Table of Contents

Loss of Hardening-Power at and near V.—We know that steel is hardened by quenching from a certain red-heat or from any higher temperature; but that if the temperature be allowed to sink below this certain point in redness, quenching will not harden the metal. In short, as steel cools slowly through redness, it loses its hardening-power. Let us learn how and under what conditions this loss occurs, and especially how it is related to the V-change; and to this end let us quench many different pieces of steel, of each of many different grades of hardness, from different temperatures and under different conditions, and examine their ductility by bending tests and by tensile tests. The latter will incidentally inform us how tensile strength is affected by these various quenchings.

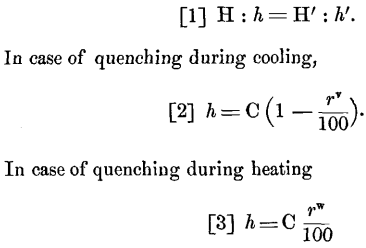

The object of this study is to learn whether the V-retardation, and hence the spontaneous evolution of heat which underlies it, corresponds to the loss of the hardening-power; and whether this loss begins at Va, ends at Vb, and progresses in the different parts of the V-range proportionally to the retardation.

Difficulty

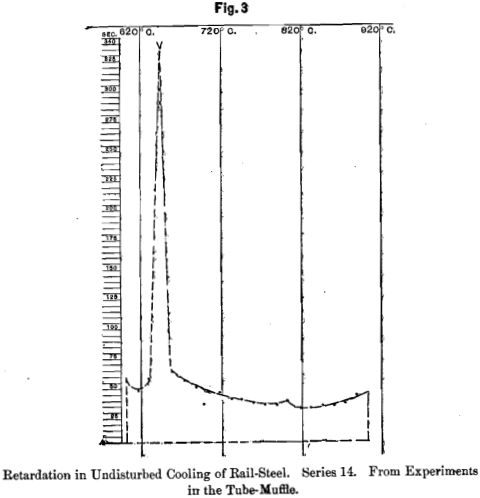

As is pointed out at the end of (18), the progress of the V-retardation varies 60 much that, without very elaborate and preferably autographic records, we cannot tell accurately what proportion of it has occurred when by quenching we interrupt our cooling above Vb. Perhaps we cannot tell accurately even with such records; and if we can, it will be with much labor. Further, any inaccuracy in this knowledge implies a like degree of inaccuracy in the correspondence which we may hope to establish between the loss of the hardening-power and the progress of the V-retardation. Let us hope that we may learn to induce these retardations to take place always in the same way.

Partly because of the labor which such elaborate records of the progress of the retardations require, partly because I originally sought only the absolute temperatures at which the hardening-power is acquired and lost, our data are far from full enough to answer completely the question before us.

Inferences

By pushing inquiry along the line we may hope to get valuable side-light on the cause of the hardening of steel. For if the “ carbon-theory ” be true, i.e., if the reason why sudden cooling hardens steel is, that it denies the time which the spontaneous change of the carbon from the hardening to the non-hardening or cement state requires ; and if this change during slow cooling progress pari passu with the evolution of heat in the V-retardation, then, comparing steels of different carbon-content, they should be alike when quenched at such stages of the V-retardation as ought to yield the same absolute percentage of hardening carbon. So also, mutatis mutandis, with the W-retardation.

Let an example show my meaning. In steel A of 1 per cent, total carbon, the hardening-carbon content should be nearly 1 per cent, after quenching from above Va; about 0.50 per cent, after quenching when half of the retardation has occurred; and about 0.25 per cent, when the steel is quenched after three-fourths of the retardation has occurred. So steel B of 0.50 per cent, carbon when quenched from above Va should contain nearly 0.50 per cent, of hardening-carbon, and about 0.25 per cent, if quenched when half the retardation has occurred : and steel C of 0.25 per cent, total carbon should have nearly 0.25 per cent, of hardening-carbon when quenched from above Va. Then on this theory steel A quenched at mid-retardation should resemble steel B quenched at above Va, because each should have about 0.50 per cent, of hardening carbon. So steel A quenched when three-fourths of its retardation is over, and steel B quenched when half its retardation is over, should each resemble steel C when quenched from above Va, for in each there should be about 0.25 per cent, of hardening carbon.

