Table of Contents

As in a pilot-plant-scale hammermill, the effect of moisture content in the pulverization of lignite in a similar size ball mill was observed to be a highly significant factor with respect to power required and in pulverization capacity. Both predrying before pulverization and drying in the mill were found to be highly beneficial in pulverization of lignite. Product fineness increased, power requirements decreased, and the capacity of the mill increased as the degree of drying was increased. Data show a remarkable similarity with respect to power requirements for lignite pulverization in both a ball mill and hammermill.

Tests on five lignites from different mine sources also demonstrated that lignite from some sources is more difficult to grind in a ball mill than others. However, no correlation between the Hardgrove index and pulverization capacity of the ball mill was established. It was also observed that physical properties of lignites are variable in the delivery rate of an auger feeder. Although the characteristics of the lignites differed with respect to performance of the feeder, this also did not correlate directly with the performance of the ball mill.

Based on the results obtained from this investigation, the ball mill is capable of pulverizing lignite to the fineness required for pc-firing of boilers. Recent tests on a commercial scale unit, observed after the experimental work for this investigation had been completed, demonstrate the validity of this conclusion. The tests were conducted by the Riley Stoker Corporation on a Riley ball-tube mill installed at the Dairyland Power Cooperative station in Alma, Wis. Lignite for these tests was supplied by the Knife River Coal Mining Company, Beulah, N. Dak. Where comparison is possible between the commercial unit and the pilot plant test unit the agreement of the test results was excellent.

North and South Dakota and Montana contain lignite deposits which amount to a little over 25 percent of the nation’s solid fuel reserves on a tonnage basis. The majority of these lignite deposits are located in North Dakota, which has an estimated reserve of over 350 billion tons. These huge lignite reserves have great potential for future electric power generation and coal- based chemical industries.

At present, nearly all the lignite mined in this area is being used for power generation. As-mined lignite is variable from one mine source to another, but is generally characterized by a moisture content which may range from 35 to 40 percent, an ash content of 6 to 8 percent, and a heating value of 6,800 to 7,200 Btu/lb. The majority of the larger powerplants now in operation utilize pulverized coal-fired (pc-fired) boilers.

For pulverized firing, lignite is pulverized in present plants to at least 50 percent passing a 200-mesh screen (0.0029 inch opening). All commercial units utilize heated air to sweep the mill and to dry, classify, and transport the pulverized product to the burners. The moisture removed from the lignite is introduced into the boiler along with the pulverized lignite and primary combustion air.

Most of the present pulverized lignite-fired boilers have pulverizers of a type which use variations of the rolling-compression grinding action, such as found in bowl mills and ball-race mills. For these plants and any future coal-based chemical industries, the type of pulverization equipment is an important consideration with respect to capital investment of the plant and to operating costs.

Ball mills, which have a different type of grinding action, are used extensively in the mineral and ore-processing industries and in power generation with other coals, but they are not used in the existing lignite industry. The operating characteristics of ball mills are favorable for certain applications. Because a large amount of active product is retained in the mill, a steady output of product can be maintained even though the feed is interrupted. This reserve can also be advantageous if there is a sudden demand for increase in product. Ball mills are very reliable and largely free from maintenance shutdowns, in that maintenance is usually limited to the periodic addition during operation of a small charge of balls to replace those which have been worn down in size.

The Bureau of Mines has been studying the pulverizing characteristics of lignite in a continuing project at its Coal Research Laboratory at Grand Forks, N. Dak. These studies have included the variations in grindability of lignite as determined by the Hardgrove grindability test machine and pulverization in both full-scale commercial mills and a small pilot-plant size hammermill. An objective of this comprehensive study has been to study lignite pulverization in units which have different types of pulverizing action. This report presents the results obtained from an investigation conducted on a pilot-plant-size ball mill to determine the pulverizing characteristics of lignite in this type of mill.

Only variables pertaining to the lignite were studied. These include moisture content of lignite, either by predrying or degree of in the mill dryings and mine source of lignite. Mill variables such as ball size, mill speed, etc., were maintained at conditions recommended by the manufacturer.

