Table of Contents

- Cutting Rocks in the Quarry (2)

- Cutting and Finishing Stone in Mills

- Limestone (4)

- Marble (2)

- Sandstone (2)

- Granite (5)

- Slate (3)

- Cutting and Polishing Gems and Semiprecious Stones

- Materials Used and Their Products (10) (16)

- Hardness of Ornamental Stones

- Principal Operations

- Sawing

- Types of Saws

- Sawing Equipment

- Grinding

- Lapping

- Sanding

- Polishing

- Polishing Buffs

- Polishing Agents

- Polishing Operations

- Drilling

- Cutting Cabochons

- Cutting Faceted Stones

- Cutting Jade

- Cutting Quartz Crystals

- Tumbling

- Special Cutting Processes

- Precautionary Measures

- Lapidary Equipment and Supplies

The mining and fabrication of structural and ornamental stones is a wide-spread industry involving the use of such rocks as granite, limestone, marble, sandstone, and slate. Granite is a medium- to coarse-grained igneous rock comprising chiefly quartz, feldspar, and either mica or hornblende. Limestone is classed as a sedimentary rock consisting essentially of calcium carbonate. Much of it has been derived from the shells of marine organisms. Marble is a recrystallized limestone and, because of its dense, crystalline nature, takes a polish. Sandstone is composed of sand grains firmly cemented together. Slate was originally a clay or shale, which by intense pressure was converted into a dense rock that has the property of splitting into thin, smooth sheets.

All these rocks may be cut or split into blocks of various shapes and sizes, but only the marbles and granites normally take a good polish.

Cutting Rocks in the Quarry (2)

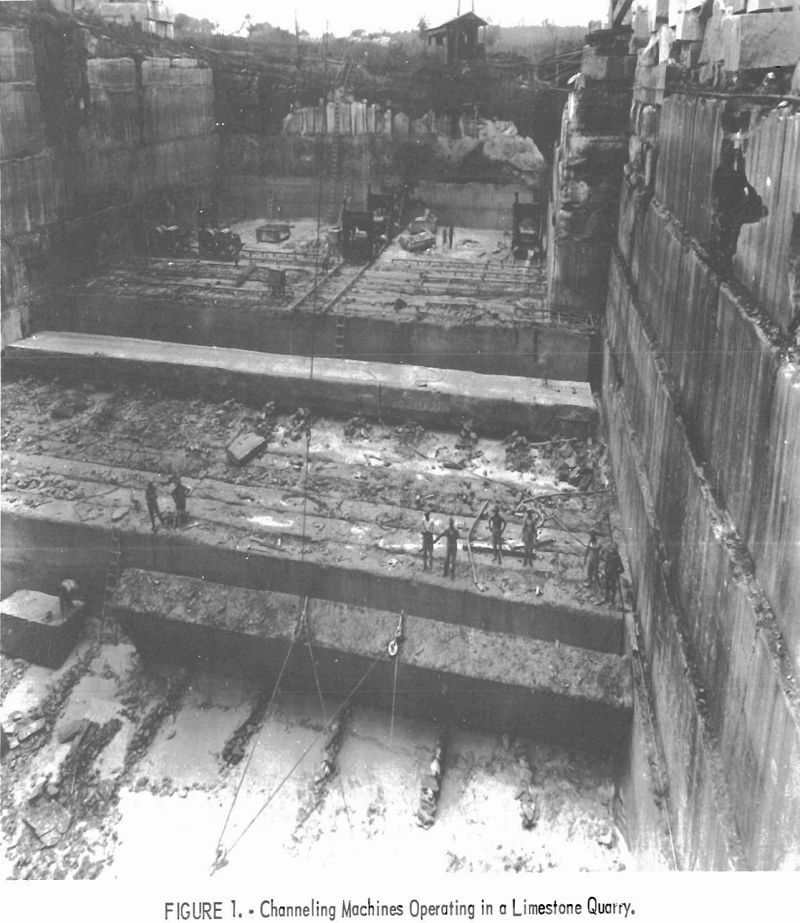

The softer rocks – limestone, sandstone, and marble – usually are cut with channeling machines. The machine is mounted on a frame and travels back and forth on a track. Chisel-edged steel bars clamped together operate with a chopping action similar to that of a reciprocating drill. Thus, a channel 2 to 4 inches wide may be cut in the rock to a depth of 10 to 12 feet. The machines may be driven by steam, compressed air, or electricity. Channels are made about 4 feet apart. Figure 1 shows channeling machines operating in limestone.

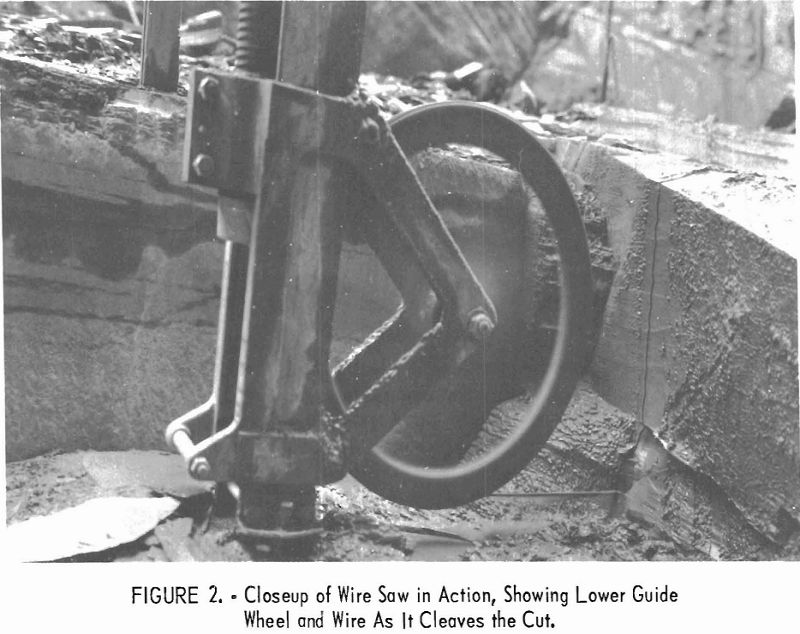

Wire saws have been substituted for channeling machines in some limestone quarries. These saws comprise a single- or triple-strand wire that runs as a belt under tension. When fed with sand or other cutting agent carried in a stream of water, the wire cuts a channel by abrasion. The wire is about 3/16 inch in diameter and makes a cut about ¼ inch wide. The single-strand wire is a twisted ribbon of high-carbon steel with the twist reversed every 50 feet to promote straight cutting. Slate quarried near Pen Argyl, Pa., was formerly cut with channeling machines, but since 1926 it has been quarried almost exclusively with wire saws. Sand is used as abrasive. Figure 2 shows a wire saw in operation in a slate quarry.

Channeling machines are used for making primary cuts in most marble quarries. Wire saws have been tried but have proved less effective in marble than in slate or granite quarries.

In slate quarries in Vermont, New York, and Virginia and in many granite quarries, blocks are broken loose by discharging light charges of black blasting powder in drill holes.

To conserve rock, many operators of granite quarries use a process known as drilling and broaching. A reciprocating drill is mounted on a horizontal bar on which it may be moved from point to point, and closely spaced drill holes are sunk in line, leaving a narrow web of rock between the holes. Then a flat broaching tool is substituted for the drill, the webs are removed, and a continuous channel is left.