To put it algebraically, let

H = the degree of hardening in any piece of steel:

h = the percentage of hardening-carbon:

rr = the percentage of the total V-retardation which occurred before the metal was quenched:

rw = the percentage of the total W-retardation which occurred before the metal was quenched :

C = the total percentage of carbon.

Then by assumption,

Accurate resemblance is not to be expected, because the different quenching-temperatures, needed to leave like quantities of hardening carbon in unlike steels, should induce different degrees of stress; and because the composition, apart from the like percentages of hardening-carbon, would be unlike. Thus the 1 per cent, carbon steel, quenched when three-fourths of its retardation is over, would contain 0.75 per cent, of cement carbon, or 11 per cent, of cementite if we admit the composition Fe3C; while the 0.25 per cent, carbon steel quenched from above Va would have none. Yet as cementite is doubtless harder and more brittle than pure iron, its presence in the 1 per cent, carbon steel should in a measure offset the greater stress which the higher quenching-temperature (Va) of the 0.25 per cent, carbon steel should induce.

Again, no matter how rapid the cooling, in the interior of the bar it will always occupy an appreciable length of time; and in this time, which will not be alike in the different steels because of their different quenching-temperatures, different percentages of carbon will slide from the hardening to the cement state. Next, to be accurate, change of carbon from one state to the other should be measured, not by the proportion of the total retardation which has occurred, but by that of the total heat-evolution, which is not exactly proportional to the retardation.

Finally, in addition to the effects of stress and those of the condition of carbon, those of what we may provisionally call structure modify the properties of the metal profoundly. Thus, as we see in Table 18, of two like bars which were cooled slowly from a high temperature, and which therefore presumably had no serious stress and should not differ greatly in the condition of their carbon, No. 44, cooled slowly after heating to 727° C., had 97,992 pounds tenacity per square inch and 32.81 per cent, elongation, while the other, No. 48, treated in exactly the same way except that it was heated to 909° C. instead of 727, had a tenacity of 125,809 pounds per square inch and an elongation of only 12.5 per cent.

We must accumulate more evidence before we can make any general application of this test to the “ carbon theory ” of the hardening of steel.

Limitations of the Ductility-tests

Let me now point out an important inference from equation [1]. We shall see that rail-steel, quenched at but little above W, has very little ductility : this indicates that some 0.35 per cent, of hardening-carbon suffices to remove ductility almost completely. Our general knowledge indicates that steels containing not much more than this quantity of carbon lose their ductility completely when thus quenched. From this we infer that a relatively small quantity of hardening-carbon, to fix our ideas let us estimate it at 0.50 per cent., suffices to remove ductility completely. If this be true, then, if we quench a series of like bars of high-carbon steel, say that of 1 per cent, of carbon, from progressively higher temperatures, though the degree of hardening should indeed go on increasing till we reach a quenching-temperature so high that all the carbon is in the hardening state; and though tests of the hardness proper should detect the increase of hardness through this whole range; yet long before the quenching-temperature reaches the upper limit of this range, enough hardening-carbon should form to destroy ductility completely, and further elevation of the quenching temperature, even if accompanied by further increase of hardness proper, should not further affect the ductility.

In other words, on the “ carbon theory,” the fact that, when the quenching-temperature in rising reaches a certain point, the ductility vanishes, is not evidence that hardening does not progress with further elevation of the quenching-temperature: nor is the fact that ductility remains nil till the progressively descending quenching-temperature reaches a certain point evidence that the loss of the hardening-power does not begin above that point.

Where is the Hardening-Power Lost

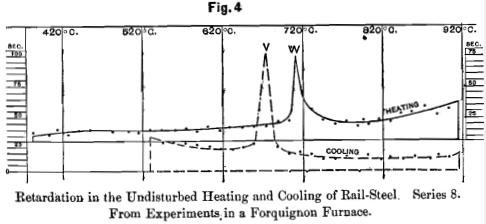

Let us now see how the degree of hardening of each series of steel taken by itself is related to the progress of the V-change as revealed by the V-retardation in cooling. Let us first consider the high-carbon steel of Series 10, because we have in (17), (18) and (20) ascertained with some care the position of V, Va and Vb, and the progress of the retardation in the V-range, for this steel.

