Table of Contents

The Bureau of Mines undertook a study of recovery of precious metal values from surplus and obsolete electronic gear as a part of its continuing effort to achieve maximum use and conservation of natural resources. During the early phase of the study it was learned that some military aircraft contained significant quantities of silver as part of honeycomb structures.

The obsolete B-58 bomber, shown in figure 1, was reported to contain over 300 pounds of silver. The silver is found in silver-brazed stainless steel honeycomb panels distributed over the surface of the airplane. These panels are found primarily on control surfaces and those surfaces exposed to high temperatures. The surfaces are composed of many, varied-shaped panels which constitute the elevons, portions of the tail assembly, engine pylons, and engine nacelles. Later on, it was learned that similar silver-brazed honeycomb structures were found in other aircraft; for example, the C-141 flame

cone assembly and the F-4 horizontal stabilator (stabilator is an aeronautical term derived from the words stabilizer and elevator). It was also reported that silver-brazed structures were used in the B-70, the Apollo command module, and the engine shrouds of some jet aircraft, for example, the 707.

The initial investigative approach was a liquid metal leach of the silver component with cadmium or zinc with subsequent separation of silver from the molten mixture. During exploratory tests, it was found that some of the stainless steel component was badly attacked and hazardous vapors were evolved. An electrolytic method was considered when a review of silver refining practices showed that stainless steel parts were used in the construction of the electrorefining cell. Commercially, silver is refined from Dore anodes in either a Moebius-type or a Balbach-Thum-type cell. These systems are well known and highly developed. Only a brief description will be given here.

Dore metal, derived primarily from electrolytic copper slimes, assays 94.5 to 98.6 percent silver, 1.0 to 5.0 percent gold, and 0.3 to 1.2 percent copper. The metal is cast into anodes for use in either the Moebius or Balbach-Thum cell. The Balbach-Thum cell differs from the Moebius, in addition to the method of construction, in that it can accept a lower grade anode. This may be any refinable metal whose silver content exceeds 75 percent.

In Moebius cell the anodes, enclosed in filter bags, are suspended vertically in an electrolytic cell. The electrolyte, through which the silver is transported, is composed of an aqueous solution of silver nitrate and copper nitrate. Wooden wiper blades scrape the silver crystals deposited during electrolysis from a vertical stainless steel cathode. The silver falls to the bottom of the cell and is collected periodically. The anodes in the Balbach-Thum cell are placed in a basket lined with filter cloth. The basket is suspended so that the anodes are horizontal and parallel to either a carbon or a stainless steel cathode. The silver is electrolytically deposited using the same electrolyte as the Moebius cell. The silver crystals are scraped periodically from the cell.

Although the Moebius and Thum cells could be modified to recover silver from the honeycomb material, neither would be satisfactory to accomplish this operation. This would be due to several factors. First, the anode volume in the Moebius and Thum cells ranges from 1.5 to 3 percent of the total cells volume. Second, the bulk density of the cast Dore anode with its average silver content of 95 percent would be 10.7 grams per cubic centimeter. Last, both cells lack a means of vigorous electrolyte circulation. Comparing the Dore anode with the shredded honeycomb anode, the shredded honeycomb has an average silver content of 10 percent, a bulk density of 0.6 gram per cubic centimeter, and the path for silver travel between the anode and cathode would involve a maze of inert stainless steel. A special cell was therefore designed and constructed to permit electrolyte recovery of silver from the shredded honeycomb scrap within these constraints,

Description of Materials and Equipment

Honeycomb Panels

Silver-bearing panels from two complete B-58 aircraft were supplied by the Department of Defense under a memorandum of agreement with the Bureau of Mines. The panels ranged in size from approximately 12 inches square to 73 by 75 inches and weights ranged from 5 to 222 pounds. The larger pieces constituted complete eleven sections which in turn were made up of smaller panels attached to supporting ribs. Owing to the size limitations imposed by some of the processing equipment used in these studies, it became necessary to disassemble the elevens into the smaller individual panels. Some of the panels had to be sawed to smaller sizes before further processing. On a commercial scale, all of the pieces, with the exception of a heavy titanium forging, used a pivotal hinge for the eleven, could be sheared to a size suitable for feed to a shredder.

