Table of Contents

Fines and concentrates must be consolidated or agglomerated into larger masses before they can be smelted in a commercial blast furnace. Such agglomeration is usually done by sintering, pelletizing, nodulizing, or briquetting. Sintering has been the more common practice, but with the advent of taconite concentrates pelletizing is increasing in importance.

Pellets in the blast furnace feed must be durable enough to withstand transportation to the blast furnace and passage through the stack to the smelting zone without excessive size degradation. For this reason pellets are fire hardened after being consolidated. Hardening is done by heating the pellets, adding fuel to the charge, and firing in a shaft furnace or moving grate. The cost of this operation on a commercial scale would be about $1 per ton.

Because it is important to take advantage of every possibility for economy in the beneficiation of taconite concentrates, the question arises: Can the waste heat in the top gases of a blast furnace be used for hardening the pellets sufficiently to resist abrasion and fracture while they are passing to the smelting zone? The only additional heat required in the blast furnace is for drying. Observations on the behavior of wet fines in the experimental furnace indicated that plastic agglomerates would not disintegrate in the stack column. The work described in this report was a preliminary test of the feasibility of direct smelting of green pellets in the Bureau experimental blast furnace at Pittsburgh, Pa.

Preparation of Pellets

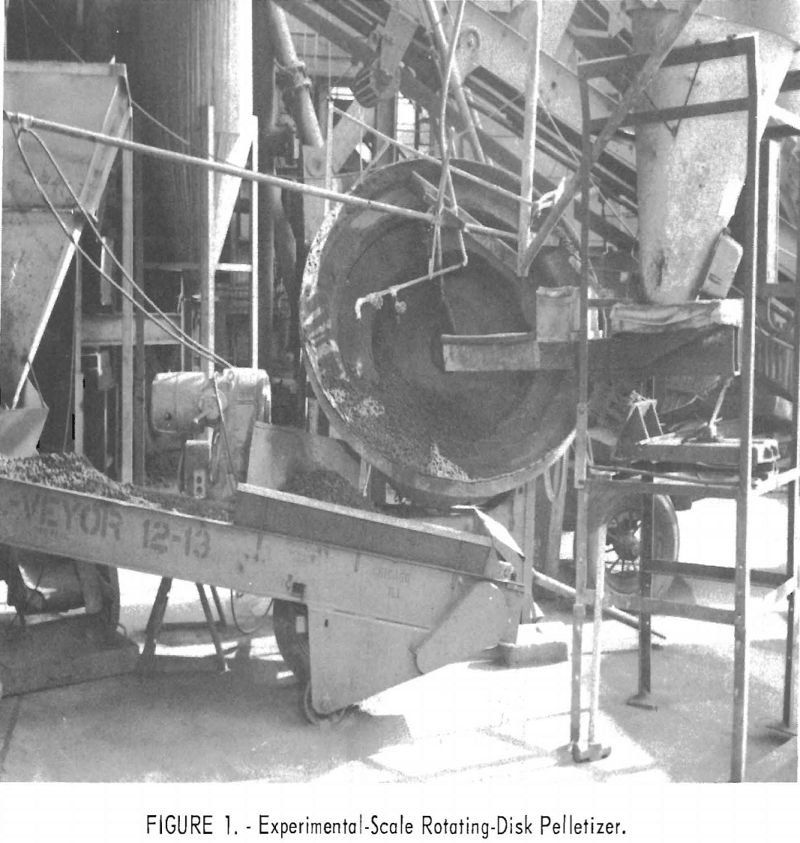

The raw pellets were formed on the pan-type pelletizer shown in figure 1. The outside diameter of the pelletizing pan was 64 inches. The bottom was stepped down 6 inches at diameters of 52 and 40 inches. The pan was mounted on a cylindrical drum that was rotated on the long axis by ring and pinion gears. The speed of rotation could be varied from 10 to 30 r.p.m. The drum was mounted in a U-shaped cradle that was adjustable through 90 degrees, whereby the bed of the pelletizer could be positioned at the proper inclination. A supply line and spray nozzles were provided for wetting to the required consistency.