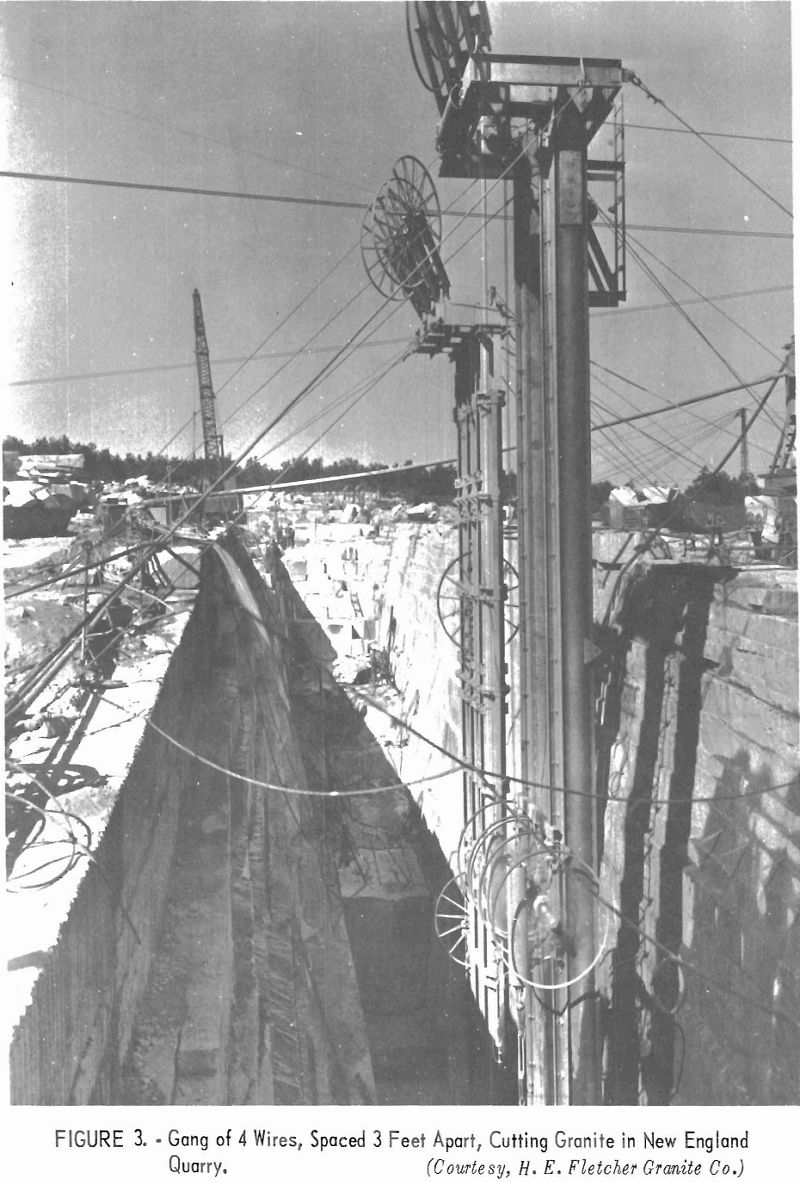

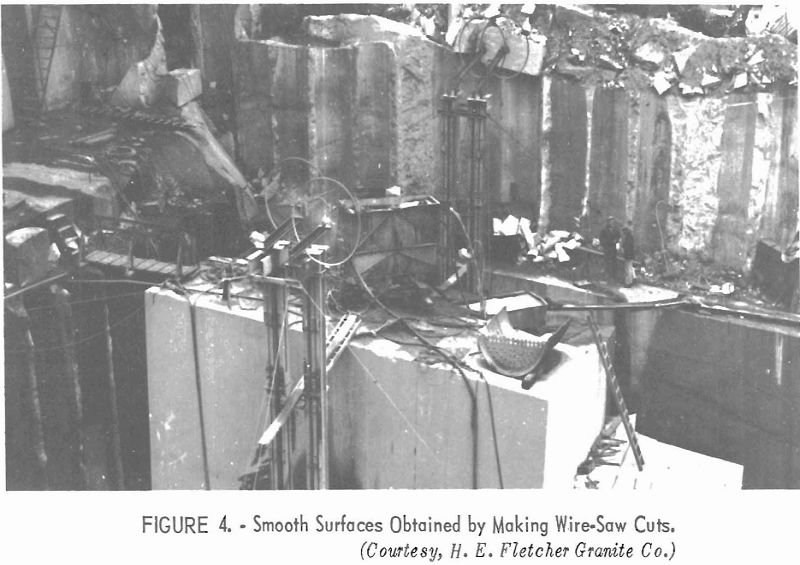

The wire saw, already described, has been used recently to advantage in a granite quarry in New England. Granular aluminum oxide is used as abrasive. The oxide is recovered in a sump and pumped back for reuse until it is worn out. In a cut 100 feet long, the wire will sink 1-½ to 2 inches an hour, and it leaves a remarkably smooth, true surface. Wires may be run simultaneously in groups of 3 or 4 and, when carefully spaced to suit the dimensions of the finished products, will save much subsequent millwork. To minimize wear, very long wires are used, even as much as 16,000 feet long.

Figure 3 shows a gang of 4 wires spaced 3 feet apart. The wires and the points at which they leave the outs are shown at the lower right side of the figure, Figure 4 illustrates the remarkably smooth surfaces obtained with wire saws.

When primary cuts, made with channeling machines, with wire saws, or by drilling and broaching, terminate at open floor seams, the removal of blocks is greatly simplified. If no floor seam is available, a floor break is made by driving wedges in horizontal drill holes at the base of the bench.