The panels were constructed in sandwich-like fashion with a honeycomb core between two sheets of stainless steel, as shown in figure 2. The steel alloy was a magnetic material of the type 17-7 PH martensitic stainless steel. One of these sheets served as the outer skin of the panel, that is, the one exposed directly to the atmospheric environment. The other formed the interior surface of the aircraft structure. Edges of the panels were formed and strengthened by laminating with additional strips of stainless steel. The two stainless steel sheets were joined to the honeycomb core using a silver brazing alloy which was found to have the approximate composition of sterling silver (92.5 percent silver, 7.5 percent copper). The strips forming the laminated edges were also brazed with this silver alloy. Interior sheets of the honeycomb sandwich measured approximately 12 mils (0.3 mm) and were generally the same thickness or thinner than the outside sheets whose thickness ranged from 12 to 53 mils (0.3 to 1.3 mm). The actual cellular honeycomb structure varied in thickness from 1/8 inch to 2½ inches (3.2 to 63.5 mm).

A sample of the flame cone assembly from a jet engine of the C-141 aircraft was also supplied by the Department of Defense. The material had been sheared into approximately 4-inch-square pieces before shipment to the Bureau of Mines. The construction appeared similar to that of the B-58 panels. Both of the covering sheets were 23 mils (0.58 mm) thick. The edge was one solid piece rather than laminated as in the B-58. One of the covering sheets had been machine welded along its edge to the solid piece, while the other edge was joined only by silver brazing. The sample pieces were uniformly ¼ inch (6.4 mm) thick.

Electrolytic Cells

Initial tests were conducted in the 200-ml rectangular glass cell shown in figure 3. One electrode which served as an anode consisted of a rectangular basket packed with shredded honeycomb. The basked, measuring ½ inch

thick by 1¾ inches wide and 3½ inches high, was formed from 30-mesh stainless steel screen. The height was sufficient to both contain the honeycomb charge and extend above the electrolyte surface. An extension of the sides of the basket served as a handle and also provided for the electrical contact. The other electrode, functioning as the cathode, was prepared from a 1- by 5-inch strip of stainless steel. This electrode was masked with pressure-sensitive vinyl electroplating tape to expose an area of 1 square inch (0.0069 square foot) to electrolytic action. The loosely adhering dendritic silver product is also visible in figure 3.

thick by 1¾ inches wide and 3½ inches high, was formed from 30-mesh stainless steel screen. The height was sufficient to both contain the honeycomb charge and extend above the electrolyte surface. An extension of the sides of the basket served as a handle and also provided for the electrical contact. The other electrode, functioning as the cathode, was prepared from a 1- by 5-inch strip of stainless steel. This electrode was masked with pressure-sensitive vinyl electroplating tape to expose an area of 1 square inch (0.0069 square foot) to electrolytic action. The loosely adhering dendritic silver product is also visible in figure 3.

