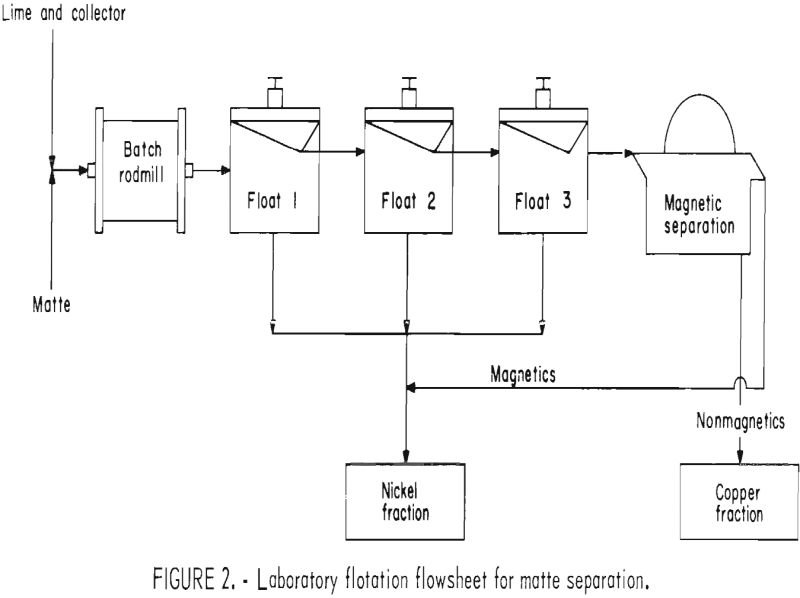

Separation of Copper-Nickel by Flotation and Magnetic Methods

As part of our mission to investigate technology options for the development of domestic mineral resources, conducted tests aimed at separating the copper-nickel values in bulk sulfide mattes into copper-rich and nickel-rich fractions. Resources in the Duluth Gabbro Complex are estimated to be 4.4 billion short tons of mineralized rock grading more than 0.50 pct […]

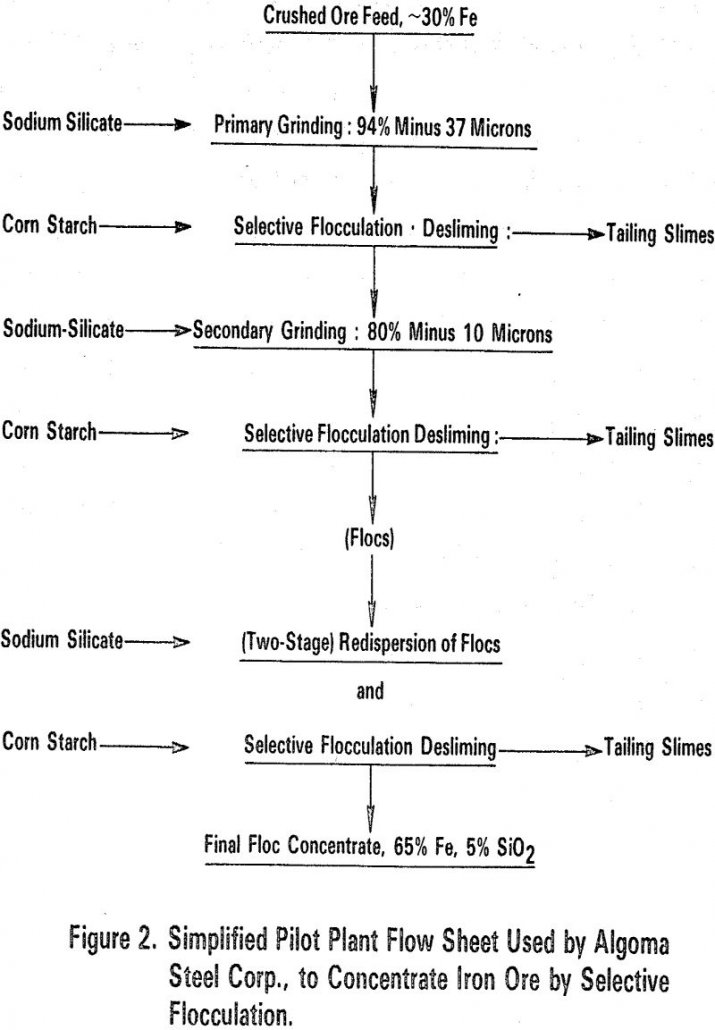

Selective Flocculation

Selective flocculation utilizes the differences in the physical-chemical properties of the various mineral components in the mixed suspension. It is based on the preferential adsorption of an organic flocculant on the particular solids to be flocculated, leaving the remainder of the particles in suspension. In order to understand the mechanics of this process, selective flocculation […]

