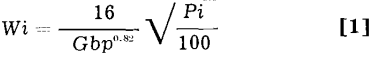

To calculate theoretical horsepower required by a grinding mill to reduce feed material to a certain size from Bond grindability test data, it is necessary to apply the “Bond Third Theory of Comminution.” The first step in this procedure is to calculate from the following formula the work index, which is the kw-hr required to grind one short ton of material from a theoretically infinite size to 80 pct passing 100 microns:

where Wi = the work index

Gbp = Bond ball mill grindability

Pi = micron size of the mesh of grind.

For 200 mesh, Pi = 74; therefore

Wi = 13.76/Gbp0.82…………………………………….(2)

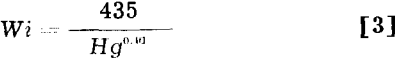

where Hg is Hardgrove grindability.

Then, from the work indices the actual work required in kw-hr per ton to grind a material from a certain size F to a certain size P can be calculated using the following formula derived from the “third theory” of comminution:

W = 10Wi(1/√P – 1/√F)……………………………………………………(4)

where W = the work in kw-hr per ton

Wi = the work index

P = the 80 pct passing size in microns of the product material

F = the 80 pct passing size in microns of the feed materials.

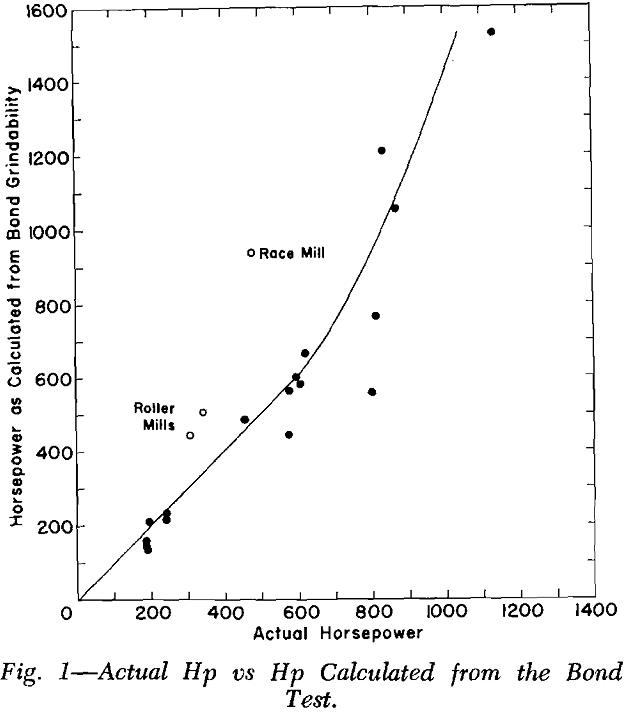

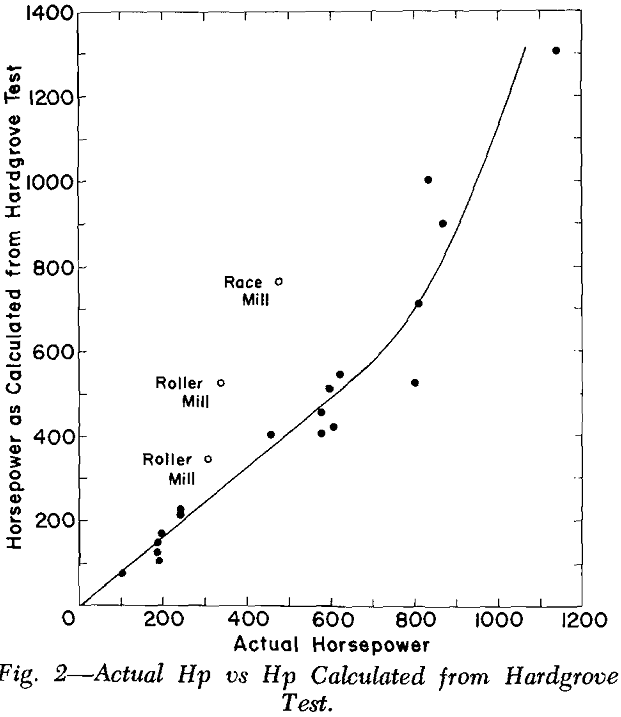

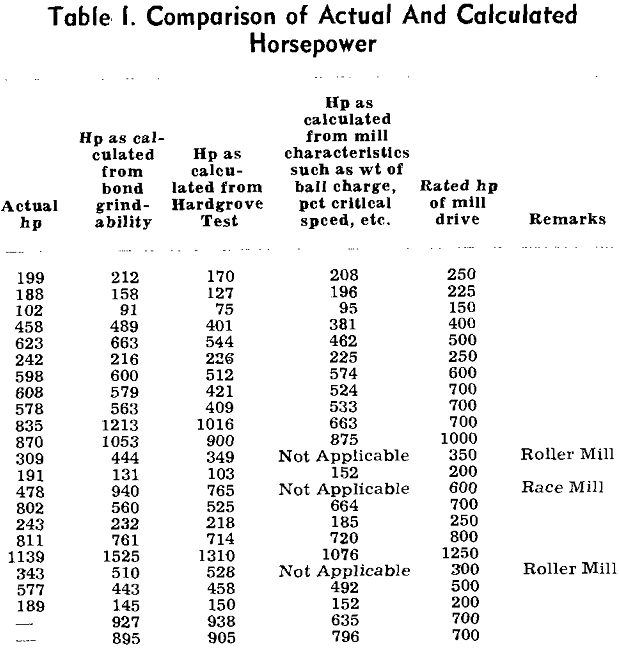

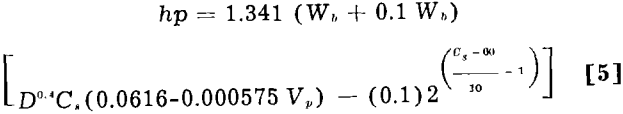

In a similar manner, horsepower figures can be obtained from theoretical power consumptions calculated from the Bond grindability test and from the Hardgrove grindability test.

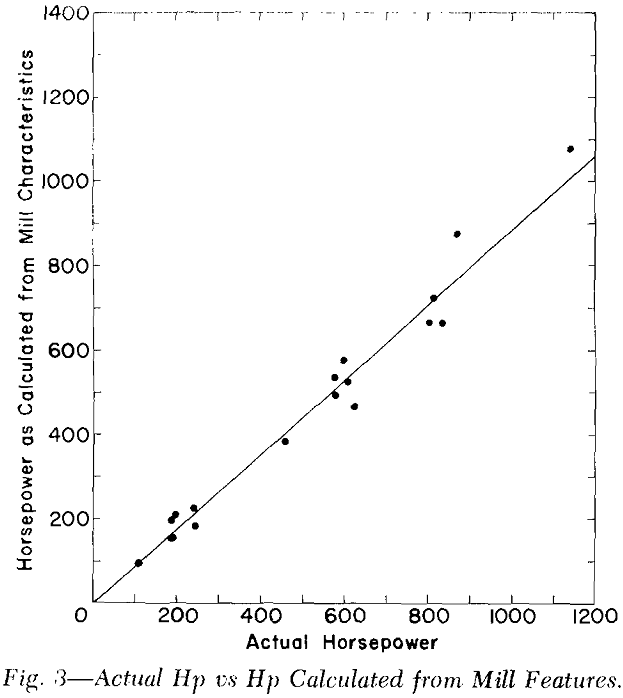

where hp = horsepower

Wb = weight of ball charge in tons

Cs = pct of critical speed of mill

Vp = pct of total mill volume occupied by ball charge

D = mill diam (ft).