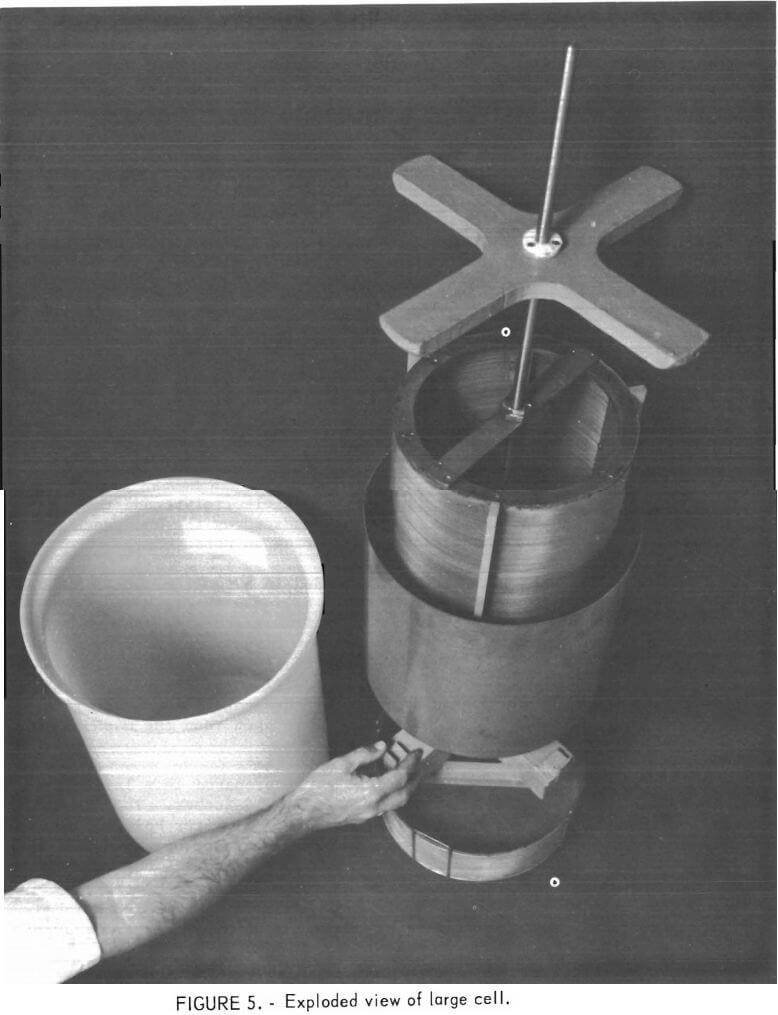

The large cell (3), shown schematically in figure 4, was made from a 10-gallon cylindrical linear polyethylene tank. The cylindrical anode basket, which contained the shredded honeycomb, was fabricated from a cylindrical stainless steel framing and covered with a stainless steel screen. The anode basket measured 10-3/8 inches ID by 12½ inches high. A central shaft of stainless steel provided rotation to the basket as well as electrical contact. Three ¾-inch epoxy-coated wooden blades were placed vertically on the outer surface of the basket to continually dislodge silver dendrites and prevent electrical short circuits. The basket was surrounded by a cylindrical stainless steel sheet, 12-3/8 inches ID and 12 inches high, which served as the cathode. The electrodes rested on an epoxy-coated wooden base inside a smaller stainless steel basket. This basket, measuring 12-3/8 inches ID by 4 inches high, caught the silver crystals scraped from the cathode. The entire assembly was contained in the 10-gallon linear polyethylene tank. An exploded view of the parts is shown in figure 5.

During the course of the investigation, the solid central shaft was replaced by a hollow one to promote better circulation of the electrolyte through the honeycomb charge. In order to accomplish this, a stainless steel tube was equipped with a rotary gland fitting made from a modified compression type tee. The standard compression elements were replaced with Teflon

sleeves, which served as seals and bearing surfaces. Recirculating electrolyte entered the hollow shaft through the tee and was discharged throughout the honeycomb charge via radially drilled holes.

Power Supplies

Direct current for the preliminary electrolytic tests was supplied by a laboratory-size rectifier with a filtered output of 0 to 7.5 volts and 0 to 3 amperes. For the major portion of the investigations, the dc power supply was a modified full-wave bridge rectifier supplied by the Department of Defense. The original unit had a rated dc output of 200 amperes at 28 volts from an ac input of 208 volts, 3 phase. The no-load voltage of approximately 20 volts was too high for operation of a single electrolyte cell with an expected maximum requirement of 5 volts dc. By using ganged variable autotransformers in the ac input circuit in place of the tap switch, it was possible to obtain a continuously variable dc output from 0 to 28 volts and 0 to 200 amperes,

Preelectrolysis Preparation of Honeycomb Panels

Shredding of Honeycomb Panels

The sandwich-like honeycomb panels had their interior surfaces sealed off from the surrounding environment. The major portion of the silver was located where the cellular honeycomb structure was actually joined to the covering sheets. To promote anodic dissolution of silver from the brazed joints, it was necessary to have intimate contact between the electrolyte and the silver-rich joints. This contact was made possible by shredding the honeycomb panels in a hammer mill as a preliminary step in preparing an anode charge.

