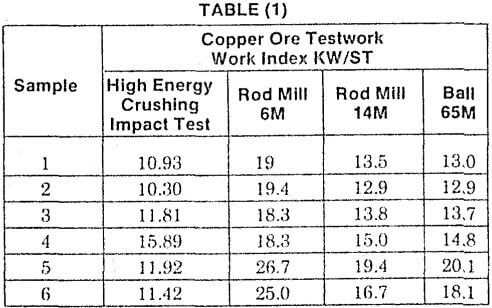

The two largest cost components in comminution circuits are energy consumption and metal wear which, for cone crushing, rod milling and ball milling, can be established by conducting laboratory bench scale tests. Pilot plant testing for these comminution methods is not normally required.

Laborary testwork performed by Allis-Chalmers to identify these parameters are covered by:

- work index tests for energy determination, and

- abrasion index tests for estimating metal consumption.

The work index tests, developed by Fred C. Bond, are conducted in various test devices at a size range for which the material will be processed in the various crushing and grinding ranges.

The bench scale test data that can be used for selection of cone crushers, rod mills and ball mills can be obtained as part of either:

- primary autogenous media competency test

- secondary autogenous media competency test

- independent tests impact tests

The data that can be obtained from the autogenous media competency test procedure are:

- Bond impact work index — low energy

- work indices from Bond rod mill grindability tests

- work indices from Bond ball mill grindability tests

- abrasion index

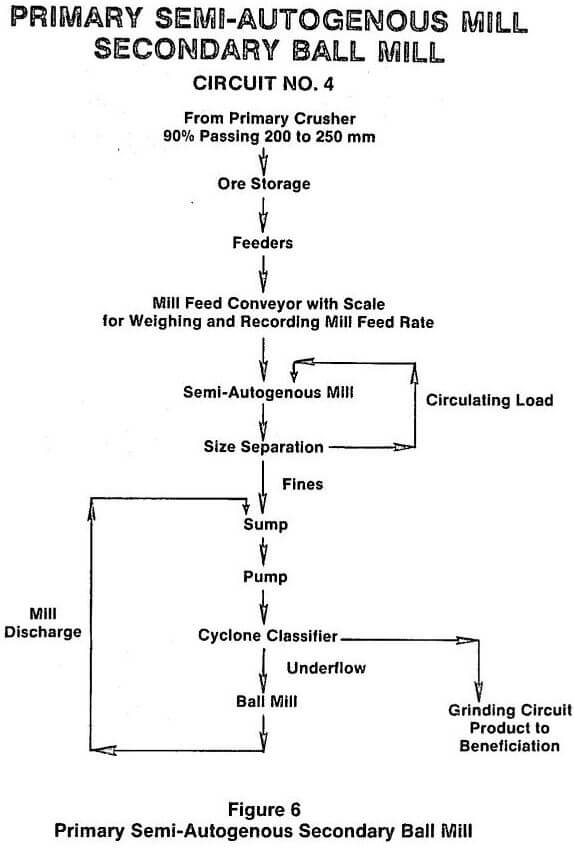

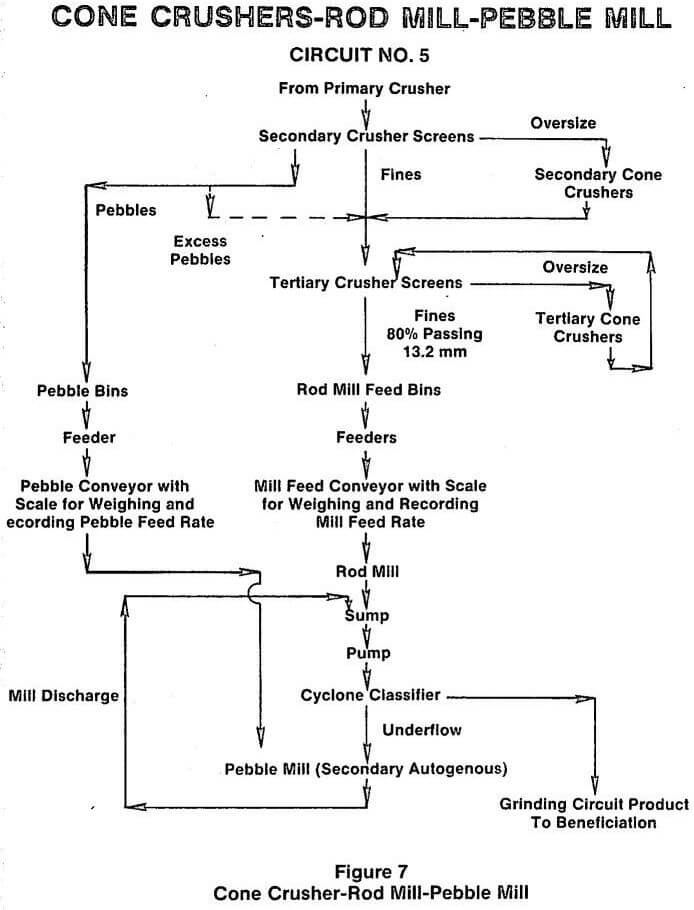

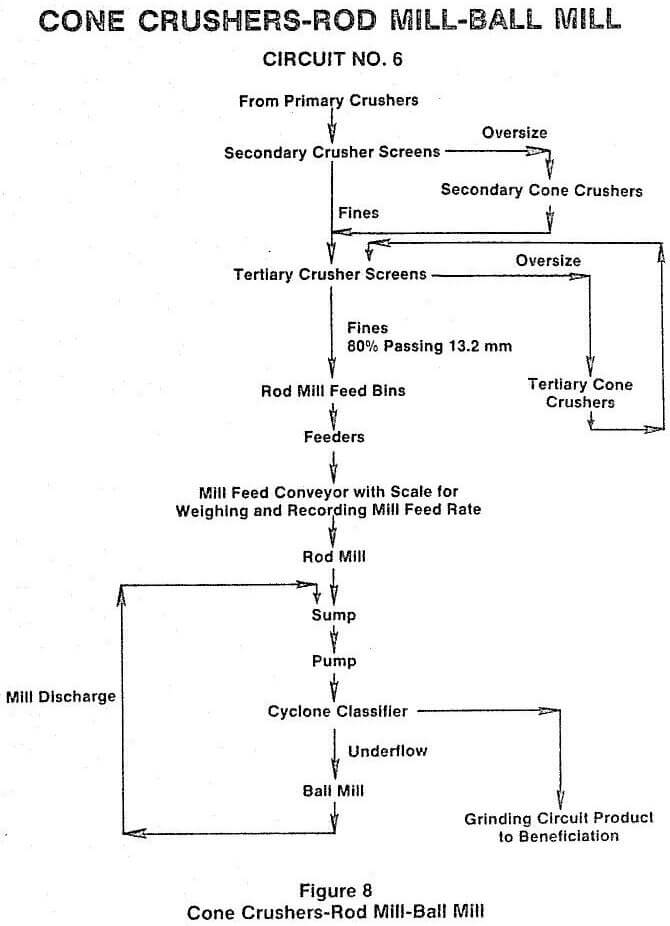

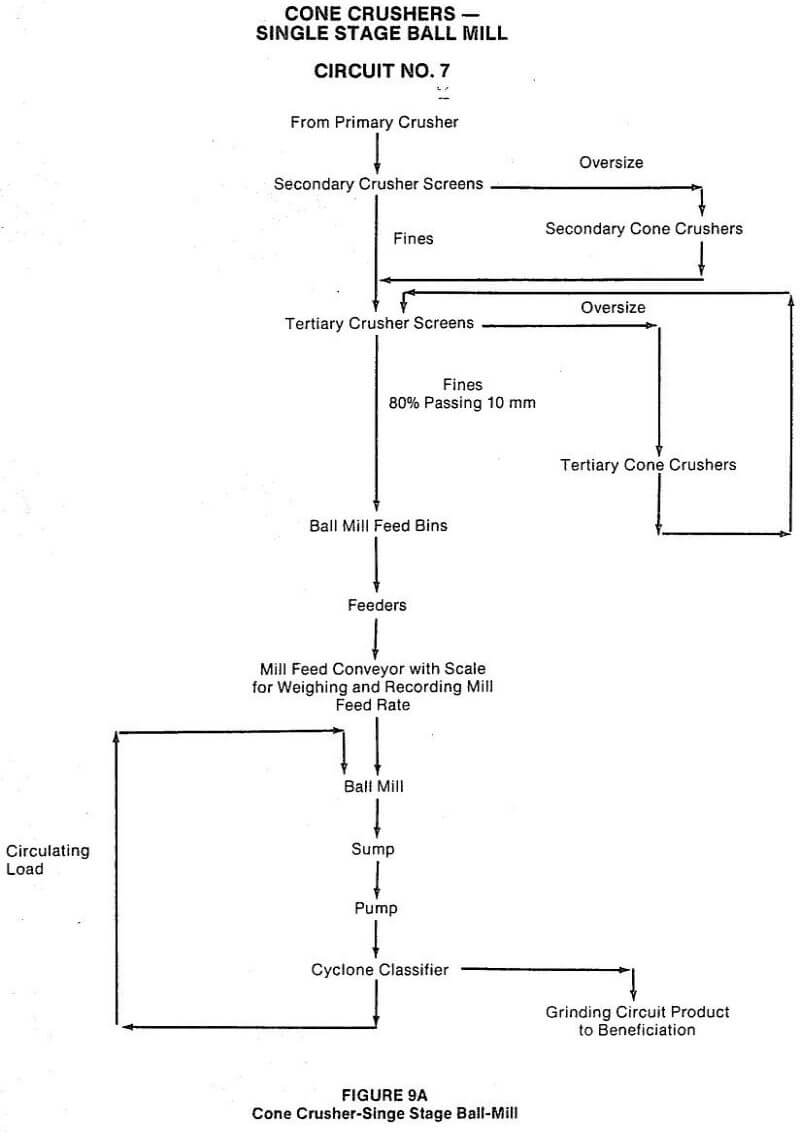

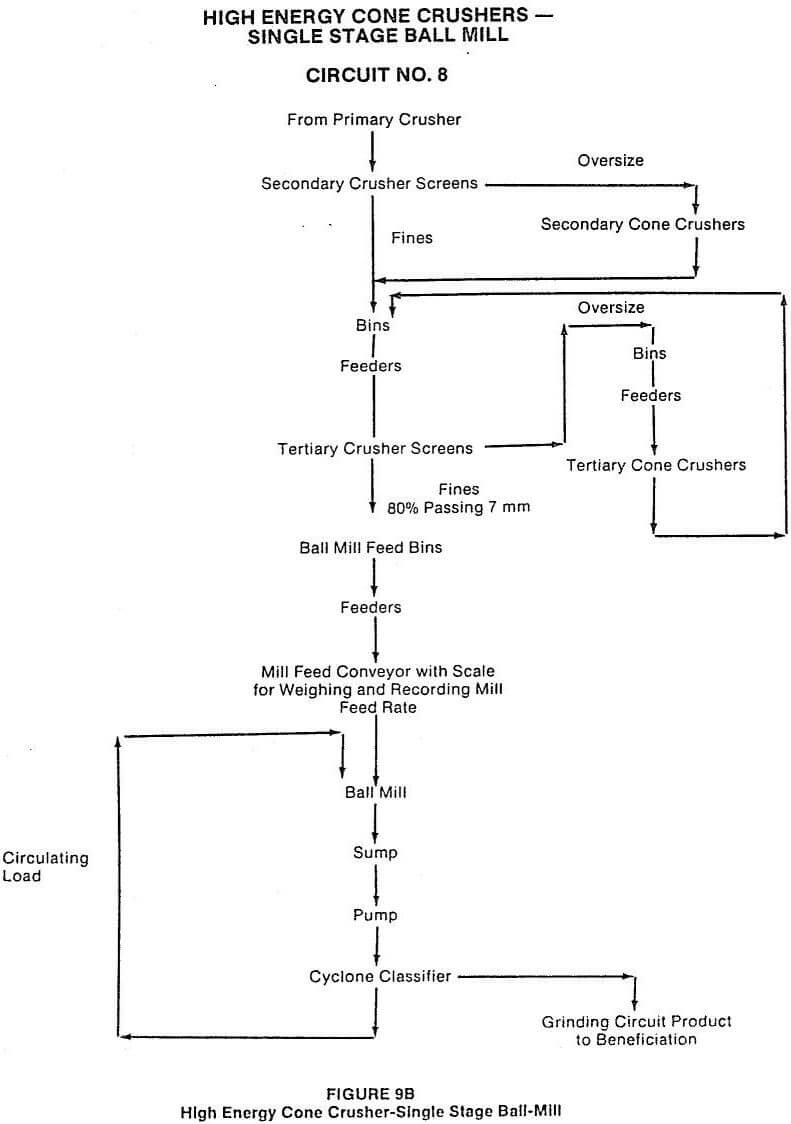

Four of the eight circuits, namely figures 7, 8, 9a and 9b, involve the use of cone crusher to produce either rod mill or single stage ball mill feed. A new test procedure, called the Twin Pendulum Impact Test, which is not part of the autogenous media competency test procedure, has been developed and refined. It gives an accurate