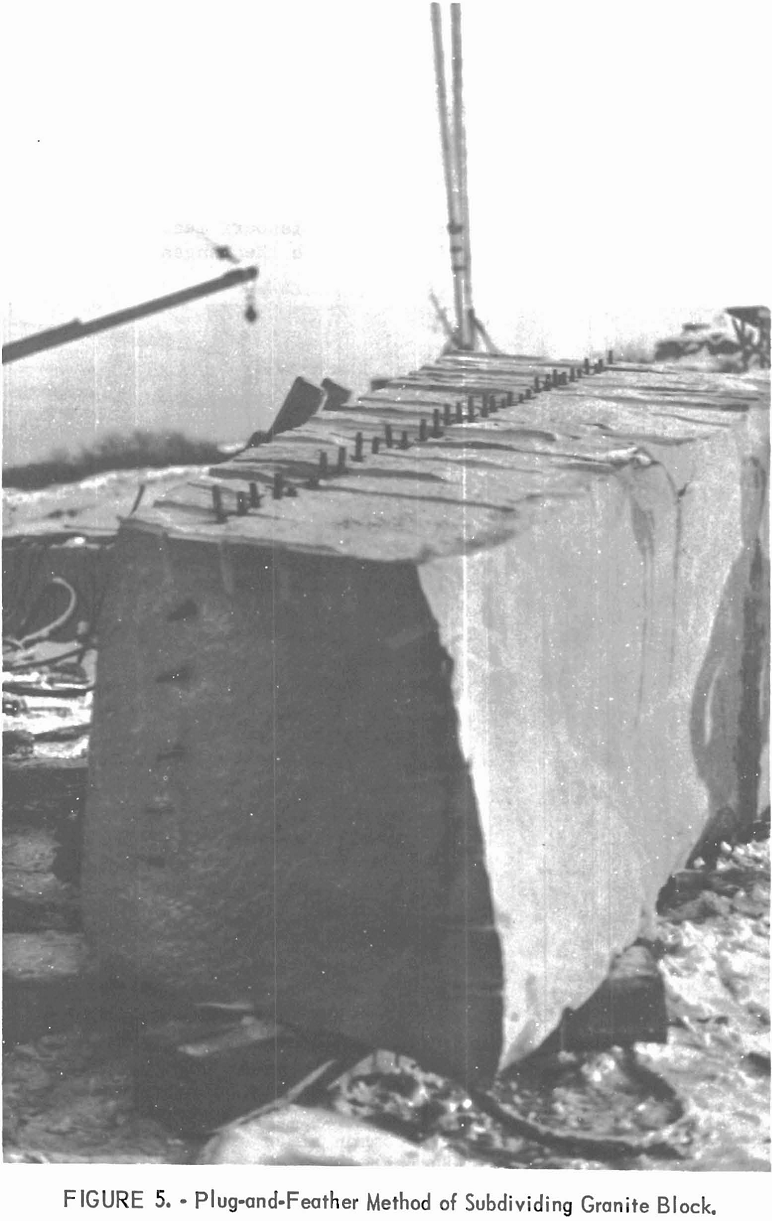

The next step is to subdivide the blocks into desired sizes. This is done by driving wedges in lines of shallow drill holes, called the plug-and-feather method. The feathers consist of iron plates rounded on one side to fit the wall of the drill hole and flat on the other for contact with the wedge. A pair of feathers is placed in the drill hole, and a steel plug or wedge is inserted between the feathers. Wedges are driven lightly in succession along a line of drill holes until a rift appears. The method is shown in figure 5. Blocks vary in size according to use. Common sizes of limestone mill blocks are 10 by 4 by 3 feet and 10 by 4 by 4 feet.

Cutting and Finishing Stone in Mills

Blocks of stone from the quarries are shaped into finished products in mills equipped with machines cf many types. Virtually all mills now have overhead traveling cranes for moving blocks and slabs of stone. Railroads or trucks are used to transport rough blocks to the mill and for shipping finished products. Mill equipment varies according to the type of stone to be fabricated. The equipment and methods used for each type of stone are covered briefly in the following pages.

Limestone (4)

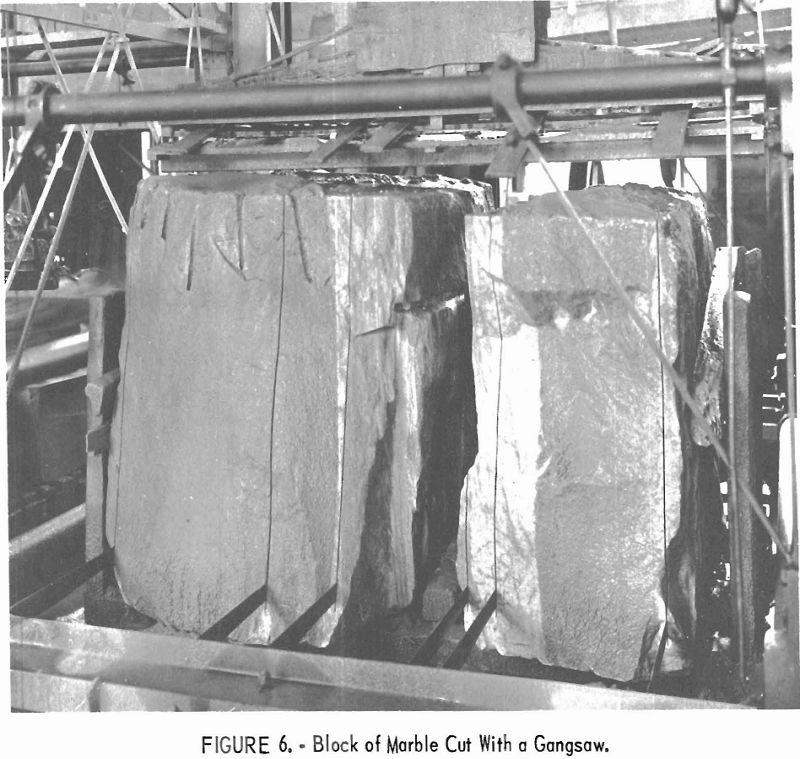

Rough blocks of limestone brought from the quarry are cut into blocks or slabs of specified sizes, usually with a gangsaw. The gangsaw consists of a series of soft steel blades set parallel in a frame that moves forward and backward. When fed with an abrasive carried in a stream of water, the blades wear their way downward at an average rate of about 6 inches an hour. Thus, the blocks are subdivided into sizes governed by spacing of the blades. Silica sand is the abrasive generally used. The sand should contain very little fine material. Chats of cherty limestone from the Missouri lead and zinc mills are sometimes used. Figure 6 shows a block on which the gangsaw cuts have just been completed.

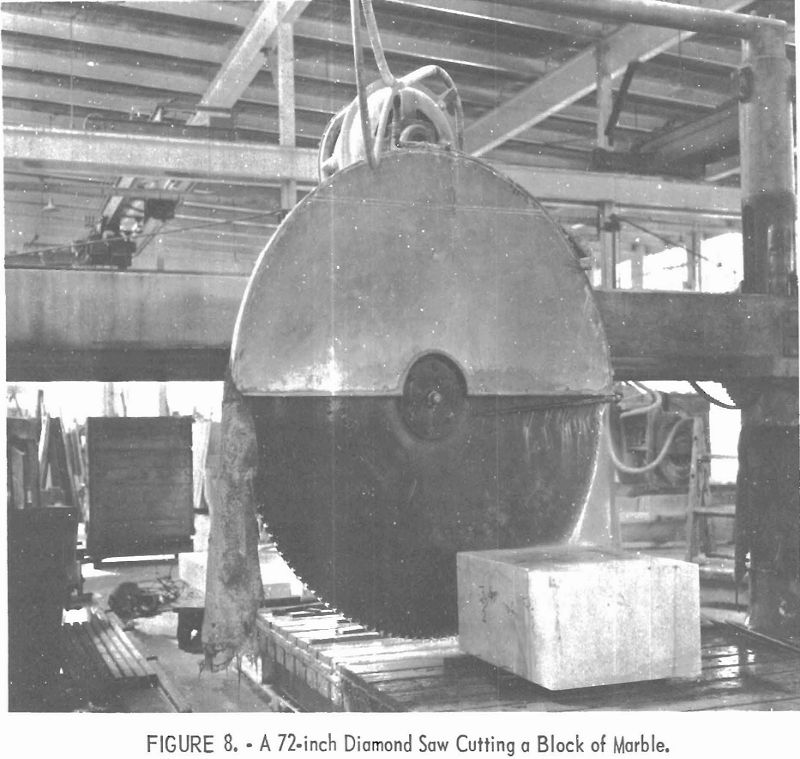

Diamond saws are widely used for making subsequent cuts. They consist of circular disks with square notches in the rim. Teeth mounted with diamonds are held in the notches by copper rivets. Common sizes are 72-inch saws with 100 to 125 teeth and 60-inch saws with 84 teeth; 36-inch saws also are used. The cutting edge must be cooled constantly with a stream of water. The saws cut rapidly and leave a smooth surface.

