Recover Aluminum by Electrowinning

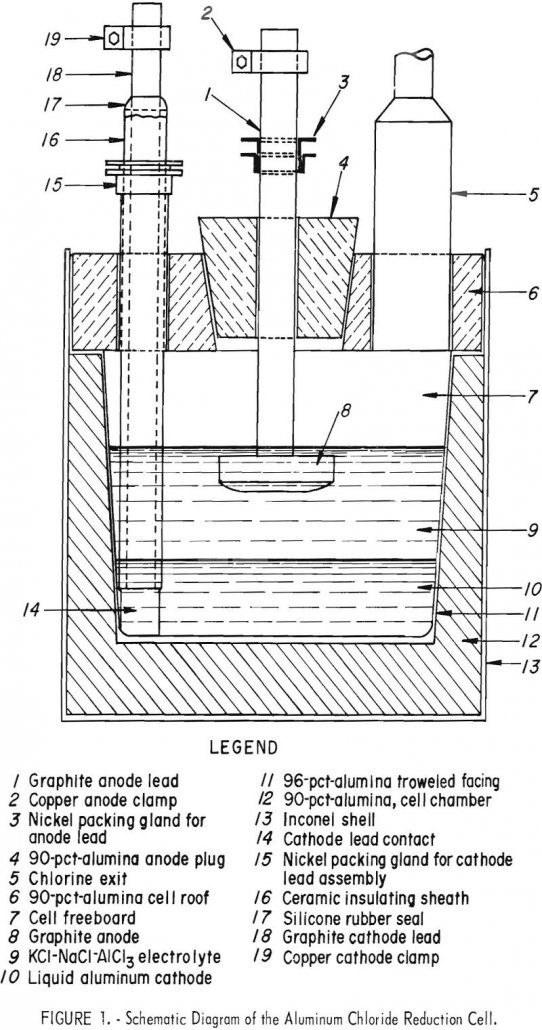

The preparation of aluminum by molten salt electrolysis of AlCl3 was undertaken as part of the Bureau of Mines overall research program to develop methods for the utilization of domestic low-grade raw materials, de Beauchamp and Thomas and others summarized the preparation and manufacture of anhydrous AlCl3 from a variety of aluminiferous materials: aluminas, bauxites, […]

