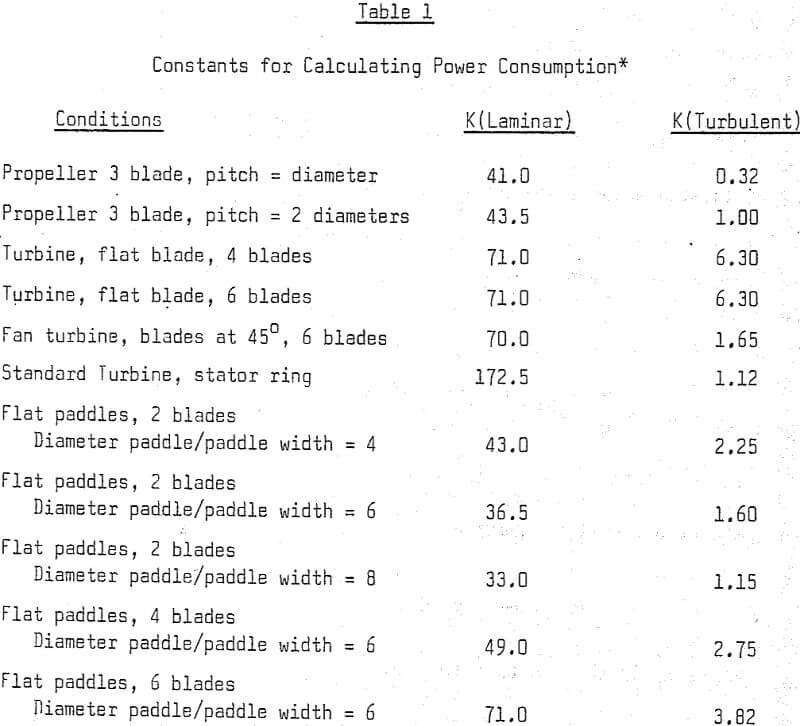

An interesting problem with which the senior author has been concerned with is the scale-up of power requirements for slurry agitators operating in the laminar region with pseudo-plastic materials. Pulps of shaly ores, after various chemical reactions in aqueous leaching systems, are often difficult to settle and filter if agitation is violent. In these cases agitation must be at a minimum, yet prevent tling such as in copper uranium ores. This mild agitation is on the laminar region.

The starting point of this investigation is the known relationships for agitating Newtonian fluids. The Reynolds number is a measure of similitude in agitation and is derived from the ratio of the internal reaction per unit volume of fluid (V²D) and a viscous force present per unit of volume (µV/D²).

For flow through pipes, this is:

RE = P V²/D/µ V/D² = D V P/µ

where: RE = Reynolds numbers

D = diam. of pipe

V = velocity

p = specific gravity

µ = viscosity

all in consistent units.

For agitation, velocity is the speed at the tip of the impeller. If N is agitator revolutions per second, then: π D N = V. Since π is a constant, the Reynolds number of agitation becomes:

RE = N D² p/µ

NP = P g/p N³D5

Where P = net power input, ft-lbs/sec

g = gravity constant, ft/sec²

f = specific gravity of fluid with respect to water

N = revolutions/sec.

D = diameter of impeller in feet.

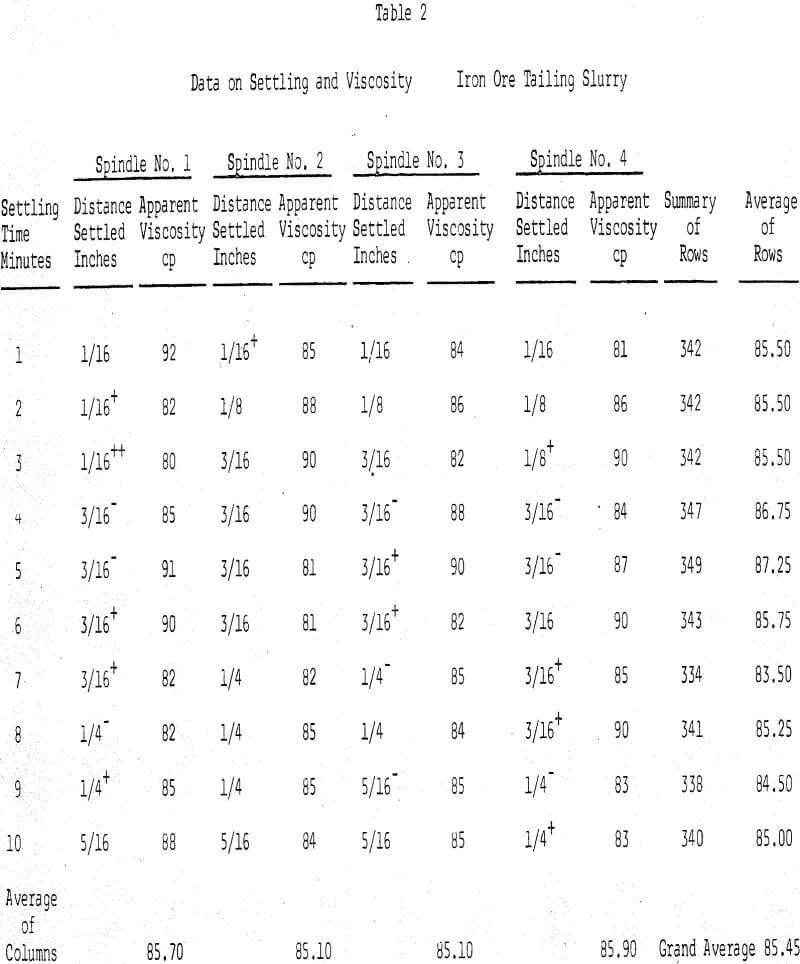

Ore, slurries are non-Newtonian, and, for the most part, pseudo-plastic. This means that the apparent viscosity constantly varies as the rate of shearing (agitation) varies. The calculation of the Reynolds number is more difficult, because of the variable apparent viscosity.

We could not test the coal slurry in the same manner as the iron ore slurry because we could not clearly discern a settling line. We found a 50% by weight slurry of anthracite coal ground to 17% minus 150-mesh apparently settled quickly because viscosity readings increased rapidly for the.10 minutes tested. On the other hand, when testing a 5.0% slurry ;made up of coal ground to 55% minus 150-mesh, we obtained consistent readings for ten minutes. This indicates at worst, a slow settling rate.