The first samples of honeycomb were shredded in a small hammer mill designed for treating ore samples. This mill, having a throat measuring 8 by 6 inches, was equipped with a swinging yoke hammer and a grate with ½- inch-diameter holes. The panels were prepared by first removing the reinforced laminated edges and then sawing the inner core into a size suitable for feed to the shredder. The mill was later modified to use swinging knifelike hammers in place of the yoke. The primary advantage of the knifelike hammers was that the shredded pieces remained more open than the mashed material produced with yoke type.

Additional samples of shredded honeycomb were prepared in a larger mill using swinging hammers and having a throat of 13 by 13 inches. The grate for this mill was either a punched plate with 1¼-inch-diameter holes or a trapezoidal bar-grate with 1-inch slots. Little difference was observed between the material from the punched plate or the bar grate. However, the larger mill was able to accept the reinforced laminated edges and in many instances open up the brazed joints of the laminations. Typical hammer mill product is shown in figure 6. Also noted in the figure are the brazed joints with the honeycomb pattern.

Sampling Honeycomb for Analysis

A major problem encountered with the honeycomb panels was obtaining representative samples for analysis. Silver appeared to be more highly concentrated at the brazed interfaces rather than uniformly distributed throughout the honeycomb core. Distribution of the silver alloy did appear to be uniform over the laminated edges. However, these edges, owing to the bulk of stainless steel, differed in silver concentration from the honeycomb core and even from each other depending on whether the construction was from three or four layers. Shredding produced pieces of varying sizes and shapes, resulting in an even more heterogeneous mixture.

Some of the variability of silver concentration in the honeycomb panels was shown from analytical results of samples submitted by the Department of Defense to other agencies. Two samples, each measuring 6 by 6 by 11/16 inches, were reported by the Bureau of Mines, Salt Lake City Research Center, to  contain 9.9 and 21.1 percent silver. The variation in results appeared to originate from differences in the skin thickness of the samples. Because of this, Salt Lake City personnel suggested that silver composition based on panel area was a more reliable figure and reported 4.42 and 4.20 troy ounces per square foot, respectively. They also analyzed the panel flanges, which consisted of four stainless steel sheets joined by silver brazing. A flange described only as being wide contained 0.21 troy ounce of silver per running foot, while a narrow flange contained 0.12 troy ounce of silver. Two honeycomb panel sections, each measuring 6 by 6 by ¾ inches, were analyzed by the New York Assay Office. One of these, designated as “heavy,” contained 3.20 percent silver. The other, designated as “light,” contained 8.17 percent silver. These values correspond to 2.50 and 2.38 troy ounces per square foot respectively. Other pieces, constituting portions of elevens, pylons, and nacelles, were anlayzed at the Oklahoma City Air Logistics Center. These pieces varied in thickness from 3/8 inch to 4¼ inches and in silver content from 9.90 to 24.05 weight-percent.

contain 9.9 and 21.1 percent silver. The variation in results appeared to originate from differences in the skin thickness of the samples. Because of this, Salt Lake City personnel suggested that silver composition based on panel area was a more reliable figure and reported 4.42 and 4.20 troy ounces per square foot, respectively. They also analyzed the panel flanges, which consisted of four stainless steel sheets joined by silver brazing. A flange described only as being wide contained 0.21 troy ounce of silver per running foot, while a narrow flange contained 0.12 troy ounce of silver. Two honeycomb panel sections, each measuring 6 by 6 by ¾ inches, were analyzed by the New York Assay Office. One of these, designated as “heavy,” contained 3.20 percent silver. The other, designated as “light,” contained 8.17 percent silver. These values correspond to 2.50 and 2.38 troy ounces per square foot respectively. Other pieces, constituting portions of elevens, pylons, and nacelles, were anlayzed at the Oklahoma City Air Logistics Center. These pieces varied in thickness from 3/8 inch to 4¼ inches and in silver content from 9.90 to 24.05 weight-percent.

In order to obtain a better picture of silver distribution in the honeycomb panels, several panels were sectioned and sampled by drilling. The layout of the various sampling areas are illustrated for three separate panels in figures 7, 8, and 9. Drillings from the blocks from each sample area were mixed, weighed, and analyzed for silver and copper. Results of these analyses are shown in tables 1, 2, and 3.