Screen Bowl Centrifuge for Dewatering Fines

Dewatering of the fine clean coal fraction, — 28 mesh (595 microns) represents one of the most difficult and costly separations in typical plant circuits. Since 1969, the Screen Bowl Centrifuge has offered an economical alternative to filtration/thermal dryer combinations. The performance of Screen Bowl Centrifuges has been continuously modified and improved to dewater not […]

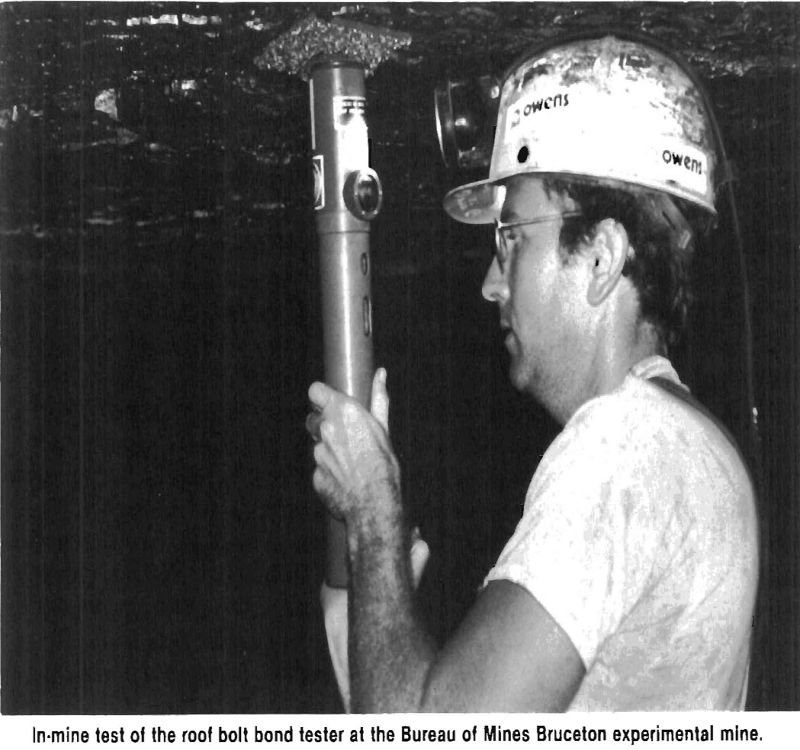

Roof Bolt Bond Tester

A measured pulse of energy is sent into the bolt by a piezoelectric transducer, and the instrument listens for reflected energy. Where the bolt is properly bonded, the energy passes from the bolt, through the resin, and out into the rock mass. Where proper bonding does not exist, a portion of the energy is reflected […]

