Table of Contents

This Bureau of Mines report results from a study on prereduced nickel concentrate from the FENI project in Yugoslavia; this study was conducted in cooperation with McKee Overseas Corp., Western Knapp Division. The Bureau was particularly interested in establishing the chemical relationships between pre-reduction of low-grade nickel ore and the ferronickel produced by smelting the prereduced material in an electric-arc furnace. It is anticipated that the prereduction-electric-arc furnace smelting concept will prove suitable for treating ores from the few known domestic nickel deposits.

The FENI project, near Kavadarci, Yugoslavia, promises to be Europe’s second largest ferronickel operation the proven reserves of 48 million tons should sustain an annual output of 18,000 tons of contained nickel for more than 20 years. Initial feasibility studies on the project concluded that beneficiation of the low-grade crude ore followed by roasting and smelting would be desirable to conserve energy. To improve the commercial viability of the project, FENI developed a process including prereduction and conventional electric-arc furnace smelting to produce ferronickel. A similar prereduction and smelting process is part of a commercial operation in Greece, and another is under development in Norway.

McKee Overseas Corp. was retained by FENI to size equipment for a processing plant and to be responsible for its construction. Familiar with the work on electric-arc furnace smelting of nickel ores that has been done by the Bureau of Mines, McKee Overseas Corp. requested a cooperative agreement with the Bureau to confirm the feasibility of electric-arc furnace smelting prereduced FENI nickel concentrate.

Objectives of the cooperative program were established as follows:

- Develop engineering data for selecting and sizing the smelting facilities of the FENI project.

- Develop optimum operating conditions for production of a 15- to 20-wt-pct ferronickel in the electric-arc furnace from partially reduced pellet feed.

- Develop engineering and process data for furnace feeds which fall above or below the optimum partial reduction level.

- Produce enough 15 to 20 wt-pct ferronickel for an oxygen-upgrading test.

The electric-arc furnace smelting of prereduced FENI nickel concentrate is described in this report. Upgrading the ferronickel product by selective oxidation is discussed in the appendix.

Smelting Prereduced Nickel Concentrate in an Electric-Arc Furnace

Materials Used for Smelting Tests in the Electric-Arc Furnaces

The nickel-bearing concentrate used during this investigation was from ore mined by FENI in Kavadarci, Yugoslavia. Two hundred tons of the crude nickel ore were received at the Institute of Mineral Research, Michigan Technological University, Houghton, Mich., for concentration. Subjecting the crude nickel ore to a low intensity magnetic separation produced a 1.14-wt-pct nickel concentrate. The nickel-bearing concentrate was sent to the Allis-Chalmers Test Center in Oak Creek, Wis., for pelletizing and prereduction. All of the concentration, pelletizing, and prereduction test work was directed by Mineral Services, Inc., of Cleveland, Ohio.

The Albany (Oreg.) Metallurgy Research Center of the Bureau of Mines received 20 tons of pelletized nickel concentrate (oxide pellets) and 30 tons of prereduced pellets. The oxide pellets were of uniform composition, but the 131 barrels of prereduced material represented varying degrees of prereduction.

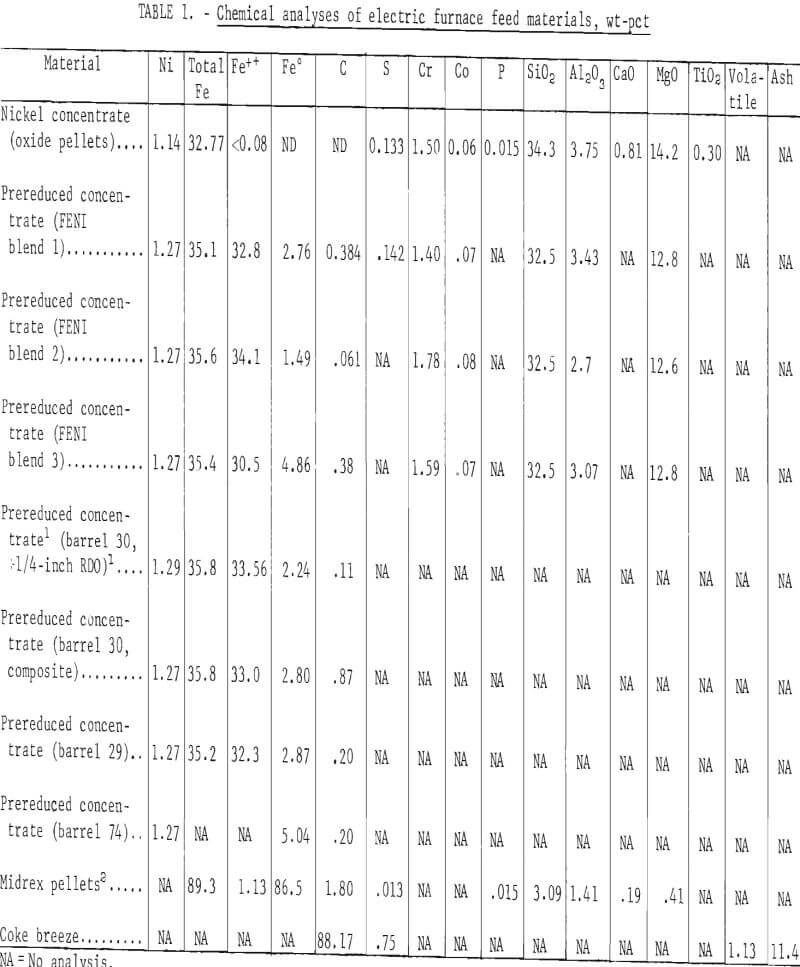

Because all of the ferric iron was consistently reduced to ferrous iron during prereduction, metallic iron concentrations were used to differentiate between products. The metallic iron concentrations (degrees of prereduction) ranged from 0.35 to 8.13 wt-pct. To obtain the desired levels of prereduction in uniform furnace charges, three composite blends of prereduced pellets were prepared. Blends 1, 2, and 3 represented metallic iron concentrations of 2.76, 1.49, and 4.86 wt-pct, respectively. Chemical analyses indicated nickel concentrations up to 1,30 wt-pct in some barrels of prereduced concentrate. However, multiple analyses confirmed 1.27 wt-pct nickel in all of the composite blends prepared for the smelting test series.

