Table of Contents

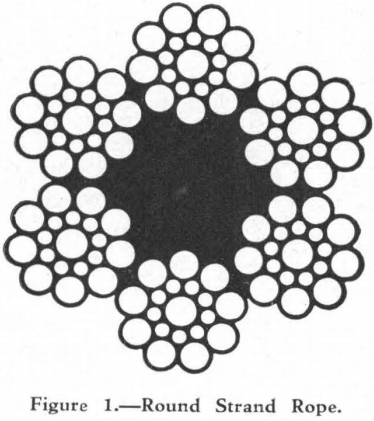

Four basic designs of ropes are now employed for hoisting duties:

- Six-strand, round strand ropes with fibre cores.

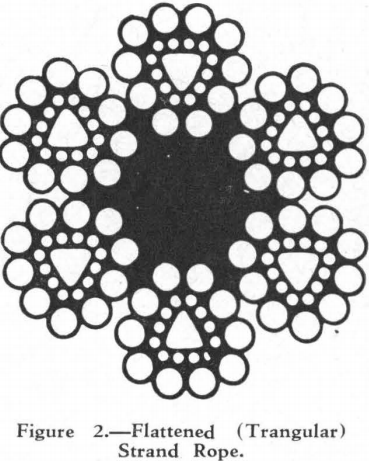

- Six-strand, triangular strand ropes with fibre cores.

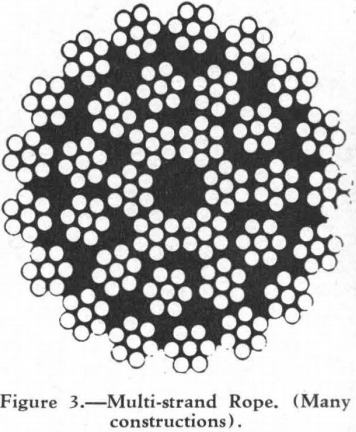

- Non-rotating, multi-strand ropes.

- Locked coil ropes.

Very solid and reliable ropes can be obtained with this simple geometric design of strand.

Owing to the fact that the wires in the strands are bent over a triangle, they do not seat quite so solidly as when they are bent over a circular core wire, as is the case with round strand ropes. Therefore, secondary bending stresses, imposed by compressive forces, can play an important part in the deterioration of this type of rope. Triangular strand ropes are most suitable where practical conditions demand relatively low factors of safety with high compressive forces. The effective surface area developed with this type of rope is much larger than that obtained with a round strand rope. This makes them more suitable for multi-layer coiling on drum hoists.

General Characteristics of Six-Stranded Ropes

The modulus of elasticity, Et, is dependent upon the size of the rope and its construction. The mean values for settled ropes are:

Small ropes — simple strand construction: E = 9,000,000 lbs./in.²

Large ropes — compound strand construction: E = 8,000,000 lbs./in.²

Two or more layers of strand are employed with this type of rope, the layers being laid in opposite directions to obtain non-rotating properties under normal loading conditions. Many designs have been tried. They have been fabricated with combinations of round, oval and triangular strands.

The modulus of elasticity of this type of rope varies from 7,000,000 to 9,000,000 lbs./in.²

This type of rope is now becoming generally accepted for both drum and friction hoists.

Owing to its simple and natural geometric construction, a very solid, yet sufficiently flexible, rope can be obtained. Its very large effective surface area means that relatively high surface pressures can be imposed without affecting the structure. This makes the rope very suitable for multi-layer coiling drums and friction hoists.

The modulus of elasticity of locked coil ropes is 14,000,000 lbs./ in.²

Hoists

Generally speaking, three types of hoists are employed for shaft use:

- Parallel drums, onto which ropes are coiled in either one or several layers.

- Koepe or friction drives, employing either a single rope or several ropes in parallel — up to eight are employed at the present time.

- The bi-cylindro-conical drum, used, however, to an ever decreasing extent.

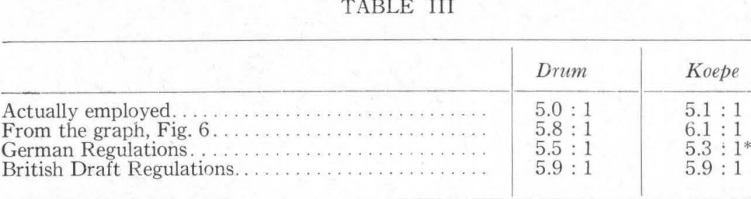

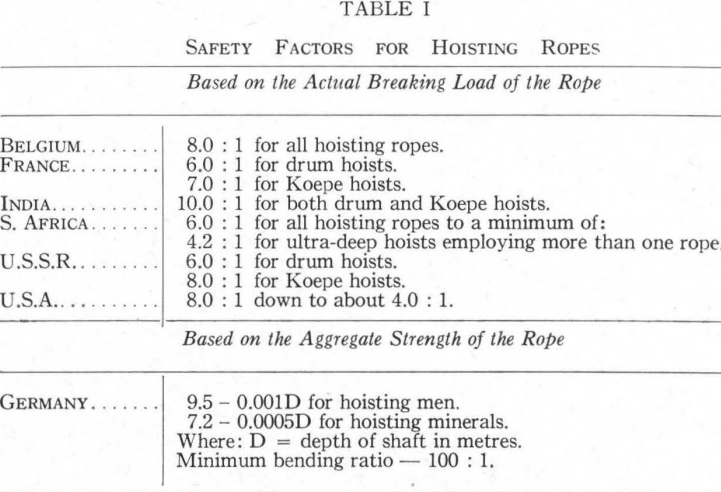

Government regulations relating to the use of wire ropes for hoisting duties demand various minimum safety factors. Some of these factors are based on the actual breaking load of ropes; others are based on their aggregate strength or on the summated tensile strength of the wires.