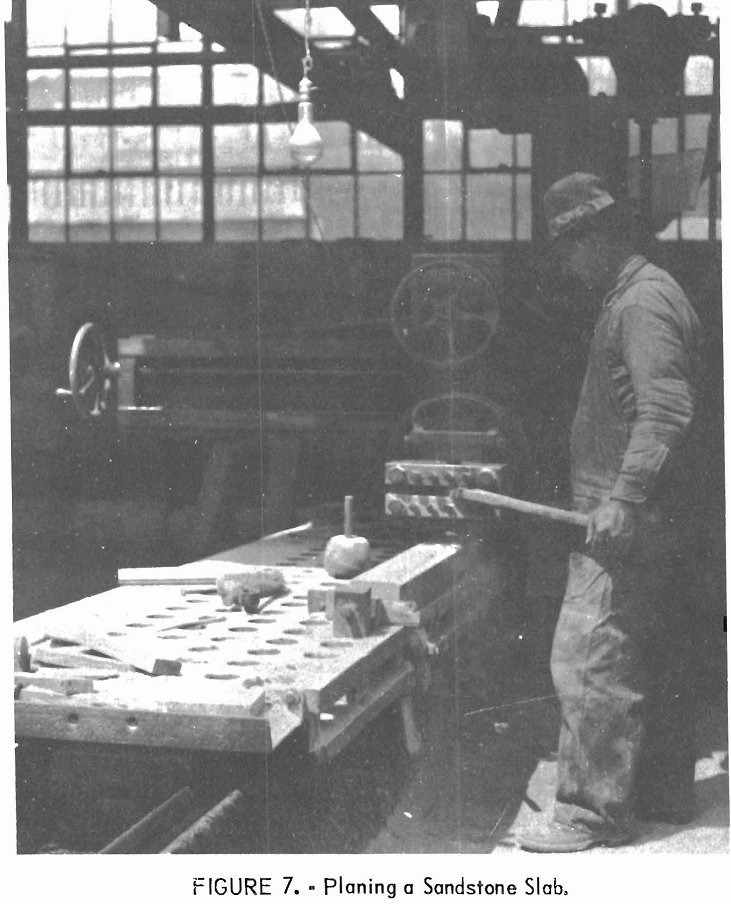

Planers are used for reducing blocks to smooth surfaces and desired dimensions. The planer blade has lateral and vertical motion. As the stone is carried beneath it on a traveling bed called a platen, the cutter scrapes a thin layer from the surface (see fig. 7). Both sides and the top of a block may be planed to desired dimensions. Moldings may be cut by using tools of any prescribed pattern. Some planers are adjusted to cut curved forms. A carborundum planer comprises two silicon carbide saws with a drum of smaller diameter between them. The planer trims the top and sides of a block with one motion. Lathes are used for making columns, and carving is done with pneumatic tools.

Building limestone is sold with various surface finishes. A tooled surface has fine, parallel grooves. A 4-cut surface is made with a planer tool having 4 corrugations to the inch. A bush-hammered surface is rough and pitted.

Marble (2)

Marble blocks are subdivided with gangsaws like those used for limestone. Generally sand is used as abrasive, but fine steel shot is used for cutting some hard marbles. Marble saws more slowly than limestone. Single cuts may be made with diamond saws. (See fig. 8.)

The terms “coping” and “jointing” are applied to the subdivision of marble slabs into baseboards, tile, steps, or other finished products. Coping is done with silicon carbide wheels or small diamond saws. Slabs and blocks cut to approximate size are sometimes squared and finished on a rubbing bed, which consists of a cast-iron disk 10 or 12 feet in diameter that rotates on a vertical shaft. The marble slab, resting on the surface which is fed with sand and water, is worn down to proper dimensions.

Gritting is a process that gives a hone finish – a smoother surface than that obtained on a rubbing bed. Gritting is done with revolving buffer heads of silicon carbide or aluminum oxide bricks.

Generally marble for interior use is polished. Polishing is done with revolving pads fed with putty powder – tin oxide or a mixture of tin oxide and oxalic acid.

Blocks and slabs may be recut to specified sizes with diamond saws, perforated steel saws employing steel shot as abrasive, or a straight diamond-toothed blade in a gang frame. Diamond saws have replaced most other types. Moldings and cornices are cut with planers or silicon carbide wheels.

Sandstone (2)

Sandstone mill blocks are subdivided with gangsaws, using sand or steel shot as abrasive. Sandstones vary in hardness according to the degree of cementation of the grains, and the sawing rate likewise varies. The blades may sink from 3 to 8 inches an hour when sand is used and 6 to 12 inches an hour when steel shot is used. Subsequent cuts are made with silicon carbide circular saws or with sintered-rim diamond saws. Wire saws are used at some plants for cutting sandstone blocks. Methods have been devised for using them to cut columns and decorative designs. Rubbing beds and planers are used in sandstone mills, as in limestone and marble mills. Curbing is sometimes made by reducing the blocks to dimensions with plug-and-feather wedges and finishing them with planers. In working hard sandstones, the planer tool must be cooled with a stream of water.

Bluestone, a variety of sandstone that splits readily into thin sheets, in past years was used extensively for flagging. Bluestone is still used for ornamental flagging and for steps, window sills, caps, coping, building stone, and curbing. Some rough blocks are sold by quarrymen to stone fabricators who fashion them into finished forms by processes similar to those used for other sandstone products. Some bluestone-quarry operators have their own mills.

Granite (5)

Blocks of granite are subdivided by driving wedges in lines of shallow drill holes. Such breaks are made in the direction of easy splitting, known as the rift. To obtain thin slabs of granite, some method of sawing must be used. The three types of saws are circular, gang, and wire. A typical circular saw is 11 feet in diameter and is equipped with detachable steel teeth. When fed with steel shot and water, it will saw granite blocks 24 to 30 inches thick at a rate of 1 inch to 2 inches a minute. The gangsaws are similar to those used for limestone, sandstone, and marble, but the blades usually are notched on the lower edge. Steel shot is used as abrasive. Wire saws, using aluminum oxide or silicon carbide as abrasive, also are employed. Although the cost per square foot of surface is considerably higher with wire saws than with gangsaws, the wire saw has two advantages. It conserves stone because the cut is only ¼ inch wide, whereas the gangsaw cut is 1-½ inches wide or more. Moreover, the wire-cut surface is so true and smooth that fewer finishing processes are needed.

When rough blocks are prepared for building stone, the rough surfaces may be worked to a smooth, even plane with a surfacing machine – a reciprocating tool covered with blunt projections. When guided over the surface, the machine chips off fragments of stone, gradually working the surface down to an even plane.

When polished surfaces are needed, 8 or 10 granite blocks are placed on a timber bed with their upper surfaces on an even plane. The blocks are surrounded by a wooden box, the bottom of which is a little lower than the upper surface of the blocks, and all cracks are filled with plaster of paris. Rotating scrolls, consisting of concentric iron rings, are fed with steel shot and water and guided over the surface. Finer shot and aluminum oxide are used in succession as the surface becomes smoother for a final polish rotating felt pads fed with putty powder are used, as in marble polishing.

Some silicon carbide wheels are used in granite finishing. Lathes are employed for shaping and polishing granite columns and spindles.

Carving may be done with pneumatic tools, but sandblasting has reduced carving to a minimum. For sandblast carving, a polished granite surface on which an inscription is to be cut is first covered with a rubberlike compound. The inscription is marked on the surface, and the coating is removed from all parts that are to be cut below the surface. Stone thus prepared is placed in a closed chamber, and a stream of sand or silicon carbide is directed against it at high pressure through a nozzle. The exposed granite is quickly cut away, but the abrasive has little or no effect on the surface coating. Designs that would require long and tedious work with hand or pneumatic tools are cut by sandblasting in a few minutes.