Chemical analyses of the nickel-bearing materials, reductant, and Midrex pellets used in the electric-arc furnaces are shown in table 1.

Equipment and Operating Procedures for Smelting Tests in the Electric-Arc Furnaces

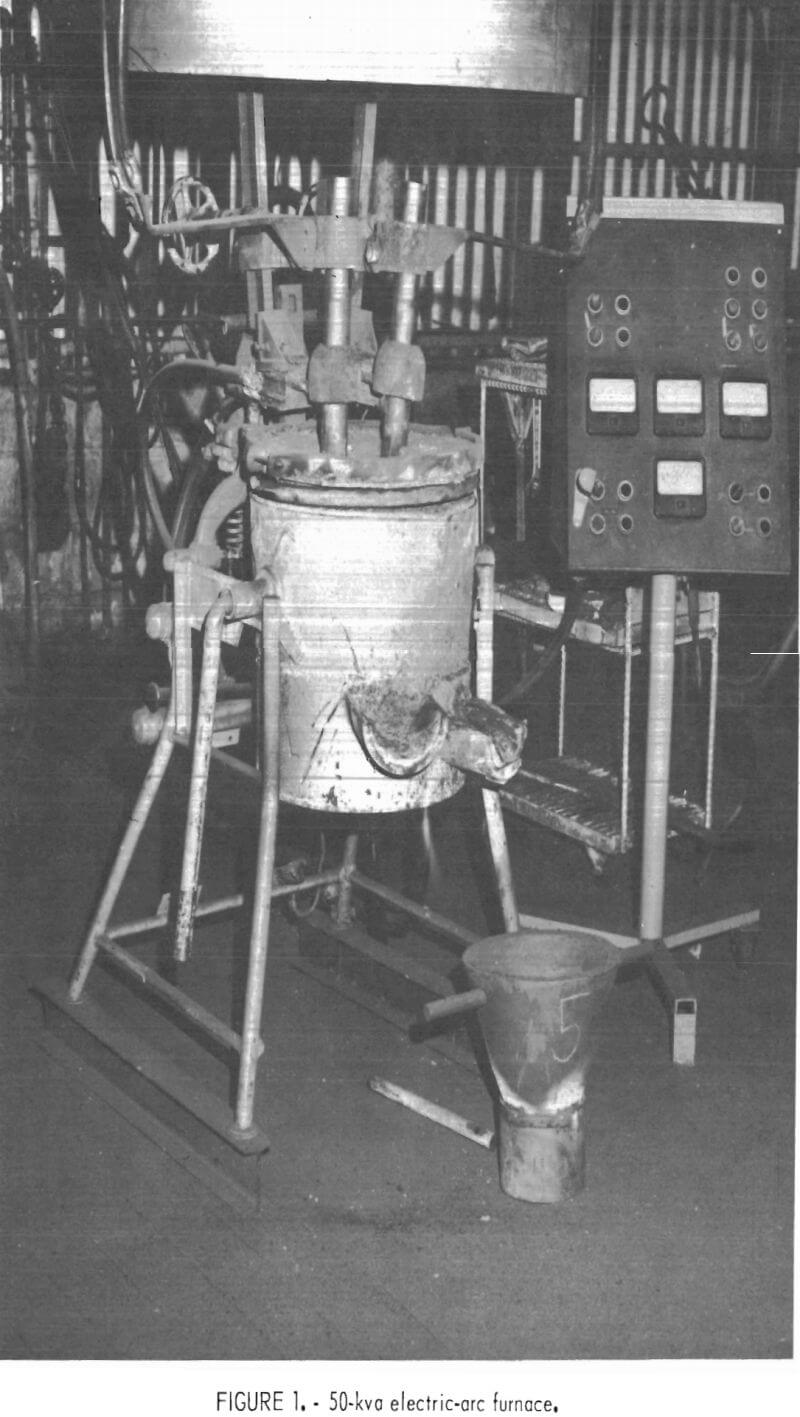

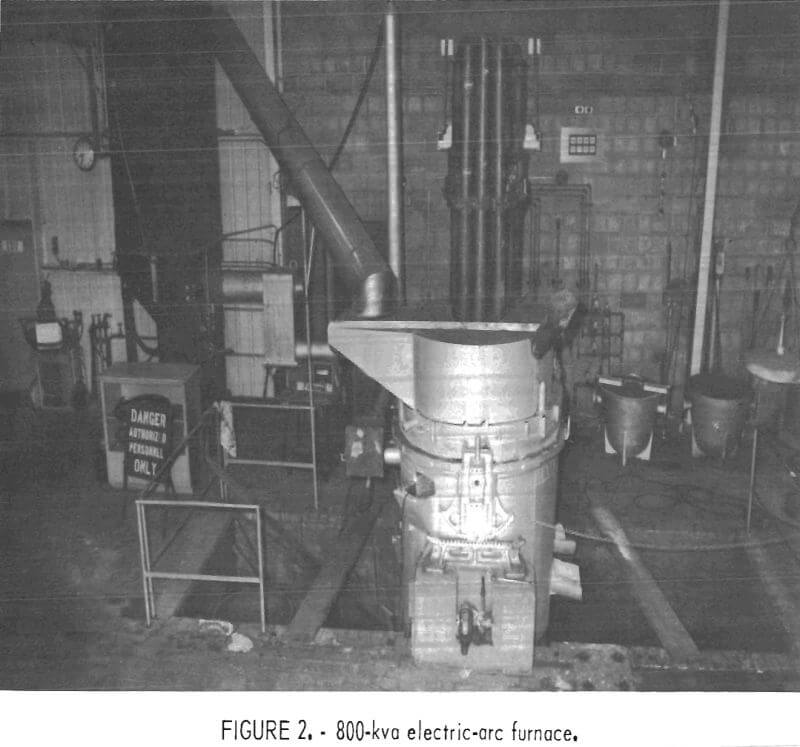

Smelting tests were conducted in laboratory- and pilot-scale furnaces. Single-phase current for the laboratory-scale furnace was supplied by a 50-kva welding transformer which was operated from a portable control panel near the furnace. Manually operated rack-and-pinion mounted electrode clamps controlled the position of the 2-inch-diameter graphite electrodes. The furnace shell, approximately 17 inches in OD and 17 inches high, was lined with high-purity castable alumina refractory to obtain a working crucible 12 inches in ID. The crucible was covered with a rammed, high-alumina roof supported by a water-cooled ring. A taphole was provided at hearth level to remove the molten products. The laboratory-scale furnace is shown in figure 1.

During a laboratory-scale test, the blended charge was fed to the furnace with a 4-inch-wide variable-speed belt feeder. The feed rates were correlated with energy input to obtain the desired smelting conditions in the furnace.

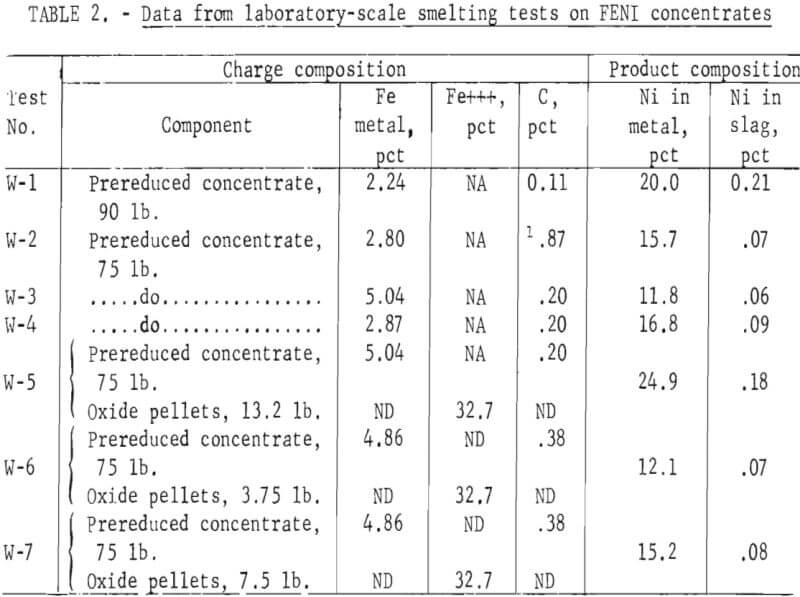

The 800-kva furnace used for pilot-scale smelting tests is shown in figure 2. Three 4-inch-diameter graphite electrodes were positioned in a conventional “delta” configuration on 12-inch centers. The cylindrical furnace shell was lined with magnesite bricks, and the furnace hearth was formed of alumina ram mix. The hearth area was 6.7 square feet, and the normal depth of the bath was 20 inches.

