“Rotary percussion” implies two types of energy, rotary and percussion. Into these categories fall rock drills of varying sizes. The larger ones drill above 6″ diameter holes; the medium size, 2 ¾-” to 4 ½” holes; and the smallest, 1 ¼” to 2″ holes.

Essentially, the larger holes are drilled with down-the-hole drills using tri-cone bits. Percussion energy evolves from the drill piston and rotation power from the rotary table or overhead drive, using drill collars or pull down mechanism to preload the bit.

Medium size holes are drilled with drifter type percussion units without rifle bar, but having air motor drive for rotation. Conventional style tungsten carbide insert bits are employed regardless of rock classification. The extent to which rotary percussion techniques are used is related to the availability of adequate torque, which is low by comparison in air powered rotary motors. Preloading is therefore low to prevent rotational stalling.

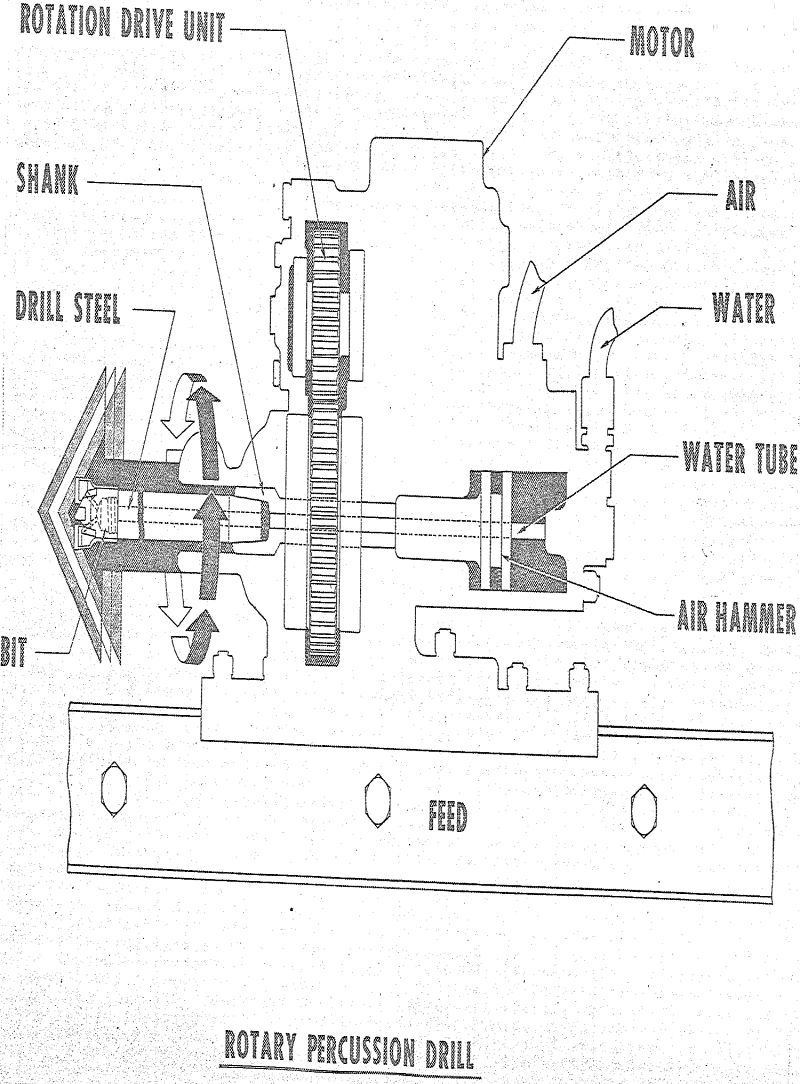

Small holes, primarily for underground mining and tunneling, are drilled by units consisting of air percussion hammers having hydraulic powered rotation and air powered feed mechanism. Each function is independently controlled — force of blow by air pressure to the hammer, rotational torque by hydraulic pressure and volume to the hydraulic motor, and preload by air pressure to the feed mechanism. This small hole type machine is the subject of the following discussion — Why, When, and Where.