The areas labeled 1, 2, 3, and 4 of figure 7 were each laid out with 13 blocks approximately 1-1/8 by 1½ inches. Each block was drilled with one 1¼ inch hole. Thus each sample consisted of the drillings from 13 holes. The areas 1 and 2 were a mixture of three layers (along each side) and four layers (along the top edge) of brazed stainless steel Areas 3 and 4 consisted of three layers only. Area designated 5, 6, 7, and 8 consisted of a stainless steel honeycomb core brazed between a two layer outer skin and a single layer inner skin. Each of areas 5 and 8 were sectioned off with 21 approximately ¾-inch-square blocks and each block drilled with a single ¼-inch hole. Areas 6 and 7 were each sampled with 30 holes drilled into a mixture of ¾ and 1-inch- square blocks. The remaining areas, 9 through 16, consisted of the honeycomb core brazed between a single inner and outer skin. Each area was marked off with 25 blocks that were 1 inch square and each block drilled with a ¼- inch hole.

The areas labeled 1, 2, 3, and 4 of figure 7 were each laid out with 13 blocks approximately 1-1/8 by 1½ inches. Each block was drilled with one 1¼ inch hole. Thus each sample consisted of the drillings from 13 holes. The areas 1 and 2 were a mixture of three layers (along each side) and four layers (along the top edge) of brazed stainless steel Areas 3 and 4 consisted of three layers only. Area designated 5, 6, 7, and 8 consisted of a stainless steel honeycomb core brazed between a two layer outer skin and a single layer inner skin. Each of areas 5 and 8 were sectioned off with 21 approximately ¾-inch-square blocks and each block drilled with a single ¼-inch hole. Areas 6 and 7 were each sampled with 30 holes drilled into a mixture of ¾ and 1-inch- square blocks. The remaining areas, 9 through 16, consisted of the honeycomb core brazed between a single inner and outer skin. Each area was marked off with 25 blocks that were 1 inch square and each block drilled with a ¼- inch hole.

The flange areas of figure 8 designated as 1 through 4, were made up of three layers of brazed stainless steel. Each was divided into 15 blocks approximately 1-1/8 by 1½ inches for the drilled samples. The remaining areas, 5 through 10, were constructed from a honeycomb core brazed between single inner and outer skins. Individual areas were sampled by drillings from 32 blocks, each measuring 1½ inches square.

In a similar fashion, the panel shown in figure 9 was sectioned off and sampled. Areas 1 through 4 were from three layered brazed stainless steel, and sampled with drillings from 15 blocks measuring 1½ inches square. The remaining areas, 5 through 8, constituted the sandwich of honeycomb core between stainless sheets. Each area was divided into 75 blocks measuring 1 inch square.

Analytical results, presented in tables 1, 2, and 3, showed higher concentrations of silver in areas where the honeycomb was sandwiched between single layers of stainless steel. Areas where the honeycomb was covered with two layers on one side and one layer on the other showed a higher percentage of silver than the flange areas. Some slight differences are noted between similar areas on the same panel.

Analytical results, presented in tables 1, 2, and 3, showed higher concentrations of silver in areas where the honeycomb was sandwiched between single layers of stainless steel. Areas where the honeycomb was covered with two layers on one side and one layer on the other showed a higher percentage of silver than the flange areas. Some slight differences are noted between similar areas on the same panel.

Copper analyses were included to indicate the ratio of silver to copper and thereby the probable alloy used for silver brazing. The predominant ratio was approximately 92-silver to 8-copper, indicating an alloy approaching sterling silver in composition.

The sampling procedure outlined above was satisfactory for silver determinations in intact panels. However, in the silver recovery process the panels were shredded to give maximum exposure of the brazed joints to electrolytic dissolution. The resultant shredded material was a heterogeneous mixture of sizes and shapes of metal pieces. Compressing the material into a more compact mass in order to obtain a drilled sample was not satisfactory, owing to the toughness of the stainless steel and elasticity of the compacted mass. The method of sampling adopted consisted of placing the batch of shredded material into a mound. The mound was then divided into quarters, opposing quarters recombined, and again mounded. This procedure was repeated until the two quarters totaled approximately 5 to 7 percent of the original batch. This entire amount then composed the analytical sample.