Electrowinning MischMetal

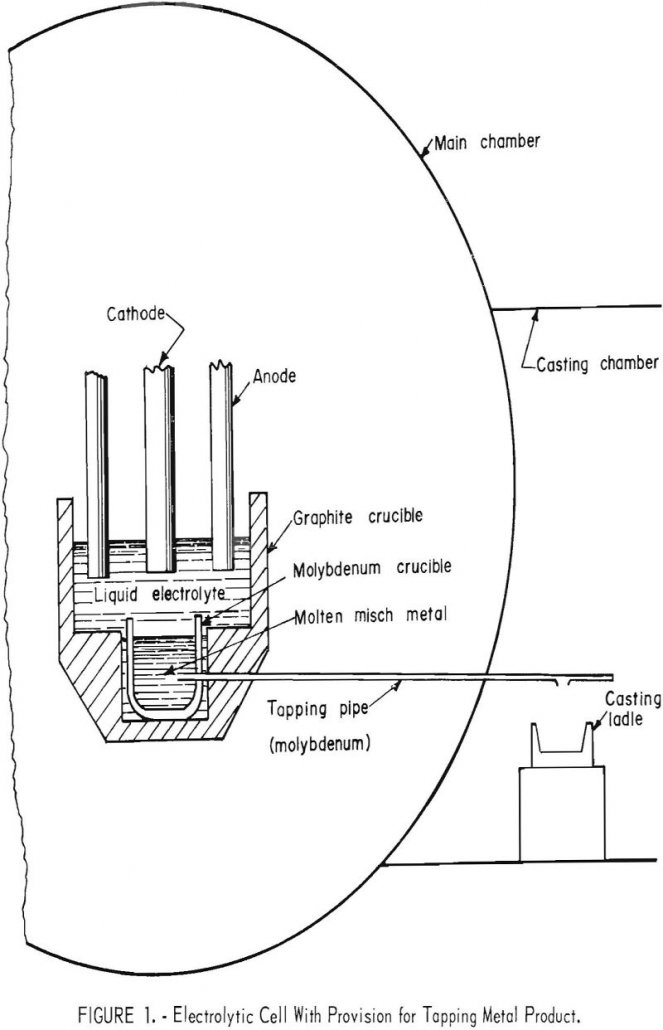

For many years, we conducted a research program on electrolytic preparation of rare-earth metals. Cerium, lanthanum, and neodymium, praseodymium, and didymium metals have been electrowon from their respective oxides dissolved in fluoride melts. Commercial production of mischmetal, a mixed rare-earth metal consisting essentially of cerium, lanthanum, neodymium, and praseodymium, is presently limited to electrolysis of […]

Roasting Copper Sulfides Chemistry

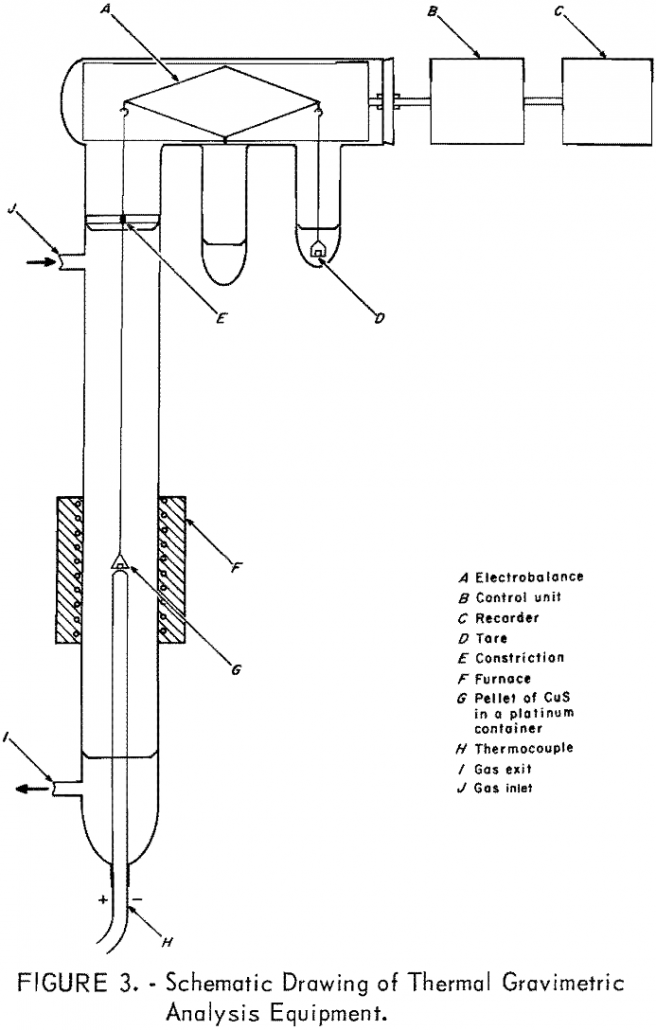

The roasting process is widely used in extracting copper from its sulfide ores. At present the development of a new process for winning copper from pelletized chalcocite concentrate is underway at the Bureau of Mines Twin Cities Metallurgy Research Center. In this process, the dead roasting of sulfide is followed by the reduction of oxide […]

