Thickener Design and Theory Problems

This paper will review thickening theory, from the study but of the practicing engineer, with particular emphasis on areas of uncertainty or disagreement. It will attempt to outline broadly what we know and what we don’t know. This should serve two purposes. First, it will warn the process engineer where he might get into trouble. […]

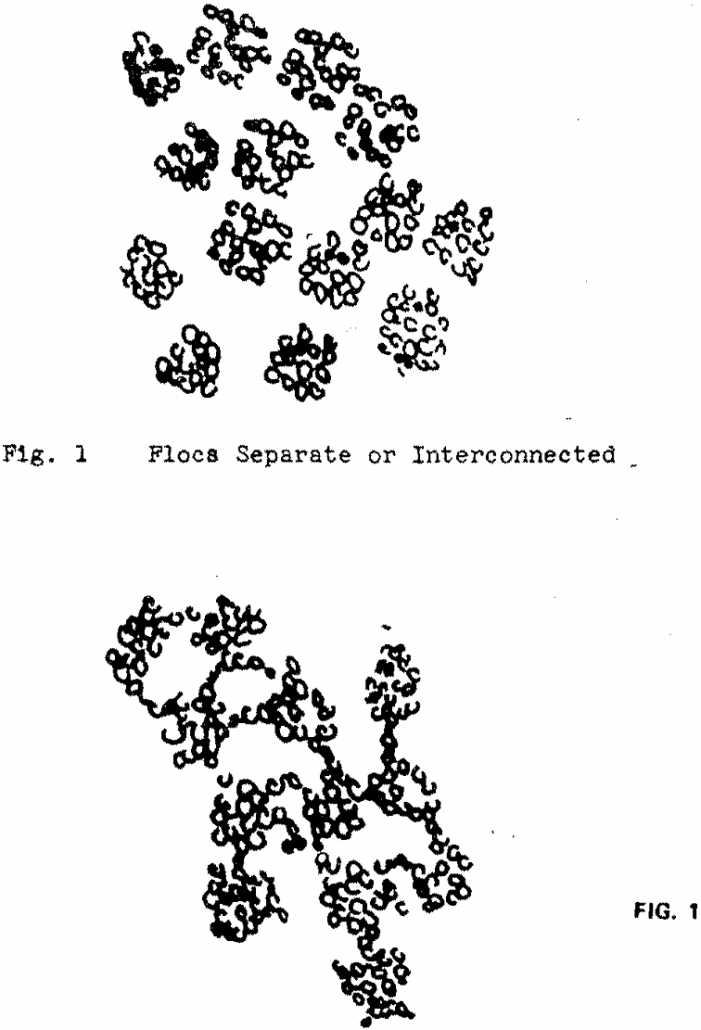

Tailings Dam Sealed by Slimes Slurry

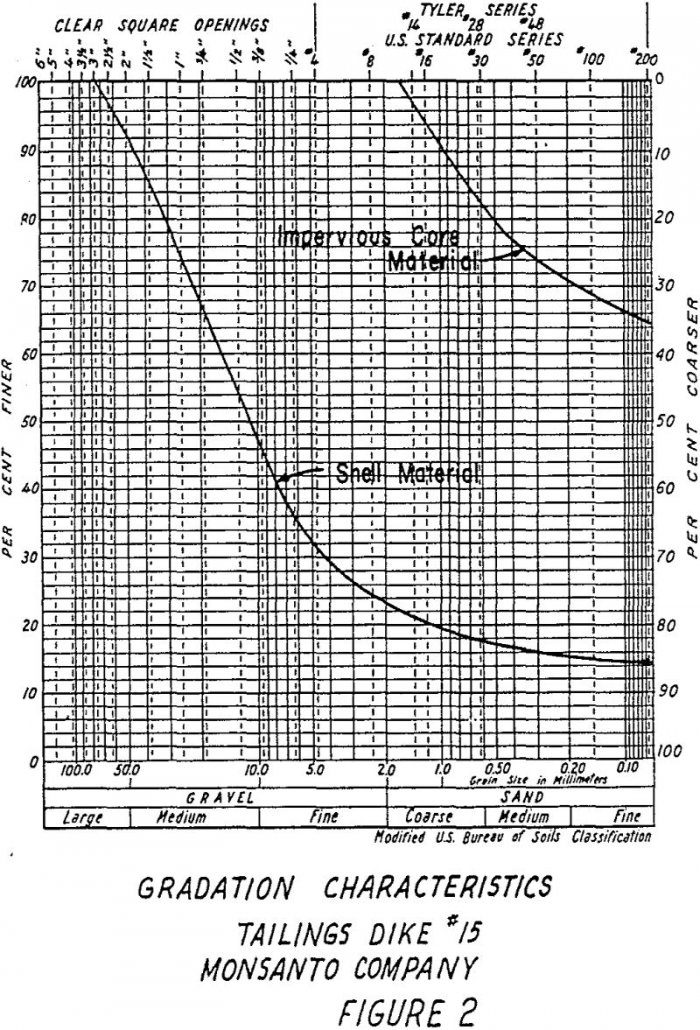

In 1965, Monsanto started planning of a new dike (No. 15) for use in disposing of ore tailings at its Columbia, Tennessee phosphorus plant. Generally, in the phosphorus industry only clay tailings are produced making it necessary to borrow fill for construction of a retaining dike. Borrow area investigations indicated that weathered shales and limestones […]