The taconite concentrate was pelletized by feeding it onto the bed of the rotating pan, which was tilted 50 degrees from the horizontal. The charge was moistened by an overhead water spray. Bentonite was intermixed with the taconite concentrates to promote coherence of the particles. Bentonite additions ranged from 0.65 to 2.10 percent of the weight of the concentrates. Approximately 1 percent bentonite proved to be sufficient.

The raw pellets were transported to the blast furnace by the same system used for other raw materials. The pellets were transported from the pelletizer to the weigh car by belt conveyor. They were dumped from the weigh car into the skip, from which they were again dumped onto the revolving distribution hopper and into small and large bell compartments at the top of the furnace. In these operations the pellets were subjected to a series of vertical drops of 3 to 8 feet.

Experimental Smelting Operation

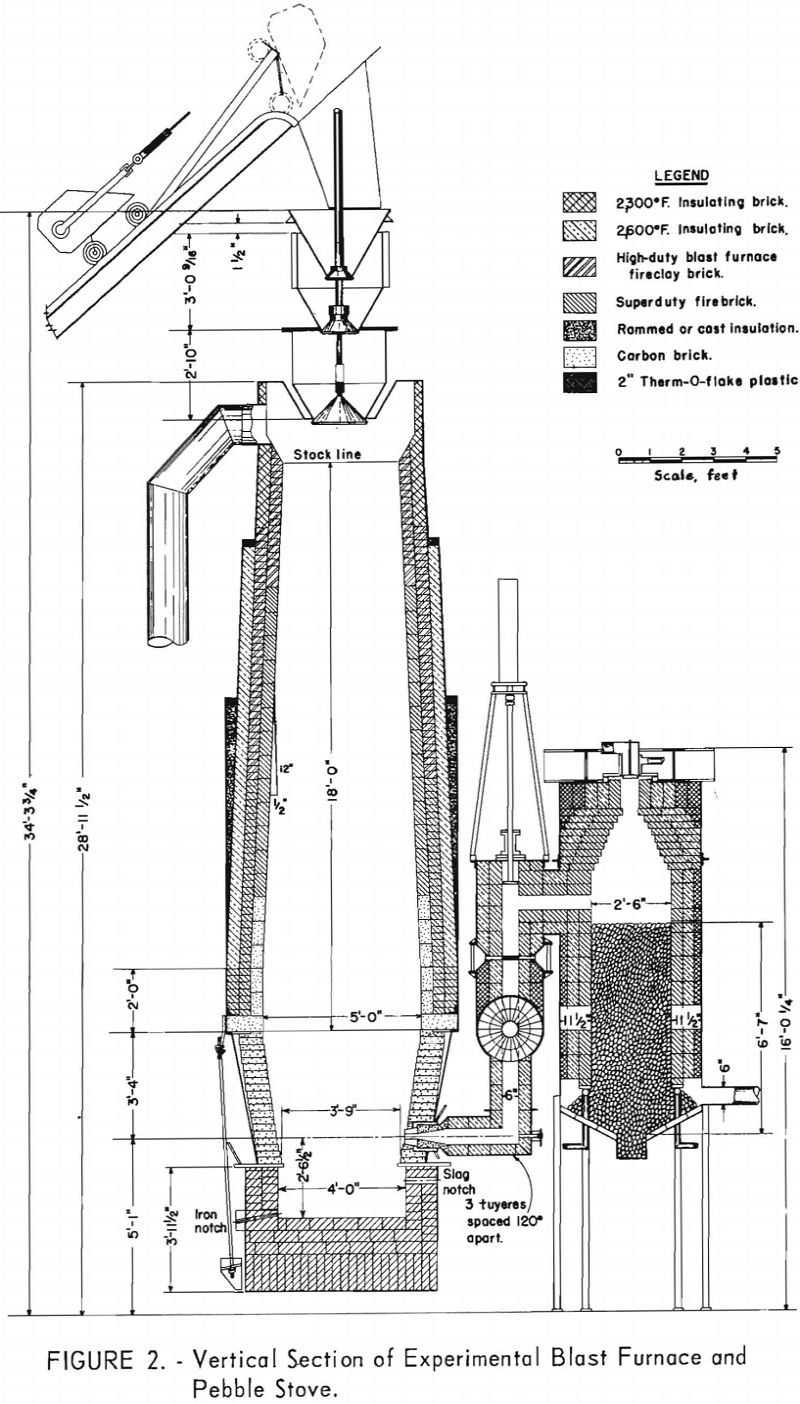

The furnace used for these smelting tests was 45 inches in diameter at the hearth and 21 feet and 4 inches from tuyeres to stock line, as shown in figure 2.

