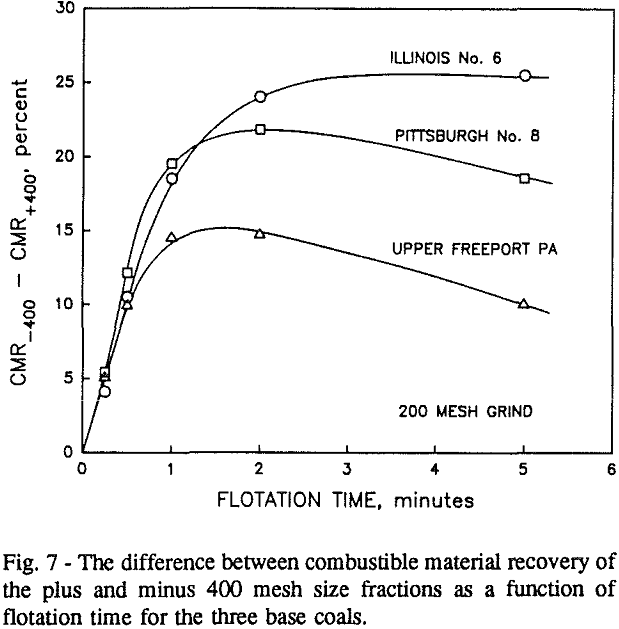

Kinetics of Coal Flotation

Desulfurization of coal before combustion is becoming important for the effective utilization of this major energy resource without polluting the environment. Because most sulfur-bearing and ash-forming minerals are finely disseminated in the coal matrix, raw coal must be ground to a fine size in order to liberate and remove them from coal to an acceptable […]

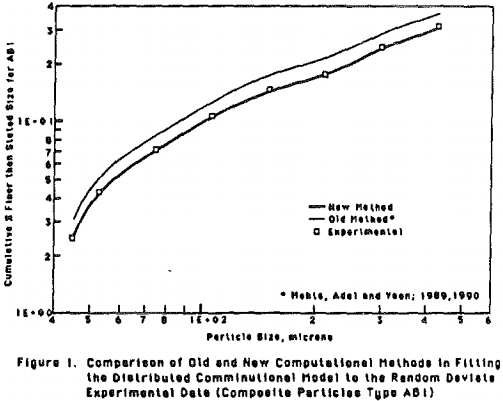

Mill Matrix of Distributed Comminution Models

Distributed Component Comminution Model The general form of the comprehensive distributed component comminution model has been described as follows d/dt(m(t)) = – [I – B]S m(t) = A m(t)…………………………………………..(1) Where A is the fundamental matrix/state companion matrix or the so-called mill matrix in comminution literature. The reason being that A as a general real matrix may […]

