The Dangers of Gold Dredging

Dredge Operation Visits The contract requirement was that nine mining dredge operations be visited to gather data on the operations, their safety hazards, and their safety management. Although the number of field trips made was the same as originally planned, 31 dredges were visited. There were several reasons, but the most important were: It was […]

Dredge Safety

The objective of the work reported here was to examine, analyze and evaluate the safety hazards which affect mining dredge workers. The safety hazard consideration involved design and environmental hazards as well as those related to dredge operation and maintenance. It included shore-based equipment which supports the dredge or which is in the production sequence […]

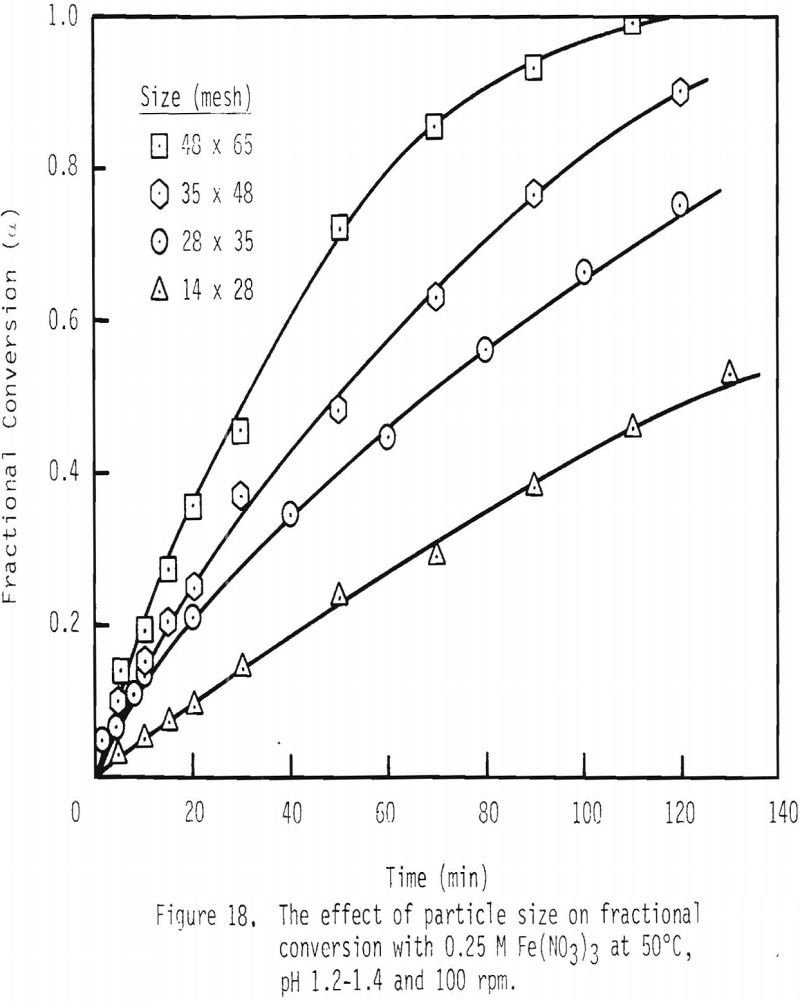

How to Dissolve Galena

There has been growing concern about the adverse effects on the environment associated with high temperature processing of galena. Because of the difficulties encountered with conventional smelting, the use of hydrometallurgical techniques for lead processing has received considerable attention in the past few years. With hydrometallurgical processing, sulfur dioxide is not produced and lead-bearing particles […]

Desliming Equipment

Filter Presses Filter presses are batch units that use higher than atmospheric pressures and a series of filter plates to separate the solids from the liquid. They are also called pressure, plate-and-frame, or press filters. Although this type of device is well known, it has had little attention or application in the U.S. minerals industry […]

Desliming

The disposal of wet fine-grained wastes from a milling operation can be a difficult challenge for the plant operator. He or she must consider the stability of the material after deposition, environmental consequences, and, above all, economic constraints. Waste material or tailings with a minimum of material smaller than 200 mesh (0.0029 in) can be […]

