Table of Contents

Most of the mines with large openings in the United States today are salt and limestone mines. Some potash and trona mines also have moderately large openings. Moreover, it is expected that in the near future numerous underground oil shale mines will be developed in the oil shale regions of Colorado, Utah, and Wyoming. These mines will also have large openings ranging up to 2,000 or 3,000 square feet in area.

In general, mines having large openings move considerable volumes of air through the mine for ventilation purposes. However, because of the large cross sections of the airways, the flowrates are often quite low, sometimes less than 100 fpm, making these ventilation systems less efficient than those in mines with small airways. In addition, poorly constructed stoppings can result in substantial lasses of intake air before it reaches the working face. If auxiliary fans are located in an insufficient air base, they can result in recirculation of return air into intake airways.

In mines with large openings, as in all mining operations, the budget and the size of the work force are limiting factors. They can have a significant influence on the manner in which stoppings are constructed. The location of the stoppings and whether they are to be temporary or permanent are important factors. If stoppings are constructed in the vicinity of the working face, they will be exposed to blasting pressures and flying debris. Stoppings in airways that carry mine traffic must be constructed to allow for the movement of mine equipment. Stoppings that are needed for only a short time can be built more rapidly and cheaply than permanent ones.

To obtain information on the current methods of closing large openings, several mines containing such openings were visited. The various procedures for closing large openings used at these mines were studied and evaluated.

Closing Openings with Waste Materials

Many hardrock mines have large quantities of mined waste materials that must be disposed of either in the mine or outside in waste piles. In some mines this waste material is being used to close up large openings. Stoppings can be built of waste material in several different ways.

One method is to pile heavy burlap sacks filled with fine waste material to form a stopping across an opening in much the same way as a levee is built to prevent flooding. Because of its high density, this type of stopping is airtight and fairly stable, even against blast forces. It also has the advantage that the waste bags can adjust and compress to allow for roof sag without weakening the stopping. On the other hand, construction of this type of stopping requires a considerable number of man-hours, especially in high openings where the difficulty of piling the bags increases with stopping height. Another disadvantage of this type of stopping Is that it closes the roadway permanently to future mine traffic. This may or may not be a problem. In the case of a mine fire, these stoppings could collapse if the burlap sacks catch fire.

In some mines where large quantities of waste material are available, a common practice is simply to close large openings by dumping the waste material in the opening and bulldozing it to the roof with a bulldozer or front-end loader. This type of stopping forms an extremely efficient, stable air barrier. Its construction is fairly time consuming because of the hauling and plowing required, but otherwise the wastes would have to be hauled away for disposal. The main drawbacks of this procedure are the difficulty of plowing the wastes completely to the roof, especially in high airways, and the gaps that eventually develop between the roof and the waste pile due to settling. Like the wastebag stoppings, these stoppings permanently prohibit mine traffic.