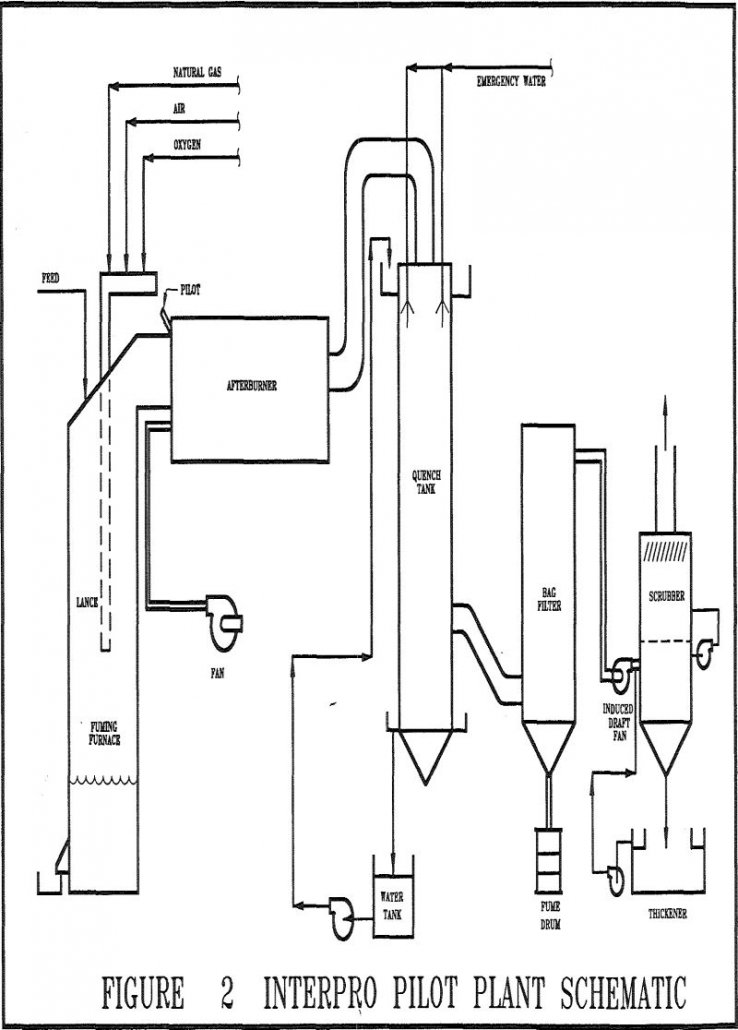

Direct Fuming of Zinc in Sulfide Ores & Concentrates

Minproc has developed a process concept of preconcentration of zinc and tin to moderate grade preconcentrates at high recovery, followed by pyrometallurgical upgrading (filming) of the preconcentrates to high grade, saleable oxide fumes. Broadly, concentrate grade is inversely proportional to recovery, and while high recoveries of zinc and tin can be achieved into low grade […]

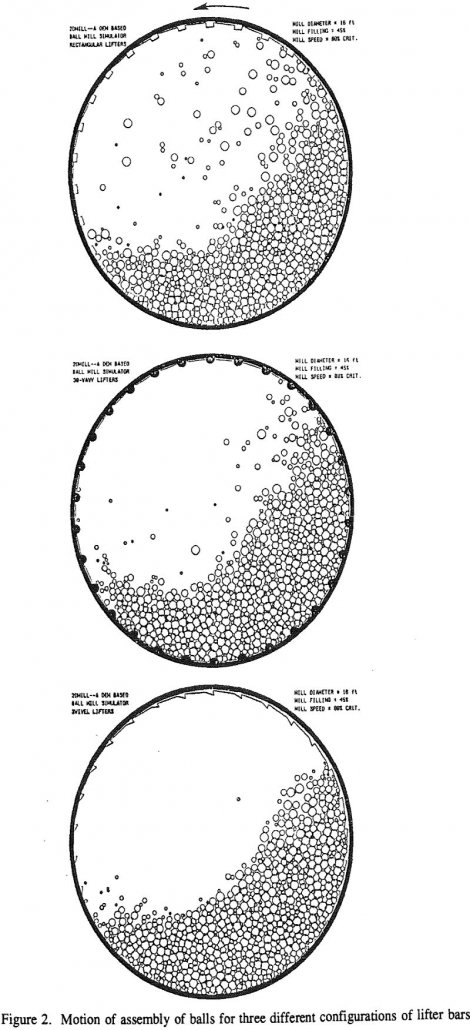

How Ball Mills Lifter Bar Affects Charge Motion

In ball mills, the grinding of ore bodies takes place due to the impact and attrition of the colliding balls. For efficient grinding of hard materials, high-impact velocities are required. For a given rotating speed and filling of the mill, impact velocities of balls and the nature of forces developed inside the mill can be […]

