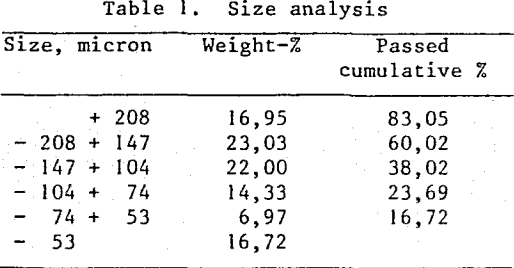

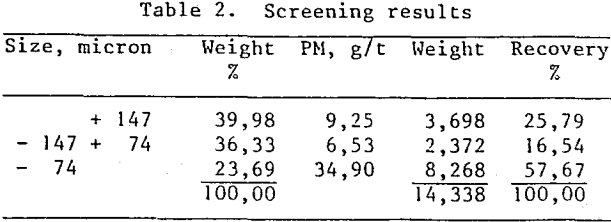

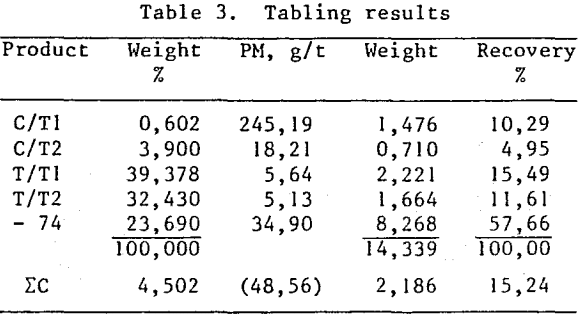

Tailings originating from the gravity concentration of a gold ore containing about 14 g/t Au have been treated by various beneficiation methods. These tailings have been screened on the 147 and 74 micron sieves and the two coarsest fractions have been separated on shaking tables with unsatisfactory results, but the concentrates have been examined in polished sections for mineragraphic analysis.

Five elements only have been assayed, with the following results:

SiO2 81,56 % Ti 1,45 % PM 14 g/t Fe 4,3 % S 0,28 %

Gold is sometimes free, in small grains of 5-6 microns, and sometimes associated with quartz pyrite, hematite and goethite, in tiny spots of about 1 micron size. Other associations include pyrite embodied in quartz, and martitisation patterns where magnetite is replaced by hematite.

A preliminary test has been carried out on a superpanner, on the tailings as such, and it has shown that the concentrates consist mainly of coarse particles containing mixed grains of gold and quartz, iron oxides and some tiny grains of gold and pyrite; however, very small grains of gold are entrained with the slimes into the residue.

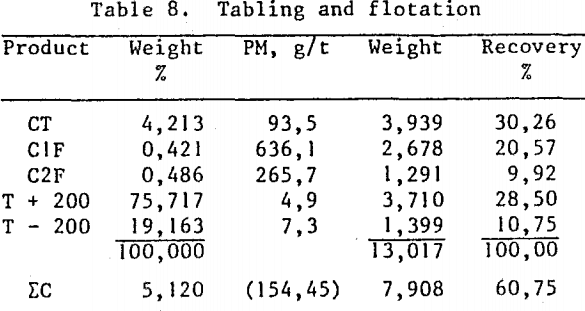

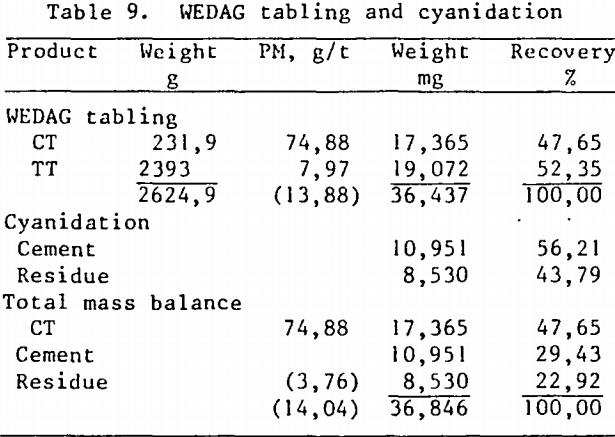

The shaking table used for the two tests is a WEDAG table, that has no riffles, but grooves along the length of the deck. The table concentrate has been further treated on a superpanner, and the superpanner middlings have been directly recycled during the test.