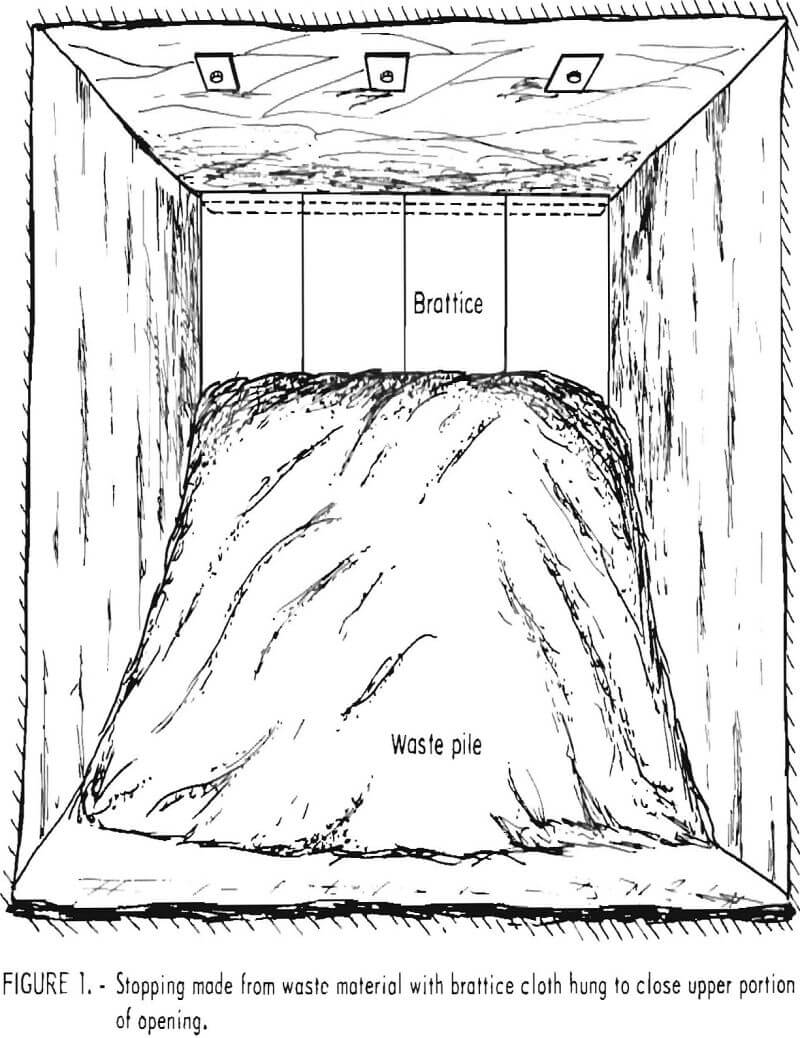

In an attempt to eliminate these problems, some mines have tried variations of this procedure. The waste material is pushed to within several feet of the roof and the remaining gap between the roof and the waste pile is closed either with bags of waste material or with brattice cloth (fig. 1). Because piling bags of waste is both difficult and time consuming, and gaps continue to form due to settling, hanging short pieces of brattice cloth

appears to be preferable. A trench 1 to 2 feet deep is dug along the top of the waste pile, and short lengths of brattice cloth are hung from the roof, extended into the trench, and secured by filling the trench with fine wastes. As the waste pile settles the brattice cloth slides up through the wastes and prevents a gap between the roof and waste pile. The major objection to using brattice cloth in this way is that the cloth may be damaged by blasting if the stopping is near the working face. All of the stoppings built by piling waste materials are fairly fire resistant.

Urethane-Foam Sealed Stoppings

In two of the mines visited, stoppings had been constructed by hanging several layers of chicken wire across the opening and coating it with a heavy layer of urethane foam. Stoppings constructed in this manner proved to have drawbacks far outweighing their benefits. As air barriers these stoppings are extremely efficient, but they are very time consuming and expensive to erect, they are too light to withstand blasting, and they permanently prevent mine traffic. In addition, the flammability problem associated with the use of urethane foam may restrict its use in many mines, although some urethane foams now contain fire-retardant chemicals.

Stoppings from Concrete Blocks or Wood

Concrete block stoppings have been employed successfully in several mines with large openings where they have proved to be effective air seals. Concrete block stoppings are also highly fire resistant. However, construction of this type of stopping should be avoided in mines where there is a gradual sagging of the roof. Salt mines are an example of this type of mine. In such mines the concrete block stoppings will be destroyed as a result of crushing. Other negative factors are the high costs of construction and the possibility of severe blast damage if the stoppings are too close to the working face. Concrete block stoppings should be constructed far enough from the face to avoid large blast pressures.

Various ways of constructing wood stoppings in large openings have been tried, but none of them have proved successful near the working face where they incur extensive blast damage. Wooden stoppings are generally constructed by building a frame with two by fours and covering it with plywood or some other sheeting. Such stoppings are fairly time consuming to construct and do not usually form a good airtight seal with the walls and roof.

One mine attempted to protect wood stoppings against blast damage by attaching the stoppings to roof bolts projecting several inches from the roof and allowing the stoppings to float a few Inches off the mine floor. It was hoped that the stoppings would swing back on the roof bolts to relieve the blast force,but they were still heavily damaged by blasting.

A second procedure that was attempted was to build swinging doors in the stoppings to relieve the blast pressures. Various sizes and types of doors were tried, but damage due to blasting continued to be substantial, because the shock wave velocities from the blasts were too high for a swinging stop-ping or a door to offer relief.

Wood stoppings also offer little resistance to fire.