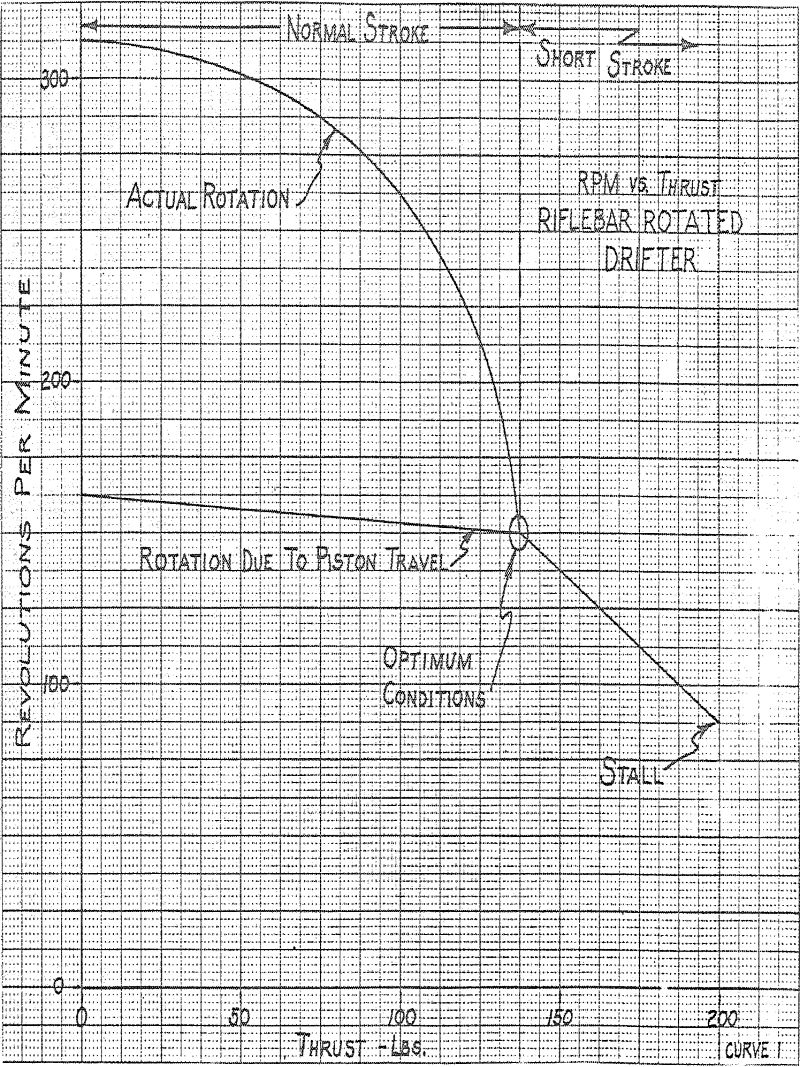

Having a given mass and constant air pressure, the energy available is constant. The requirements are a much different story. Preload on the bit and frictional losses of rotating parts vary continuously as a result of bottom hole variation and viscosity of lubricant. At any instant torque requirements may be less than that available, allowing the rotational parts to revolve at a greater speed than the piston stroke along the rifle bar provides, due to imparted rotational inertia.

On the other hand, excessive preload will require more torque than the oscillating mass can provide. This results in less than normal length traveled by the piston along the helical spline. As a result of changing rotational requirements, the piston has a changing working stroke. It then becomes apparent that the impulse developed by the reciprocating mass varies for each blow. Varying distances traveled by the mass result in changing time per stroke which controls the velocity of the mass at the time of impact.

With all three fundamental functions — preload, torque, and impulse — changing continually, it is impossible to obtain maximum drilling performance. Evidence is shown by curve 1 that only one condition without latitude is optimum. It is impossible to maintain this ideal condition in actual mining practice.