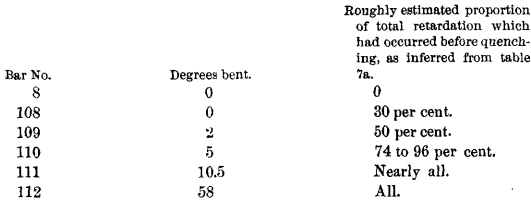

(30) Series 10.—Several bars of this steel (group IV., Table 20), were heated to about the same temperature, then quenched after partial slow cooling to different points near V. In case of bar 108 the loss of the hardening-power between Va and the crest of the recalescence, corresponding according to table 7a to somewhere about 30 per cent of the total retardation, was not enough to give the quenched metal any measurable ductility. In case of bar 109, quenched soon after the middle of the recalescence, when the temperature, after rising 9° spontaneously, began spontaneously to sink, and when probably somewhere about half of the retardation had occurred, the hardening power had so far diminished that the quenched bar took a permanent set of 2° on rupture.

Bar 110, quenched at the end of the recalescence, when the temperature after rising spontaneously 9° from V had re-descended to V, and when by table 7a from 74 to 96 per cent, of the retardation should have occurred, bent 5°.

Bar 111, quenched when the temperature had fallen somewhat below V, and when the retardation should have nearly ended, bent 10.5° : while 112, quenched when the temperature had fallen below Vb, and therefore after the retardation should have become complete, bent 58°, or more than the untreated steel (bar 1), and actually more than one of the bars (No. 12, group VIII.) which was cooled slowly completely. Some might call it “ water-annealed.” I here recapitulate:

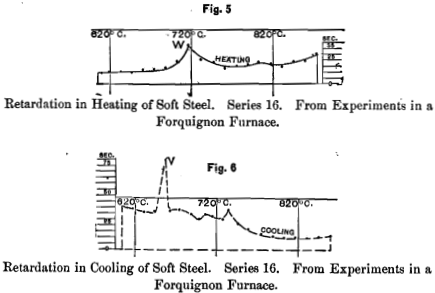

The fact that steel which takes a permanent set of 58° if quenched when the V-retardation is complete, can be bent only 5° if quenched when at least 74 and possibly 96 per cent, of this retardation has taken place, certainly suggests that the loss of the hardening power lags behind the retardation. Yet we should be cautious in admitting this. First, at the end of (18) we saw that we may have over-estimated the percentage of the V-retardation that occurs before the end of the recalescence. Next, admitting that 74 per cent, had occurred when bar 110 was quenched, should it on the “ carbon theory ” bend more than 5° ? It should have about 1.20 x (1 — 74/100) = 0.30 per cent, of hardening carbon: it should then, according to equation [1], resemble steel of 0.30 per cent, total carbon when this is fully hardened. Should such steel bend more than 5° ? The evidence in hand does not imply that it should. Thus in Fig. 4 we find that Wb seems to lie at about 750° for steel of Series 8, which contains about 0.35 per cent, of carbon. Table 17 shows us that this steel (bar 27), quenched from 736°, or when nearly all its carbon should have changed to the hardening state, bends just 5° ; bar 26, quenched from above Wb, bends slightly less, only 2°, and this bend gradually falls off to nil as, with further rise of temperature, the induced stress doubtless increases. Table 22 shows us that the still softer steel of Series 16, containing about 0.22 per cent, of carbon, when quenched in brine from 808°, which to judge from Fig. 5 should be above Wb, and when therefore it should contain nearly 0.22 per cent, of hardening carbon, bends 5°. This case, then, far from opposing the carbon theory, seems rather to support it. But a single case should weigh lightly, unless its teachings be corroborated by other parallel ones. I give it rather as a nucleus for further evidence, and for illustration.