Experimental Procedures and Results

Small Rectangular Cell

Preliminary electrorefining tests were conducted in the 200-ml rectangular glass cell shown in figure 4. In operation the cell was filled with a solution prepared from reagent grade silver nitrate and cupric nitrate dissolved in distilled water. The concentrations of AgNO3 and Cu(NO3)2 were adjusted to produce a solution containing 30 g/l and 20 g/l of silver and copper, respectively. These values fall in the concentration range used by commercial electrorefiners. A charge of ½-inch shredded honeycomb was packed tightly into the rectangular anode basket that was suspended vertically in the cell. The cathode was suspended vertically, directly opposite and approximately ¾ inch from the anode basket.

Tests were started by the passage of a direct current of 0.2 ampere through the cell. All tests were conducted at room temperature and without electrolyte circulation. As the tests progressed, dendritic crystals of silver grew from the cathode face toward the anode basket. To prevent an electrical short circuit between the electrodes, it was necessary to periodically agaitate the cathode, causing the dendrites to fall and collect in the bottom of the cell. The voltage drop across the cell gradually decreased as the cathode surface became covered with silver crystals and as the dendrites grew toward the anode. Fluctuations of the voltage between approximately 1.5 and 0.4 occurred cyclically with the initiation and growth of the dendrites. The range of operating data for tests in the 200-ml cell are shown in table 4. Detailed data for individual tests are shown in the appendix (table A-1).

At the end of the test period the cell was dismantled. Silver crystals were recovered from the electrolyte by filtration. Loosely adherent silver was scraped from the cathode and added to the crystals collected on the filter. After thorough washing, the silver crystals were dried, weighed, and stored without further treatment. The cathode current efficiency, expressed as percent, was calculated as the ratio of the weight of crystals collected to that expected theoretically on the basis of time and current. A sample of the combined silver product from several of the small scale tests was examined spectrographically. The results presented in table 5 indicated that the purity of the silver was greater than 99.3 percent.

The concentration of silver in the electrolyte at the end of each test was significantly lower than that at the start. This decrease was a result of the low (approximately 10 percent) silver content of the shredded material composing the anode charge. Thus, more silver was deposited at the cathode than was dissolved at the anode because of the codissolution of copper and silver. The silver deficiency was made up by the addition of fresh AgNO3 crystal to the electrolyte. The increased copper concentration in the electrolyte appeared to cause no problem with silver recovery.

Large Cylindrical Cell

The investigations were continued in the large cell shown in figures 4 and 5. The cylindrical stainless steel anode Basket holds approximately 30 pounds (13.6 kg) of shredded honeycomb material. Actual charge weights varied from 6.1 to 14.8 kg depending on changes in the bulk density of the shredded material. The differences in bulk density resulted primarily from different skin thicknesses found in various panels as well as the total thickness of the honeycomb core. Initially, the area of the cylindrical cathode for a test was dependent on the depth of solution in the cell and ranged from 2.6 to 2.9 square feet out of a possible surface of 3.2 square feet.

The series of tests was started with approximately 30 liters of the same electrolyte used in the smaller cell. Shredded honeycomb material making up the anode charge was loaded loosely into the basket to assure free circulation of the electrolyte and access to silver-brazed joints. After an initial sample of electrolyte was removed, basket rotation (2 to 4 rpm) was started and the output of the rectifier adjusted to the operating current. The tests were started at room temperature without provisions for cooling. As a result, solution temperature gradually approached 50° C. Initially, the only circulation was that imparted by rotation of the basket.

At the end of a test, the cell was disassembled. The basket was drained for approximately an hour and then rinsed in a separate tank. The charge was removed from the basket, spread out to air dry, weighed, and stored. The silver product was recovered from the inner collection basket with an additional small amount recovered from the bottom of the tank after decanting the electrolyte. The silver was washed with water and then air dried, weighed, and stored. Wash water from the silver powder was added to the electrolyte and then the solution was sampled. Volumes of solution and concentrations of Ag, Cu, and Fe for the starting solution, and this final solution are listed in table 6. The amount of silver depleted from solution during a test was determined from these values. Determination of the amount of silver in solution at the end of the electrolysis period generally showed less silver than found in the final solution. This led to the conclusion that some slight but varying amount of silver redissolved in the electrolyte before all the product could be collected and washed.