The procedure followed in making these experimental tests was to start with the furnace operating on sinter and gradually replace sinter in the charge with unfired pellets. A hard sinter of Venezuelan fines was smelted during a base period of 2 days. The burden ratio of sinter to coke was

maintained at 1.7:1. The coke ranged from 1,695 to 1,780 pounds per ton of hot metal.

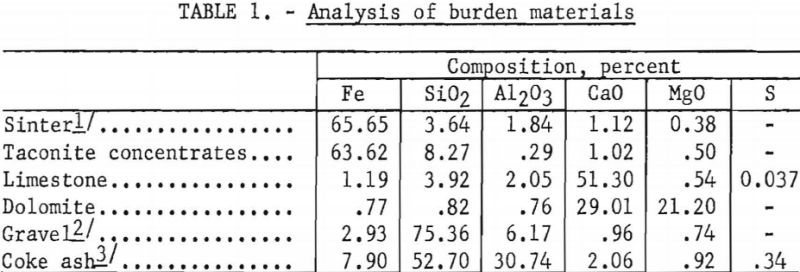

The chemical composition of the raw materials comprising the burden for the operations on raw agglomerates is shown in table 1.

The sinter was much lower in gangue than the taconite concentrates; therefore, gravel and requisite quantities of limestone and dolomite were included in the charge. The slag-forming materials were decreased proportionately as the taconite-concentrate pellets were added to the furnace burden, the gangue content of the taconite being sufficient to supply the necessary slag volume for desulfurizing the pig iron.

After the furnace reached stable conditions, the raw taconite pellets were charged every 10th round to establish the proportion of raw pellets in the charge at 10 percent. Thereafter, the proportion of raw pellets was successively increased by charging raw pellets every fifth, third, etc. round until the charge was 100 percent pellets on test day 11. The relative quantities of stone, dolomite, and gravel were adjusted to maintain the weight ratio of basic oxides to acid oxides in the range 0.95 to 1.10.

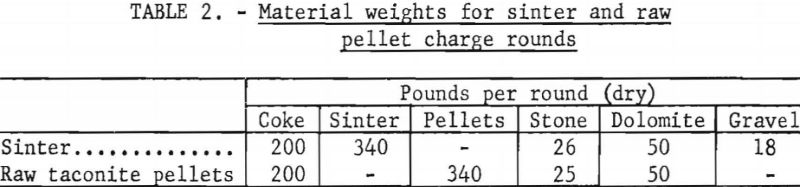

Each charge consisted of 340 pounds of sinter or raw pellets together with coke and flux. The component weights of sinter and pellet charges respectively are shown in table 2.

The wind rate averaged 825 std. c.f.m. throughout the test period. The temperature of the air blast was regulated to maintain regular movement of the stock column and normal concentration of sulfur and silicon in the pig iron.

The principal difficulties encountered during these operations were mechanical ones such as water leaks in the tuyeres and malfunctioning of the charging-bell mechanism. Because of these difficulties, smelting operations were discontinued before the minimum coke consumption had been established for a burden of 100 percent raw pellets.