(31) With Series 9, soft tool-steel, we get like results (group IV. of Tables 18 and 19). At the beginning of the recalescence, at its crest, and even when the temperature has begun to sink from its crest, so much of the hardening-power remains that the steel, when quenched after slow cooling to these points, has not acquired any measurable ductility, nor has its tensile strength increased (bars 45, 43, and 251). But by the time the quenching-temperature has redescended to V at the end of the recalescence, though the gain in ductility is so slight as to be within the bounds of observational error, the hardening-power has decreased so far as to cause a great increase of tenacity, which, as we should expect in this high-carbon steel, thus responds earlier to the decrease of hardening than the ductility does. Bar 58, quenched at 7° below V, and therefore probably above Vb, shows a very great gain in ductility ; while bar 40, quenched at 69° below V, and therefore probably far below Vb, has greater tensile strength than some of those cooled slowly completely, and far greater ductility than others (Nos. 48 and 57). Some would call it water-annealed.

We thus see that in a series of slow coolings in which all other conditions are substantially constant, by postponing the quenching from the crest to the end of the recalescence, though we thereby lower the quenching-temperature by only 12°, we increase the tenacity by some 20,000 pounds per square inch, while further lowering the quenching-temperature to 69° below V increases the tenacity by less than 12,000 pounds ; the increase of tenacity per degree of descent of the quenching-temperature is thus nearly ten times as great in the decline of the recalescence as in the 69° below the recalescence.

(32) Series 8.—Among the bars of the rail-steel of Series 8 which were quenched after cooling at substantially similar rates, we find like results, though they are less conclusive because the position of V was not noted. When the quenching-temperature descends 21°, from 678° to 657° C., there is no very marked change in ductility ; when it further descends another 22°, from 657° to 635° C., the permanent bend increases more than four-fold. Comparing this result with Fig. 4, we find that the increase in ductility comes after most of the retardation is past.

(33) Series 16.—So with group IV. of the soft steel of Table 22. These bars were heated to about the same temperature, and later quenched after cooling slowly to points near V As the point to which they were cooled descends progressively from 794° C. to 650° C. (1202° F.) near the end of the retardation, their bend increases gradually from 9° and 5° to 81°. When in No. III. the slow cooling was carried but 8° farther, or 9° below V, the bend increased abruptly from 81° to over 190°. Indeed the bar was bent double, so that its ends touched, though it had been quenched in brine.

Thus a decline in the quenching-temperature, even when it is as high as V + 54 (bar 3), increases the ductility; but, while a further descent of 49° increases the bend by only 37°, a still further descent of only 13° C., which passes V, increases it by 135°. The permanent bend thus increases much more rapidly as the quenching-temperature sinks past V, than when it descends through the 49° above V. Nevertheless, the increase in the bend from 9° at 794° C. to 18° at 704° C., is a very strong indication that there is a real and serious loss of the hardening-power in this upper range.

(34) Series 15.—The loss of the hardening power of the basic steel of Series 15 cannot be detected readily by means of the bending test; for this steel is so tough that such small bars bend double and are squeezed tight together without cracking, even after quenching in cold brine from a high temperature. One bar which I quenched in a freezing mixture at — 5° C., did crack slightly when bent double, squeezed tight in the press.

The tensile tests in Table 23 indicate that the ductility of this steel in the quenched state gradually increases as the quenching- temperature sinks. Unfortunately, five of these bars broke outside of the marked area, and the elongation of three others had to be measured in one inch or three inches, instead of in two inches; our record of the elongation is so incomplete that no trustworthy inferences can be drawn from it.

I detect no regular variation in the tenacity as the quenching- temperature gradually descends from 822° to 650°, or apparently slightly above V. But as it sinks gradually along the lower slope of the V-retardation curve, the tenacity now decreases, at first by some 6 per cent., then very rapidly; a descent of the quenching-temperature through only 8° here diminishes the tenacity by 25,162 pounds, or about one-quarter; a further and great fall of 110° lowers the tenacity by very much less, viz., by about 18,000 pounds. Here again the effect of quenching-temperature on tenacity clearly passes a well-marked critical point, which is certainly very near V, though the most marked loss of tenacity seems to come after most of the V- retardation has taken place. The V-retardation in case of this steel is, however, so slight, that I could not confidently identify the position relatively to V of some of these quenching-temperatures.

Agreement with Thermal Curves

I must defer the general discussion of the correspondence between the retardations, as shown by thermal curves, and the loss of the hardening-power, confining myself now to two important points.