method to establish the work index of ore to be crushed in cone crushers and to predict the particle size distribution in the crushing plant product. This has led to more accurate selection of cone crushers. New control systems and chamber designs have allowed obtaining better utilization of the power available for crushing and thus, better capacity and finer products. Crushing clean friable ore to products containing 80% passing 7 mm and finer, is possible. This makes better feed for single stage ball mills than feed containing 80% passing 10 mm.

With finer crushed products, the impact of higher power and metal wear encountered in rod and ball mills with coarser feeds can be minimized.

Finer crushed products for many ores, might permit the elimination of rod mills and the problems associated with rod mills. The limits on rod mill sizes, requiring more grinding units, and the added space required for rod charging, have contributed to the development of single stage ball mills. In some areas of the world, good quality rods are not economically available, thus eliminating rod milling as a viable alternative.

At this time, ball mills larger than 5 meters in diameter, when charged to normal ball levels in the area of 40 to 45% of mill volume while drawing rated power, do not utilize the power efficiently. There seems to be a limit either on ball mill diameter or on the amount of ball charge that mills larger than 5 meters in diameter can carry and grind efficiently.

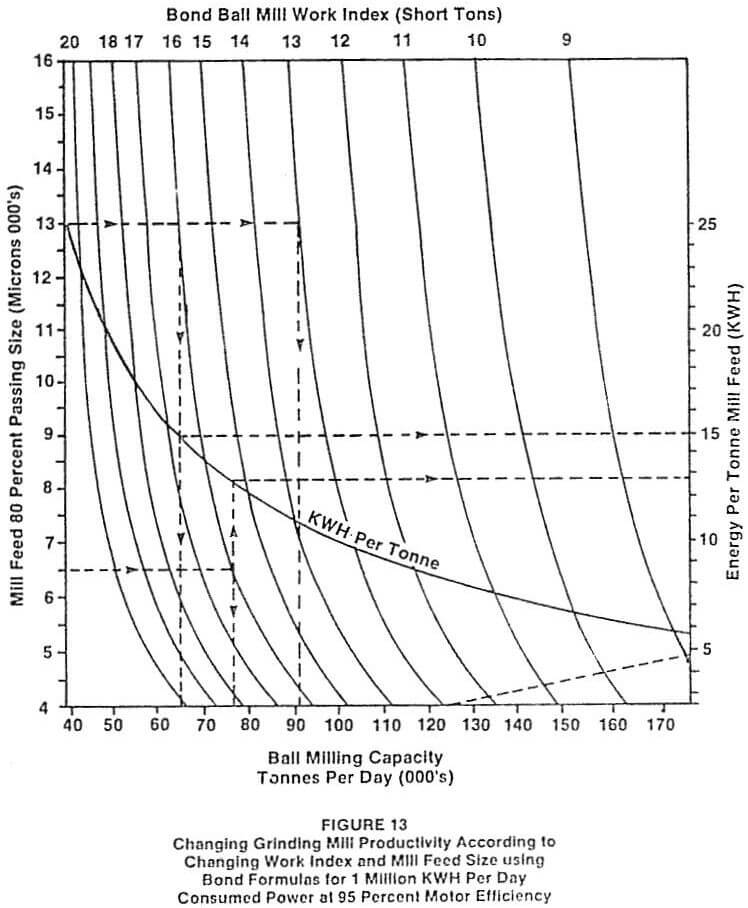

Assuming a constant work index, a graph, as shown on Figure 13, can be used to estimate the effect of changing the size distribution of the crushing plant product on grinding power and grinding mill capacity for single stage ball milling.