Experimental Test System

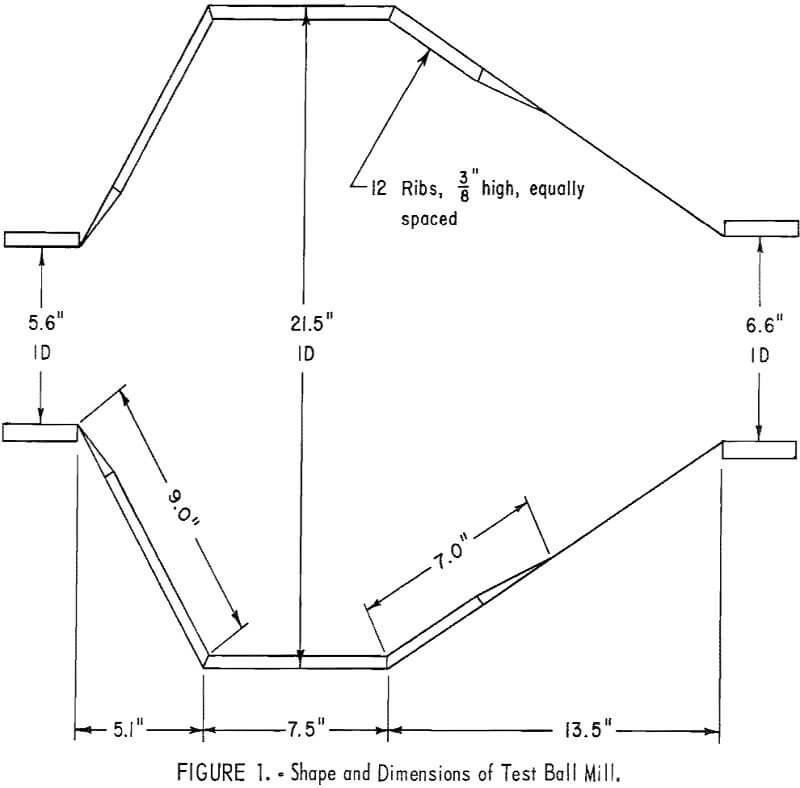

The test unit was a conical ball mill purchased from a commercial manufacturer (Hardinge Company, Inc., York, Pa.). The internal mill dimensions are given in figure 1. Twelve ribs, 3/8-inch high uniformly placed around the mill inner surface serve as charge lifters or risers. The ball charge in these tests consisted of 200 lb of 2-inch and 200 lb of 1-¼-inch balls which gives a ball charge to mill volume ratio, or degree of ball loading of about 0.41. The mill was driven by a 2-hp motor at a rotation rate of 39.3 rpm.

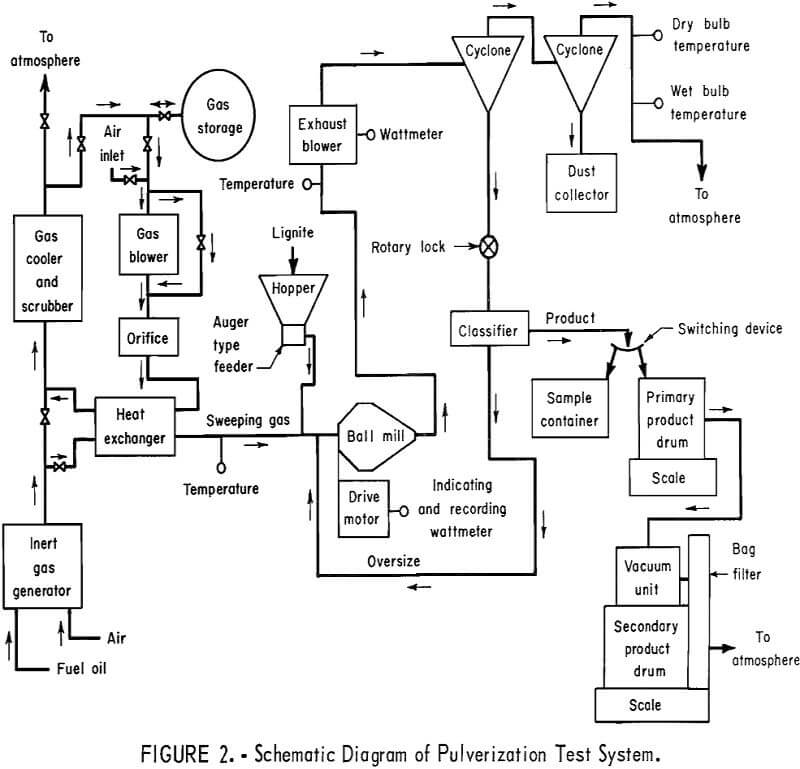

The ball mill was incorporated into a test system as shown schematically in figure 2. Fuel oil burned with stoichiometric quantities of air, produced both inert sweeping gas and heat for mill operation at elevated temperatures.