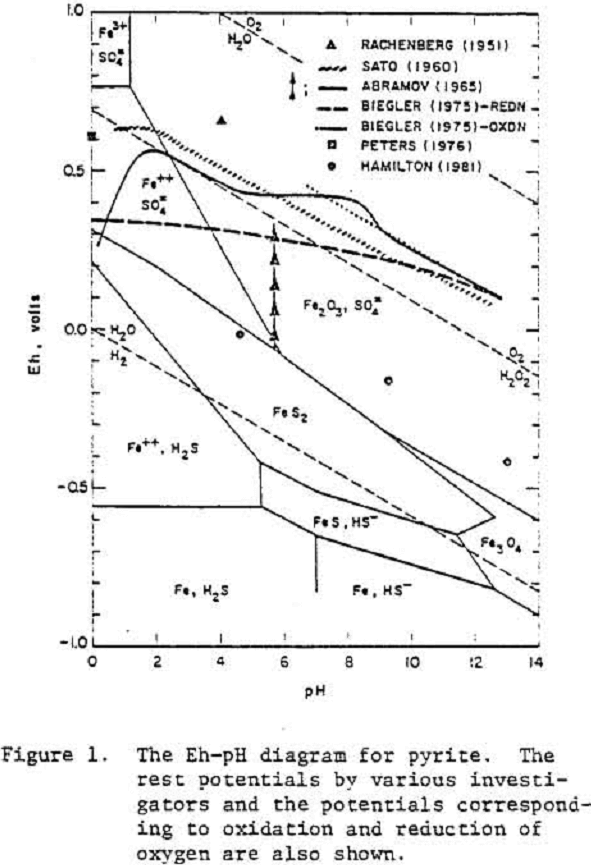

Oxidation Reduction Effects in Depression of Sulfide Minerals

Although a variety of inorganic and some organic reagents are used as depressants in the flotation recovery of sulfide minerals, a complete understanding of the mechanism of depressant action is still lacking. The progress in the development of depressant mechanisms have been hampered by several factors which include: tendency of sulfide minerals to oxidize in […]

Ceramic Materials are Resistant to Nitric Acid

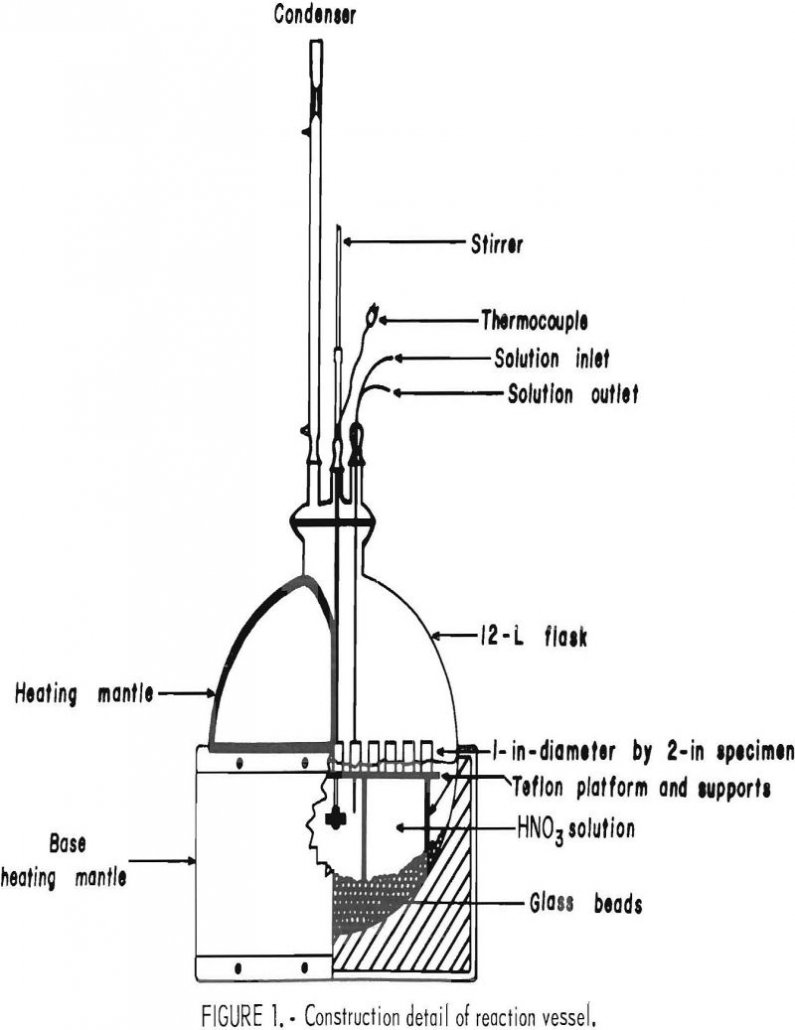

New mineral processing techniques being investigated by the Bureau of Mines and others, such as processing at elevated temperatures, leaching with acids and bases, chloride leaching, and dissolution in fused salt baths, may require the use of construction materials that, have good corrosion resistance. One example is the construction material needed to line leaching vessels […]