Closing Large Openings with Brattice Cloth

Methods of hanging brattice cloth to close large openings and the types of brattice cloth used for this purpose vary considerably from mine to mine. Most of the damage to stoppings built with brattice cloth is caused by blasting or moving equipment. Blasting damage can vary from complete destruction of the stopping by shock waves to holes caused by flying debris. Moving equipment generally damages the brattice cloth by snagging as it moves through the stopping.

Most of the mines visited had at one time or another used jute brattice. Where the humidity was high, the jute cloth proved unsatisfactory. Both the additional weight due to the absorbed moisture and the gradual decay which occurred to the moist jute made the useful life of stoppings constructed with this material very limited. In mines with low humidity the jute brattice appears as good as any other material. One of the mines was using jute brattice coated with plastic on one side, which made it stronger, less absorbent, and more airtight than plain jute cloth. Although it was not observed to be in use, jute brattice with plastic coating on both sides; is also available commercially and would eliminate the problem of moisture absorption.

The most common type of brattice material employed in large opening mines is plastic brattice which can be purchased in various thicknesses and strengths. Plastic brattice is generally preferred because it is airtight, does not absorb moisture, and slides easily over moving mine equipment.

In all of the mines visited in this study, the brattice materials used were in conformity with the ASTM, E-162 flame spread specifications. They all had a flame spread index of less than 25.

All types of brattice material can be easily damaged by blasting and by moving, mine equipment. This, coupled with the need for stoppings which act as efficient air barriers, points to the importance of having workable methods for building and repairing brattice cloth stoppings.