Slate (3)

For roofing slates, blocks of slate are split by hand with a thin chisel and mallet, the split always being made in the center of the block. The slates are split to a thickness of about 3/16 inch. The trimmer takes the slate from the splitter and trims it to the largest commercial size obtainable. The trimming machine is a straight blade operating like a papercutter.

For millstock products, such as blackboards, stair treads, or window sills, the quarry blocks are first cut to size with circular saws equipped with carbide-tipped teeth. The slaty cleavage permits slate to be split into slabs of any desired thickness, whereas sawing is required to make slabs from stone of almost all other types. Planers are used to reduce some products to proper dimensions. Diamond saws and silicon carbide wheels are used to cut slabs of slate to proper widths for window sills, baseboards, or other products. Smooth surfaces are obtained by using rubbing beds and buffer heads, as described under marble finishing.

Cutting and Polishing Gems and Semiprecious Stones

Materials Used and Their Products (10) (16)

Objects of unusual charm in brilliance, color, pattern, or form may be fashioned from many minerals and rocks by sawing, grinding, and polishing.

Suitable minerals and rocks are numerous and varied. They include agate, amethyst, jasper, onyx, opal, chalcedony, alabaster, malachite, beryl, garnet, zircon, obsidian, silicified wood, sapphire, ruby, emerald, tourmaline, topaz, jade, turquoise, and lapis lazuli. Even rocks and pebbles that appear commonplace, such as granite, syenite, marble, or conglomerate, when cut and polished may show surprisingly attractive colors and patterns. Many of these naturally occurring rocks may be fashioned into stones for rings, bracelets, brooches, pendants, or earrings. Some may be shaped into gift novelties, such as book ends, inkwells, pen sets, ashtrays, and vases, or they may be prepared as larger display specimens with highly polished surfaces.

Hardness of Ornamental Stones

Most gem and ornamental stones are very hard; therefore, the abrasives used to cut, grind, and polish them must also be hard. Quartz minerals (silicon dioxide), such as rock crystal, amethyst, agate, jasper, flint, chalcedony, or petrified wood, have a hardness of 7 in Mohs’ scale, which is harder than ordinary steel. The hardness of beryl (aquamarine and emerald), garnet, tourmaline, and zircon is about 7-½, topaz 8, and corundum gem stones (ruby and sapphire) 9. Diamonds are designated as 10 in the Mohs’ scale of hardness but are actually much harder. Abrasives commonly used, such as silicon carbide and aluminum oxide, have a hardness of as much as 9-½. Diamond dust or chips are the hardest of all abrasives, and they cut and grind much faster than other abrasives.

Principal Operations

The main operations in cutting precious and ornamental stones are sawing, grinding, lapping, sanding, and polishing. The processes are described briefly in this paper; further details are given in the literature.

Sawing

Types of Saws

The type of saw used widely in early days, and still used to some extent, is the mud saw. It consists of a mild-steel, circular, rotating blade fed with a mud made of clay and 100- or 220-grit silicon carbide. The mud is supplied constantly to the blade, which carries it to the stone surface, where it advances the cut by abrasion. Saws of this type are employed chiefly today for making cuts so large that using a suitable diamond saw would be very expensive.

Diamond saws are the most widely used type. They differ from mud saws in one important respect – the abrasive is locked in the saw rather than being carried with the blade in the form of mud.

A popular diamond saw is the notched-rim-blade type. It consists of a disk of mild steel or copper, in which evenly spaced notches about 1/8 inch deep are cut in the rim. Diamond dust is introduced into each slot, sometimes in the form of vaseline paste. The slots are then closed with a steel roller that presses the metal over the diamond dust. At the same time the roller enlarges the edge to give the set or clearance that any saw must have.

Another popular diamond saw is the sintered-rim-blade type. Diamond grit is mixed with powdered metal and compressed into a hoop, which is subjected to a temperature high enough to fuse the metal particles. The hoop is then soldered to the edge of the saw disk. The sintered-rim saw is more expensive than the notched-rim saw.

The action of both saws is the same. When the rotating blade comes in contact with the stone, the surface metal is quickly worn away, exposing the diamond particles, which do the cutting.

Very large stones usually are cut with handsaws. A typical bandsaw consists of a 21-foot, endless ribbon of steel, 1-¼ inches wide and approximately 1/16 inch thick. The steel ribbon is carried as a belt over two 42-inch wheels at a speed of about 2,200 surface (wheel circumference) feet per minute. The specimen to be cut is firmly clamped and brought in contact with the edge of the ribbon by means of a screw-feed table. No. 100-grit silicon carbide abrasive is fed to the edge of the ribbon with a small stream of water. About 1 pound of abrasive is used per hour, but the abrasive may be recovered and reused. A wire is sometimes used instead of a steel ribbon.

When a band or wire saw is properly operated the cut is smooth and flat. A wavy surface indicates that the feed pressure is too great. Uneven cutting is undesirable as it involves additional grinding.

Sawing Equipment

The circular diamond blade is mounted on a shaft provided with a pulley and belt to connect with a source of power, such as an electric motor. Saw speeds usually range from 2,000 to 3,000 surface feet per minute. The manufacturer of the saw probably will specify the speed at which it should be run.

A moving carriage also is needed to carry the specimen to be sawed. It should have a strong vice or clamp to hold the specimen firmly. It is of primary importance that the specimen be held firmly so that it cannot shift while the cut is being made, because lateral movement of the stone while the saw is running in the cut might so damage the saw that it could not be used until repaired.

The stone may be moved against the saw by hand, but a mechanical feed is preferable. The simplest and least expensive mechanical feed is the gravity or weight type. A cord or wire, fastened to the carriage and passing over a pulley, carries a weight that furnishes the force necessary to move the carriage. The weight must be carefully adjusted. If the weight is too heavy, the saw will cut too rapidly, resulting in an uneven cut and excessive wear on the blade. If the weight is too light, the cutting rate will be unnecessarily slow. A screw feed is preferred by most operators. It consists of a mechanically rotated threaded shaft connected with the carriage, which it moves at a constant rate. It costs considerably more than the weight feed but is far more efficient. A hydraulic feed is also employed.