Rod mills can require as much as twice the power and consume up to 20 times as much steel as cone crushers when producing the same product size as produced by the cone crushers. This crusher product size range is however considered a coarse product for rod mills.

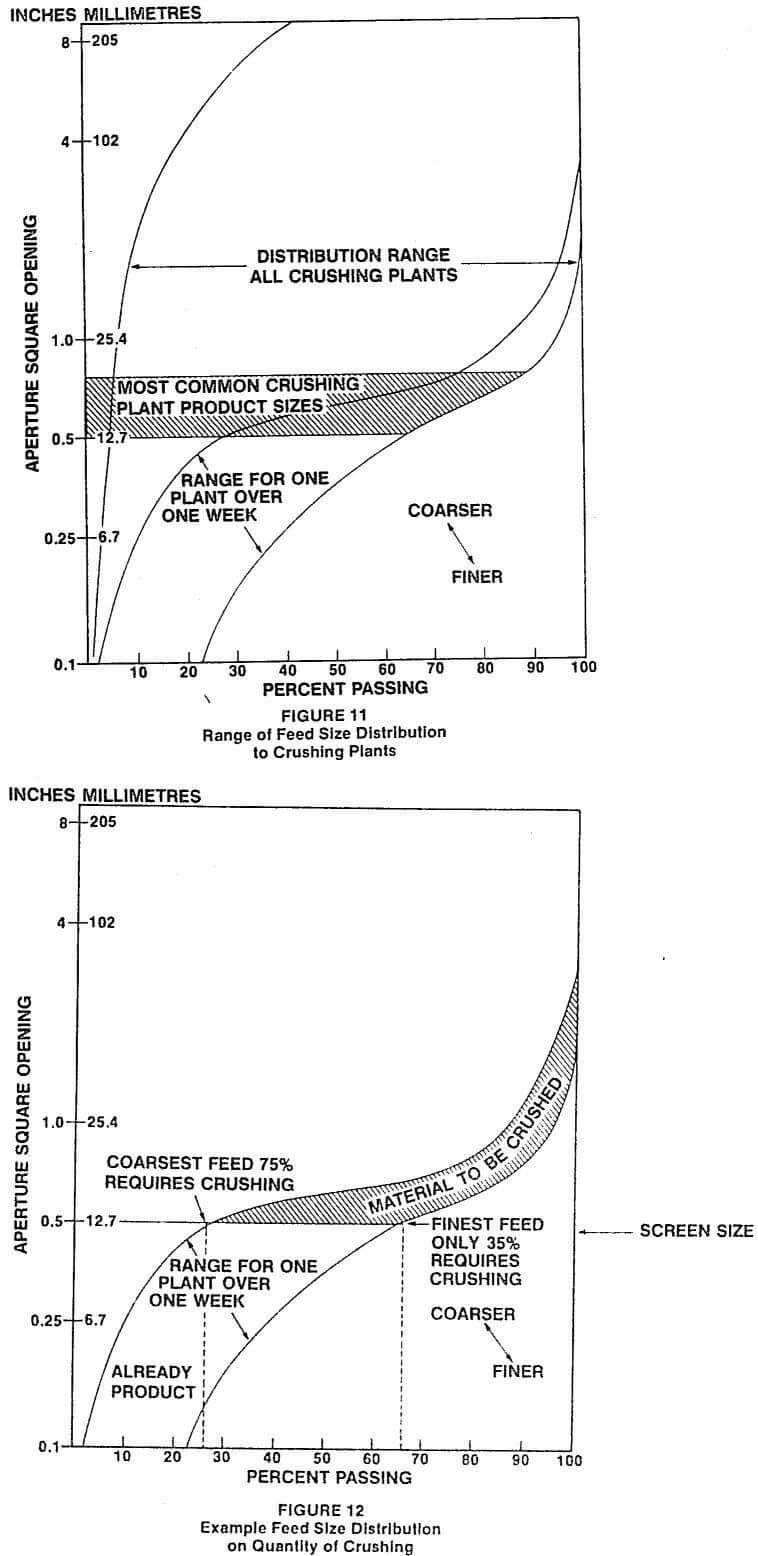

An evaluation of the ore, as to how fine it can be crushed without serious blinding of vibrating screens and packing in cone crushers, will determine how fine the ore can be crushed. The power for cone crushing can be determined using the procedure given in “Energy Mathematics for Crushing Applications and Systems for Optimizing Comminution Costs”. Whether preparing feed for either rod milling or single stage ball milling, closed circuiting of the last crushing stage is recommended. As discussed in Chapter 12, “Minerals Processing Plant Design”, and in earlier papers, rod mills lose efficiency if subjected to variations in feed size as would come from open circuit crushing.

If the ore contains materials that are sticky and could cause problems with fine screening and crushing, and if single stage ball milling is to be selected, scrubbing the primary crusher product can be considered. This requires sufficient testing to determine:

- retention time required for the digestion of the sticky component into the slurry.

- if the slimes from the washing plant contain mineral values, and whether these slimes can be treated in the beneficiation circuit, or if they need to be treated in a special beneficiation section.

- work indices for crushing, rod milling, and ball milling of the washed ore.

After the product size to be produced in the crushing plant is established, this establishes the feed for the grinding section.

Work indices data from standard Bond grindability tests are used to determine the power required for grinding in rod mills and ball mills, following the procedures described in Chapter 12 “Minerals Processing Plant Design”. This requires the use of the Bond work index equation,

W = 10Wi/√P – 10Wi/√F

Where

W = Kwh per ton or tonne

Wi = Work index for a ton or for a tonne