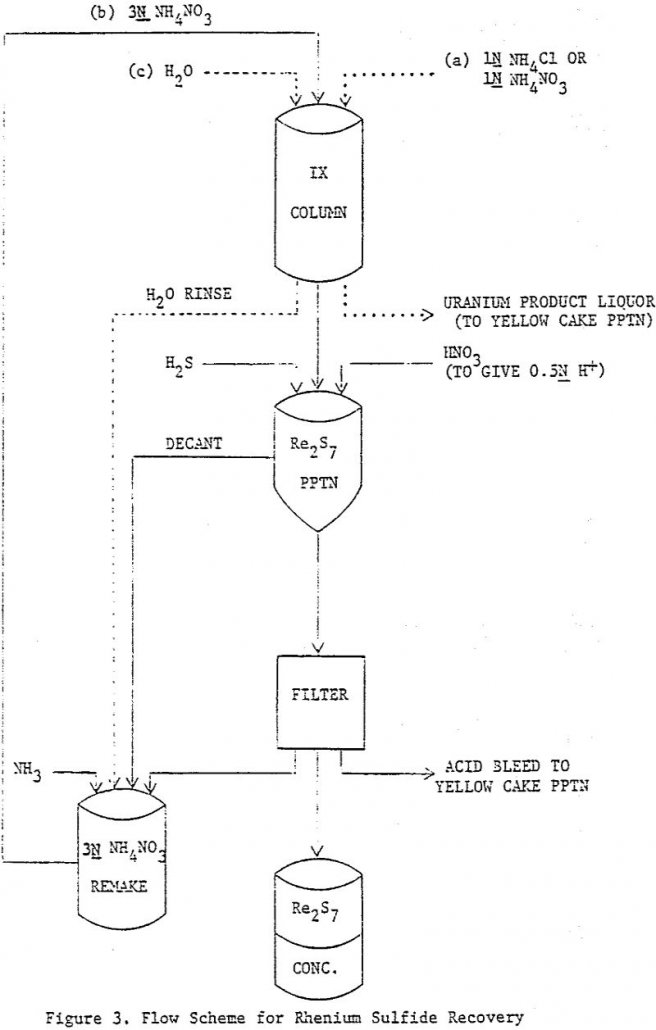

How to Recover Rhenium from Uranium Leach Liquor

The discovery of rhenium on the ion exchange resin used at the uranium in-situ leach operations at Palangana (Texas) led to a laboratory study on the possible methods of recovery. Rhenium, present in small amounts in the ammonium carbonate leach liquors as the perrhenate anion, ReO4-, concentrated on the anion exchange resin, which was a […]

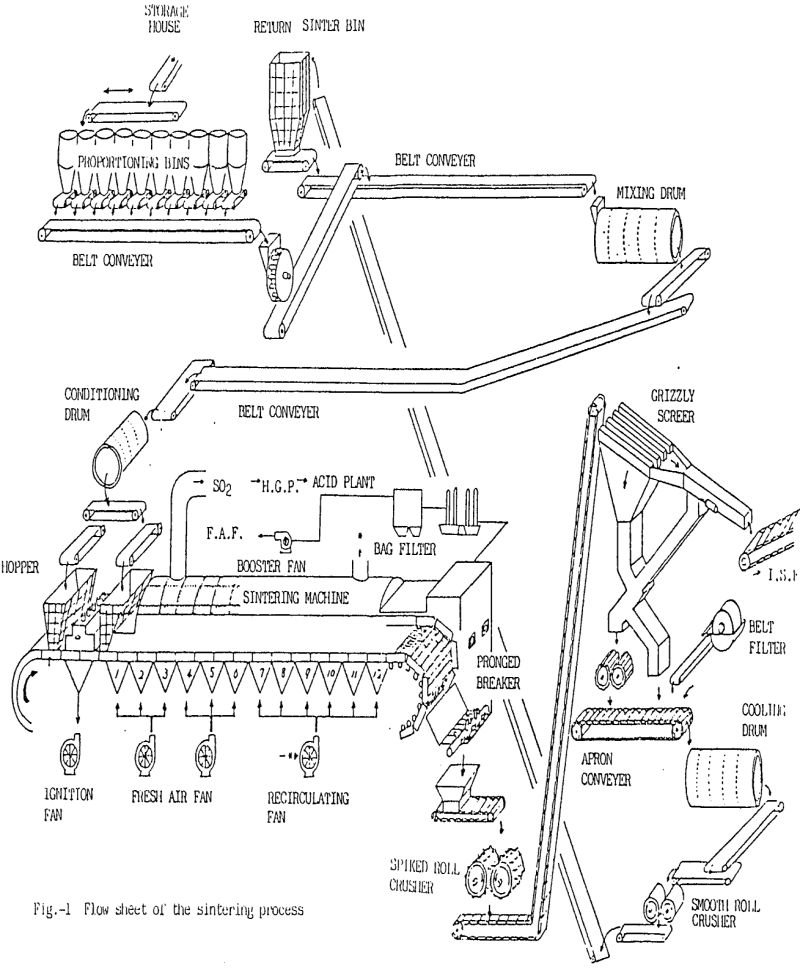

Sinter Plant Operation

The sintering process for the preparation of raw materials to be fed to the Imperial Smelting Furnace (I.S.F.) is rather diversified in its characteristics. In comparison to the other preparation process for zinc extraction, i.e., fluidized bed roasting, the sintering process enables the Imperial Smelting Process (I.S.P.) smelter to treat a variety of raw materials. […]