Building a Junk Car Incinerator

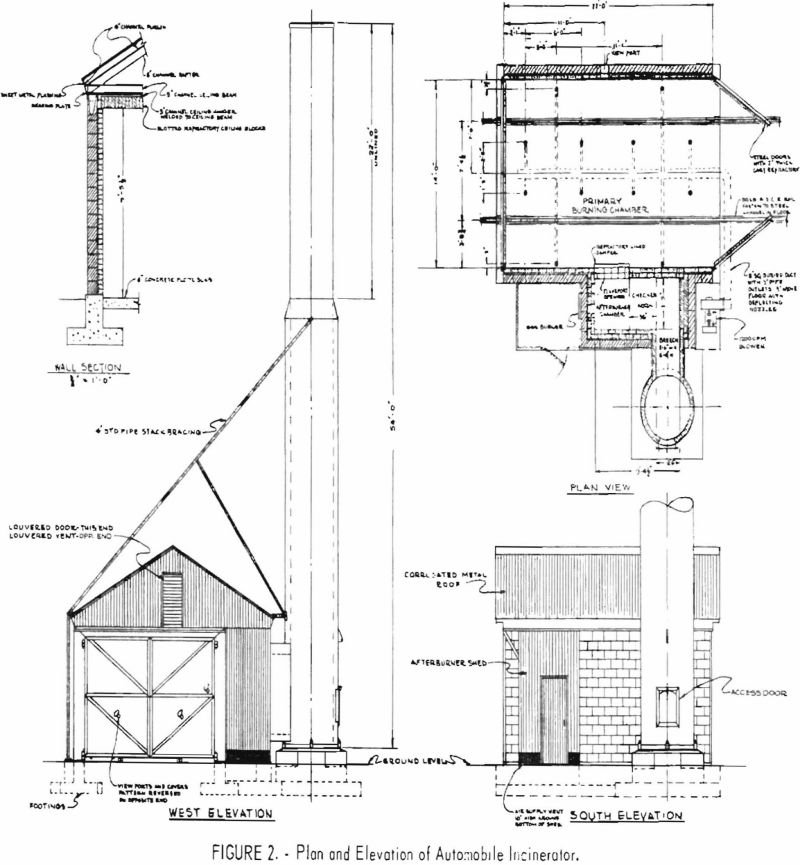

Congress, by the Solid Waste Disposal Act of 1965, delegated to the Bureau of Mines responsibility for conducting research on solid waste problems. The accumulation of abandoned automobiles is one of these problems, and this paper reports the efforts of the Bureau’s Salt Lake City Metallurgy Research Center in attempting to resolve the abandoned car […]