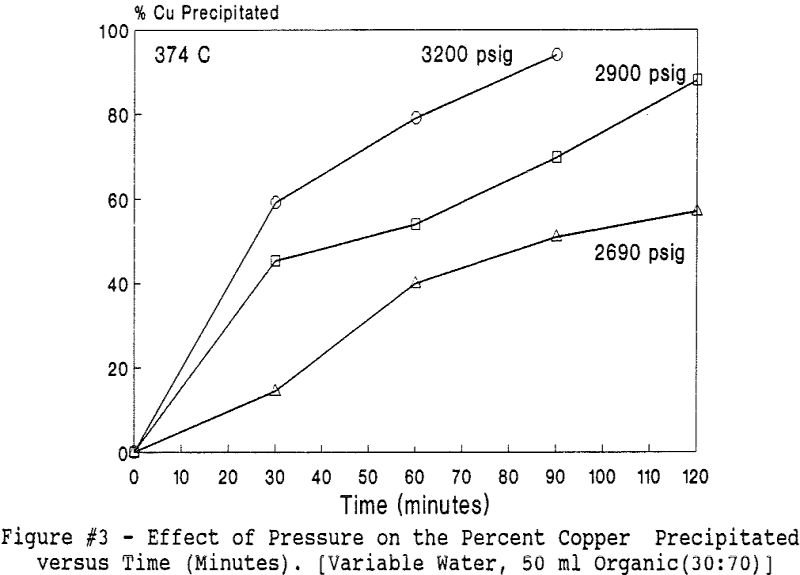

Hydrolytic Precipitation

In the chemical and hydrometallurgical industries, solvent extraction is a well established and widely used extractive metallurgical process by which desired metals are loaded onto an organic phase from an aqueous solution. However, the recovery of such metal values is conventionally carried out by suitable fluid stripping, whereby metal ions in the loaded organic are […]

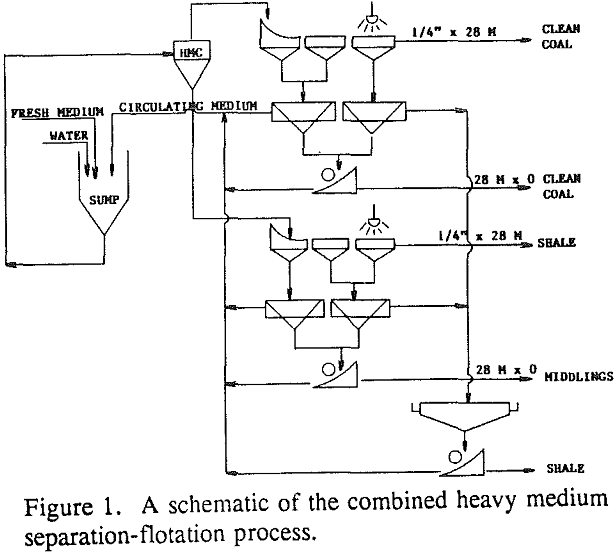

Integrated Heavy Media Cyclone & Flotation System

Heavy medium cyclones make use of a medium which is a homogenous mixture of water and dispersed magnetite. Density of the medium is regulated by adjusting the amount of magnetite in the mixture. Coal is mixed with the medium in a sump and fed to the HMC where the heavier ash material is separated from […]

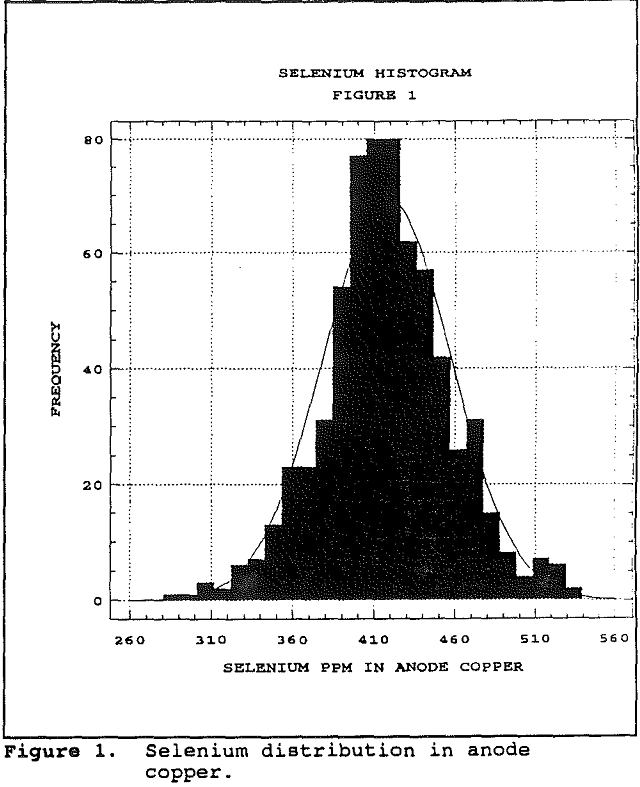

Flash Smelting Process

Process Flow Description: Concentrates and other copper bearing material are blended and conveyed from two separate areas of the plant to three 464 ton capacity wet charge bins located above the rotary dryer. Flash furnace silica flux is conveyed to a 250 ton capacity fine flux bin located adjacent to the wet charge bins. The concentrate […]