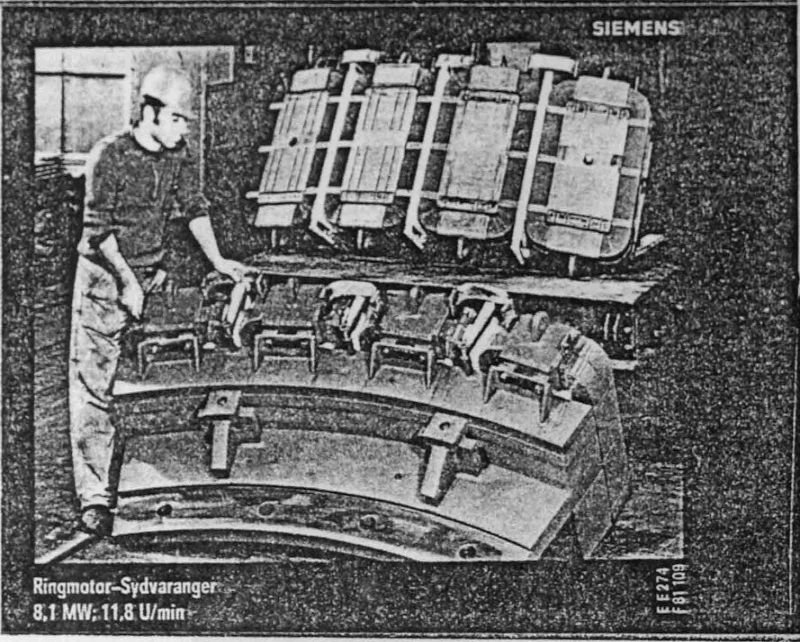

Gearless Warp Around SAG Mill

For almost a decade now, very good operating experiences have been gained with a total of 28 gearless ring motor drives in the cement industry, driving tube mills with diameters of 2.5 to 4 meters with drive powers ranging from 3000 to about 5000kW. Why then did the mineral ore processing industry hesitate till 1980 […]

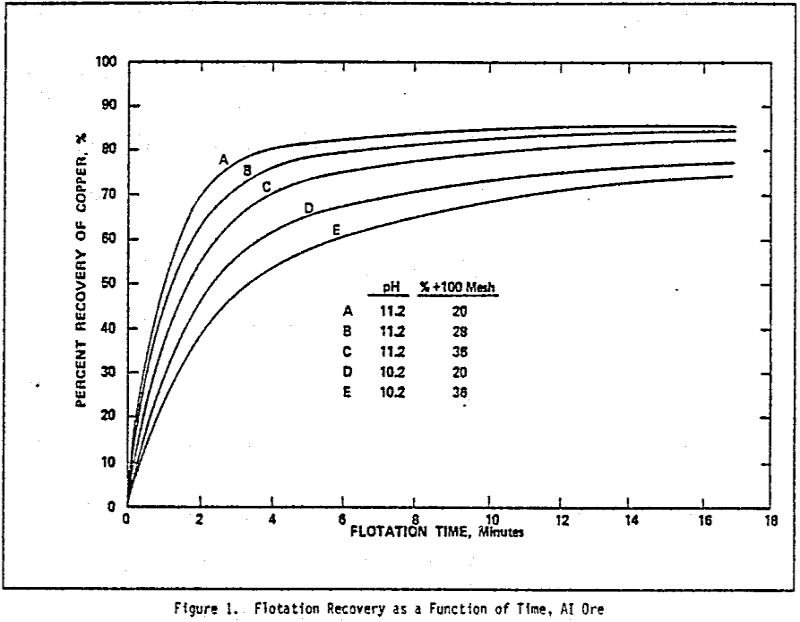

Flotation Kinetics Data Analysis

Several reasons contribute to the wide gap in the industrial application of the academic models. These include: 1) the lack of generality in the model, e.g., the model is limited to certain size ranges; 2) the academic models involve complicated mathematics 3) confusion about the order of the flotation rate, e.g., several authors proposed a […]