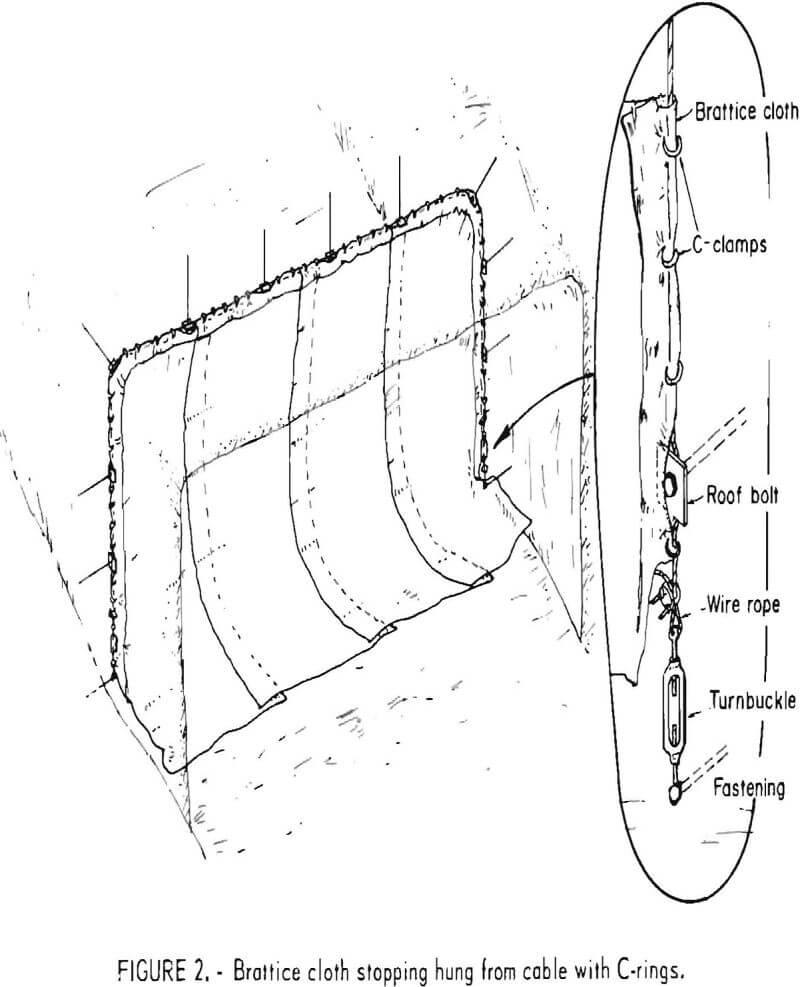

One of the more frequently employed methods of hanging brattice cloth in large opening mines is to hang the cloth from a wire cable attached to the roof and ribs of the opening. Several variations of this method were observed. In one mine, the wire cable was attached to the rib by means of a turnbuckle located a few feet from the mine floor. The cable was then run up along the rib, across the roof, and down the other rib where it was attached to a second turnbuckle. The cable was fastened to the roof and ribs by clamps or roof bolts driven into the rock. The brattice cloth, which generally comes in widths of from 7 to 9 feet, was lapped about 6 inches over the cable and clamped to the cable at the roof and ribs about every 6 inches with small metal C-rings that were squeezed shut around the cable (fig. 2). The individual widths of brattice cloth that were hung side by side were overlapped 1 to 2 feet to cut down on air leakage. An extra 2 or 3 feet of brattice were allowed at the floor for the same purpose. The brattice cloth used in constructing these stoppings was purchased in long rolls, and the individual vertical panels were cut to the desired length.

Another mine used a similar technique, except that the brattice cloth was purchased in precut lengths to exactly match the openings and grommets were attached along the top of each brattice panel. The wire cable can be passed through the grommets before being raised and attached to the roof and ribs, or the cable can be hung first and the brattice cloth attached to the cable by running plastic fasteners through the grommets and around the cable. All of these methods of hanging brattice result in stoppings that are good air seals if they are properly maintained. They also offer the advantage of allowing

mine traffic to pass through them if care is taken not to snag the brattice material. Their big drawback is that they can be easily torn at the points of attachment by blasting.

In two of the mines visited, some brattice cloth was attached to the roof and ribs with a spad gun at intervals of about 1 foot. This is not a recommended technique because the brattice can easily be torn where the spads are driven through it. In one area where jute brattice was hung in this manner, the brattice tore away from the spads after increasing in weight as a result of moisture absorption. However, if a short-term temporary stopping is needed, then this method of hanging brattice cloth might be acceptable.

Several mines had tried purchasing brattice materials in single precut sections, sewn to fit the openings. In some cases these premade sections were as much as 40 feet high by 60 feet wide. These sections were purchased with grommets along the top edge by which a section could be attached to a wire cable as described in one of the previously discussed methods. Such stoppings are more severely damaged by blasting than those hung as a series of smaller vertical panels. The premade curtains are also substantially more expensive

than buying rolls of brattice material and cutting smaller panels to the required lengths.