Experimental Results

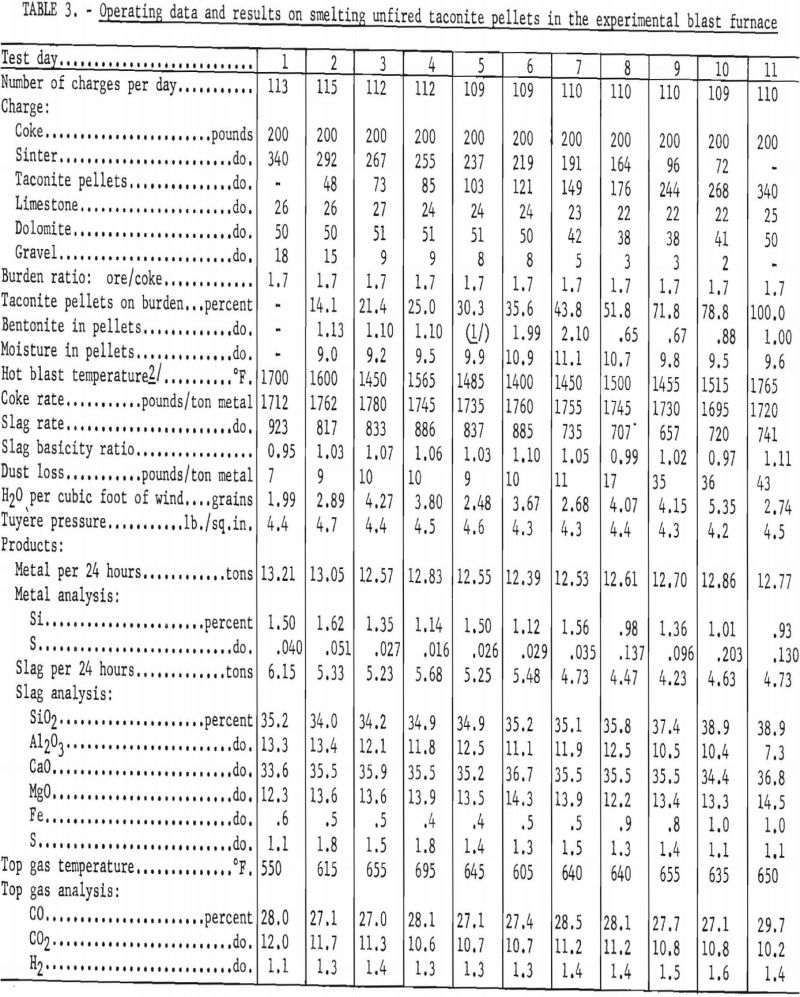

Data on the smelting operations are summarized in table 3. Raw pellets were not intermixed with the sinter but were charged in units of 340 pounds per charge in the proper sequence to attain a specified proportion of pellets and sinter.

The metal quality with respect to sulfur content was good in the 20- to 45-percent range of raw pellet burden, the basicity factor of the slag, CaO + MgO/SiO2 + Al2O3, having been maintained in the 1.03- to 1.10-percent range. Sulfur content was above the 0.05-percent specification on test days 2, 8, 9, 10, and 11. It is notable that the basicity factor was 1.03 or less for these periods except for the 100 percent pellet burden, when the basicity factor was 1.11. However, the bases-to-silica ratios on test days 10 and 11 were much lower than in earlier periods (test days 3 through 7), and sulfur removal was poor.

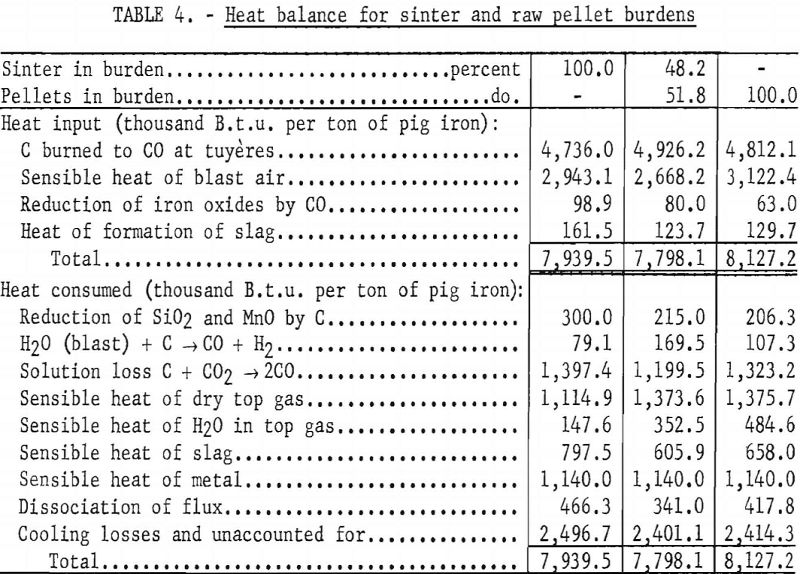

Heat balances for smelting operations on burdens containing no raw pellets, half pellets-half sinter, and 100 percent pellets are shown in table 4. There are only slight differences in the thermal requirements for the various burdens reported. The most evident variation is in the lower solution loss on the burdens containing raw pellets and the increased heat content of the top gas and associated water content.