A heat exchanger was used to heat any desired mass flow of sweeping air or inert gas to temperatures up to 700° F. The sweeping gas carried the feed into the mill and the pulverized product through the classification system.

A variable drive auger-type feeder introduced the lignite into the sweeping gas stream to which was also added the oversize product from the classifier as feed to the mill. The sweeping gas and pulverized lignite it entrained were removed from the mill by an exhaust blower and carried into a primary cyclone which separated the major portion of the lignite from the sweeping gas. From this cyclone the gas passed through a second cyclone to remove additional dust and then was exhausted to the atmosphere. The lignite collected in the primary cyclone dropped through a rotary air lock into a classifier. The oversize material separated by the classifier returned to the mill feed line. The classified product was collected in product drums or by means of a switching device diverted to a separated container as a sample. A vacuum transport system allowed product drum exchange during mill operation. Both primary and secondary product drums were placed on scales for continuous cumulative weight determination.

The power consumption of the 2-hp mill drive motor was determined by an indicating and recording wattmeter, and an indicating wattmeter was used to determine mill exhaust blower power consumption. Commercial bimetallic thermometers were used to measure the temperature of the sweeping gas before it contacted the feed lignite, and of the mixture of pulverized lignite and sweeping gas as it left the mill. The wet and dry bulb temperatures of sweeping gas were obtained in the duct through which the sweeping gas was exhausted to the atmosphere.

Test Procedures

The objectives of this investigation were primarily concerned with comparing the effect of variables associated with the lignite on the capacity and power requirements in ball milling to produce a pulverized lignite suitable for pc-fired boilers. As with most ball mills, the power consumption of the test unit was almost independent of mill loading. For all tests performed, the mill drive motor power requirement was almost constant at 1.2 kw. The greatest observed influence on the power necessary to drive the mill was the state of lubrication of the bearing surfaces. Before and during each test, a specific lubrication procedure was used to assure comparable test conditions. The power consumption per ton of product was therefore a direct function of the mill product rate. and is at a minimum at the maximum product rate which the mill can maintain.

In a ball mill, the product rate is a function of the mill loading. As the feed rate is increased the mill loading increases and the product rate increases until mill capacity is achieved. If the feed rate is increased further the mill becomes overloaded, the product rate drops off, and eventually the mill plugs.

It is this direct relationship of power consumption per ton product to the product rate that makes it essential to establish either the mill capacity or optimum loading of the mill for each proposed test condition. Attempts to establish optimum mill loading by utilizing electronic sound analyzation to aid control of the lignite feed rate proved to be unsatisfactory,