Grinding Ball Wear & Corrosion

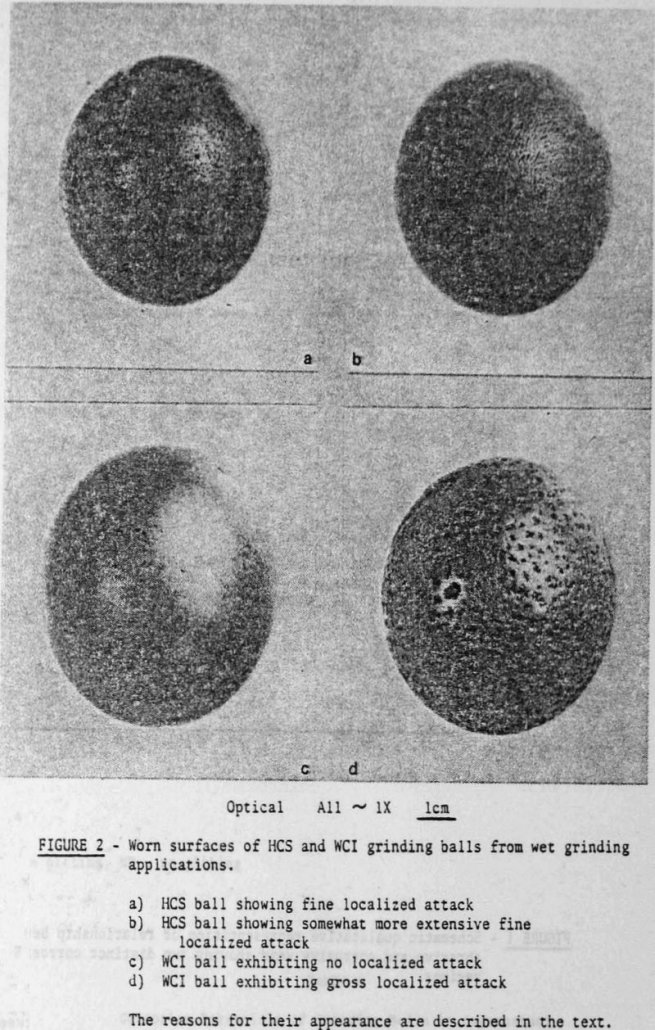

Wear of grinding media represents a significant cost in the wet grinding of ores in commercial ball mills. The total wear process of grinding involves a number of mechanisms including abrasive and corrosive wear. More knowledge about the wear mechanisms and the relative importance of each wear component would enable one to better select grinding […]

How Minor Element Affects Copper Matte Smelting

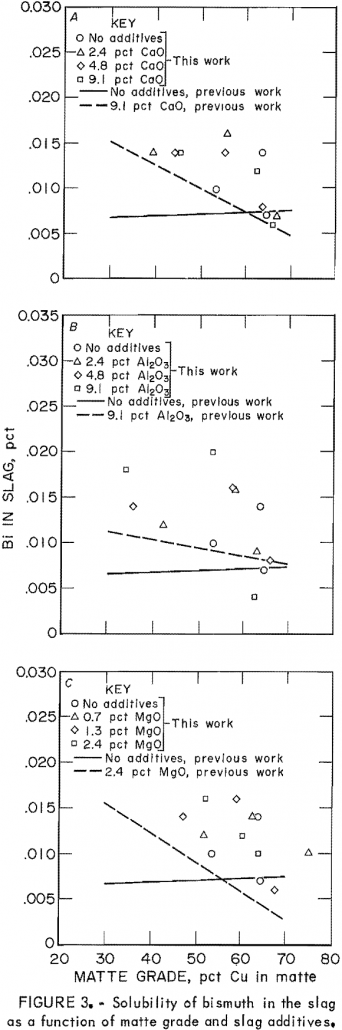

Minor-element interactions in equilibrated samples of copper matte and silica-saturated iron silicate (fayalite) slag have been studied by the Bureau of Mines to gain basic and fundamental scientific information that will support the mineral industry’s effort to improve productivity, increase energy efficiency, and reduce undesirable environmental impacts. This work was carried out as an adjunct […]

Copper Concentrate Enrichment Process

Most copper ore currently being mined contains copper mainly as chalcopyrite. Since chalcopyrite by itself is only about 35 percent copper, it is difficult to upgrade a concentrate by flotation to more than about 25 to 28 percent copper without losing a significant amount of copper during the cleaning steps. Some ores have associated problems […]