Charge material was gravity-fed through the furnace roof. A stainless steel feed chute extending downward inside the furnace from the roofline was equipped with a dispersion plate to prevent the feed from piling in one place on the molten bath. Feed rates were controlled with a 4-inch-wide variable-speed belt feeder.

The small baghouse to the left of the furnace in figure 2 collected the entrained dusts from the furnace offgases. The baghouse and plenum hood were evacuated by a 7,500-cfm fan that exhausted into a positive pressure cyclone, baghouse, and countercurrent-scrubber system.

Metal products from the pilot-scale smelting tests were cast into 50-lb pigs. The slag was cooled in conical slag ladles that formed approximately 1,000-lb casts containing all of the slag poured during each tap.

Stream samples were taken during each slag and metal tap. The slag samples were ground to minus 80 mesh and thoroughly blended before they were submitted for chemical analyses. Sample buttons were prepared during each metal tap and submitted for rapid nickel analyses by X-ray emission techniques. In addition to the stream samples, drillings were taken from the metal pigs, and a composite sample was prepared from each tap for complete analyses.

Results of Smelting Tests in the Laboratory- and Pilot-Scale Furnaces

Smelting tests in the laboratory-scale (50 kva) furnace were based on furnace charges containing 75 lb of prereduced concentrates. On the average, 6,000 lb of prereduced concentrate were smelted during each test in the pilot-scale (800 kva) furnace.