The average production rate of 12.78 tons over the range 10 to 100 percent raw pellet burden was 3.3 percent below the 13.21 tons produced on the 100 percent sinter burden base period. Also, it is to be noted that the 12.77 tons metal-product weight from the 100 percent raw pellet burden was 3.3 percent less than the production attained during the operations on sinter. The operating periods on which the comparison is based are of limited duration, and the slight production loss experienced could have been caused by prevailing operational conditions in the furnace rather than by the raw pellet burden.

The bentonite additive for improving cohesion of the taconite concen-trates ranged from approximately 0.7 to 2.0 percent by weight of the taconite material subjected to agglomeration. The furnace operated smoothly for the various loadings of raw pellets, and it appeared that the agglomerates with 0.7 to 1.0 percent bentonite additive were as satisfactory as those containing 2 percent.

The nominal weights of dry-dust effluent at the various raw pellet loadings indicate that the pellets withstood abrasive degradation through the successive handling stages from the pelletizer to the furnace stock line and in the downward passage in the furnace stack. The 43 pounds dry-dust production per ton of pig iron occurring on the 100 percent raw pellet burden represents only 1.5 percent of the pellet charge. This compared favorably with the 1.0 to 3.0 percent of the ore charge that had been appearing as dust when natural ore materials were smelted.

The experimental smelting operations on unfired pellets furnished evidence that virtually all of the material remained in the agglomerated state during passage from the pelletizer to the smelting zone of the furnace. The evidence includes the small quantity of fines carried out by the stack gases. Also, pellets of original form and discrete fragments of original pellets were recovered from the smelting zone when the furnace was cleaned out at termination of the smelting campaign. These recovered pellets and fragments were in a definitely hardened state, indicating that the hot furnace gases functioned as drying and sintering agents to the extent that the raw agglomerates remained consolidated during resident passage in the stock column. Furthermore, the use of raw pellets caused no significant change in production or coke rate. Apparently, the porosity of the stock column and its permeability to gas flow were not impaired by the raw pellet burden. The tuyere pressure for the operations on raw pellets remained at approximately the same level that prevailed when the burden consisted of all sinter. This relative stability of pressure indicates that no evident massing or compacting of the semi- plastic pellets occurred in the furnace stack.

Industrial Application

Information on the physical character of raw pellets in transit to the stock line of a large furnace was desired prior to any consideration of the use of raw agglomerate in an industrial furnace burden. Such subjects as possible sticking of the moist pellets on conveyors and the various hoppers, the degree of pellet degradation to fines during the successive handling stages, and the kind of pellet product most resistant to handling degradation were tested at an industrial furnace site under regular operating practice. Batch loads of 19,000 to 20,000 pounds of raw pellets were produced and moved directly to the stock line of the blast furnace through the normal sequence of weigh hopper, skip car, and small and big bell compartments.

The tests showed that the raw pellets discharged satisfactorily from the various hopper units. The pellets prepared with 3 percent bentonite binder additive withstood degradation through the various handling stages to a high degree, less than 5 percent of the mass being broken to minus-8-mesh size on placement in the big bell compartment. The 2 percent bentonite pellets were less resistant to degradation, and about 17 percent minus-8-mesh material was produced in transport from the pelletizer to the big bell compartment of the blast furnace.

These preliminary tests to gain practical experience on the physical aspects of raw pellets on charge handling provide basic information for use in a projected application of raw agglomerates in an industrial furnace to determine the economic value of direct use of unfired agglomerates in blast furnace smelting.

- Raw taconite pellets can be charged into a blast furnace with only slight degradation during handling and charging and little increase in the production of flue dust.

- Raw taconite pellets, although subject to some degradation, did not seriously lower permeability in the furnace, and an all-pellet charge was smelted satisfactorily in the experimental blast furnace.

- The use of raw pellets in the experimental blast furnace caused no unusual operating problems as compared with a base period using high-grade sinter. A 4-percent drop in production from all-sinter to all-pellet burden, at the same coke rate, resulted in part from a decrease in the metallic content of materials charged.