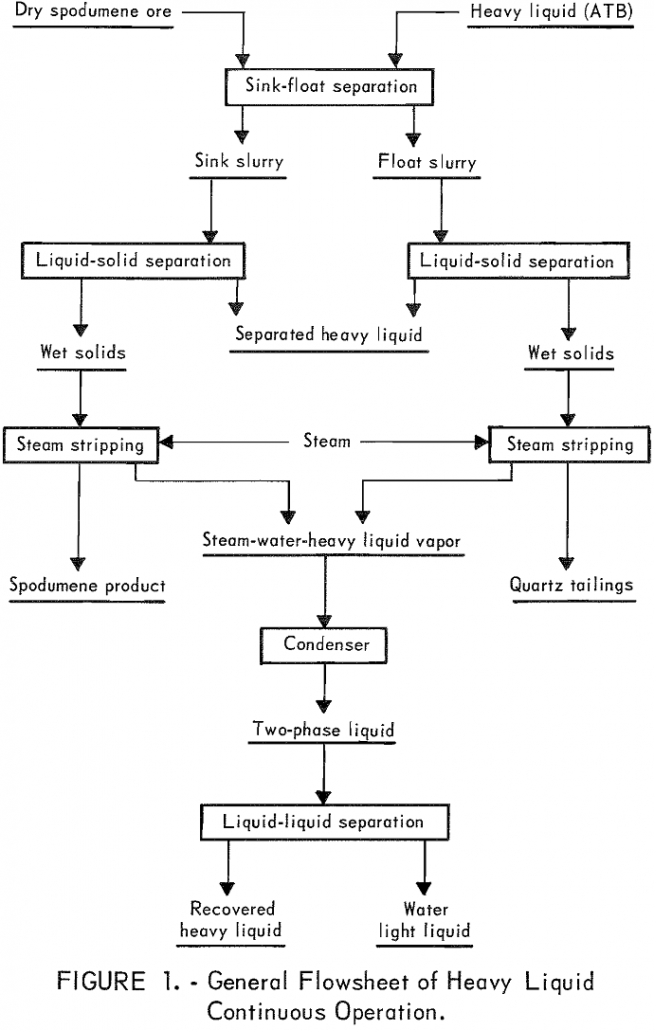

Heavy Liquid Separation

We are continuously engaged in research activities to develop or improve methods of utilizing our mineral resources. One such method, heavy liquid separation (HLS), has long been a recognized laboratory technique to separate minerals but only in recent years has this method been considered as a continuous process. The best prospects appear to be the […]

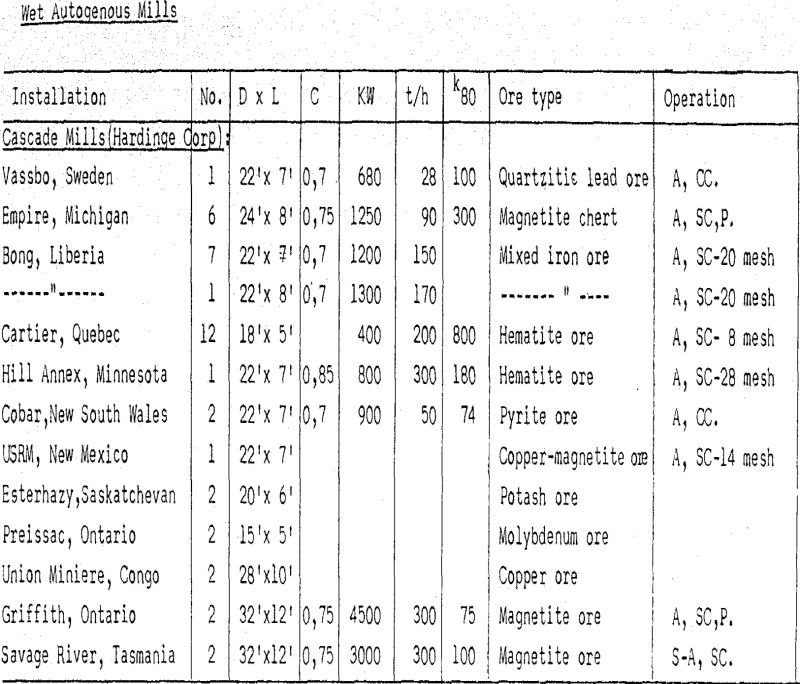

Wet Autogenous Grinding in Tumbling Mills

The autogenous grinding method has been progressively employed in mineral dressing plants during the last 15 years. The term has been used with somewhat different meanings. In this paper the author will use it in the most restricted way, for processes where run-of-mine ore (rock) in one step is reduced to a grind product by […]