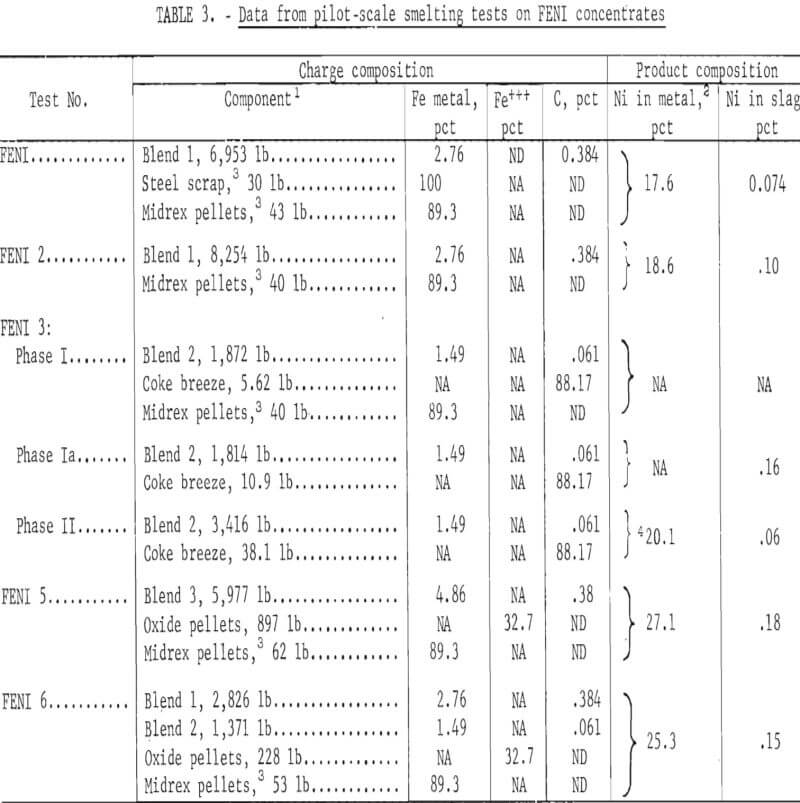

Seven laboratory-scale smelting tests were run to determine the requirements for promoting high nickel recovery and producing 15 to 20 wt-pct ferronickel. Data from the laboratory-scale tests are summarized in table 2. Tests W-1 and W-4 were designed to determine how the ferronickel products and nickel recoveries were affected by varying metallic iron concentrations (degrees of prereduction) in the “as-received” materials. Although it was difficult to deduce a quantitative effect because of the small number of tests, the low grade of ferronickel (15.7 wt-pct Ni) produced during test W-2 indicated that the residual carbon remaining with the prereduced material affected the nickel and iron distribution in the smelting furnace. Results of the last three laboratory-scale tests indicated the ferronickel grade could be increased by adding oxide pellets to a charge of overreduced concentrate.

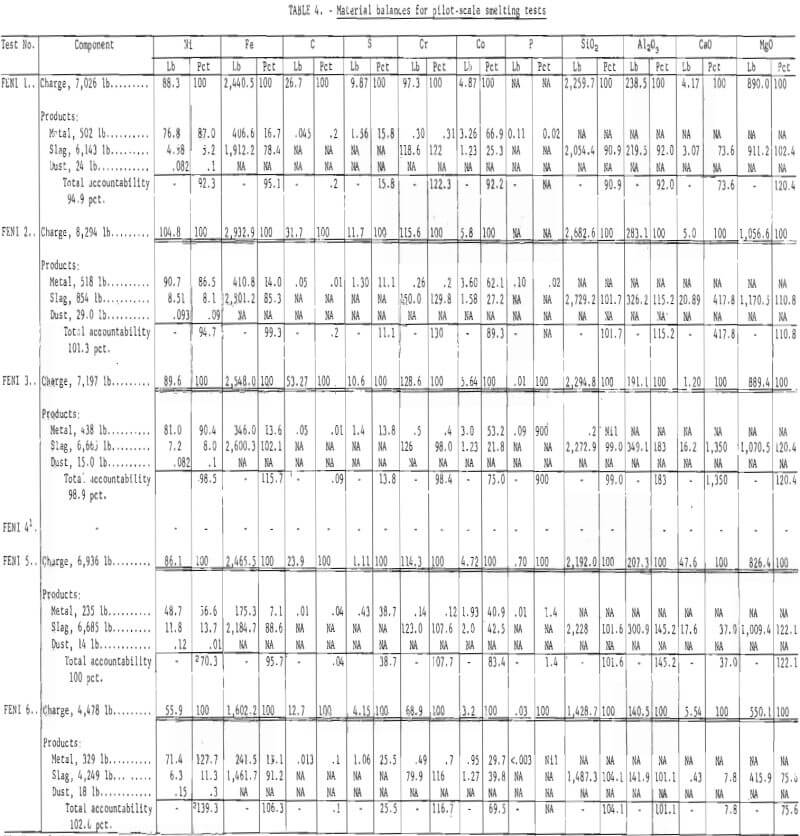

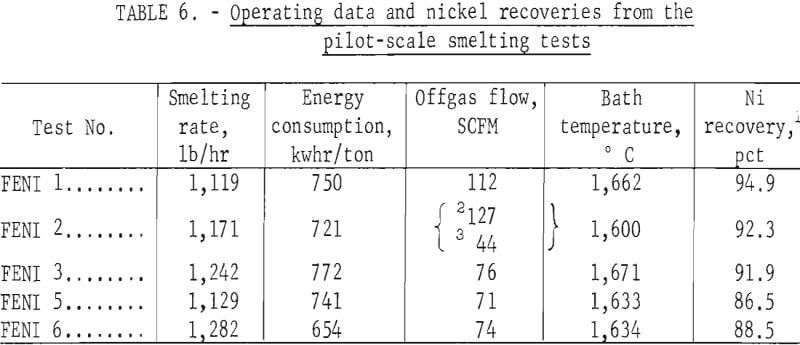

During six pilot-scale tests, approximately 1 ton of ferronickel was produced from blended concentrates with concentrations of 2.76, 1.49, and 4.86 wt-pct metallic iron. Furnace charge and product analyses, and material balances from the pilot-scale smelting tests are summarized in tables 3-4.

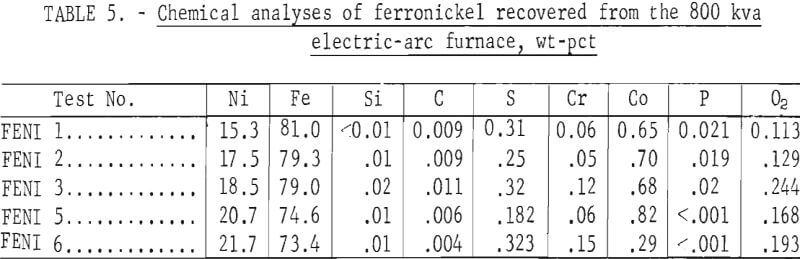

Midrex pellets were nested on top of each furnace charge to establish conductivity between electrodes for the initial arc. The iron-bearing material diluted the ferronickel appreciably. However, the dilution was accounted for when calculating the nickel concentrations shown in table 3. The calculated values were used to identify the real effects of furnace charge compositions and to keep the pilot-scale test data consistent with the laboratory-scale test data where a starting material was not required. Chemical analyses of the ferronickel recovered from the 800-kva furnace are listed in table 5.

