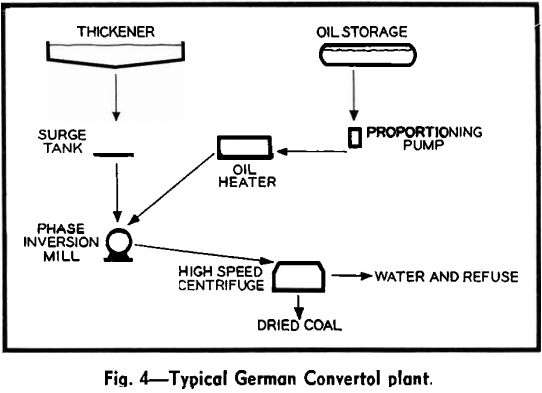

Convertol Process

In the last several years the coal industry has intensified its effort to solve the growing problem of cleaning and recovering fine mesh coals. On one hand there has been increasing civic pressure for cleaner streams, and on the other hand there has been increasing production of fine mesh coal, resulting directly from adoption of […]

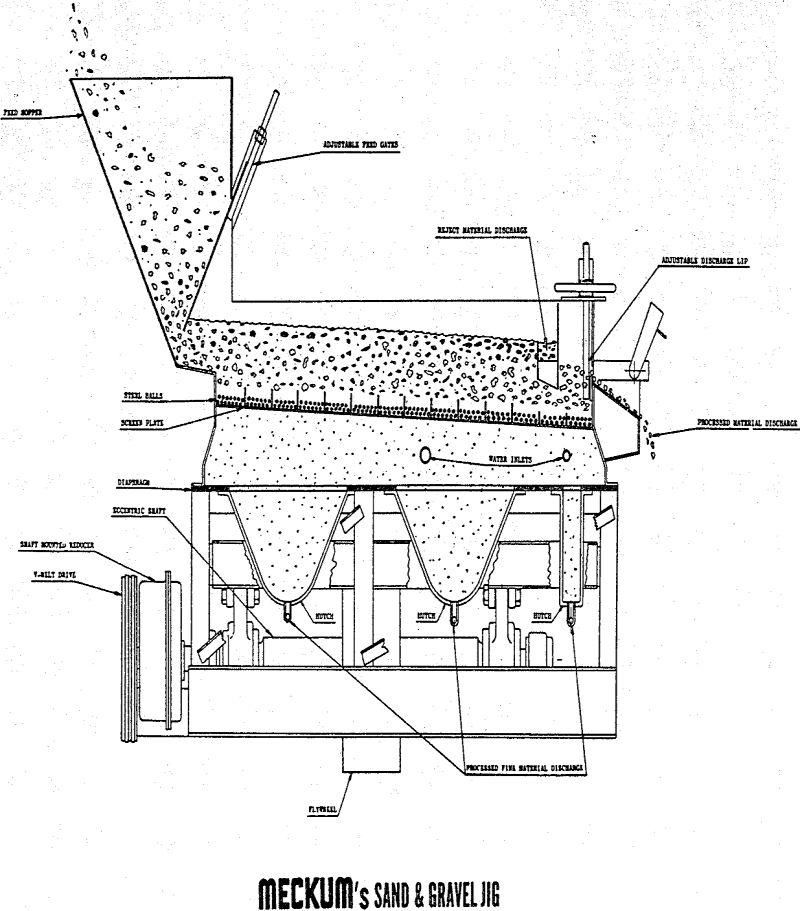

Sand and Gravel Jig

In general, the beneficiation of sand and gravel consists of the removal of certain low specific gravity deleterious particles from the sand and gravel. These particles are coal, lignite, ochre, chert, sandstone, wood, clay, shale, and chalk. These deleterious materials almost always have an apparent specific gravity which is less than 2.35 while good sand […]