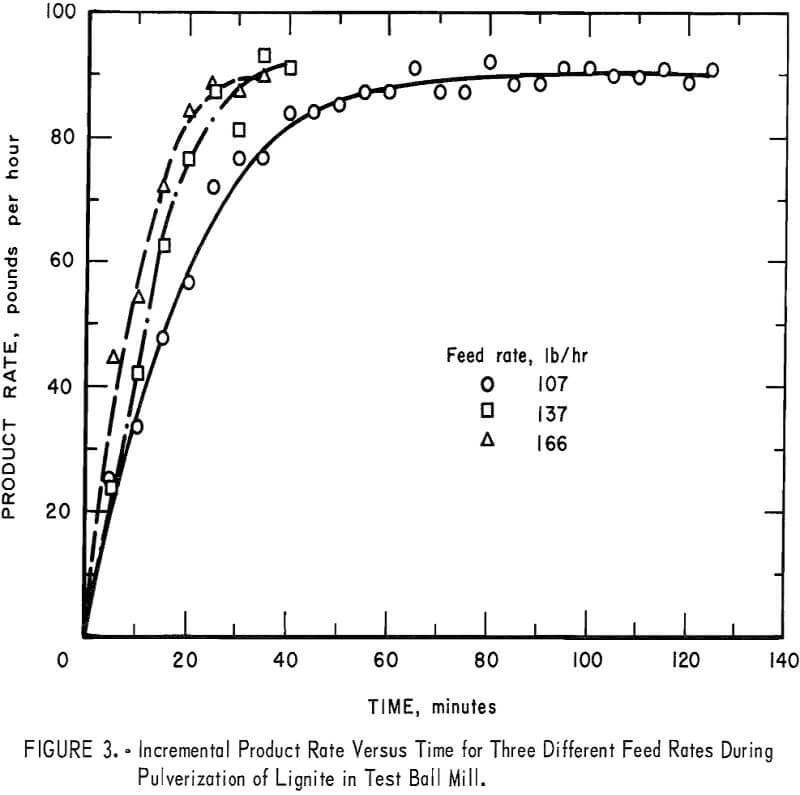

A method for determining the maximum product rate, or mill capacity, at any test condition was devised based on the operating characteristics mentioned previously. It entailed recording all data and weighing the pulverized product at 5-minute intervals after startup. The incremental product rate was then calculated and plotted versus time. When the incremental product rate was at a maximum, the mill was under optimum loading for that test condition. The value of this maximum product rate was not affected by the actual feed rate, provided that the feed rate was higher than that required to achieve optimum loading.

In the tests described, the feed rate was adjusted to a value anticipated to be somewhat higher than that required to achieve maximum product rate. Figure 3 shows the product rate increase versus time at three different feed rates. The maximum product rate obtained by the test procedure is essentially independent of feed rate. At the two higher feed rates, the mill exit plugged due to overloading almost immediately after peak capacity of 90 lb/hr was achieved. At the lower feed rate, mill operation continued at a product rate of 90 lb/hr indicating that it was reproducible and could be maintained if the proper feed rate was used. The feed rate is necessarily higher than the product rate primarily because of moisture loss and also because of dust loss which occurred in recovery of product.

The mill sweeping rate did not affect the maximum mill product rate within the capability range of the sweeping gas system. The minimum sweeping rate at which the mill could be operated was 6,800 cu ft/hr. Below this rate the horizontal mill exit plugged because the gas velocity was not sufficient to entrain the larger particles which entered the exit. Rate increases to 8,800 and 10,300 cu ft/hr (which was the maximum capacity of the equipment) did not change the product rate. A rate of 8,800 cu ft/hr (60° F, 14.7 psia) corresponding to an average mass flow rate of 672 lb/hr was used in all subsequent tests. The vacuum system which collected the product withdrew some gas through the oversize return line before it entered the ball mill. The system could not be altered to prevent this without undue difficulty; therefore, a correction was made in the measured sweeping gas flow rate to compensate for the amount withdrawn from the system by this means. The lignite was double screened to ½ by ¼ inch to eliminate feed size as a variable. For tests on dried lignite, the feed was crushed and sized after drying.

Test Results

As-mined lignite has a moisture content which may range from 35 to 40 percent. Particles are fibrous, resilient, and tough. As it loses moisture at particle surfaces, the exterior surface becomes brittle and particles spall off without application of physical force in the process termed “slacking.” This structural weakening of lignite is beneficial in pulverization if the lignite is dried either before or during grinding.

Drying lignite before grinding has several potential advantages, one of which is to remove water which, when introduced into the combustion chamber, must be heated and is ultimately discharged at stack exit temperatures. It has not, however, been found economically justifiable by industrial users to date. Nearly all powerplants with pc-fired boilers utilize in the mill drying in which the mill sweeping gas is heated to 600° to 700° F before it is introduced into the mills. This procedure accomplishes lignite drying simultaneous with the grinding and thereby takes advantage of the resulting power reduction.

Influence of Initial Moisture Content of Lignite

To study the effect of drying lignite before grinding, samples of lignite were obtained from the Kincaid mine, Truax-Traer Corp., Columbus, N. Dak., and the Baukol-Noonan mine, Baukol-Noonan, Inc., Noonan, N. Dak. Quantities of lignite from each mine were dried to various moisture contents and then prepared to size before testing in the ball mill.