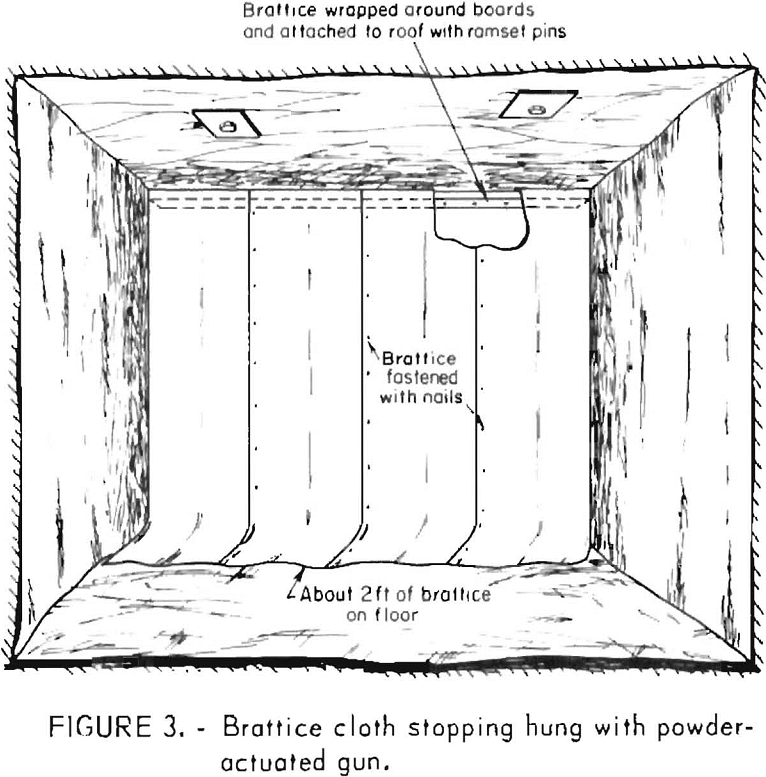

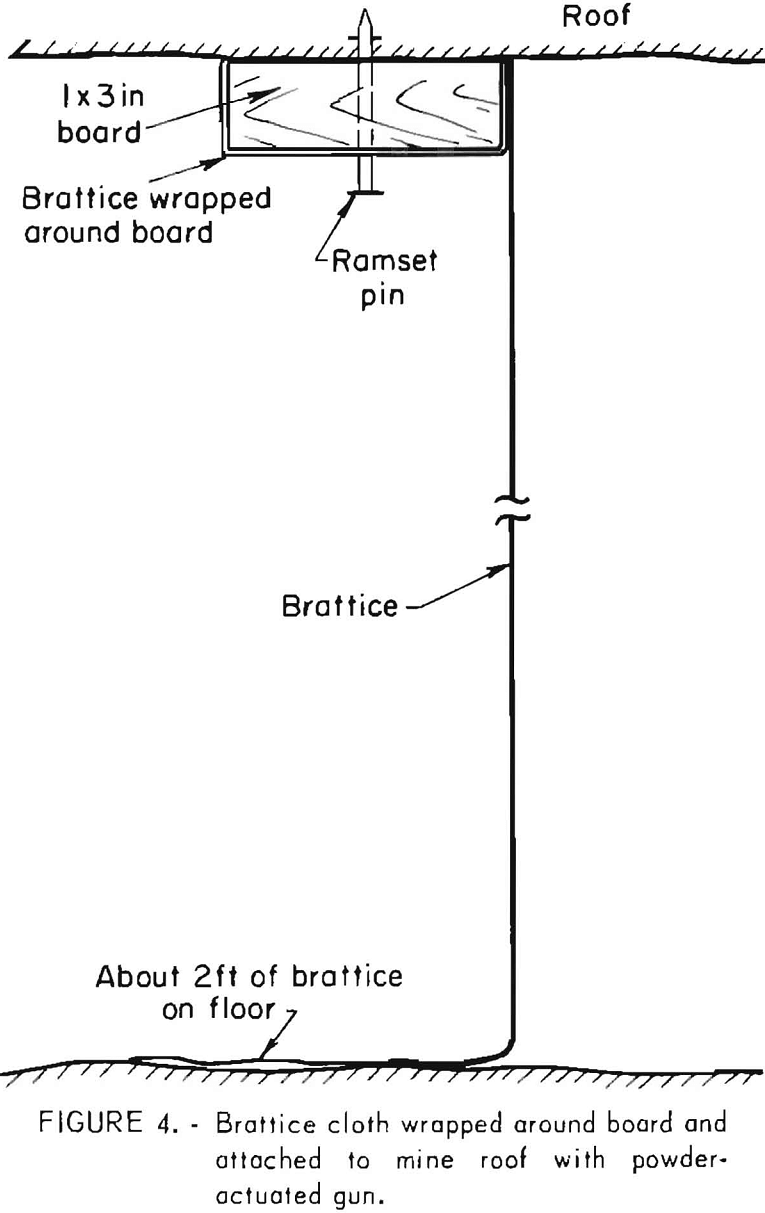

Of all the brattice hanging techniques observed, the following is considered to be the most effective. The brattice cloth, either jute, plastic-coated jute, or plastic, is purchased in long rolls, 8 feet wide. A length is cut from the roll about 4 feet longer than the height of the opening to be closed. One end of this panel is then wrapped a few times around a 1 – by 3-inch board, 8 feet long. This board is attached to the roof with pins fired by a powder-actuated gun and spaced about 18 inches apart (figs. 3 and 4). Hanging the brattice in this way leaves about 2 feet of excess material at the floor for an improved air seal. The individual 8-foot-wide panels overlap from 6 to 12 inches and are pinned together with nails. The big advantage to this form of stopping is that it does not tear away at the roof because the stress on the material at the roof is equally distributed, whereas if the connections are made with spads, grommets, or C-rings, the tears begin at these locations. The nail pins connecting the individual panels cut down on air leakage, but will be torn out to relieve blast pressure without any serious damage to the stopping. If traffic is to move through the stopping, the lower part of one panel is not pinned to the adjacent panels so that it can slide over the moving vehicle.