Operating data and nickel recoveries from the same tests are shown in table 6. The smelting rates included in the table are average values representing ranges as wide as 800 to 1,600 lb/hr from the start of a 7-hour test in a cold furnace to the end under equilibrated furnace conditions.

The offgas flow rate was restricted as much as possible during each test. However, the measured values far exceed theoretical reaction offgas volumes. Carbon monoxide and carbon dioxide measurements in the offgas stream confirmed that most of the flow could be attributed to ambient air leaking into the furnace, but the ambient air did not have any detectable effect on the smelting process.

Discussion

Laboratory- and pilot- scale smelting test data were used collectively to evaluate the experimental results. Graphical analyses did not identify any inconsistencies between data from the two types of tests.

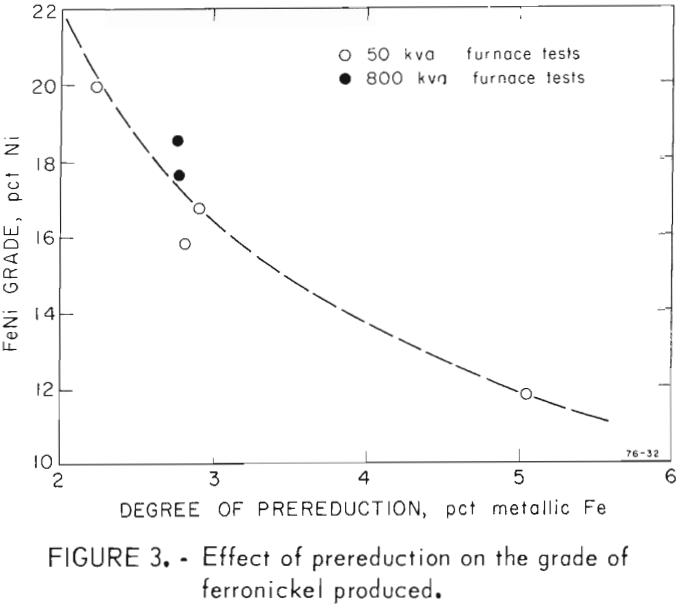

Smelting prereduced concentrates as received under different lot designations made it possible to observe how varying the metallic iron concentration (degree of prereduction) affects the grade of the ferronickel product, as shown in figure 3. It is evident that 15 to 20 pct ferronickel can be produced by smelting prereduced materials with 2 to 3 wt-pct metallic iron concentrations. Some variation in the data can be attributed to residual carbon concentrations ranging from 0.384 to 0.87 wt-pct in the prereduced materials. No attempts were made to account for the residual carbon concentrations because carbon utilization during the smelting process was not established.

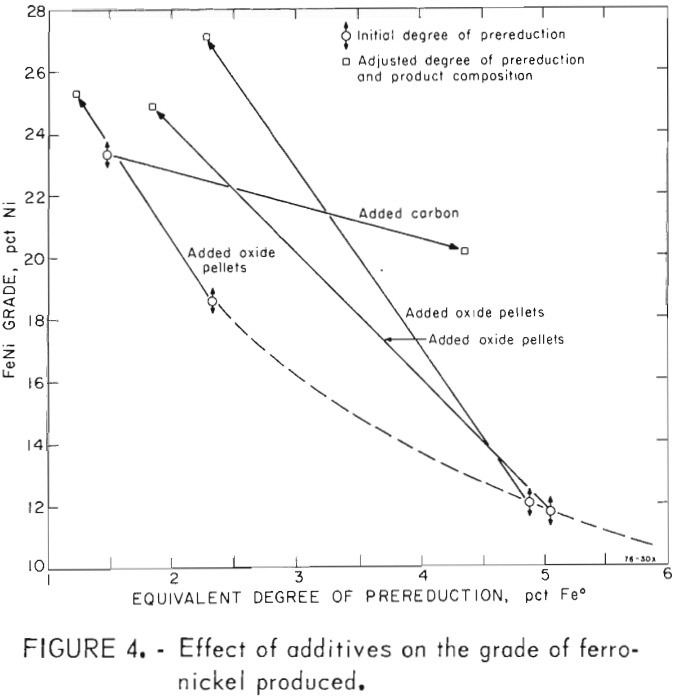

Having established the degree of prereduction to produce 15 to 20 pct ferro-nickel, attempts were made to compensate for varying degrees of prereduction by adding oxide pellets or carbon to the smelting furnace feed. The results are shown in figure 4 along with a dashed line representing the results anticipated from the relationship in figure 3. Calculations to determine the required additives were based on stoichiometric requirements for the following reactions:

Fe2O3 + C → 2 FeO + CO……………………………………………………..(1)

FeO + C → Fe + CO……………………………………………………………..(2)

Fe + Fe2O3 → 3 FeO……………………………………………………………(3)

The grades of ferronickel produced from charges containing oxide pellets were generally higher than estimated from the stoichiometric requirements. The higher grade products were attributed to utilizing only about 50 pct of the residual carbon in reaction 2. Consequently, the equivalent metallic iron concentrations were lowered by reaction 3. A higher grade ferronickel and lower nickel recoveries resulted. FENI 3 was the only test based on carbon additions to an underreduced nickel concentrate. Because the ferronickel grade plotted in figure 4 is the net result of three different carbon additions, it is difficult to conclude why the net results did not fall on the dashed line as anticipated.