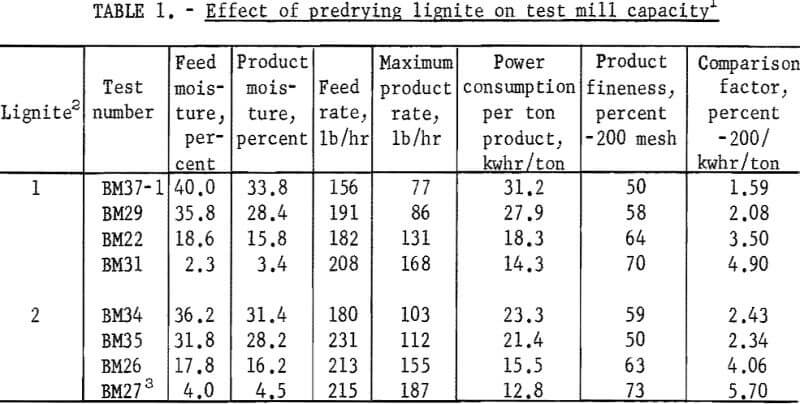

Data and results for tests at different moisture contents are given in table 1. The maximum product rate for both lignites increased markedly as the feed moisture decreased–nearly doubling when the moisture content was reduced to the very low levels of 2-4 percent. This increase in capacity is highly significant when power consumption per ton product is compared. The power required per ton of product dropped from 31.2 and 23.3 kwhr to 14.3 and 12.8 kwhr for lignites 1 and 2, respectively, when they were dried from the raw or as-mined condition to almost bone dry.

The product fineness increased with decreasing moisture content for both lignites. The percent of product passing through a 200-mesh sieve divided by the kwhr/ton of product power input is an empirical method used to compare the power requirements and to account for variation in fineness between tests. This computed factor has been termed the “comparison factor” and is given for each test in table 1. When test results are compared on this basis, the effects of drying prior to grinding are even more pronounced, showing a three-fold improvement for lignite 1 and better than a two-fold improvement for lignite 2.

Air at room temperature was used as sweeping gas in these tests. Despite temperatures which ranged from 70° to 78° F, the lignite moisture content was reduced to some extent in all tests, with the exception of the tests on very low moisture content lignite. In these tests, BM31 and BM27, the lignite gained moisture on exposure to air during the grinding. At similar feed moisture contents, the test ball mill performed significantly better on lignite 2 than on lignite 1. This variation in capacity as a function of the lignite source was investigated as another variable and is discussed in a later section.

For tests BM27 of lignite 2, a smaller bottom screen size had to be used to obtain enough lignite for a test; however, this difference in feed size did not affect the results.

In-The-Mill Drying

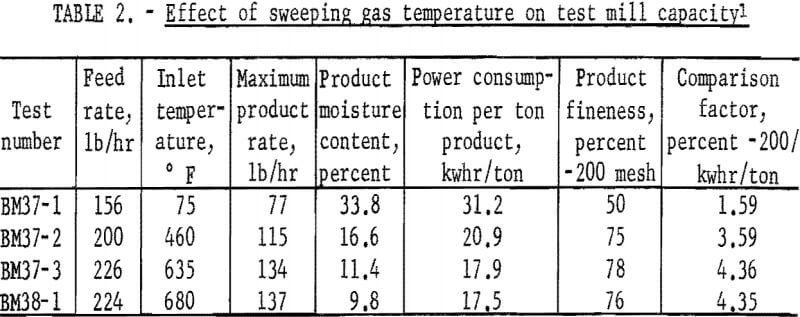

The effect of in-the-mill drying on pulverization of lignite in the ball mill was studied on a sample of lignite from the Kincaid mine, Truax-Traer Corp., Columbus, N. Dak. A series of tests was performed on this lignite, prepared to ½ by ¼ inch size, in which the sweeping gas temperature to the test mill was varied to obtain different degrees of drying during pulverization. The sweeping gas mass flow rate was kept constant at 672 lb/hr corresponding to that used in previous tests. Data and results are given in table 2.

With in-the-mill drying the maximum product rate could be nearly doubled, from 77 to 137 lb/hr, when the sweeping gas temperature was increased from 75° to 680° F. In addition to this capacity increase, the product moisture content was reduced to 9.8 percent from its initial moisture content of 40.0 percent.