Electrochemistry of Pyrite and Sulphide Flotation

In spite of the importance of the presence of pyrite in the flotation of sulphide ores, not many studies have been made from the electrochemical point of view. It is generally recognized that the oxidation of sulphide minerals is one of the most important factors among those which affect the floatability of sulphide minerals. The […]

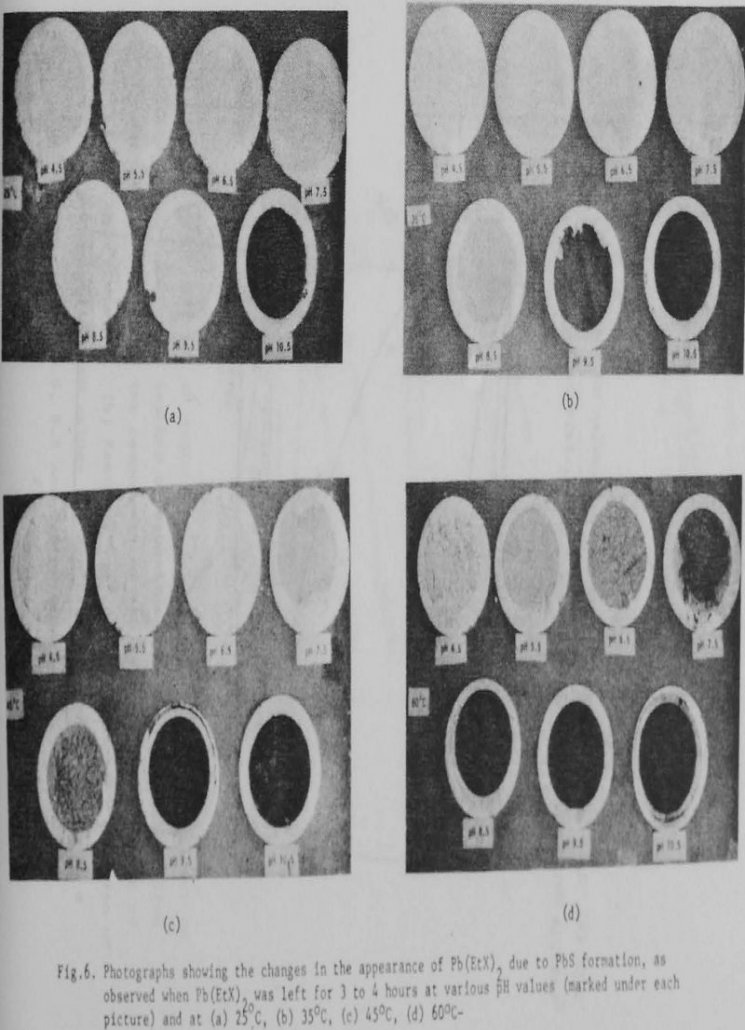

Stability of Lead Ethylxanthate in Aqueous Systems

In galena flotation, lead ethyl xanthate, Pb(EtX)2, is precipitated and is physically adsorbed in the form of multilayers on the chemically adsorbed first layer of Pb(EtX). The solid particles are coated with layers of Pb(EtX)2 in heterogeneous manner over surface areas possessing both anodic and cathodic character. It is anticipated that the mode of formation […]