Other elements associated with the brazing alloy and the stainless steel were allowed to accumulate in the electrolyte. Within the scope of this research, none of these in the amounts accumulated (table 6) appeared to cause problems in the recovery of silver from the aircraft parts. During the course of these investigations the concentration of copper more than doubled, while chromium and nickel had increased to 2 and 3 g/l, respectively. The concentrations of iron which was zero initially, appeared to be self-regulating at 1 to 3 g/l at the start of all further tests. This resulted when the spent electrolyte, with wash water, was heated to evaporate excess water. Some portion of the dissolved iron hydrolyzed during heating to settle as an insoluble material on cooling. The iron precipitate was not readily filtered and was removed from the electrolyte by decantation.

The cathode current efficiency, determined from the ratio of the amount of silver collected and the amount theoretically obtainable, was markedly lower than the approximately 100 percent found for the 200-ml cell. Several additional tests were conducted in the 200-ml cell to determine any adverse effect of known differences between the two cells such as temperature, soluble iron in the electrolyte, and the ac component of the power supply. None of these appeared to have an effect.

Changes in both current density and circulation in the large cell combined to show a slight increase in observed current efficiency. The change in current density was accomplished by masking the cathode with vinyl electroplating tape and varying current through the cell. Individual disconnected cathode areas formed by masking appeared to be unsatisfactory. Better results were obtained by masking the original cathode into a combination of equally spaced vertical bars connected at the midpoint by a continuous circumferential band. The six bars were each 2-7/8 inches wide by 6¾ inches high joined by a ½-inch band to give an effective cathode area of 0.88 square foot. In the strict sense, cathode current density figures, except for the very start of a test, were not exact owing to a progressive increase in surface resulting from growth of dendritic silver crystals. Anode current density figures were more ambiguous as the entire stainless steel wire screen of the basket was conductive. For comparative purposes it was estimated on the basis of the surface area of the basket associated with the depth of charged material.

Circulation of electrolyte through the charge was improved by replacing the solid central shaft of the anode basket assembly with a hollow tube having equally spaced radial holes. In this manner fresh electrolyte was continuously distributed throughout the charge. Variations in flow rate from 0.5 to 6 gal/min appeared to produce minimal improvement.

The range of operating data for tests conducted in the large cell is shown in table 7. A more detailed summary for individual tests is shown in the appendix (table A-2),

During the course of the electrolysis, very little indication of complete dissolution of silver from the stainless steel base was observed. Within the range of this investigation, this had an affect on silver recovery data shown in the tables.

To obtain a more complete silver balance, the “soft core” area of several panels was sampled prior to shredding. This was the area where the honeycomb core was covered by only a single inner and outer stainless steel sheet. Each panel was marked off in sections which were drilled for a sample. The weight and silver content for the “soft core” area of each panel is listed in table 8, The heterogeneous nature of silver distribution is further demonstrated by these data. Following sampling, the panels were fed to the hammer mill for shredding. The combined shredded panels then comprised the anode charge for the refining cell.

The test using these panels is shown as test 11 in table A-2 of the appendix. The portion of the silver product which was estimated to come from the silver-brazing alloy, determined as the difference between the total product (1,108 g) and the amount of silver depleted from solution (116 g), was 992 g. Recovery, based upon this amount and upon the silver on the honeycomb charged at the start of the test (1,395 g), was 71 percent. Sampling the honeycomb residue from the test showed it to contain 7.1 percent or 375 g silver. The recovery figure developed from 992 g silver from the honeycomb and the total amount of silver (1,367 g—determined as the sum of 992 and 375) was 73 percent. The length of this test was insufficient for recovering a greater amount of silver. A complete silver balance for this test is shown in table 9. The data shown in the table indicate a difference of 27.2 g (1.2 percent) silver between the amount charged and the amount accounted for at the end of the test period. This was felt to be within the accuracy limits of sampling the honeycomb before and after shredding. For this reason it appeared unnecessary to determine the amount of silver charge to the cell. Subsequent recovery calculations were based on the amount of silver estimated to come from the honeycomb and the residual silver not stripped from the honeycomb charge.