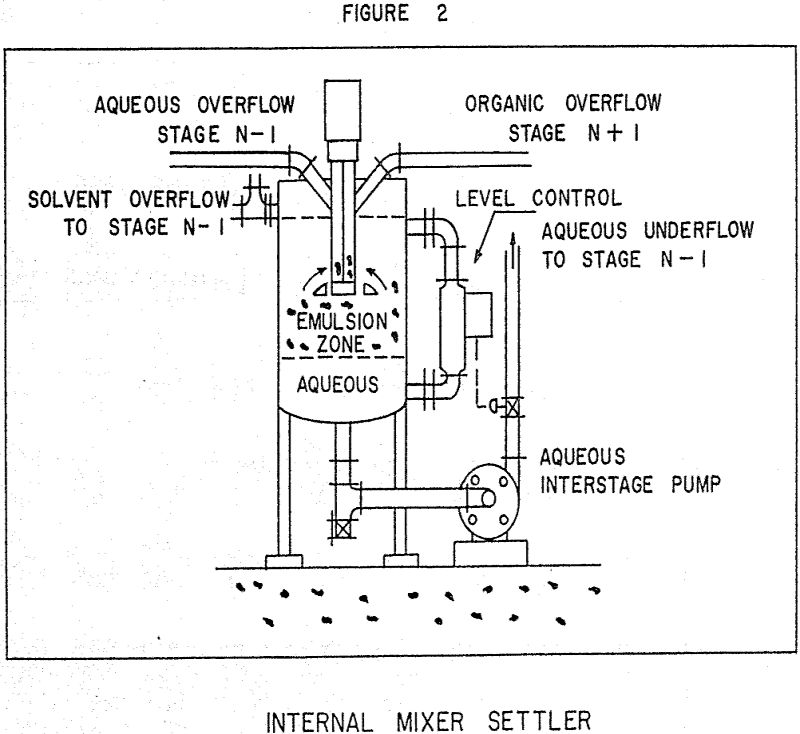

New Solvent Extraction Techniques for Uranium Purification

This paper reviews several new applications of solvent extraction developed in conjunction with a research project carried out under the AEC Raw Materials Division by the Dow Western Division laboratories during the last two years. Several methods for direct solvent leaching of ores have been investigated by AEC contractors. The method studied at this laboratory […]

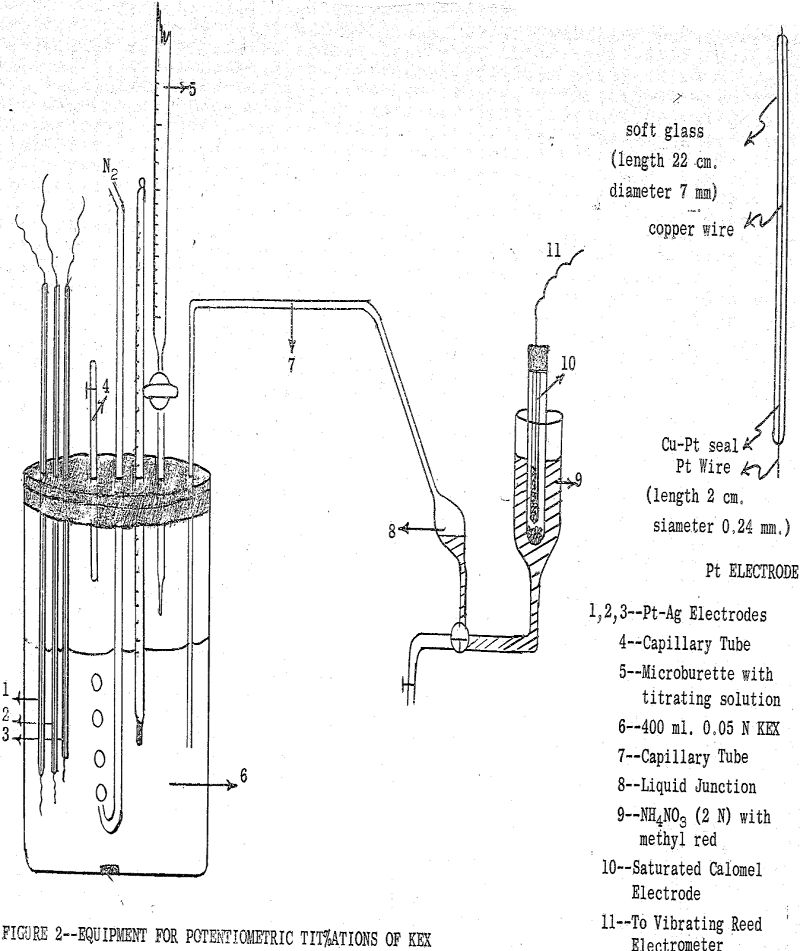

Metal Ethyl Xanthates Solubility

The flotation system is usually distinguished from other physical chemical systems by the importance of interactions at the solid-liquid and solid-gas interfaces. In recent years, numerous quantitative studies have been made of the distribution of common collectors between the solid and aqueous solution phase. Although in flotation the main emphasis is placed on the adsorption […]