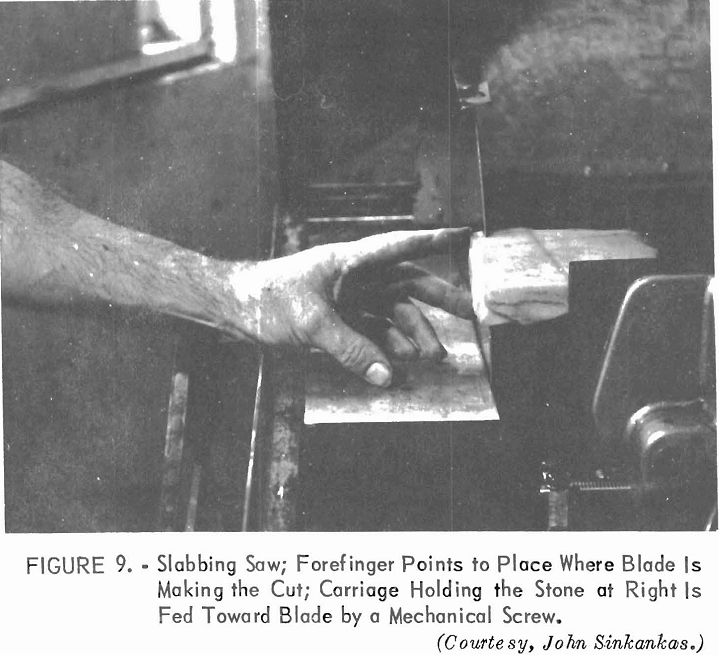

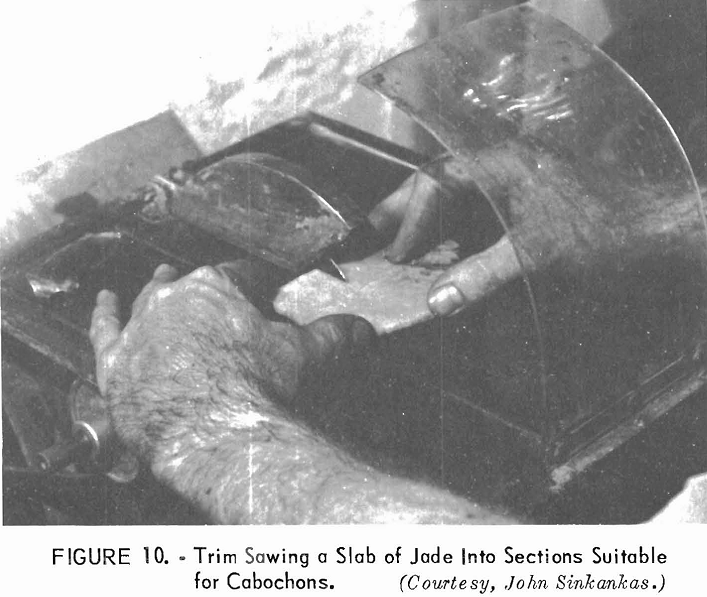

A tank must be provided beneath the saw to hold a cooling liquid that covers the lower segment of the blade. The coolant may consist of equal quantities of kerosene and motor oil, but a mixture of 5 parts kerosene to 1 part motor oil has been used successfully. A splash hood to catch the spray and return it to the tank is also necessary. Figure 9 shows a slabbing saw and figure 10 a trim saw.

Grinding

Grinding is the process of shaping stones with abrasive wheels. Silicon carbide wheels are used almost exclusively for grinding gems. In making abrasive wheels, clay mixed with water is added to the grit and the mixture compacted in a mold. After drying, the molded wheels are heated to a high temperature. The heat fuses the clay into a strong bond that holds the abrasive grains together. If considerable clay is used, a hard wheel is formed, but with a small quantity of clay the wheel is soft. A hard wheel wears slowly and tends to glaze, resulting in very slow grinding. With a soft wheel the abrasive grains break away, leaving a fresh surface that cuts the stone rapidly, but the wheel wears out rapidly. A medium-hard or medium-soft wheel is preferable for lapidary work.

The coarseness or fineness of the wheel depends upon the size of the grit. For rough grinding and shaping, a 100- or 120-grit abrasive wheel generally is used, but to obtain a relatively smooth surface a 220-grit abrasive wheel is used. A coarse wheel and a fine wheel may be mounted on the same shaft. Information on safe and effective speeds of rotation is supplied by the wheel manufacturers. Common speeds are 4,000 to 6,000 surface feet per minute.

Wheels should always be operated wet. A drip container placed above the wheel can supply water at any desired rate. A splash hood is necessary to collect the spray from the wheel and to protect the operator in the rare event of wheel breakage.

Grinding should always be done in the direction the wheel rotates. Holding a specimen slanting toward the approaching wheel surface is dangerous, because edges or corners may chip and damage the wheel or the stone may be plucked from the hand.

Lapping

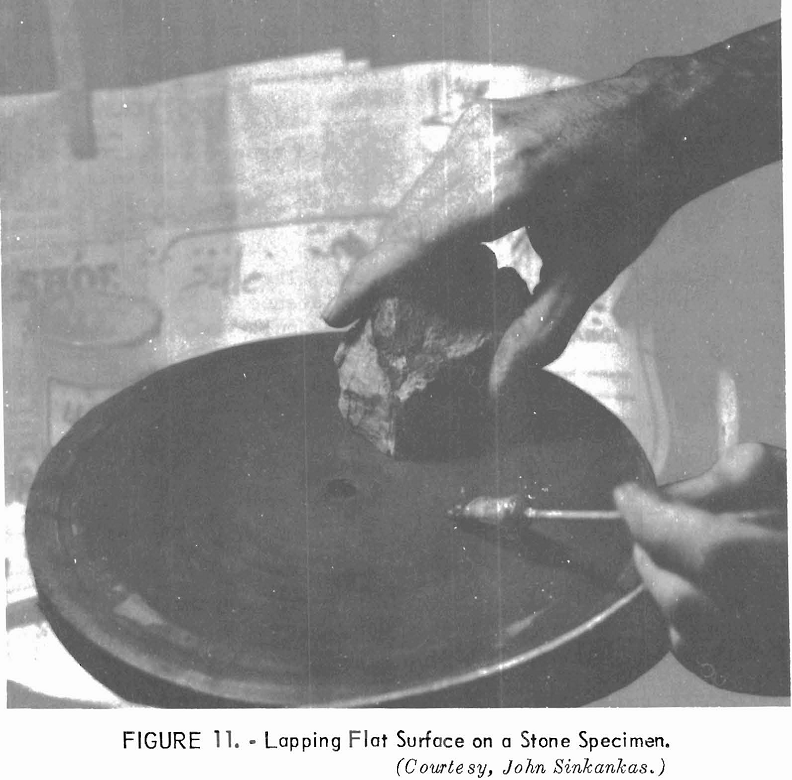

The lap is an important piece of grinding equipment. It consists of a disk of metal or other material that rotates on a vertical axis. A wet abrasive is placed on the surface, and the stone is generally held by hand. A drip container keeps the surface wet. The lap plate is enclosed in a splash pan and is removable so that the pan can be cleaned. Mild-steel or cast-iron plates are preferable because they wear slowly. The plates vary considerably in size. A plate 16 inches in diameter is common. The speed of rotation may

range from 250 to 300 revolutions per minute. If the wheel is rotated too rapidly, the abrasive is thrown from the surface by centrifugal force.

It is important that the surface of the lap plate be worn evenly; hence the stone should not be held in one position but should be moved back and forth from the center to the circumference of the plate.

Lapping (see fig. 11) usually is done in several stages, For coarse grinding, a 220-grit silicon carbide may be used; for the second step, a 400 grit is suitable; and for the third stage, which gives a smooth surface ready for polishing, a 1,200 grit may be employed. The abrasives should be stored in well-marked containers. A small quantity of the grit is placed in a cup, an equal quantity of water is added, and the mixture is applied to the lap with a brush. Fine abrasives should be used sparingly.

The lap should be cleaned thoroughly at the end of each stage so that no coarse particles will remain to mar the effect of lapping with a finer abrasive. Frequent and careful inspection of the stone surface is necessary to insure that scratches are completely removed before finer grinding is undertaken.

Sanding

Sanding is the process of smoothing a stone surface with a flexible sanding cloth. Obviously, if the stone has been ground with a 1,200-grit abrasive on a lap, sanding may be unnecessary, but frequently sanding is the best preparation for final polishing. Grinding on a lap may be partly a shaping process, but the purpose of sanding is to smooth and not to shape.