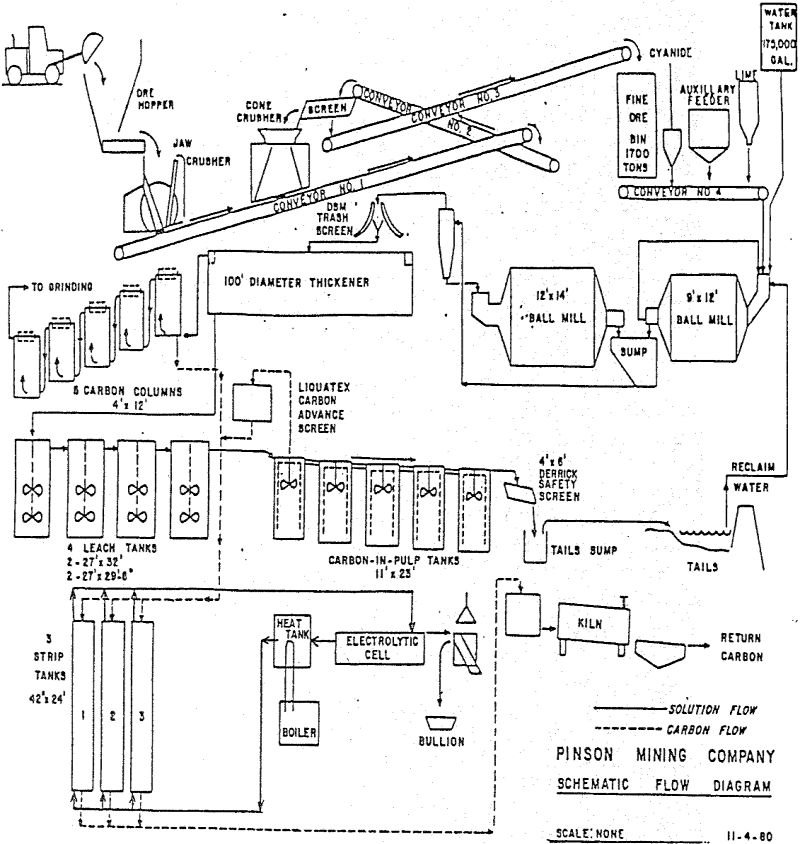

Mill Design Example

Pinson Mining Company was formed to develop a gold orebody located in northern Nevada near Winnemucca. A feasibility study was undertaken in 1979 by a consortium of three Toronto-based mining companies arid a Reno-based exploration company. The Pinson plant has been described in some detail by Mcquiston and Shoemaker in the AIME’s Gold and Silver […]

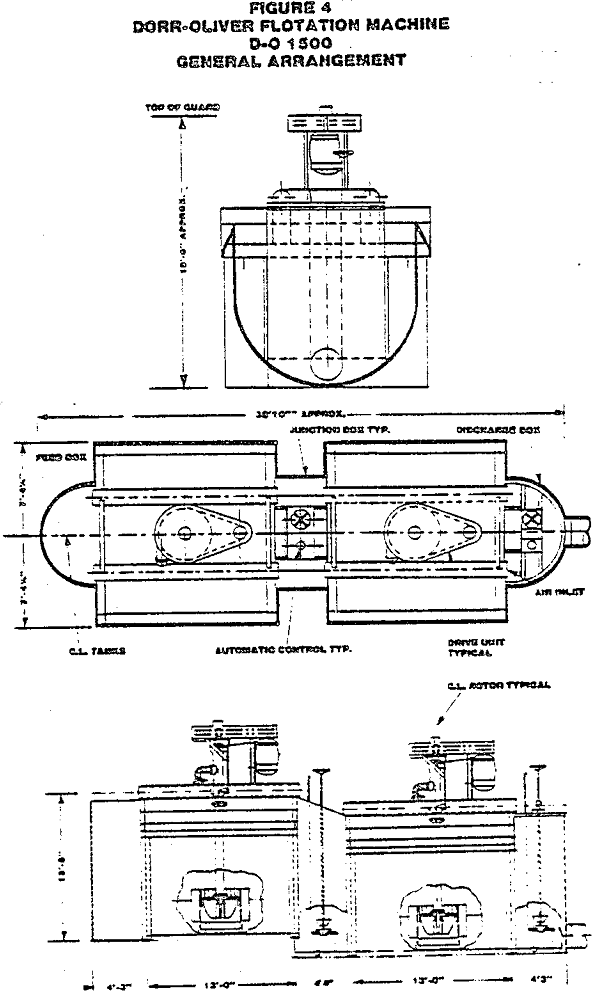

Large Flotation Cells Mechanism

The development of larger size flotation machines, which started in the 1950’s and 1960’s, is still proceeding. The largest mechanical flotation machines available today have unit volumes in the range of 38 to 42 m³ (1,350 to 1,500 cft). In fact, the motivating forces of increasing capital and energy costs and decreasing ore grades, which […]