Cost Considerations

A cost comparison of the different methods of closing large mine openings is difficult because of variations from mine to mine both in available materials and in labor costs. However, it is possible to draw some generalized economic conclusions from the data obtained in this study.

- If waste material is available and if no problems are created by permanently closing certain openings to mine traffic, then the most economical method of closing a large opening is by using waste material in one of the techniques discussed. The labor costs associated are high, but they are partially amortized by the resulting disposal of the waste material and increased utilization of available air.

- Foam-covered stoppings are generally very expensive because they use not only foam but backup materials such as chicken wire over which the foam is sprayed. In some cases it may be advisable to use foam around the edges of a stopping to improve the air seal, but this would depend upon individual circumstances.

- Concrete block and wood stoppings are expensive to construct as a result of the high costs of both material and labor.

- The material cost of available brattice materials varies substantially. If 14-ounce material is considered, the cost ranges from about $0.50/yd² for jute brattice to 1.70/yd² for plastic brattice, with jute covered with plastic on one side running about $0.90/yd².

- In the case of brattice cloth stoppings, the labor costs also vary considerably with the method of construction. Hanging the brattice with a spad gun is relatively inexpensive, but is not the best in terms of stopping durability. Wrapping the brattice around a board and attaching the board to the mine roof with a powder-actuated gun is not only the best technique for building a brattice stopping but also requires less labor than most of the other brattice-hanging techniques, and the increased durability of the resulting stopping has obvious financial benefits.

Conclusions

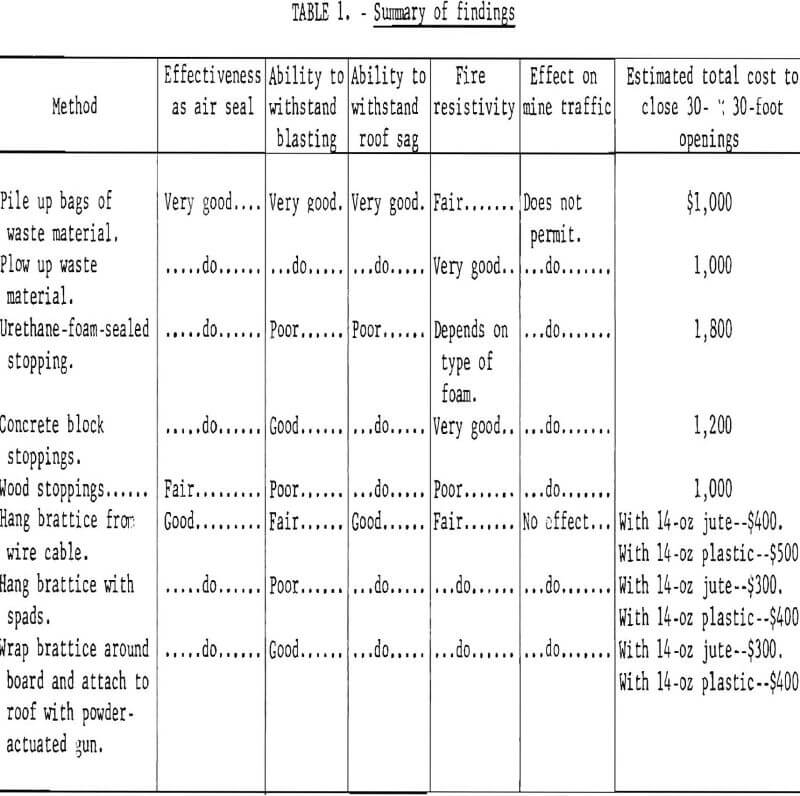

The results of this study are summarized in table 1. Each of the methods for closing large openings that were investigated is rated on several key points and its cost is estimated. The estimates include labor and material costs, and are based on a 30- by 30-foot opening. It should be noted that the costs of techniques involving piling waste material are partially amortized by the cost of the labor that would be required to remove waste material if

it were not utilized to build stoppings. With this in mind, the table shows that piling waste material is a good method of closing a large opening.

It will also be seen that if a brattice cloth stopping is to be constructed, the most efficient and economical method is to wrap the brattice around a board, attach it to the roof with a powder-actuated gun, and pin the separate panels together with nails.