Sanding cloth consists of a strong cloth covered with a uniform layer of carefully sized silicon carbide grit. For coarse sanding, a 220-grit cloth may be used and, for finer work, a 400- to 600-grit cloth or finer. Sanding may be done either wet or dry, but wet sanding is preferable because dry sanding generates frictional heat that may be detrimental to the stone. Moreover, with dry sanding the surface becomes clogged with dust, whereas with wet sanding the surface stays clean. For wet sanding, the abrasive is attached to the cloth with a plastic resin glue that is moistureproof.

Sanders may be in the form of disks, drums, or belts. Disk sanders are of two types – horizontal and vertical. They are similar, except that one rotates horizontally and the other vertically with the sanding cloth on one side. The disk is usually made of wood, about 1 ¾ inches thick and 8 inches or more in diameter. The surface is covered with a ¼-inch layer of sponge rubber to give the sander resiliency and flexibility. The abrasive cloth is stretched over it and may be held in place with a metal hoop or snap rim or may be cemented in place.

Drum sanders 2 to 3 inches thick are also used. Abrasive cloth is wrapped around the drum over a sponge-rubber cushion. The ends are inserted in a slot that is closed with a screw. Either the wet or dry process may be used.

Belt sanders are becoming more popular. The belt of abrasive cloth passes over two rubber-faced pulleys some distance apart. Flat surfaces can be sanded best where the belt passes over the pulley, because pressure can be applied at that point. Rounded stones or gems can be sanded best on the unsupported belt between the pulleys, which yields to pressure and conforms to the shape of the stone.

Sanders give best service when run at high speeds. Metal-hoop or snapring disks may be run at a maximum speed of about 3,000 surface feet per minute, cemented disks and drums at 4,000 surface feet, and belt sanders at 3,000 to 4,000 feet. For the wet process a water tube or drip container must be provided, and a splash hood is essential.

Flat surfaces can be sanded best on belt or drum sanders. Disk sanders are satisfactory for curved surfaces. Sanding is continued until all scratches made with the lap are removed, leaving a smooth, uniform surface ready for the final polish.

Polishing

Polishing is the final stage in finishing the surface of a gem or other ornamental stone. It is done by pressing the stone against a soft, rotating buff charged with a water suspension of an extremely fine polishing powder. The polishing process is not fully understood. It is not simply another smoothing process. A brilliant polish appears to result from flowage of an infinitesimal surface layer caused by the intense heat generated by friction of the buff on the stone surface.

Polishing Buffs

Polishing buffs are usually wheels or disks. Most wheels are made of compressed wool or felt, 1 inch to 2 inches in thickness and 6 inches or more in diameter. They give best service at relatively slow speeds – 1,000 to 2,000 surface feet per minute. As the buff tends to wear rapidly, the wear should be distributed over the entire surface. Solid felt wheels may be hard or soft. Soft wheels generally are used for polishing the softer stones.

Other buffs consist of wooden disks covered with felt. They may be 1 inch to 2 inches thick and 6 inches or more in diameter. The felt sheet is about ¼ inch thick. Leather buffs give good service. They may be made of solid leather, such as walrus hide, or of a sheet of leather glued to a disk. Cloth also is used on disk and drum buffs. Wooden buffs of teak, mahogany, beech, birch, or cherry are used widely in some European gem-cutting centers.

Polishing Agents

Tripoli (finely divided quartz), aluminum oxide, and tin oxide are popular polishing powders. Tripoli is a general-purpose agent. Aluminum oxide gives the best service on the softer stones, particularly with leather or wooden buffs. Tin oxide (putty powder) is used in most monument shops and other commercial-stone-polishing establishments. It is often used in lapidary work to give a final, glossy finish. Cerium oxide, one of the newer polishing agents, is preferred by many for polishing quartz minerals. Chrome oxide and ferric oxide (rouge) are effective but are objectionable because they stain hands and equipment.

Polishing Operations

The polishing powder is mixed with water and applied to the buff with a brush. Addition of a few drops of a household detergent is said to promote even distribution of the polishing agent. The material should be applied in small quantities only. A separate dustproof receptacle and brush should be provided for each powder. It is important also to use only one polishing agent on a buff. If it is desirable to use several polishing powders, a separate buff should be furnished for each powder. If the surface has been properly prepared, polishing requires only a short time.

Drilling

For pendants and some other ornaments, the stone must be perforated. To drill small holes, a rotating needle is fed with an abrasive such as diamond dust, silicon carbide, or boron carbide. The drill press should be rigid and true. Moreover, the stone should be held firmly in place so that it cannot move. It may be cemented to a block of wood with dopping wax.

For small holes, a 220- or 230~grit abrasive is used, A 100-grit abrasive is employed for larger holes. The drill should be raised and lowered frequently to permit the abrasive to fall below the point; otherwise, the needle will wear and possibly jam. Some drills run at speeds of 3,000 to 5,000 revolutions per minute.

Larger holes may be drilled with rotating tubes of iron, copper, or brass.

As with needle drills, the tubes should be raised or lowered frequently to keep a supply of abrasive at the cutting edge. Some drills have mechanisms for making such motions automatic.

Cutting Cabochons

The cabochon is the simplest form in which precious or ornamental stones are cut for jewelry. The visible surface of the stone is domed, and the back is usually flat. The edge or outline of the stone is known as the girdle. The dome may be high or almost flat. Double cabochons are those that have domed surfaces on each side of the plane formed by the girdle. They are commonly used as pendants. The standard shapes include the oval or ellipse, the circle, and the rectangle. Hearts and crosses also are made, but their fabrication is difficult.

Various minerals may be used for cabochons. Agate, jasper, opal, turquoise, tourmaline, tiger’s eye, labradorite, and petrified wood are popular. Fibrous minerals should be cut with the fibers paralleling the base of the cabochon. Banded stones, such as agates, are cut in directions that will give the most attractive patterns. Many show concentric bands of varying colors. Stones having attractive inclusions, such as moss and landscape agates, are cut in directions that will exhibit the inclusions to best advantage.

The first step in making a cabochon is selecting the proper direction for cutting and sawing a rough slab. Slabs usually are 1/8 to ¼ inch thick but may be thicker for larger cabochons. Patterns of the desired size and shape are placed on the slab in positions selected carefully to avoid flaws and imperfections and exhibit the most desirable inclusions. The most interesting and colorful parts are used for the front or top of the finished stone. The outline of the pattern is marked on the slab with a sharp aluminum pencil. The slab is then cut with a trimming saw to separate the blank, but the cuts should not be made too close to the line. At least a 1/8-inch margin is provided because of possible chipping. The crude blank is then trimmed with a coarse grinding wheel to within 1/16 inch of the pencil line.

The blank is then mounted on a dop stick, which is similar to a penholder and is about 5-½ inches long. The stone is attached to the stick with dopping wax ~ a mixture of sealing wax, shellac, clay, and a small quantity of beeswax. The stone is brought into contact with the grinding wheel in such a position that a band will be cut above the girdle slanting toward the top of the stone at an angle of 20° to 25° from vertical. A second band is then ground above it at a flatter angle. For thick stones, more beveled bands may be ground before the flat top is reached. The sharp edges between the bevels are then rounded off with the grinding wheel. Thus the cabochon has been shaped to rough but true form.

The next steps are designed to give a smooth, uniform surface. These steps include fine grinding, coarse sanding, fine sanding, and polishing, as already described. The base of the cabochon may be simply ground or, for translucent or transparent stones, polished.