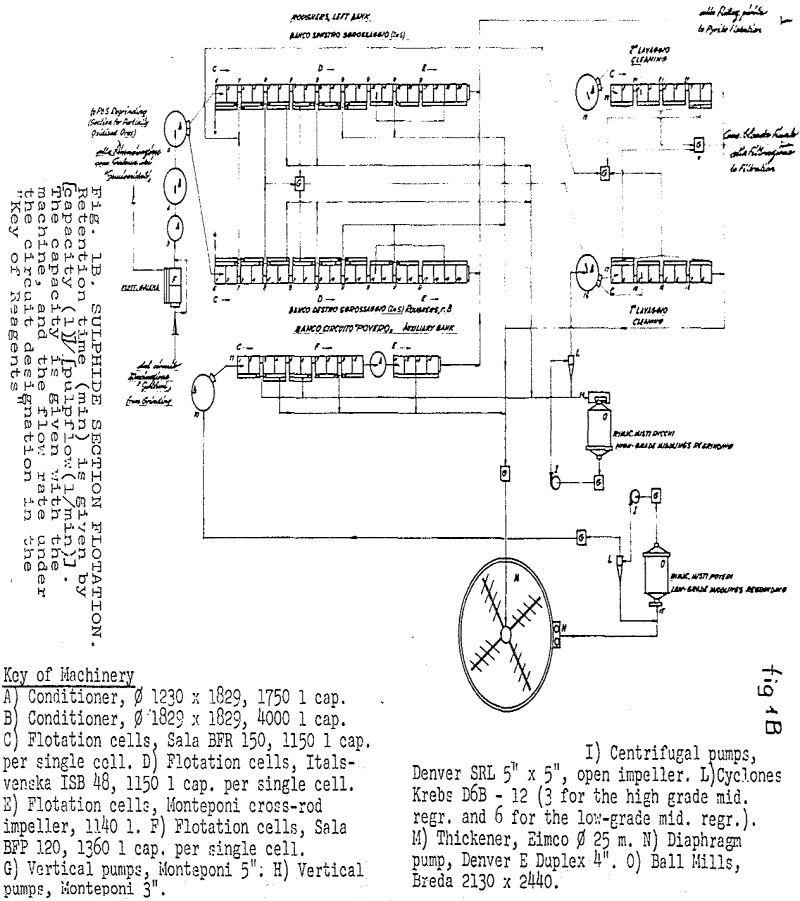

Sphalerite Activation by Copper Sulphate-Cyanide Combination

The main constituent of the feed to the “Sulphide Section” (31 t/h), in the F. Sartori Plant (6000 t/d) of the Miniere di Monteponi(Sardinia), is the ore of the Campo Pisano – Funtanaperda Mine. Difficulties have always been experienced in the treatment of this ore, owing to the extremely fine Pyrite-Sphalerite intergrowth and to the […]

Solving Industrial Mineral Flotation Problems

Flotation was practiced by this and succeeding engineers to concentrate many of the non-metallic minerals available from Canadian resources. Experimentation, and some extensive experimentation. A number are still under investigation. A few have evolved into producing plants. The results obtained for some have been used to increase efficiencies in existing plants. Results for others have […]

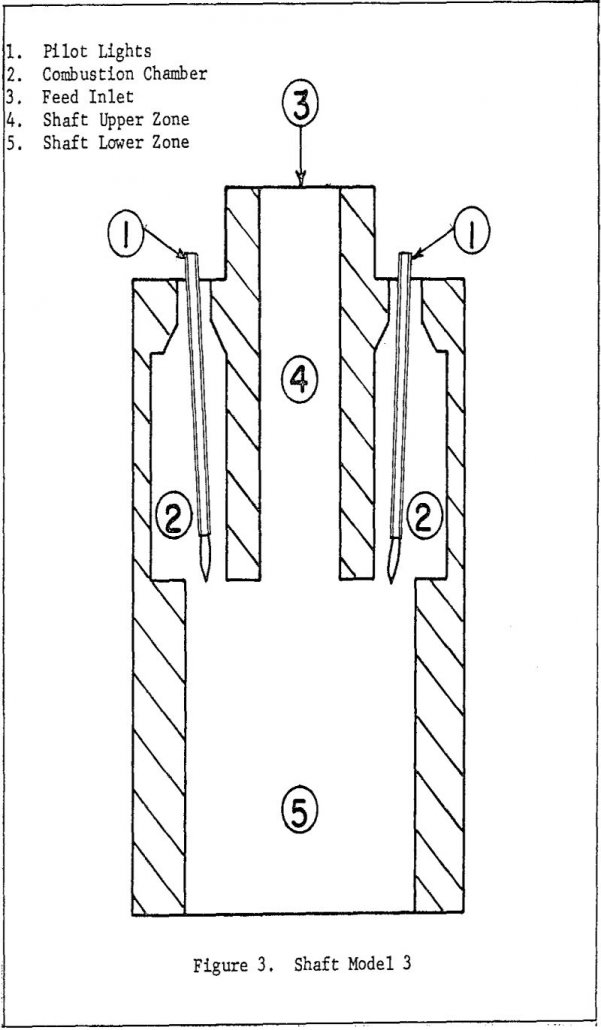

A Shaft-Electric Furnace for Melting and Smelting

The electric arc furnace has characteristics which make it attractive for a number of metallurgical applications. Some of these characteristics are: high thermal efficiency, the possibility of attaining very high temperatures, low off-gas volume compared to fuel-fired furnaces, no impurities are introduced by the heat source, and impurities in only minor amounts are introduced by […]

