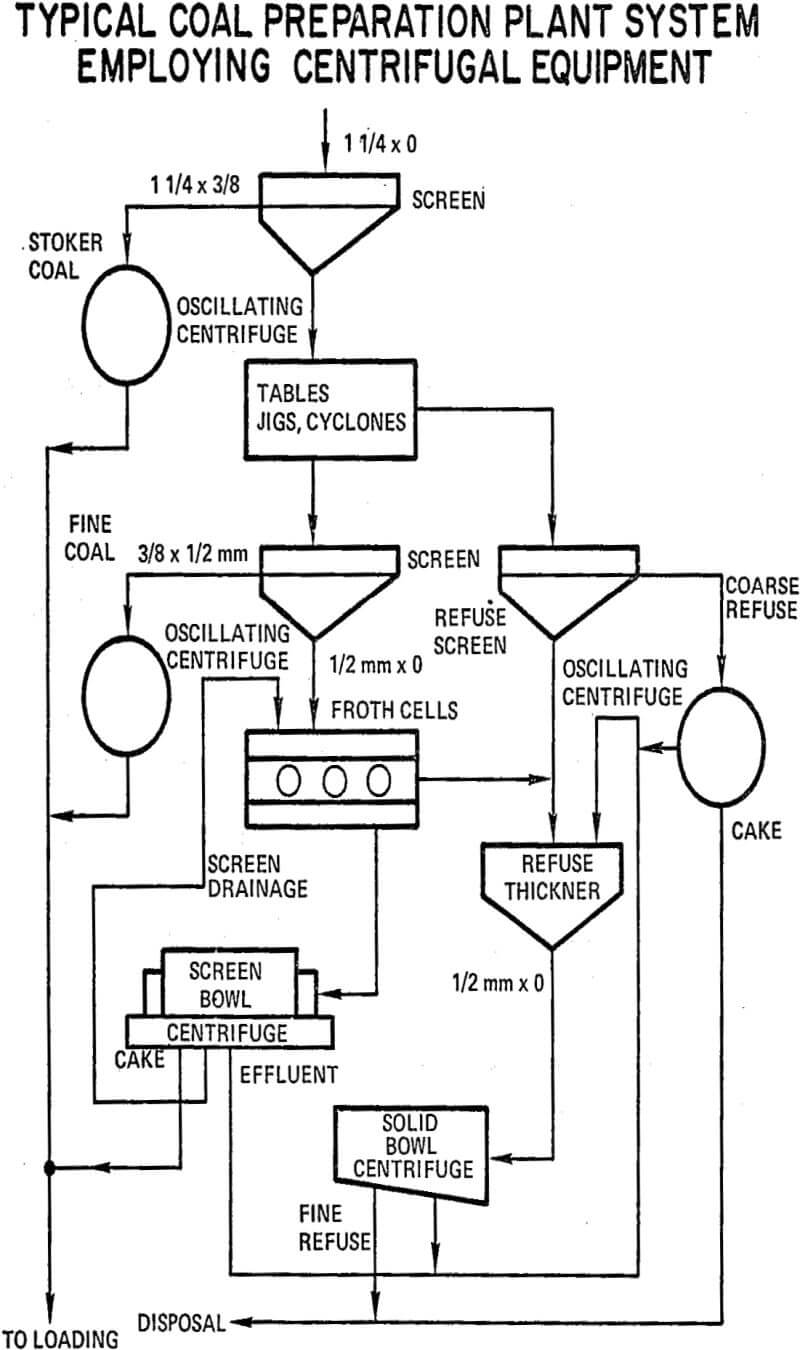

To help eliminate stream pollution and the hazards created by tailing ponds, the coal industry is using centrifugal dewatering equipment. Use of centrifugals to dewater fine refuse for disposal would eliminate refuse ponds or extend their life. In doing this effectively and economically, preparation plants have the option of recycling the clarified water to close the water circuit or of discharging the water into receiving streams with the assurance that it contains an acceptable amount of refuse solids.

The industry reports that maintenance and power costs for centrifugally dried coal is in the range of 8-15¢ per ton compared to 35-40 ¢ per ton for thermally dried coal. The cost variation for centrifugal drying is due to the various types of coal processed, either hard or soft, (grindability of 50-120).

Performance is for screen bowl centrifuges installed on either cyclone underflow or froth flotation circuits; the cyclone circuits having a solids concentration of 35-40%, and the froth flotation circuits in the range of 20-25%. Other dewatering equipment, such as disc vacuum filters under the same conditions, have shown an average of 8 to 10 percentage points greater moisture levels in the dewatered product.

The coal industry is currently employing at least 100 solid bowl centrifuges in various applications. Dewatering finer clean coal products with solid bowl centrifugals was standard practice until the screen bowl was introduced in 1969. Many solid bowl installations have been converted to the screen bowl design in order to get the lower moisture level benefits obtainable.