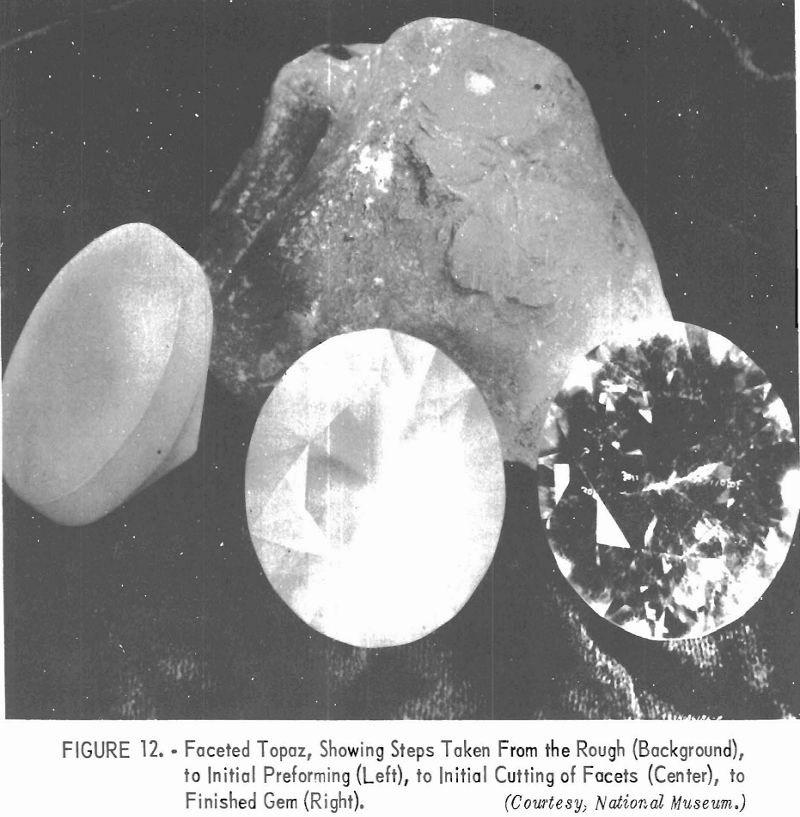

Cutting Faceted Stones

Instead of the curved surface of the cabochon, the faceted stone has small plane surfaces uniformly spaced in matching sets, pairs, or series. The principles involved in cutting and polishing cabochons also apply to fashioning faceted stones, but considerable skill is required in proportioning the facets properly and in determining their positions and angles of intersection. Actually only two angles must be determined for each face – the angle of elevation to cut the sloping step and the angle of rotation to fix the position of the facet on the circumference of the stone. Crude hand methods are widely used, and through long years of experience the artisans attain surprisingly accurate results, Mechanical faceting heads have displaced much hand equipment, particularly in the United States.

Facet cutting, illustrated in figure 12, is a special art, and many amateur lapidaries lack the skill or equipment to do it effectively. If the amateur wishes to venture into this field, several excellent books are available that describe the processes and equipment in detail. One recent book devotes nearly 100 pages with many illustrations to this art. The subject is too complex and the descriptions are too voluminous to be covered in this report.

Cutting Jade

Jade (jadeite or nephrite) is not only hard but extremely fine grained and tough. Cuts can be made satisfactorily in large masses with wire saws. Subsequent operations may be carried on with regular equipment described in this paper, but the successive steps may require more time than is needed with many other rocks and minerals.

Jade-cutting technique recommended by an experienced lapidary involves: (1) Rough grinding with a 100-grit silicon carbide wheel; (2) finish grinding with a 180-grit wheel; (3) sanding with a 200-grit abrasive; (4) finish sanding with a well-worn sander of the same grit; and (5) polishing on a leather lap with tin oxide (6). Various modifications of these steps have been advocated by artisans who have devised and perfected special processes.

The Chinese are noted for their outstanding work in cutting and carving jade. Their intricate carvings are highly prized among collectors- A white jade object in a London museum is said to have been carved by 3 generations of Chinese workers over a period of 85 years.

In 1928 Frank L. Hess of the Bureau of Mines visited several jade-working establishments in China. He reported that the workmanship was excellent but that the methods were crude. Jade was sawed with a wire attached to a bamboo bow; 60-mesh silicon carbide was used as a cutting agent. Circular cuts were made by tin-plated cylinders rotated in alternate directions by means of a leather strap motivated by a foot treadle; silicon carbide was used as abrasive. Grinding was done with a wheel, the rim of which was fed with silicon carbide powder. The wheel also was driven by strap and treadle. The jade was polished with ocherous clay and water on small leather wheels.

Cutting Quartz Crystals

Quartz crystals suitable for controlling frequency in electronic communications equipment are important in industry as well as In the military program. The crystals are cut into thin wafers with large diamond saws. The wafers are then “diced” into “blanks,” a process that involves removing imperfections and cutting to desired dimensions. Dicing is done with smaller diamond saws. The blanks are then lapped to smooth, parallel surfaces and to precise thicknesses. In lapping, successively finer grits of abrasive powder are used. Thickness tolerances are less than 0.0001 inch. This branch of mineral cutting and grinding is highly specialized.

Tumbling

Stones for inexpensive jewelry may be ground and polished by tumbling them in rotating cylinders. There are many types and sizes of tumbling equipment. Cylinders may be small enough to hold only 1 pound or more of stones or large enough to hold 100 pounds or more. Usually the cylinders are rotated simply by resting them on rubber-covered rollers driven by small electric motors .

The materials to be treated are gem or other ornamental stones in various shapes and sizes, Generally, the fragments are of approximately the same hardness.

There are three principal tumbling operations. First, a coarse abrasive, possibly an 80 grit, is added to the charge, and the cylinder is rotated continuously for 3 or more 24-hour days. This coarse grinding is followed by a similar period of tumbling with a fine abrasive such as 400 grit. The final stage, which also may require several days, is to give the stones a final polish, after the charge is thoroughly washed to remove all grit; a polishing agent such as tin oxide is used.

The stones may not be as brilliant as those polished by ordinary methods, but they are adequate for costume jewelry and similar uses. The labor involved in tumbling is small compared with that required for standard cutting and polishing, and little skill is needed. Be sure to choose a rock tumbler from our recently updated guide for 2022.

Special Cutting Processes

Some newer techniques for machining and grinding have created considerable interest in abrasives. Although these techniques have been used little if at all in cutting or finishing ornamental stones, advances have been so rapid that their use in lapidary work is a definite possibility.

Electrodischarge processes, including electrosparking and electroarcing, and electrolytic processes apparently are applicable only to metal working. The so-called electrosonic process, however, might be applied to stone cutting. In this process the grinding or cutting tool is vibrated at a frequency of 16,000 to 29,000 cycles per second through an amplitude of not more than a few thousandths of an inch. The abrasive usually employed is a 280-grit boron carbide which is carried in water to the tool at the cutting surface. Further information has been published.

Precautionary Measures

As most minerals and rocks cut for ornaments are very hard, the sawing and grinding equipment must be handled with care and the processes conducted slowly. Efforts to speed the rate of sawing by increasing unduly the pressure against the blade not only shortens the life of the saw but results in an uneven cut. Saws must not be run dry, and grinding wheels must never be operated above speeds recommended by the manufacturers.

Lapidary Equipment and Supplies

Amateur lapidaries may obtain equipment and supplies from many sources. The popular magazines listed in the bibliography advertise many firms that furnish gem-cutting equipment, supplies, and raw gem stones. Simple, low-priced machines are described and illustrated, as well as more elaborate and costly machines,. These magazines also contain many articles on gem cutting, gem-stone occurrences, and earth sciences in general.