Slurry Pulp Distributor

The practical and effective pulp distributor here presented is believed to be of a completely new and innovative design. It was developed at the San Nicolas Plant of the Marcona Mining Company in Peru, where it has been thoroughly plant tested using iron ore slurries of a particularly abrasive nature. As indicated, the motivation for […]

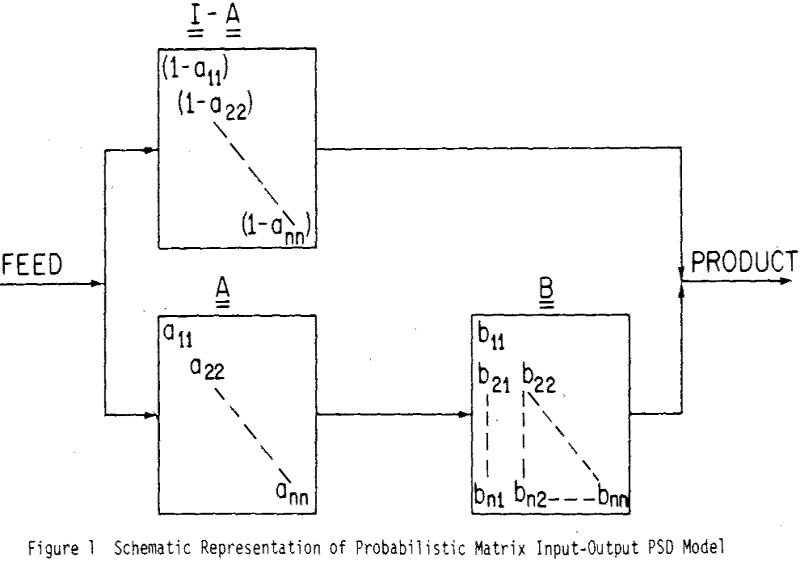

Population Balance Models for Predicting Grinding Mill Performance

Comminution represents one of the major costs.of mineral recovery from low- grade ores. Efficient mineral recovery in a typical low-grade ore grinding-flotation process depends on grinding the ore small enough to liberate mineralization without producing excessive slimes, which would result in higher power and flotation reagent costs. Size criteria for efficient grinding should be stated […]

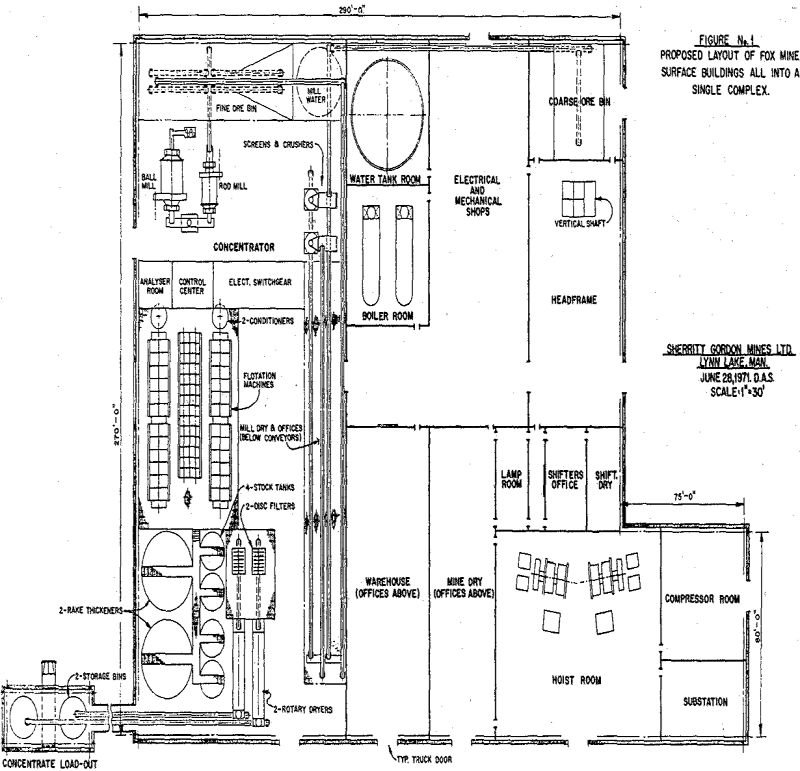

Plant Layout – Cold and Remote Areas

Basic things to remember in plant design for cold and remote areas are, everything in these areas is more expensive due to long and difficult supply lines. Fuel is expensive and would be a major cost item even if it were not expensive, due to the extended periods of low temperatures. Building volumes should therefore […]