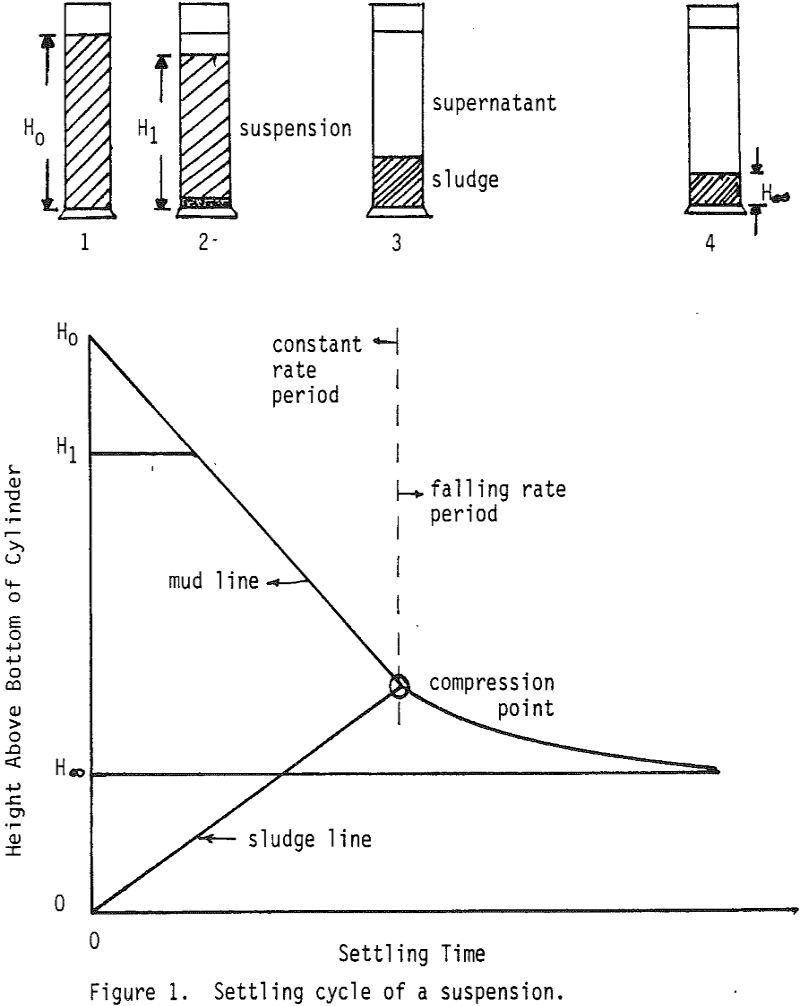

Solid Suspensions Settling Modeling

Sedimentation is used to clarify process effluents or to thicken process slurries. The sedimentation cycle of a suspension is presented as a settling curve. This curve is simply a plot of the height of the interface between the settled suspension and clear liquor versus time. The interface between the supernatant and suspension is termed the mud […]