As in the tests on pre-dried lignite, the product fineness increased as the product moisture decreased. There was almost a three-fold increase in the comparison factor, and power consumption per ton of product was reduced by almost one-half.

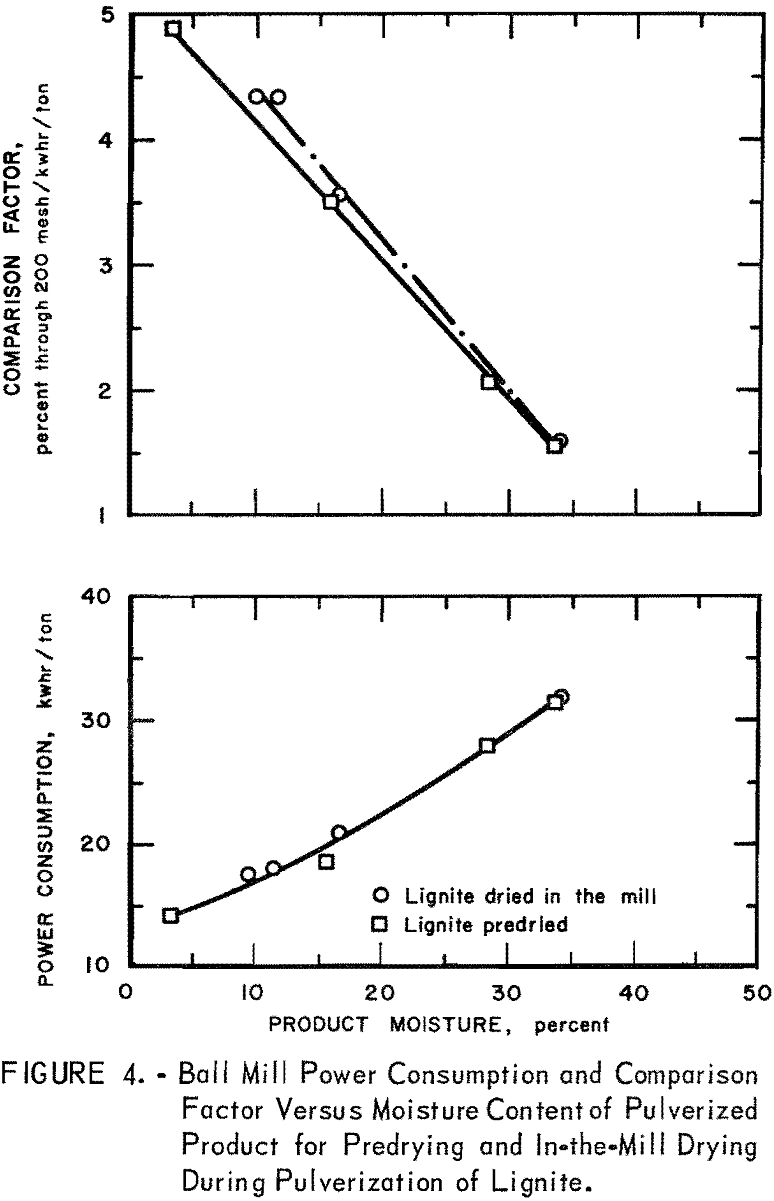

The effect of predrying lignite is compared to in-the-mill drying in figure 4. At the same product moisture, the power consumption per kwhr is nearly identical for the two methods of grinding. However, when product fineness is accounted for, as it is in the computed comparison factor, in-the-mill drying has a slight advantage over predrying.