Spectrographic analyses of the silver product from the large cell were similar to those obtained for the 200-ml cell. It was found, however, that the sample had to be cleaned of magnetic particles before analysis. These particles, comprised of minute pieces of stainless steel, were either originally a part of the shredded charge or liberated during electrolysis. These particles comprised between 0.05 and 0.1 percent of the total product weight. Results of optical spectrographic analysis are shown in table 10. The purity of the silver product was greater than 99.3 percent.

In contrast to the use of AgNO3 crystal to replace silver depleted from the electrolyte of the 200-ml cell, a portion of the silver product was used for the large cell. The silver powder was first freed of magnetic materials and then dissolved in reagent grade nitric acid at a ratio of 1.6 moles of acid per mole of silver. The silver was slurried with a volume of water equivalent to the amount of acid used. Dropwise addition of acid to this slurry resulted in a controlled nonviolent reaction. The resultant solution was filtered and added directly to the main electrolyte. On an industrial scale, makeup silver would be prepared in a system such as the Kestner- Johnson Dissolver.

Conclusions

Laboratory tests have shown that silver can be recovered from the silver brazing alloy used to join certain stainless steel aircraft structures. Parts of the obsolete B-58 bomber which constitute the elevons, pylons, and engine nacelles ranged in silver content from 1 to 33 weight-percent. The C-141 flame cone assembly, of similar construction, has approximately 11 percent silver. The material was shredded to expose silver-brazed joints and then was used as an anode charge in an electrorefining cell. Silver was recovered as a dendritic powder with a purity greater than 99.3 percent. Recoveries of silver from the shredded honeycomb ranged from 67 to approximately 100 percent with an average energy consumption of 0.02 dc kwhr/troy ounce of silver.

The electrolytic solution, which had been partially depleted of silver during electrolysis, was reconditioned with silver obtained by dissolution of a portion of the product in nitric acid. Other metals, which accumulated in solution during the limited scope of the study, appeared to have no harmful effect on recovery of silver.

Recommendations for Future Work

The stainless steel anode basket sustained a mediocre amount of anodic attack. Any additional work should explore the use of either another metal which would be more stable in a nitrate electrolyte, or an inert plastic basket. Use of the basket in the horizontal position rather than vertical may further lessen anodic attack, In addition, tumbling action of the anode charge would increase exposure of the silver brazed joints and may beneficially aid overall silver recovery.

An alternate source of silver for use in regenerating silver depleted from solution during electrolysis should be developed. A technique using spent electrolyte to leach silver from either fresh or spent shredded honeycomb should be explored, Other waste silver resources such as film scrap or rich fractions of electronic scrap might be used for this purpose.

The refining system described in this report had a maximum capacity of approximately 15 kg, which at 10 percent would contain 1,500 g (48 troy ounces) of silver to be recovered. Current practice in the Moebius or Balbach-Thum cells is to treat approximately 78 kg of Dore anodes containing an estimated 98 percent or 2,500 troy ounes of silver. Additional work should include the scaleup of the refining system to process larger practical size samples.

Appendix

Detailed data for operations in both the 200-ml cell and the large cell are shown in tables A-1 and A-2, respectively.

The Bureau of Mines, through a memorandum of agreement with the Department of Defense, conducted research to recover silver from aircraft scrap. Silver was recovered by an electrolytic method from stainless steel honeycomb sections separated from the aircraft. These sections had been constructed by sandwiching a stainless steel honeycomb core between stainless steel sheets and then brazing the assembly with a silver alloy. Over 300 pounds of silver was used in the B-58 bomber, concentrated in certain honeycomb sections of the aircraft. Following shredding of the aircraft parts, an average of 95 percent (ranging 67 to 100 percent) of the silver was recovered in a single electrorefining step. After the electrorefined product was magnetically cleaned, purity of the recovered silver was greater than 99.3 percent.