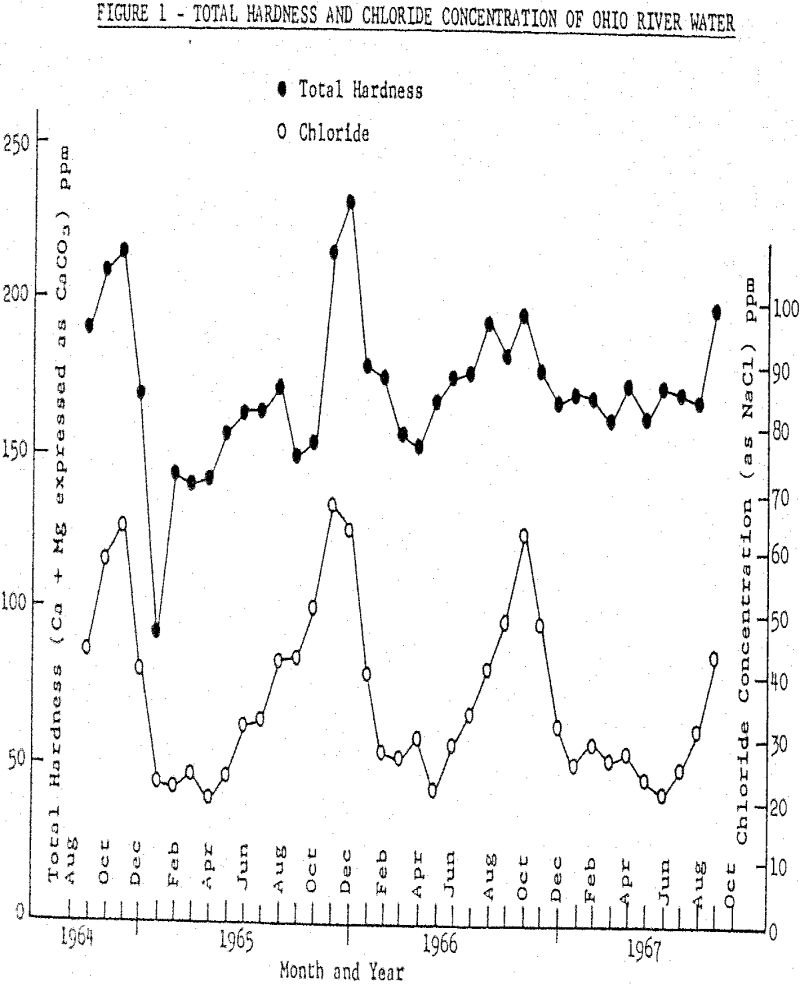

Water in Fluorspar Flotation

Water has received little attention as a variable in flotation, even though it is a known fact that water hardness often has an adverse effect on purity and recovery, particularly on the flotation of non-metallic minerals. Because of this fact, process water used in some flotation plants is treated to reduce hardness to an acceptable […]

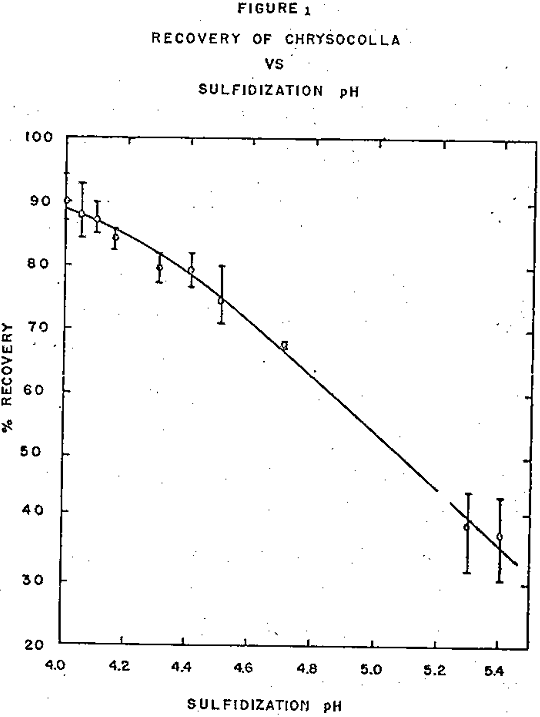

Chrysocolla Sulfidization and Flotation

Studies of sulfidization and flotation of chrysocolla involving the use of pH and sulfide ion instruments, a Zeta meter, microflotation techniques, and sensitive determinations of adsorbed sulfur have given new insight into the mechanism of the process. Factors that affect the recovery of sulfidized chrysocolla by flotation appear to be the pH at which it […]