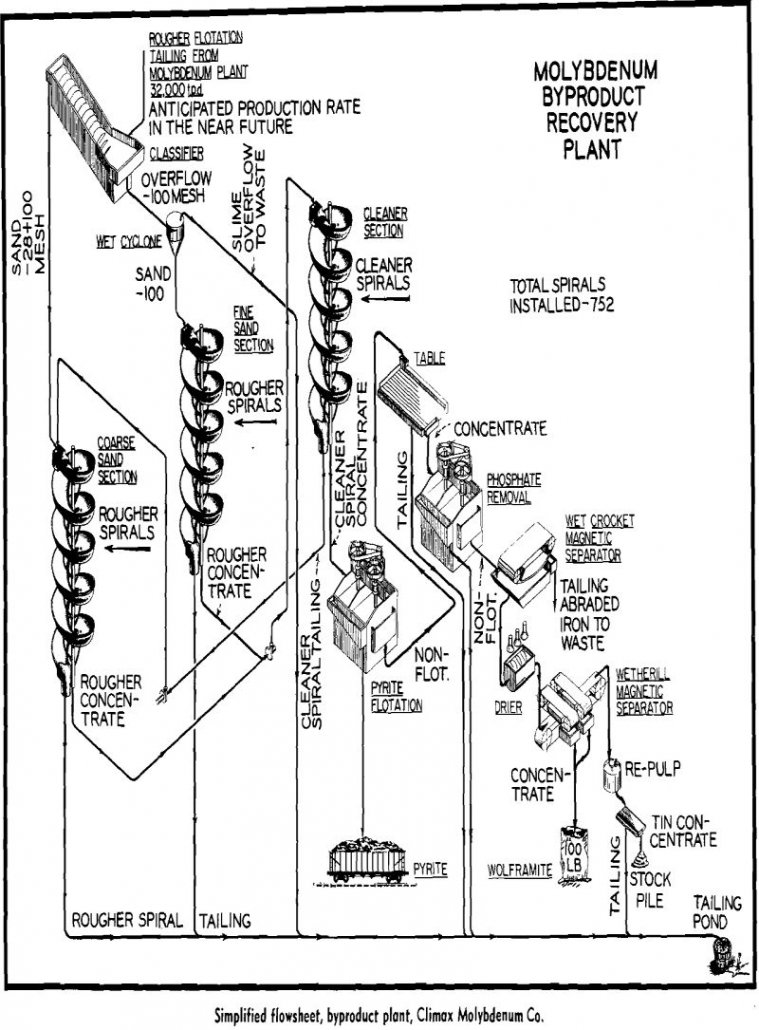

Humphreys Spiral Concentrator

Since it was introduced in 1943 to recover chromite from Oregon beach sands, the Humphreys spiral concentrator has proved successful in several fields of wet mineral beneficiation. By the end of 1957, 9390 Humphreys spirals had been manufactured. Most of these are still in service. Requirements for Spiral Concentration: Valuable heavy minerals to be recovered […]

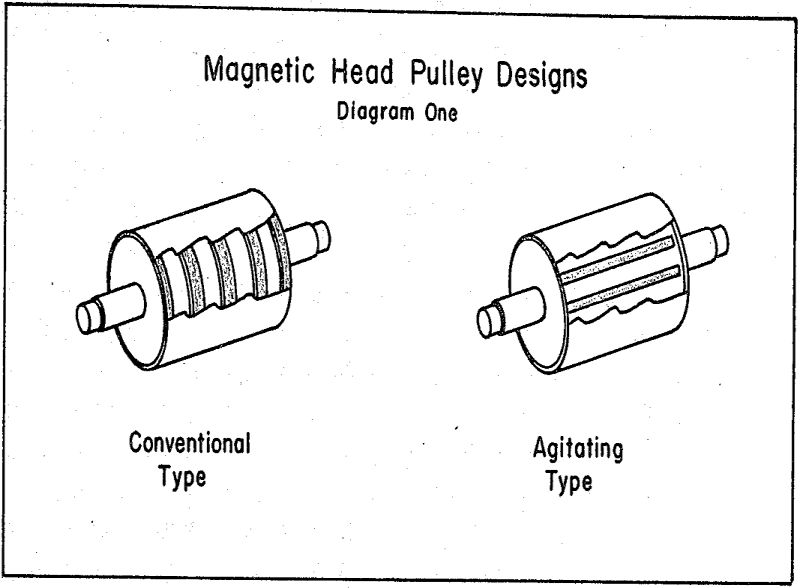

Dry Magnetic Cobbing Separation

Cobbing, as used in this paper, refers to coarse dry magnetics separation. It is applicable when, by its practice, plant cost can be reduced or the value of its products increased by the removal of a barren or lean reject or a high grade final product. This paper attempts to describe cobbing as it is […]