Basing the factor of safety on the aggregate strength of a rope enables the employment of additional clauses with regard to the permitted number of broken outer wires which can exist in a rope before it must be taken out of service. German regulations state, in effect, that a rope shall be discarded when the total number of visible broken outer wires in (a) a 4-metre length, or (b) a 1-metre length multiplied by 4, reduces a rope’s aggregate strength to less than 85 per cent of the calculated minimum for a given depth of shaft.

Without a doubt, the new German regulations are a step in the right direction. They act not only as a guide as to when a rope should be removed, due to the development of broken outer wires, but also permit the use of lower safety factors as shafts increase in depth.

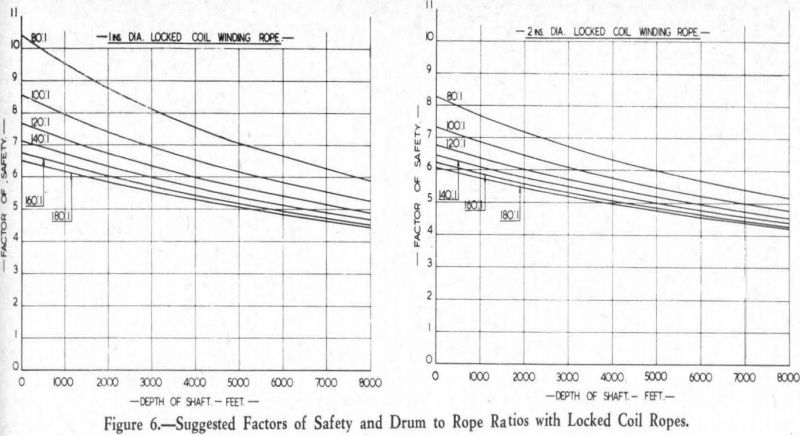

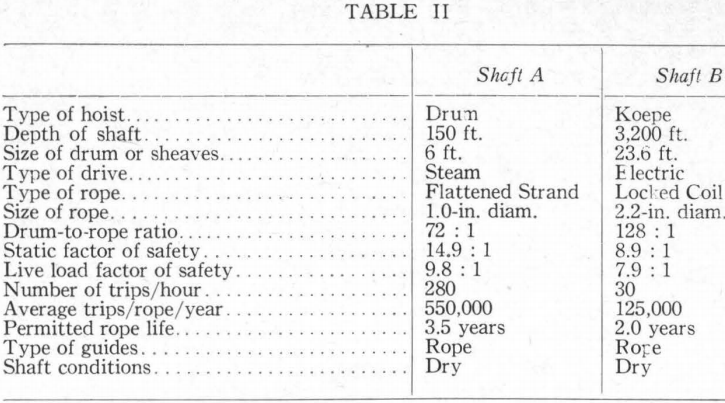

Factors of Safety and Bending Ratio Relationships

Based on the assumption that a suitable type and size of rope is employed on a hoisting installation, where the effects of adverse mechanical and corrosive reactions are negligible, the life of a rope is mainly dependent upon the safety factor and the bending ratio relationship. Within reason, ropes operating with very high factors of safety and low bending ratios will deteriorate far

more rapidly than those, with lower safety factors and higher bending ratios.

This is due to the fact that secondary bending stresses can play a most important part in inducing fatigue into the steel, and in the resultant fracturing of the wires. Unless ropes are reasonably tensioned, the wires do not settle into a solid unit. This is due to inherent manufacturing stresses which tend to lift the wires off the central cores. Therefore, the lower the applied tension and bending ratio the greater the reactive effects of the compressive forces inducing secondary bending stresses in the wires. On many installations, rope lives have been considerably increased by simply reducing the size of a given construction of rope and thus producing a more compact and solid unit. In some cases, however, the steel tensiles have been increased for no other reason than to conform with the local minimum safety factor regulations.

Drum to Hope Diameter Ratio

For main shaft hoists, where long and expensive ropes are employed, it is advisable to have bending ratios of not less than 100:1. For shallow shafts, employing smaller and shorter ropes, quite economical rope lives are obtained with ratios of about 80:1. For friction and Koepe hoists, the bending ratio should not be less than 80:1 for small ropes, and 100:1 for large ropes. For small underground shafts, where excavations are costly and the ropes are relatively short, very economical conditions can be obtained with bending ratios as low as, or even less than, 50:1. Such ratios, in fact, are quite common. Naturally, owing to the high frequency of hoisting with these shallow installations, the number of trips obtained from a rope is a factor which must be considered, rather than the length of time the rope remains in service. On these installations, the most economical rope lives are obtained with safety factors in the vicinity of 11.0:1.