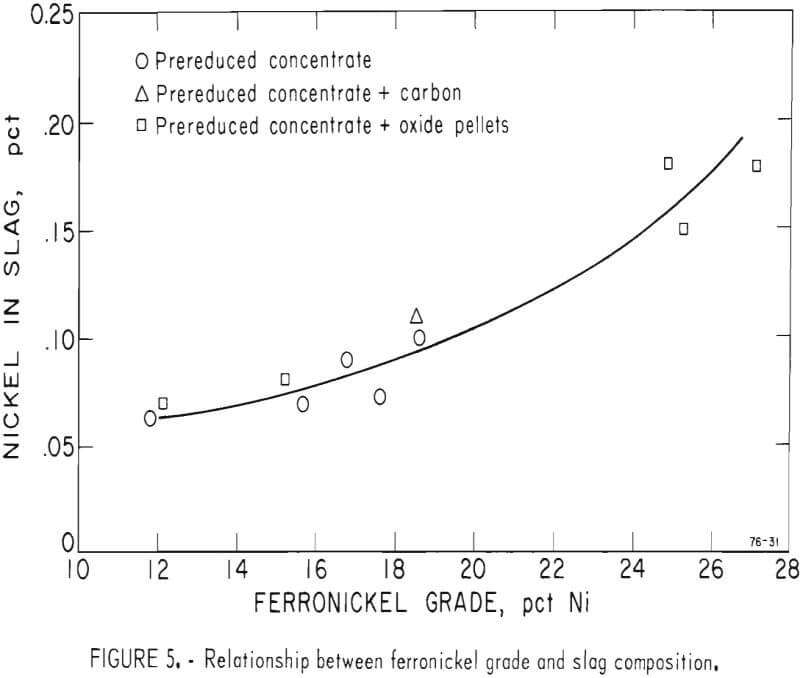

The grade of ferronickel produced in the electric smelting furnace affects the nickel recovery appreciably. Nickel concentrations of the slags plotted in figure 5 are typical of the losses associated with nickel recoveries ranging from 86.5 to 95.4 pct. According to the literature, the

shape of the curve in figure 5 is about the same for any nickel-bearing material that is prereduced before electric-arc furnace smelting. However, the curve shifts up or down as the total iron concentration in the nickel bearing material increases or decreases. Higher iron concentrations increase the nickel losses when producing any given grade of ferronickel and vice versa. Satisfactory nickel recoveries have been obtained when producing 40 to 50 pct ferronickel from prereduced materials with lower iron levels than found in FENI concentrate.

It is important to note in figure 5 that corrective additions of oxide pellets or carbon to prereduced concentrates did not adversely affect the nickel recoveries. Consequently, a degree of prereduction dictated by convenient operating parameters for any given material can conceivably be compensated for in the prereduction-electric-arc furnace smelting process.

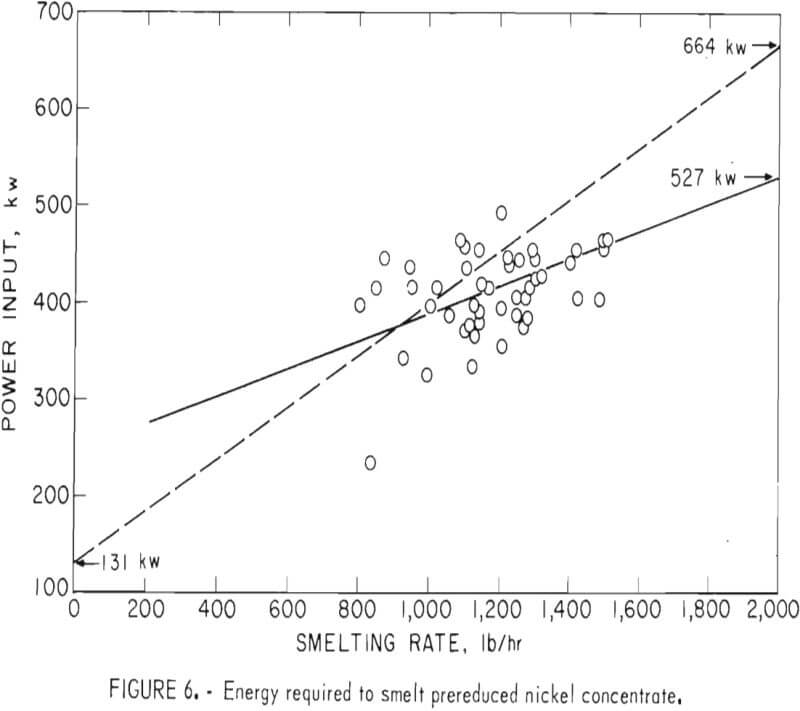

Power inputs and smelting rates realized in the 800-kva electric-arc furnace were used to project the energy consumption that might be expected when smelting a preheated charge in a continuous operation. An extrapolation of the data is shown in figure 6. Each point on the graph represents approximately 700 lb of furnace charge. The initial furnace charges could not be preheated without reoxidizing the prereduced nickel-bearing concentrate and the cold start necessitated slower smelting rates toward the beginning of each test. Consequently, the 700-lb units smelted below 1,100 lb/hr at the beginning of each test reflected power losses that were not indicated by the

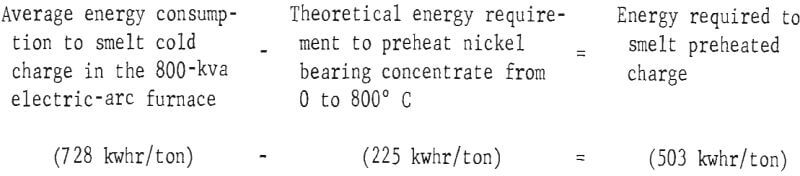

700-lb units smelted under equilibrated conditions toward the end of each test. Least squares fits were estimated independently for the data points below and above a smelting rate of 1,100 lb/hr. Extrapolating the straight line from the low smelting rates to 2,000 lb/hr and subtracting the power loss (131 kw) at a smelting rate of 0 lb/hr) indicated an energy requirement of 533 kwhr/ton. The extrapolated value from the higher smelting rates was 527 kwhr/ton. Both of the extrapolated energy requirements are only slightly higher than an equivalent value calculated as follows:

Conclusions

Low capital and operating costs are providing incentive to produce ferro-nickel by prereducing and electric-arc furnace smelting nickel-bearing ores or concentrates. By utilizing gas fired rotary kilns for a solid-state prereduction, fossil fuel is burned directly in relatively inexpensive equipment, and heat losses are minimized by operating at the lowest possible reaction temperatures. The partially reduced feed requires less power and generates less offgas during the smelting process. The smelting conditions in a balanced system with prereduced feed are such that appreciable energy can be saved by maintaining acceptable smelting rates under “cold-top” operating conditions. Consequently, every component of an electric-arc furnace system can be smaller than for producing equivalent amounts of a ferronickel by conventional techniques.

During this investigation, FENI concentrates with several different metallic iron concentrations (varying degrees of prereduction) were successfully smelted in an 800-kva electric-arc furnace. The relationship between the degree of prereduction and the grade of ferronickel recovered from the electric-arc smelting furnace were established. Although optimum control of reducing conditions in a pilot plant rotary kiln was not experienced by the cooperators, any fluctuations in prereduction were compensated for by oxide or carbon additions to the electric furnace feed.

Over 90 pct of the contained nickel was recovered from prereduced FENI concentrates when producing 12 to 20 pct ferronickel and other investigations have shown that higher grades of ferronickel can be produced at acceptable nickel recovery levels from materials with lower iron concentrations. The test results confirmed the feasibility of continuously smelting prereduced FENI concentrate in an electric-arc furnace.

Comparing FENI concentrate, other nickel ores that have been put through a similar process, and ores from domestic nickel deposits indicates the two-step process is directly applicable to the domestic materials. The economy and versatility of prereducing and electric-arc furnace smelting nickel-bearing ores should be exploited here in the United States. Developing the process to produce high-grade ferronickel while realizing acceptable nickel recoveries from domestic ores would increase the country’s domestic nickel supply and enhance energy conservation.

Appendix.-Upgrading Ferronickel by Selective Oxidation

One test was run to determine the feasibility of upgrading 15 to 20 pct ferronickel by selective oxidation. Emphasis was on the quality of the upgraded product and the ferronickel grade that could be achieved.

Materials

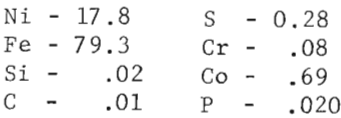

Metal pigs from smelting tests FENI 1, 2, and 3 were used as starting material for the upgrading test. The smelting products represented ferronickel grades of 15.3, 17.5, and 18.5, respectively. The resulting composite weighed 1,022 lb and had the following composition, in percent:

The test was designed to desulfurize and dephosphorize the molten ferronickel before it was upgraded by oxidizing much of the contained iron. A reducing mix consisting of 62 pct lime, 7 pct silica sand, 7 pct fluorspar, 12 pct calcium carbide, and 12 pct petroleum coke was added to the molten bath during the desulfurization steps. The empirical blend was intended to maintain reducing conditions in the molten bath and to lower the sulfur concentration in the ferronickel by the formation of calcium sulfide. Burnt lime was added to the molten bath during the dephosphorizing step. The addition was made to form the slag constituent 4CaO·P2O5 with the phosphorus oxidized by the initial oxygen blowing.

Test Procedure and Results

The ferronickel pigs were melted in a 1,200-kva electric-arc furnace. The furnace was powered through three 4-inch-diameter graphite electrodes positioned in a conventional delta on 12-inch centers. The molten bath was heated to approximately 1,600° C, and as constant a bath temperature as possible was maintained throughout the test.

Desulfurization, dephosphorization, and oxidation procedures were followed consecutively. Solids were added to the top of the molten bath through the furnace door, and oxygen was injected to the bottom of the bath through a ½-inch black iron pipe that was coated with ¾ inch of alumina castable. Slag was removed from the bath by tilting the furnace and raking it through the furnace door.

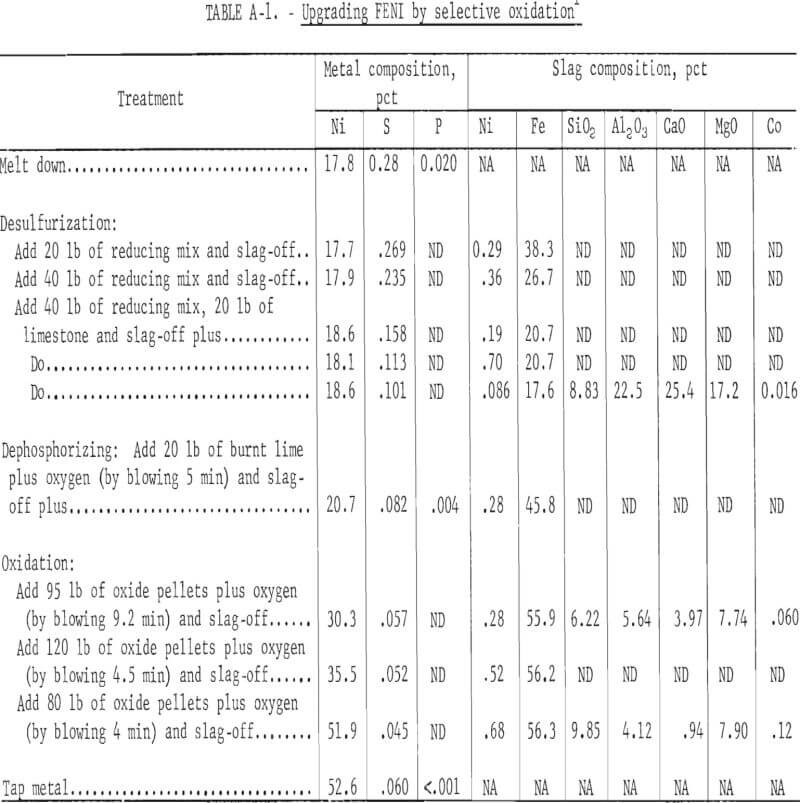

The slag was sampled during each slag-off, and the metal bath was sampled after each processing step. A chronological description of the upgrading test including analyses of the metal bath and slags is shown in table A-1.