Lignite Source

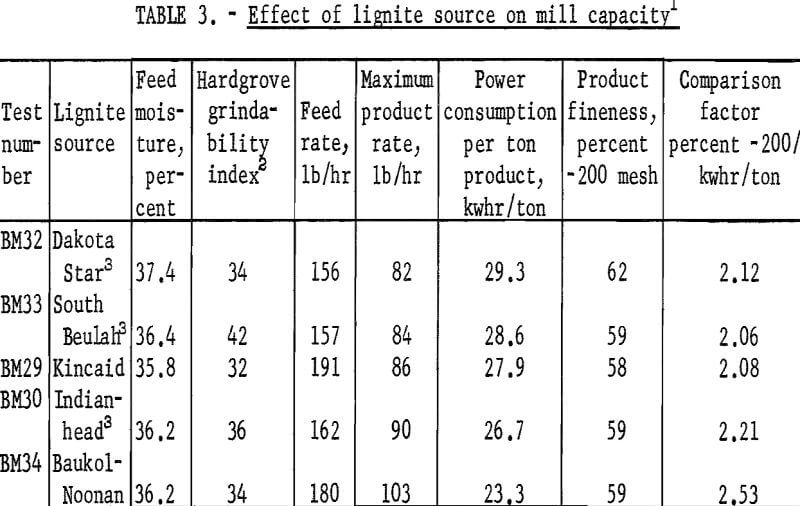

Previous work on lignite indicated a significant variation in grindability for lignites from different mines. To determine whether these differences have a correspondence to the performance of a ball mill, lignite for testing was obtained from five of the larger commercial mines in North Dakota. In these comparison tests, the maximum mill capacity for each lignite was determined.

The lignites, sized to ½ by ¼ inch size, were tested at as-received moisture content. Air at room temperature was used to sweep the mill at the mass flow rate of 672 lb/hr, as in previous tests. Moisture content of pulverized product was not determined, but the drying which occurred during pulverization would be comparable to the previously described tests series conducted under similar conditions. Data and results from these comparison tests are given in table 3.

The maximum product rate obtained for the different lignites ranged from a low of 82 to a high of 103 lb/hr. Product fineness was nearly the same for all five lignites but power consumption per ton for each lignite reflects the difference in capacity for the different lignites.

A number of methods were attempted to relate the differences in grinding characteristics of the lignites in the ball mill to other physical tests or observations. The Hardgrove grindability index was determined on samples of each lignite according to ASTM Standard Test 409-51 at a sample moisture

content of about 15 percent. There does not appear to be a relationship between capacity or comparison factor for pulverization in a ball mill and the Hardgrove grindability index determined by the standard method. If the Hardgrove index is to be used to predict pulverization of lignite in a ball mill; a much more extensive background of data should be accumulated.

It was observed also that although all five lignites were of the same feed size and the auger feeder rotation rate was nearly identical for each test, the feed rate obtained by measurement of weight per unit time varied from 156 to 191 lb/hr for the different lignites. This would indicate a difference in flow characteristics or shape factor, but it does not seem to be directly related to the mill capacity or to the Hardgrove grindability index.