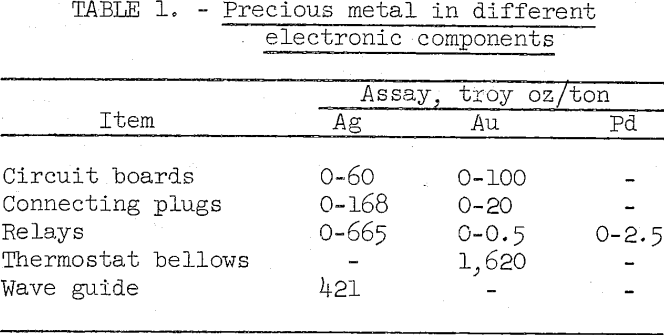

Smelting of Military Electronic Scrap

Gold, silver, and platinum group metals are widely used in electronic and electrical components to provide long-term reliability, Construction of military equipment consumes the largest proportion of the precious metals used in the electronic and electrical industry. Due to obsolescence and damage, military electronics are presently being scrapped at the rate of about 15,000 tons […]

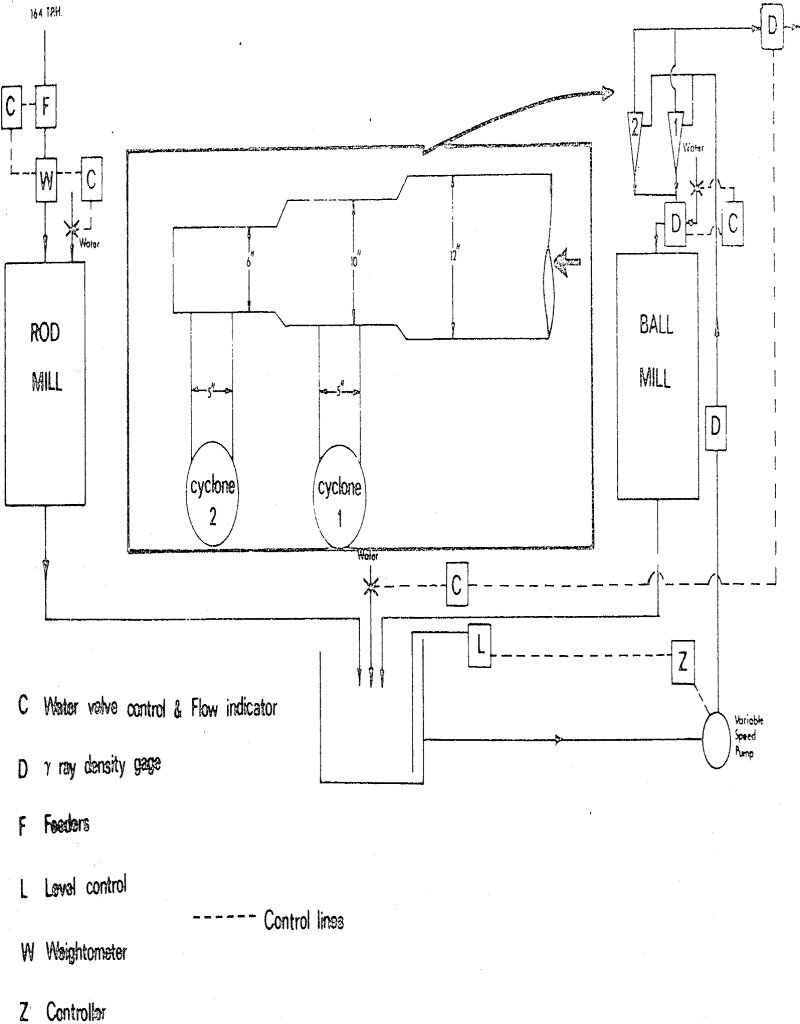

Parallel HydroCyclone Simulation

In order to simulate a grinding circuit, it is necessary to obtain valid mathematical models of the grinding mills and classifiers in the circuit. Several models of grinding mills have been proposed and models of cyclone classifiers are available. Description of a Circuit New feed enters an open circuit rod mill at a rate of […]