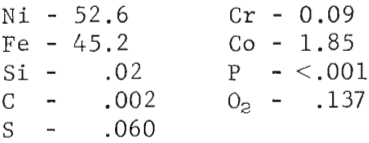

The upgraded ferronickel was cast into 50-lb pigs. Random drill samples were collected from the pigs and blended into a composite sample that analyzed as follows, in percent:

Discussion

Ferronickel produced by smelting prereduced FENI concentrate in an electric-arc furnace was upgraded to 52.6 pct nickel by selective oxidation. Performing consecutive desulphurization, dephosphorization, and oxidation procedures in a 1,200-kva electric-arc furnace produced a metal suitable for normal stainless steel production.

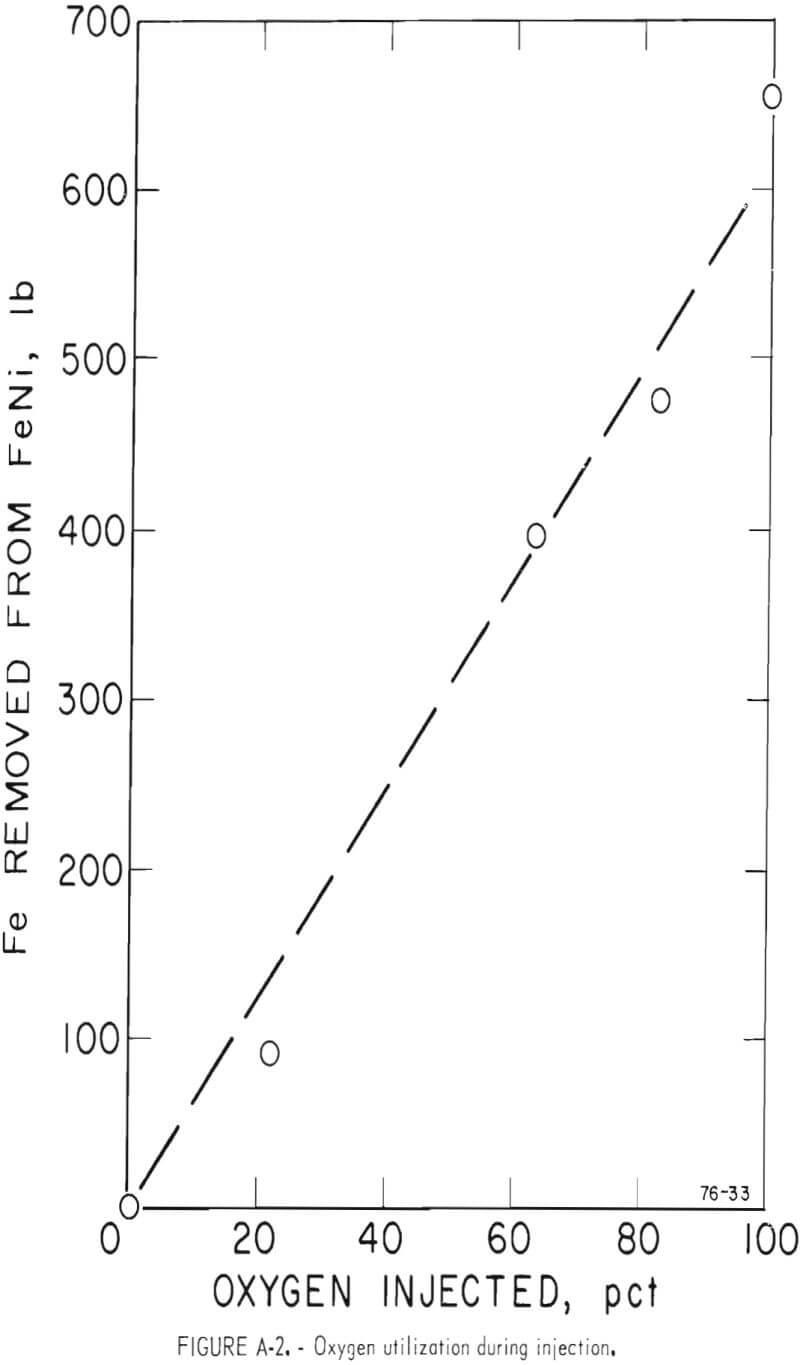

Quantitative measurements of the oxygen consumed during the injection steps were questionable. Flow rate measurements and pressure data recorded during the test only guaranteed that the oxygen injection rate was the same during all of the injection steps. Consequently, the oxygen consumptions at various stages of the selective oxidation process are presented as a percentage of the total consumption in figure A-1. An oxygen utilization of 80 pct was estimated from the available data. However, such a value is more a function of the injection technique than the chemistry of the system. It is more important to note the oxygen utilization remained constant during the entire test as indicated by the linear relationship shown in figure A-2.

The test confirmed that a ferronickel product of pre-reduction and electric furnace smelting can be upgraded by selective oxidation. Atleast a 52.6-pct ferronickel grade can be achieved without realizing any lowering in oxygen efficiency.