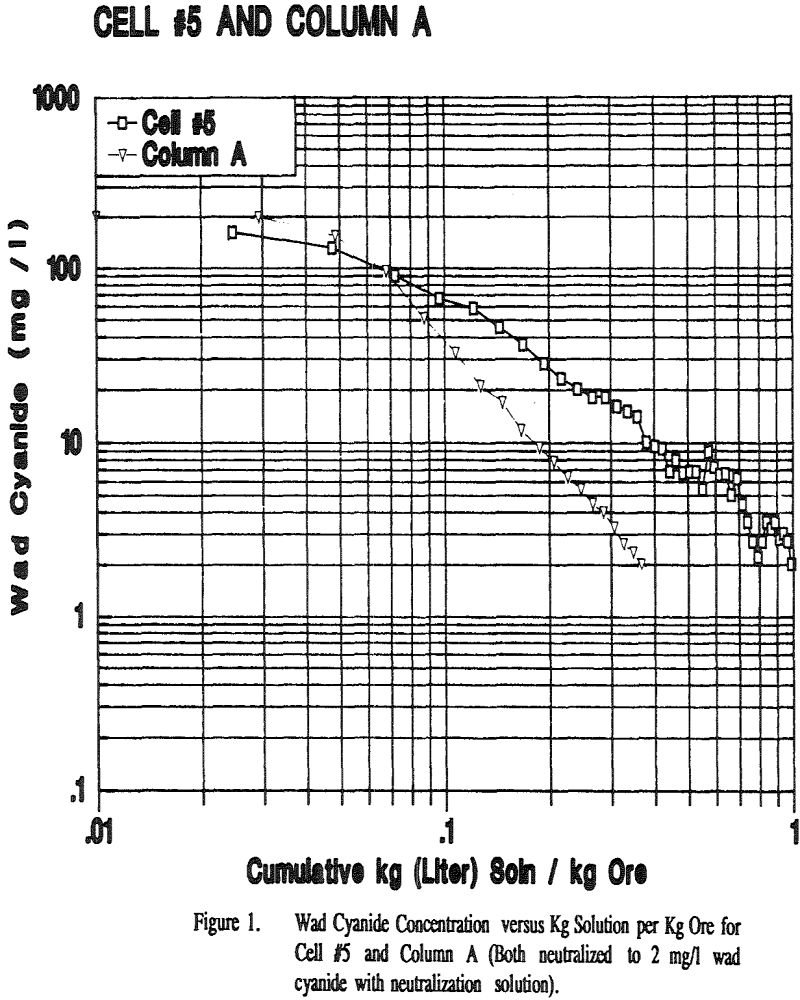

Leach Pad Cyanide Neutralization

In a “load/unload” gold heap leach operation, the time that a heap is on the reusable leach pad is of critical economic importance. The turnover of heaps must flow in a consistent and cyclic manner in order to leach the gold bearing ore in an economically feasible manner. The process cycle is time dependent on […]

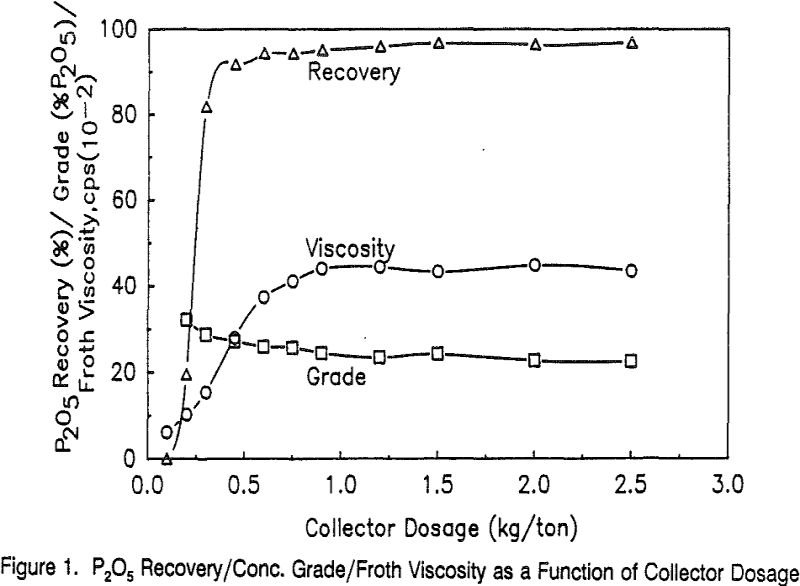

Froth Viscosity & Flotation Efficiency Relationship

Flotation efficiency is governed by the wettability of the solid as well as the surface tension at the liquid/gas interface. Both these properties in turn determine the frothing characteristics encountered in a flotation process. A number of studies have focussed on the correlation between wettability as monitored by contact angle and flotation recovery. Frothing properties […]