P = Size in micrometers, which 80% of the product passes

F = Size in micrometers, which 80% of the feed passes

and, the application of any of the eight efficiency factors, which apply to the calculation:

EF1 Dry grinding

EF2 Open circuit ball milling

EF3 Diameter efficiency factor

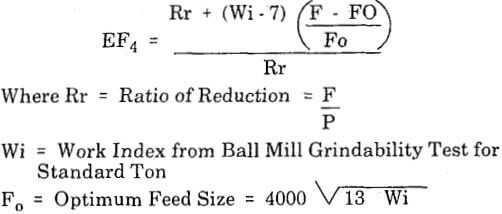

EF4 Oversized feed

EF5 Fine grinding in ball mills to product sizes finer than 80% passing 75 micrometers

EF6 High or low ratio of reduction rod milling

EF7 Low ratio of reduction ball milling

EF8 Rod milling

In studying the application of cone crushing, rod milling, and ball milling, observations have been made earlier that because it fits between fine crushing and the ideal feed for ball milling, rod milling can be eliminated from consideration for some ores. For these ore conditions, and/or economic factors, eliminating rod milling can be justified.

When considering energy usage, in some cases, the rod mill-ball mill circuit consumes less energy for comminution. In addition, the cyclone classifier feed pump requires less energy because the circulating load on the ball mill is considerably less than it would be in single stage ball mill circuits.

Crushing finer in cone crushers covers some of the work done by rod mills in an area where rod mills might be less efficient. However, the cone crusher does not cover the whole range of rod mill work and does not eliminate the oversized feed factor EF4 for ball milling which is calculated from the following:

The EF4 factor drops out when the work index from the ball mill grindability test is 7 or less or when the factor (F – Fo) is negative. Therefore, a study has to be made evaluating the higher crushing efficiency with the effect of the ball mill oversized feed factor EF4 in deciding whether or not to eliminate rod milling.

Crushing surface wear, rod consumption, ball consumption, and grinding mill liner wear can all be estimated using the abrasion indices procedures given in Chapter 12, “Minerals Processing Plant Design”. Pebble wear can be estimated from results of the secondary media competency test.