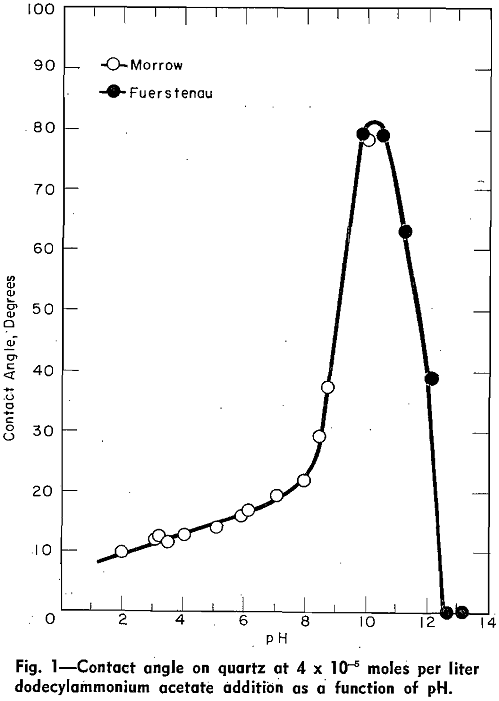

Contact Angles and Flotation Rate

The object of this article is to point out the experimental relationship which exists among contact angle, adsorption density, zeta potential, and flotation rate data. In each of the experiments discussed in this article, the surface properties of quartz, as a function of pH, were measured in solutions to which constant quantities of dodecylammonium acetate […]

Earthquake Design for Metallurgical Plants

All persons and communities that have experienced strong-motion earthquakes are convinced of the importance and complexity of earthquake problems that must be solved in order to reduce the personal hazards and property losses to a reasonable minimum. It is also clear that absolute elimination of all risks is impossible. Reduction of existing hazards and precautionary […]

Analyzing Ore Reserves: Statistical Method of Calculating

There are certain data handling techniques used by statisticans that can help one to calculate the size of an orebody and to develop some of the relationships between size, cutoff grade, average grade, mining cost, and profit. Knowing the relationships amongst these factors can help determine the most desirable operating conditions. A statistical technique that […]

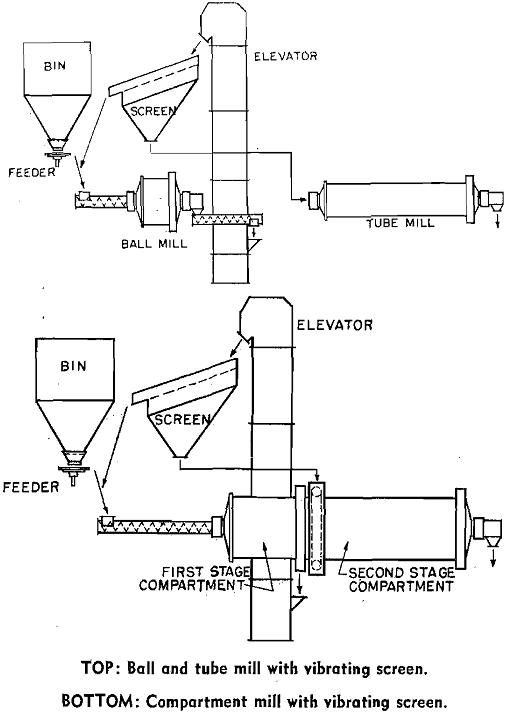

Cement Grinding Plant Design

Grinding is a large and costly part of Portland cement manufacture. Prior to clinkering in the rotary kiln, raw materials are ground to a fineness of 80 to 90 pct passing 200 mesh. Then, after burning and cooling, the resulting clinker is ground to about 92 pct passing 325 mesh. Open Circuit Clinker Grinding: Many […]