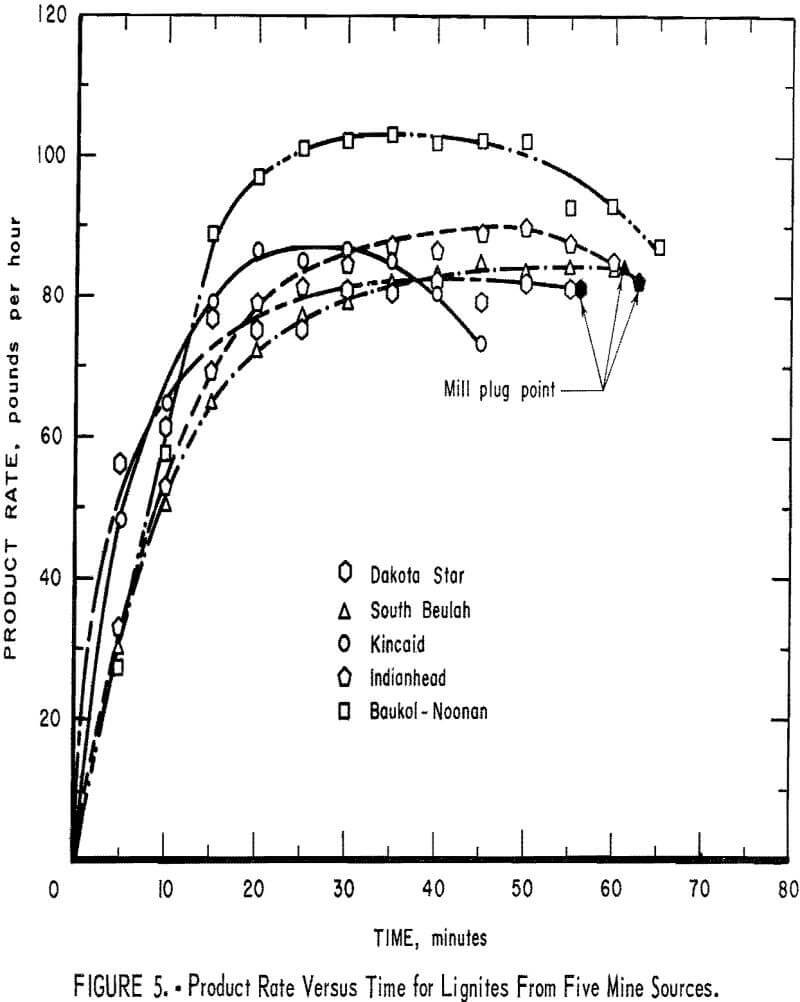

The difference between lignites is pronounced also when the variation of product rate with time is studied. Product rate for each lignite is plotted versus time in figure 5. When operating on lignite from the Kincaid mine, the mill rapidly reached optimum loading and very quickly became overloaded. For the other four lignites, the buildup was slower and the time over which they maintained the maximum product rate was more extended. For lignites from the Indianhead and Baukol-Noonan mines, the product rate dropped off after overloading. For lignites from the Dakota Star and South Beulah mines, the mill became plugged before noticeable product rate drop occurred. The rate of lignite accumulation in the grinding circuit is nearly identical for all lignites with the exception of Kincaid lignite, but this in itself does not account for the variation in mill performance near optimum loading. The most desirable operating curve is one in which the maximum product rate is maintained for an extended period followed by a sharp drop in product rate before plugging, as an aid to detecting mill overloading.

Comparison of Results to Pulverization in a Test Hammermill

Many factors are involved in comparing pulverization in one type of mill to another. This is particularly true for lignite pulverization during which drying almost always occurs, and because pulverization characteristics are so directly related to moisture content. Moisture content of lignite was a principal variable in tests conducted in both the ball mill and the hammermill but the drying which occurred in one is not exactly duplicated in the other. A second consideration is that lignite was tested from the same mine source in each mill, but samples for the hammermill tests were collected several years prior to those used in the ball mill tests. In this time interval, the individual mine operations undoubtedly moved some distance from the point of first sampling and the inherent variability of a lignite within a mine also detracts from the value of a comparison.

When pulverizing lignite of as-received moisture content, with both mills loaded to capacity and with room air sweeping the mill, the comparison factors for both types of mills are surprisingly comparable. For the five lignites tested in the ball mill, the comparison factor ranged from about 2.1 to 2.5 compared to a range of 1.9 to 2.3 for four of these lignites in hammermill pulverization. The one significant exception is the lignite from the Indian-head mine with a comparison factor of 1.3.

The kwhr/ton requirement in pulverization which has no correction for differences in fineness produced, ranged from 23.3 to 29.3 for the ball mill and from 23.0 to 38.0 kwhr/ton for the hammermill. Pulverization of the lignite from the Indianhead mine in the hammermill is again the exception; this required 46.0 kwhr/ton. There is good evidence that the pulverizing characteristics of the two samples collected from the Indianhead mine demonstrate the wide variation which may be encountered in lignite from the same mine sources.

When Kincaid lignite was pulverized utilizing in-the-mill drying at product moisture content in the range of 11 to 12 percent, the comparison factor was 4.4 for pulverization in the ball mill and 4.5 in the hammermill. Power requirements at these conditions were 17.9 kwhr/ton in the ball mill and about 17 kwhr/ton in the hammermill. There is no practical difference between the two mills compared on this basis during operation with in-the-mill drying. A comparison of pulverization of predried lignite in both mills cannot be made because the tests in the hammermill were not performed at its capacity loading.

The range of values for power consumption and the comparison factor is greater for the hammermill than for the ball mill indicating that the hammermill type of mill is more sensitive to variations in the feed than is the ball mill. Despite factors which tend to restrict the value of this comparison, the test data indicates that in both types of mills the power requirements to produce minus 200-mesh product are very similar and no distinct advantage can be attributed to one method over the other.