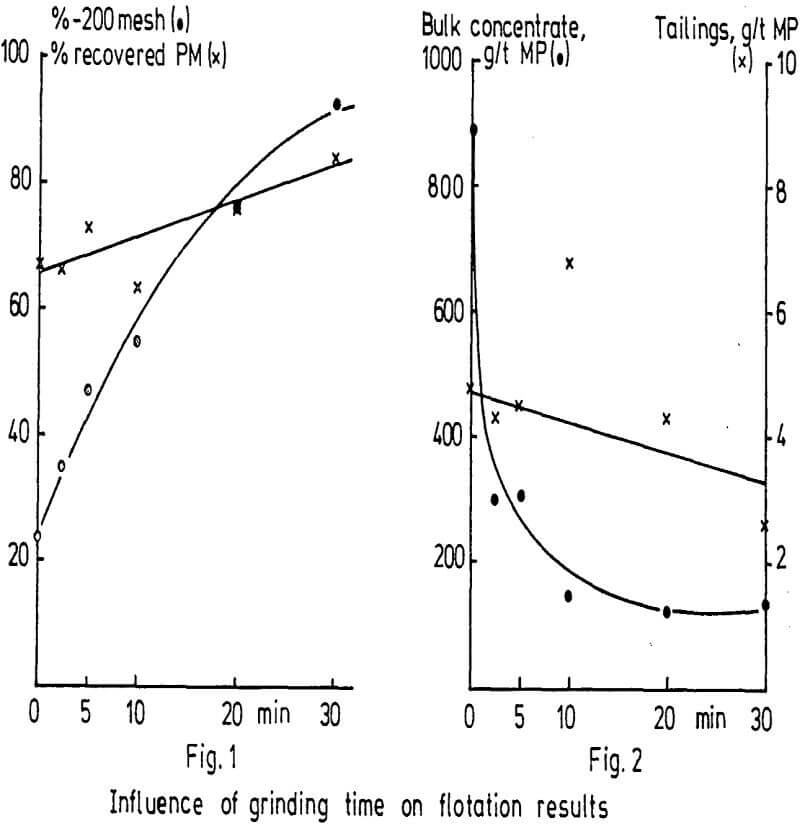

A systematic study of the grinding time ahead of flotation has been carried out, and the flotation tailings have been wet screened on the 200 mesh sieve and assayed separately.

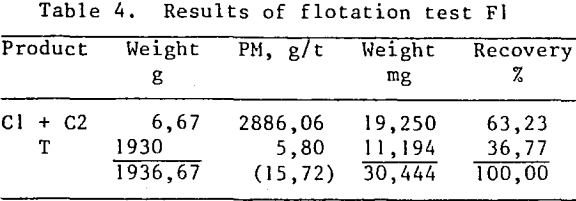

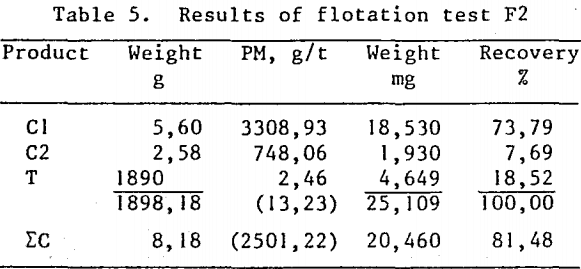

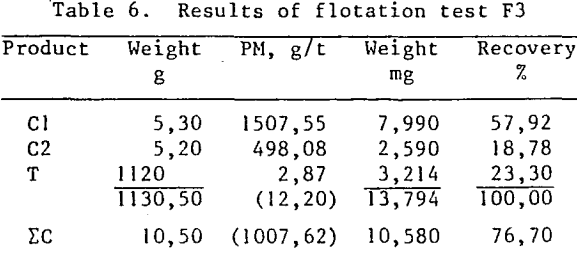

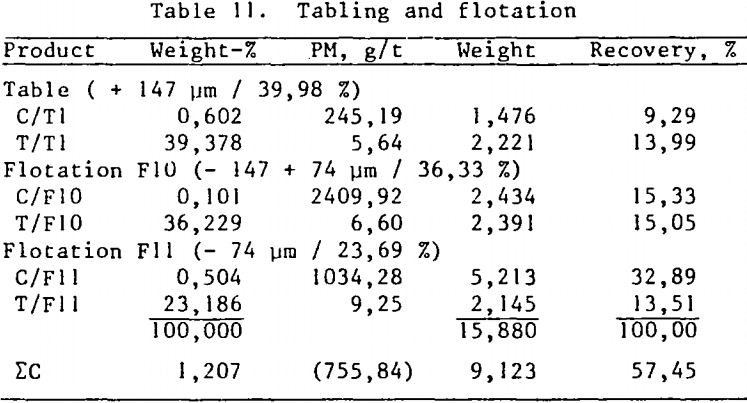

In order to recover the gold content of the table residues, shown here above to be too rich to be discarded, they have been floated as such at natural pH, using Aerofloat 208 as promoter.

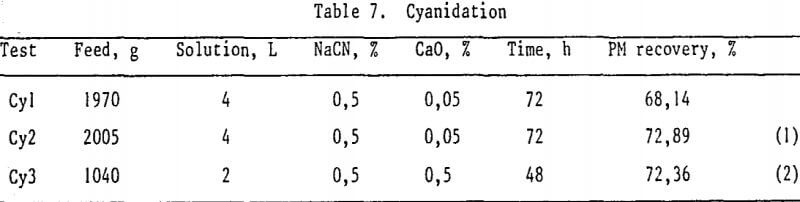

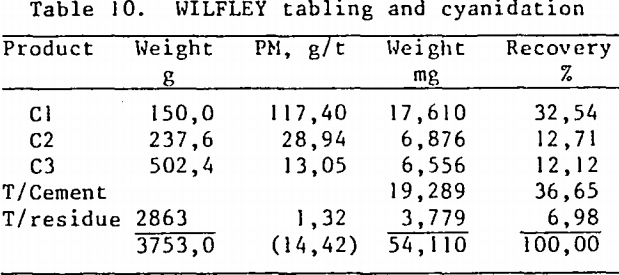

Another possible process to recover the gold lost in the table residues is cyanidation.

A sample of the tailings of flotation test F9, containing 2,63 g/t PM and 96.3% – 200 mesh, has been cyanided in a solution containing 10 %, solids, 0,5 % NaCN and 0,5 % CaO.