Uranium Solvent Extraction Process

Uranium Geology The ore occurs as uraninite adhering to the outside of sand grains in the Wind River formation which rest unconformably upon Cretaceous shales. The ores are relatively low in clay content and generally regarded as exceptionally clean ores from the standpoint of objectionable impurities. The arkosic sands in which the ore occurs are […]

Effect of Ion Concentrations on Uranium Absorption

The effect of various ion concentrations on uranium absorption from a sodium carbonate solution by a strong-base, anion resin was investigated by the Bureau of Mines in support of its objective to help assure an adequate uranium supply for future needs. The studies were conducted to improve the recovery of uranium from in situ leach […]

How to Recover Radium, Uranium & Vanadium #6

Recovery of Uranium In the extraction process practically all of the uranium in the ore is dissolved in the nitric acid, a little remaining in the insoluble residue because of incomplete washing. An average of 2.3 per cent of the uranium oxide in the ore has remained in the residue, varying in different carload lots […]

Processing, Extraction & Recovery of RADIUM from Uranium Ore #5

Radium Measurements One of the most essential factors in the successful production and concentration of radium consists in following the material being concentrated, by means of careful quantitative determinations, through all the various operations from the original ore to the final product. This involves the radioactive analysis of a large number of products differing widely […]

RADIUM Extraction & Recovery #4

Refining in the Plant The first treatment of the radium-barium sulphates is of great importance, as the whole capacity of the plant, as far as the radium goes, depends upon this first treatment. If the sulphates can not be handled as rapidly as produced, the actual amount of radium refined each year must necessarily be […]

VANADIUM & URANIUM Extraction and Recovery #3

As the sodium uranate requires re-treatment, owing to the fact that it carries vanadium, it is not necessary to wash the cake as completely as might otherwise be required. Most of the sodium uranate carries 7 to 9 per cent V205. It has been found practically impossible to obtain a precipitate that does not carry […]

URANIUM, RADIUM & VANADIUM Ore Processing #2

The method of treating carnotite, a uranium, ore used by the Bureau of Mines is outlined in this chapter. Leaching, Filtering, and Washing Ore The ore is ground to 20 mesh and is leached with strong hot nitric acid in acid-proof earthenware pots. The amount of acid used is 121 pounds of 100 per cent […]

RADIUM, URANIUM & VANADIUM Extraction & Recovery #1

Until recently little had been published on methods of treating any of the uranium ores for the extraction of radium, although a number of patents have been issued both in this country and abroad. Therefore persons interested in methods of extracting radium have had little to guide them, as details of the methods in use have […]

URANIUM METALLURGY

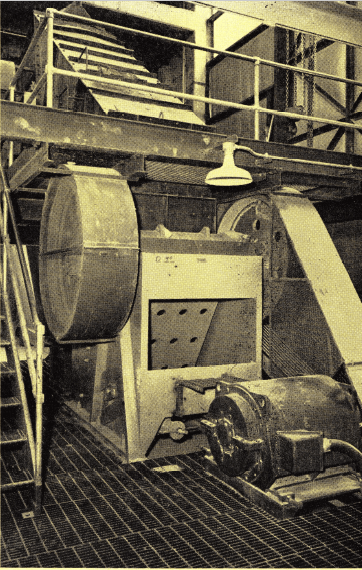

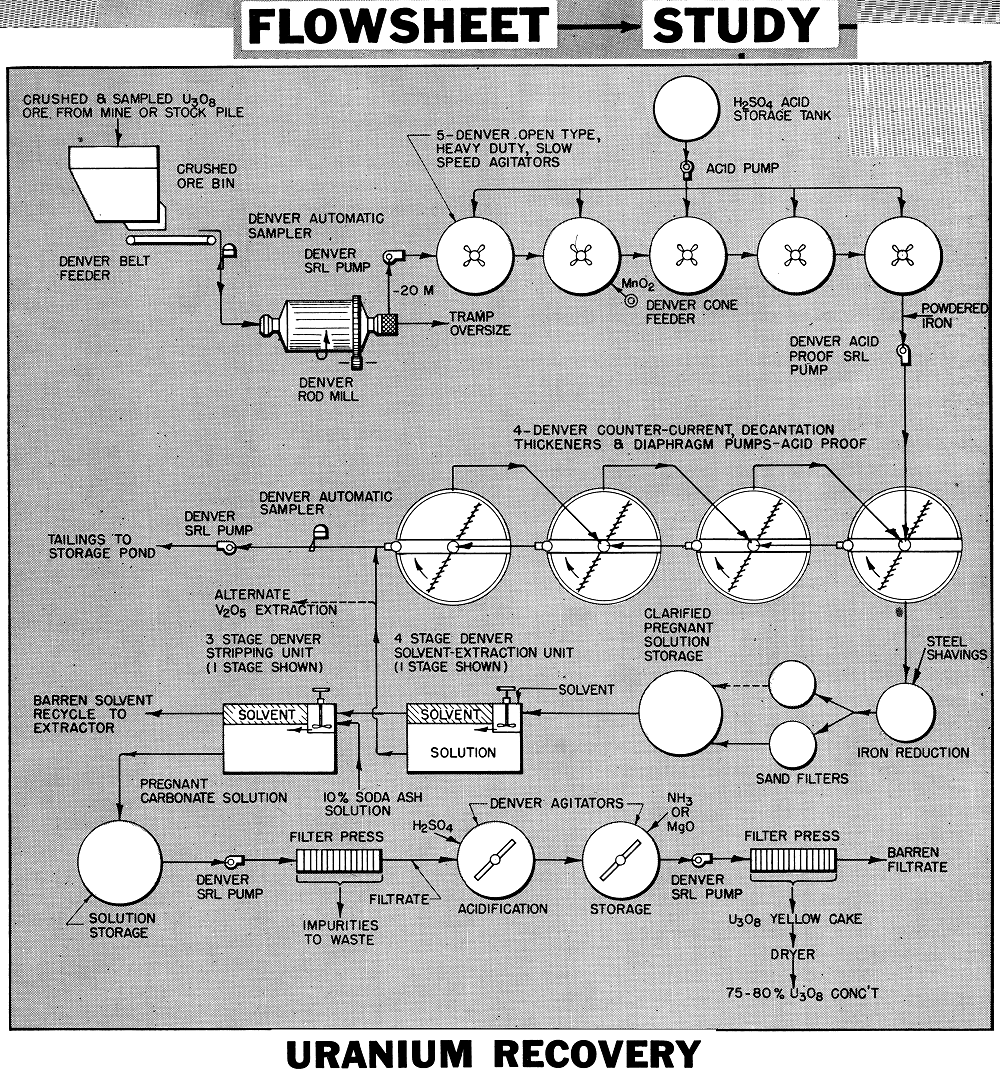

In the metallurgical treatment of uranium ores large tonnages must be handled. Many ores are low grade so it becomes necessary to employ systems which can be operated on a continuous basis at low cost. A vast amount of research has gone into the development of suitable processes. One is solvent extraction, which has proven extremely […]

Uranium Extraction Process

The plant was originally designed to treat uranium ores with low lime-high vanadium content from the Lukachukai Mountains. The process utilized is known as the “Acid Cure” and had been developed for the most part by the AEC to increase recovery of vanadium values. Briefly, it involved “pugging” the ore with 10% water and 400-500 […]