Casting Manganese Steel Liners for Mills or Crushers

When mixed with common cast steel in quantities ranging from 11 to 13½ per cent. and properly treated, manganese increases the ductility of the metal and adds greatly to its toughness and resistance to abrasive action, which properties comprise the distinctive characteristics that make manganese steel so valuable for many purposes at the present time. […]

Hydrometallurgical Equipment

The object of the first classification done in cyaniding work was to produce a leachable sand and overflow as small an amount of sand as possible with the ‘slime, which was usually run to waste. In the early days various arrangements of adjustable tank gates were used, and sometimes direct overflow of tanks filled with a […]

Rock Hammer Drills

The hammer drill rightly receives the credit for having made the one-man drill possible, and so many economies seem possible through the proper application of different types of hammer drills to various mining, quarrying, and excavating operations, that an indication of the economies effected by the New Jersey Zinc Co. at its Franklin mines may […]

Gold Bearing Gravel

Discovery of Gold Bearing Gravel in Canada A woman first discovered gold in the Chaudiere Valley near the mouth of Gilbert River. No attention was paid to the discovery, but a young girl named Clothilde Gilbert, taking a horse to water, found in the creek, close to the location of the previous discovery, a nugget of gold […]

How to Recover Radium, Uranium & Vanadium #6

Recovery of Uranium In the extraction process practically all of the uranium in the ore is dissolved in the nitric acid, a little remaining in the insoluble residue because of incomplete washing. An average of 2.3 per cent of the uranium oxide in the ore has remained in the residue, varying in different carload lots […]

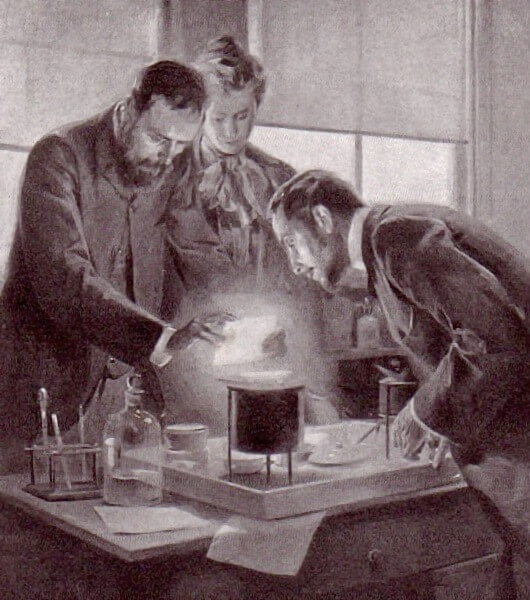

Processing, Extraction & Recovery of RADIUM from Uranium Ore #5

Radium Measurements One of the most essential factors in the successful production and concentration of radium consists in following the material being concentrated, by means of careful quantitative determinations, through all the various operations from the original ore to the final product. This involves the radioactive analysis of a large number of products differing widely […]

RADIUM Extraction & Recovery #4

Refining in the Plant The first treatment of the radium-barium sulphates is of great importance, as the whole capacity of the plant, as far as the radium goes, depends upon this first treatment. If the sulphates can not be handled as rapidly as produced, the actual amount of radium refined each year must necessarily be […]

VANADIUM & URANIUM Extraction and Recovery #3

As the sodium uranate requires re-treatment, owing to the fact that it carries vanadium, it is not necessary to wash the cake as completely as might otherwise be required. Most of the sodium uranate carries 7 to 9 per cent V205. It has been found practically impossible to obtain a precipitate that does not carry […]

URANIUM, RADIUM & VANADIUM Ore Processing #2

The method of treating carnotite, a uranium, ore used by the Bureau of Mines is outlined in this chapter. Leaching, Filtering, and Washing Ore The ore is ground to 20 mesh and is leached with strong hot nitric acid in acid-proof earthenware pots. The amount of acid used is 121 pounds of 100 per cent […]

RADIUM, URANIUM & VANADIUM Extraction & Recovery #1

Until recently little had been published on methods of treating any of the uranium ores for the extraction of radium, although a number of patents have been issued both in this country and abroad. Therefore persons interested in methods of extracting radium have had little to guide them, as details of the methods in use have […]